Introduction

In the era of Industry 4.0 and the Industrial Internet of Things (IIoT), seamless connectivity and real-time monitoring are crucial for efficient industrial processes. However, a common challenge in this field is the quick access to HMI visualization interfaces, especially when dealing with multiple PLCs scattered throughout a factory or during maintenance operations. Traditional HMI interaction methods often require personnel to be on-site, which is highly inconvenient. To address such scenarios, Siemens has integrated web servers into all 1500 series PLCs, supporting remote interaction. With the “View Of Things” (VOT) feature, users can create HMI visualization interfaces directly within the PLC and access them via a web browser.

This example will implement a visual dashboard control system that interacts with data through a web browser and PLC by creating a VOT application in the 1500 series CPU. The PLC program development will be completed step by step, building an interactive dashboard through VOT, and finally testing it using the PLCSIM Advanced simulation environment.

TIA Portal VOT (View Of Things) Feature

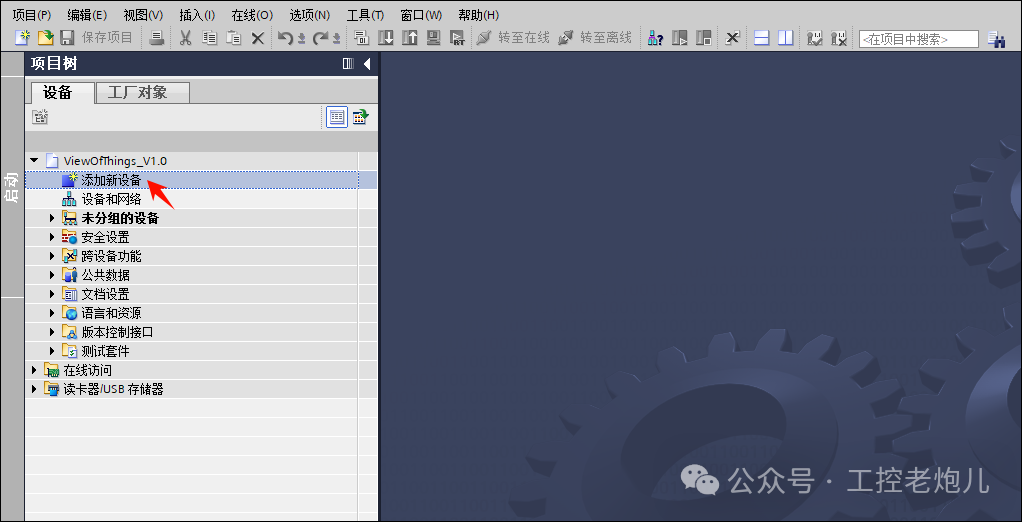

First, create a new TIA Portal project. Once created, click “Add New Device” in the project tree.

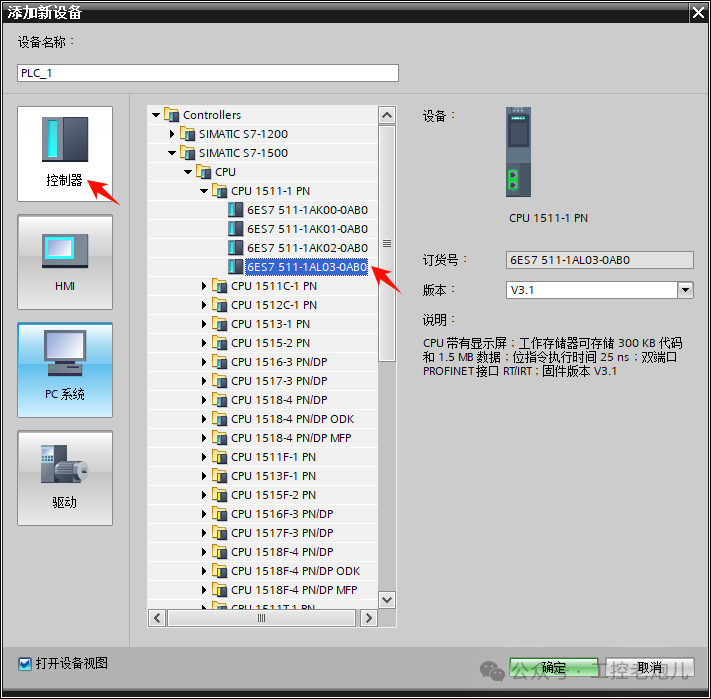

In the device selection interface, choose a 1500 series CPU. All 1500 series devices come with a built-in web server, which is key to running the VOT (View Of Things) application. Here, we will take the 1511-1 PN CPU as an example.

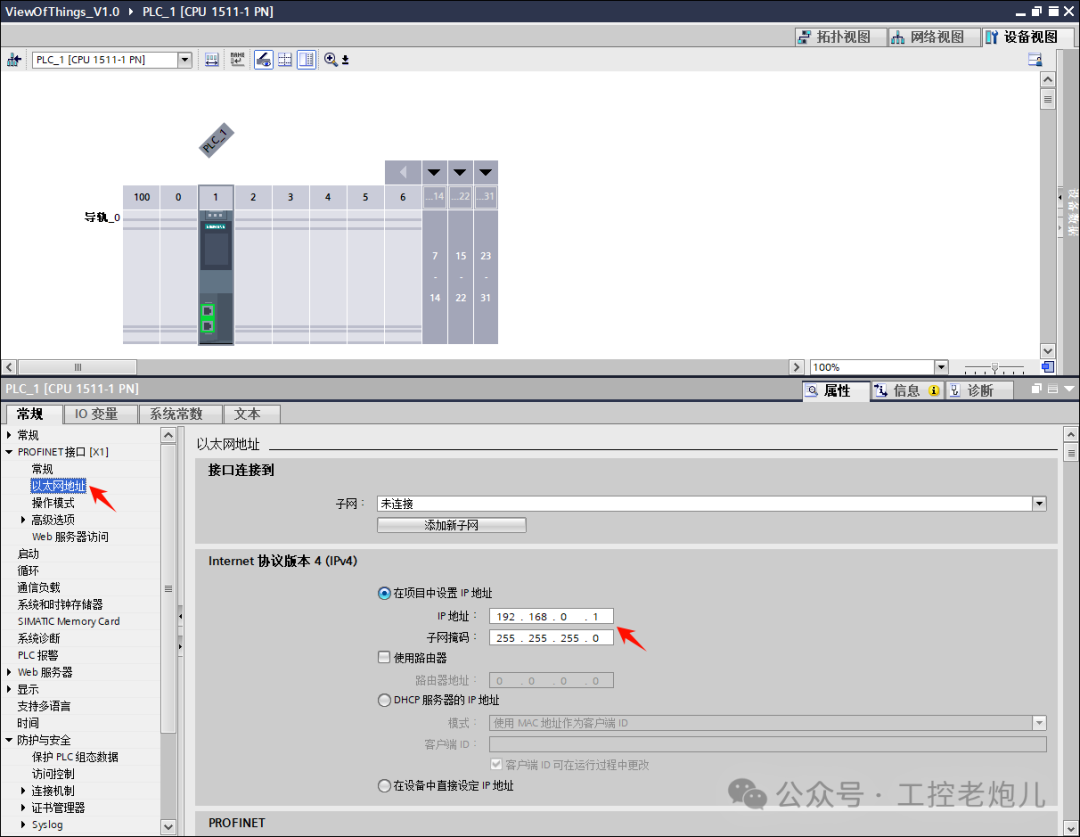

After adding the device, it needs to be configured.

Expand the PROFINET interface configuration item in the properties tab and set the following:

- Set the IP address to: 192.168.0.1

- Set the subnet mask to: 255.255.255.0

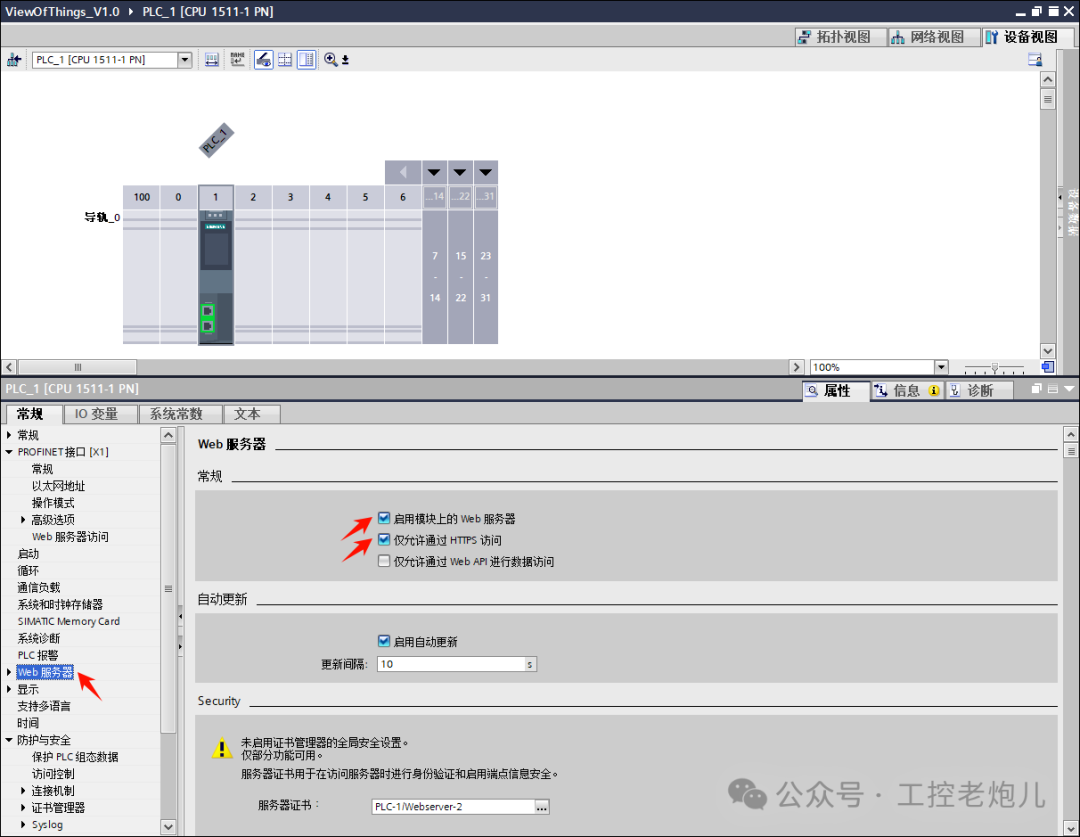

Next, open the web server configuration item in the properties and check the following two checkboxes:

- Enable the web server on the module

- Allow access only via HTTPS

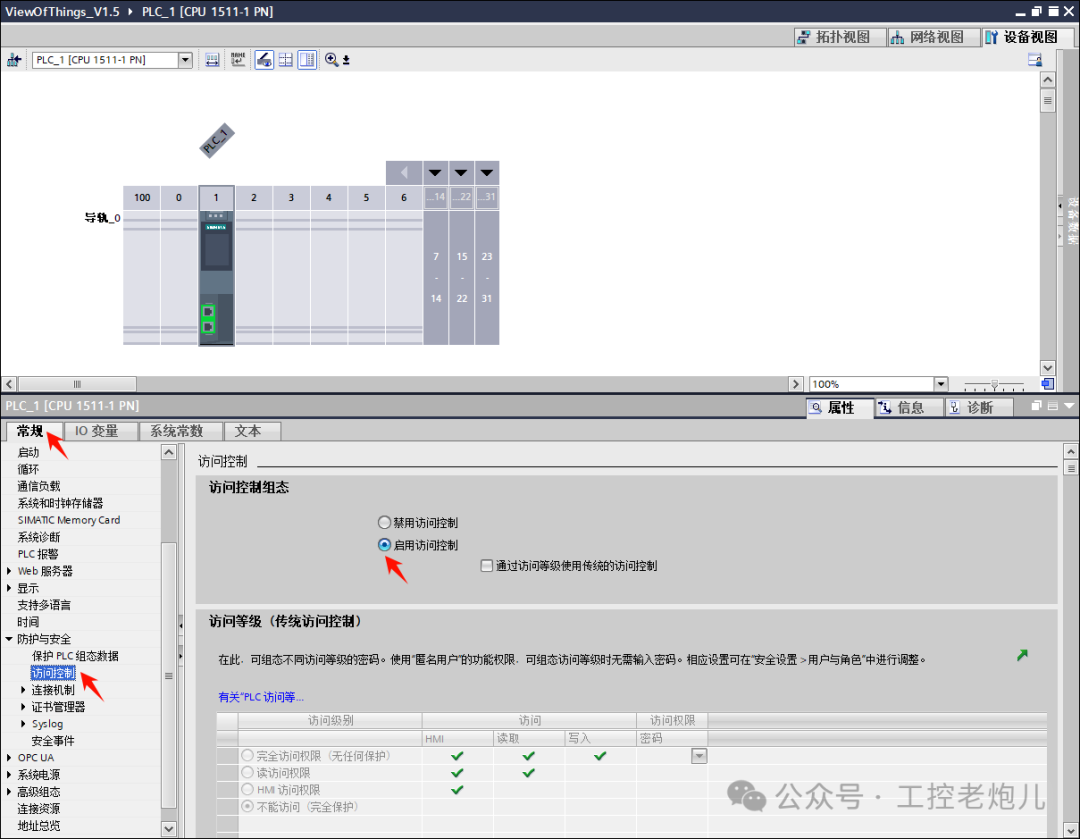

Next, open the protection and security configuration item in the properties to set access control. In this example, access control is enabled, and traditional access control using access levels is not enabled.

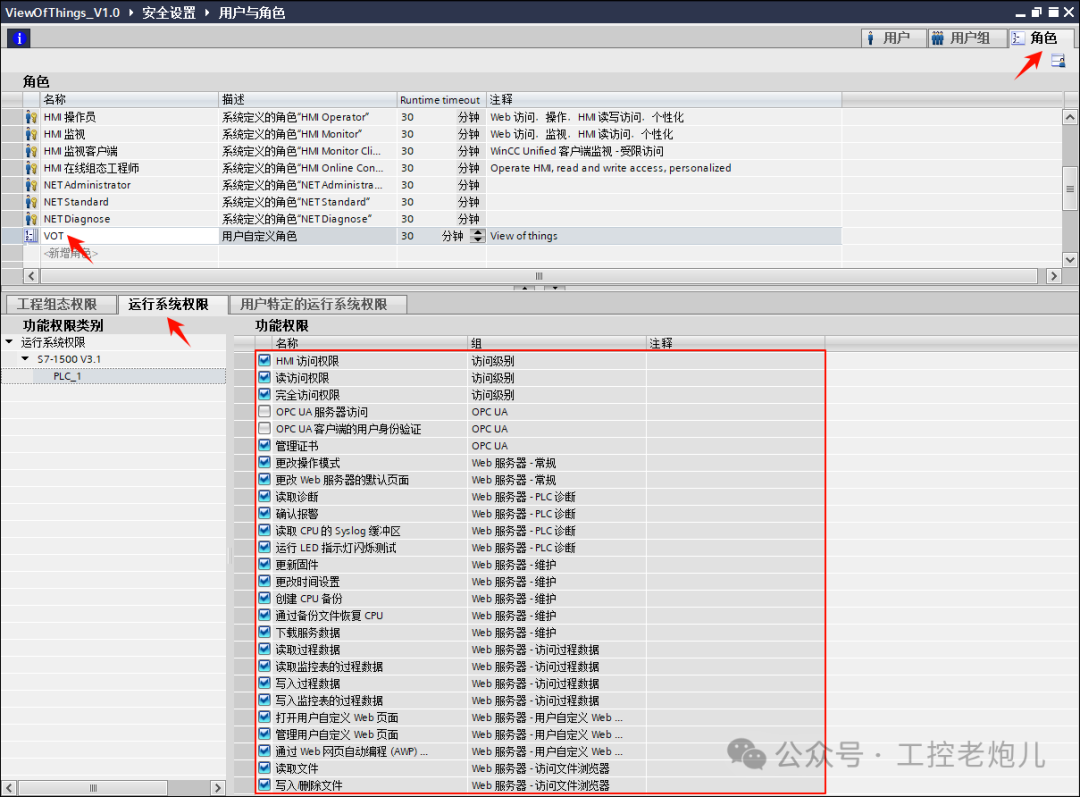

Expand the security settings item in the project tree and open users and roles. Add a new role named: VOT. Then, enable all relevant permissions in the running system.

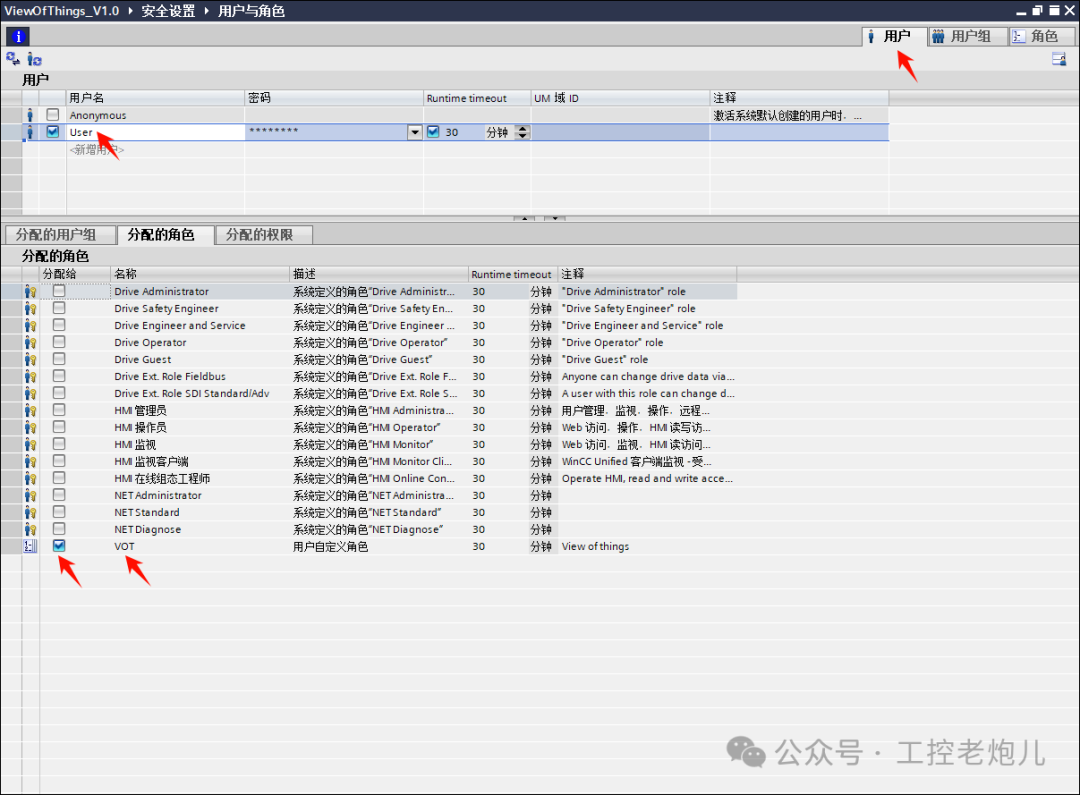

Add a new user named: User, set a password, and assign the VOT role just created.

User configuration is complete, and the CPU configuration work is now finished.

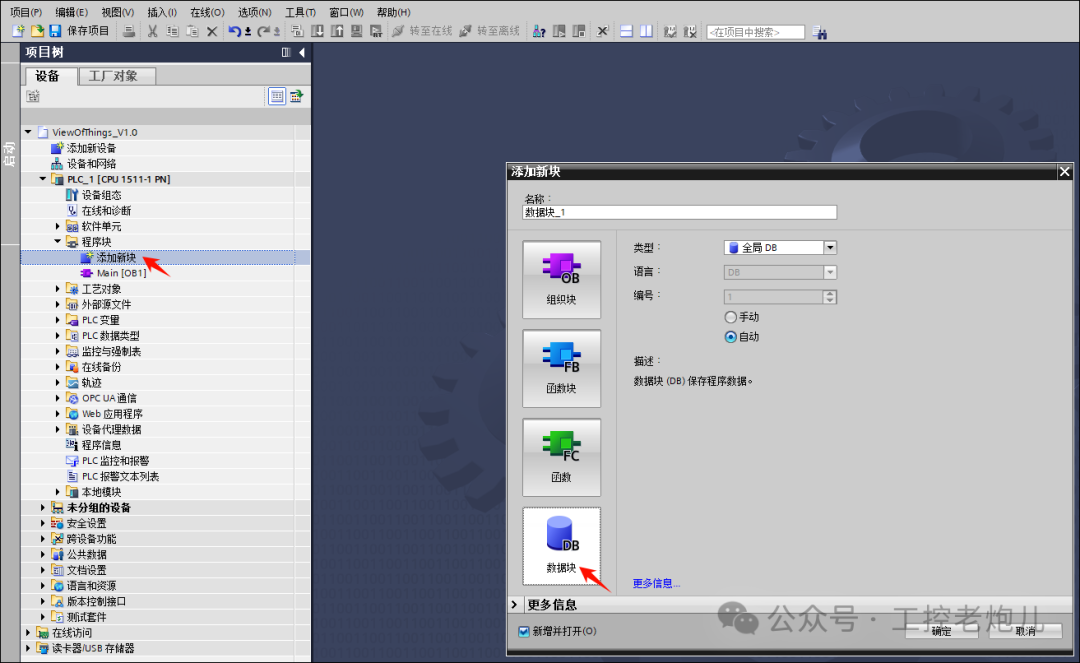

After completing the CPU configuration, a test program needs to be created to associate with the VOT application.

The steps are as follows:

- In the program block section of the project tree, click “Add New Block”

- Select “Data Block” type

- Click “OK” to complete the creation

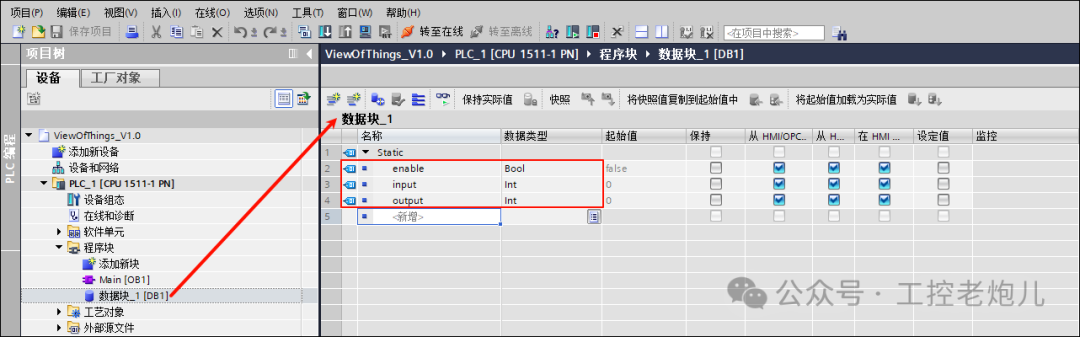

Add the following elements to the data block:

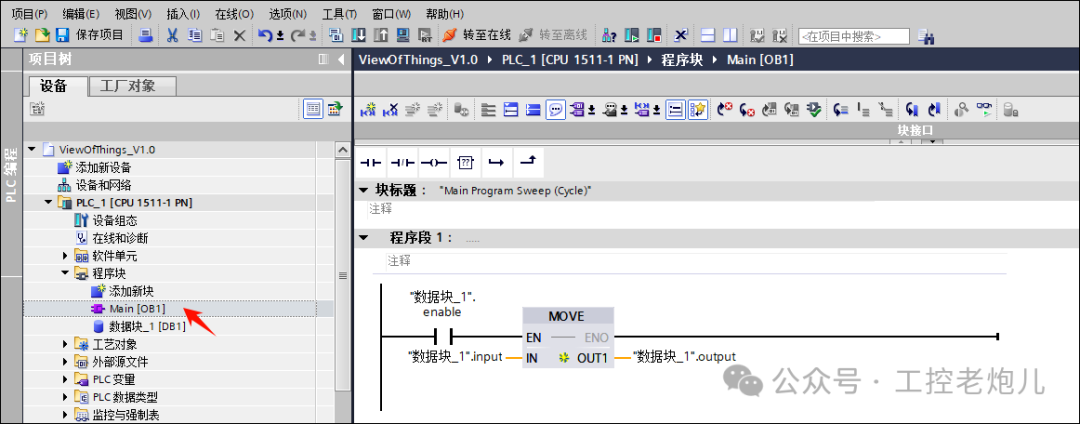

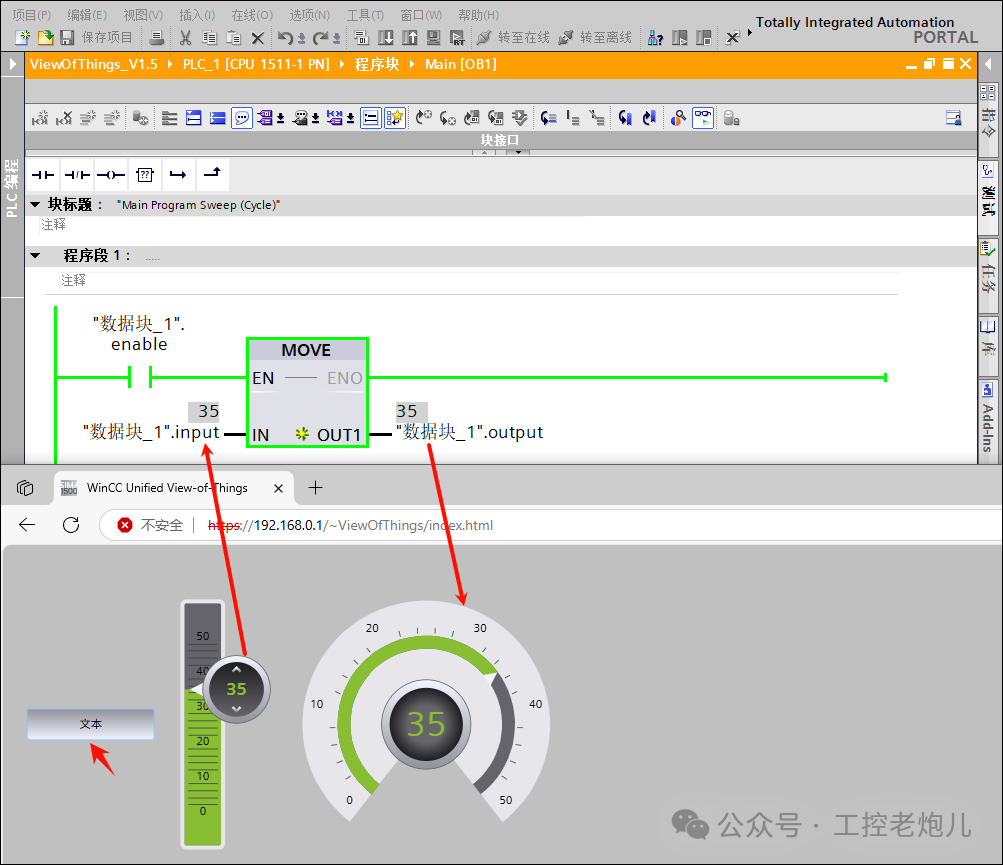

Next, open the main program OB1. Create a small program to transfer data from one element in the DB data block to another element (input/output), controlled by a boolean value.

The program is now complete. When the “enable” boolean value is 1, the “MOVE” instruction will transfer the data from the input element to the output element.

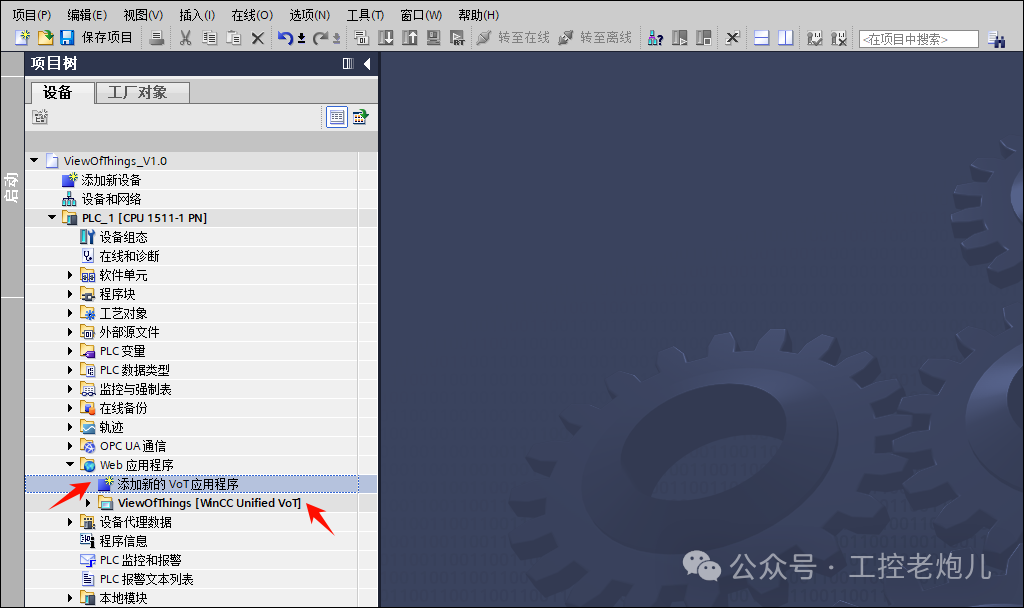

Next, create the VOT application. In the project tree, expand the web application section and click “Add New VoT Application”.

At this point, the VOT application is displayed in the project tree. This is a simplified HMI interface that includes system settings, screens, and HMI variables. Now let’s create a new screen by clicking “Add New Screen”.

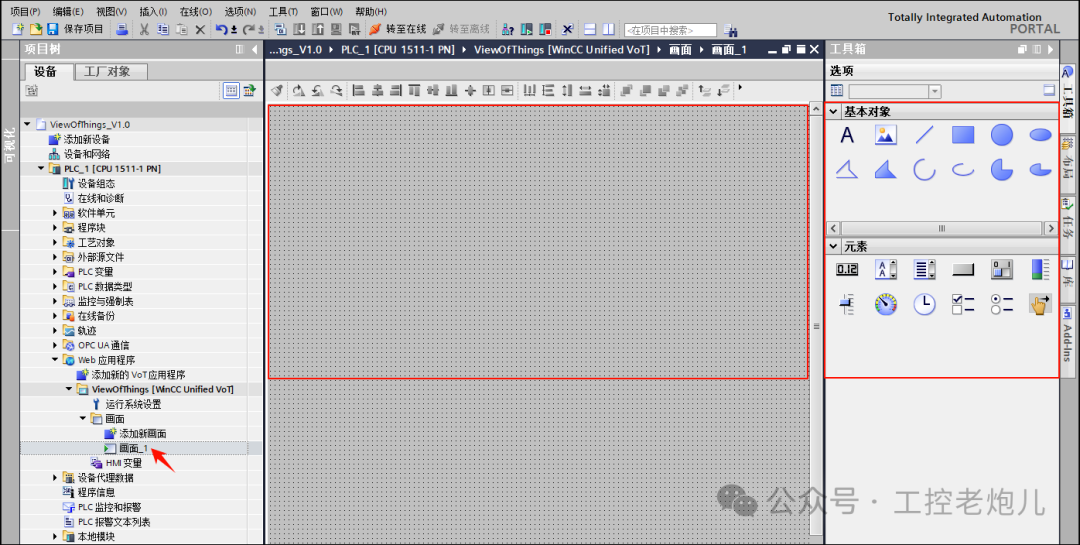

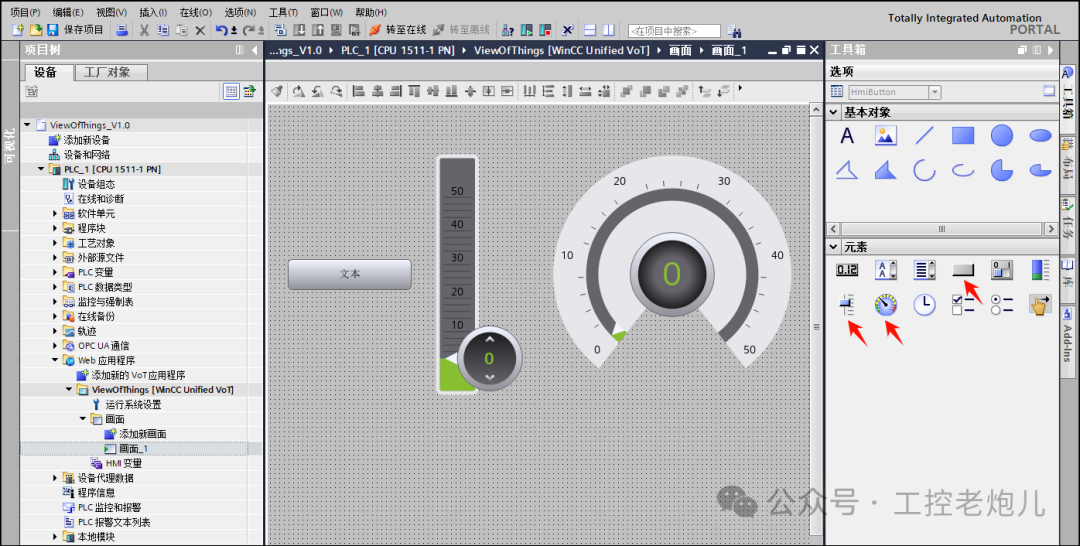

You can see that the screen interface is identical to a conventional HMI screen interface. The VOT application is developed based on the WinCC Unified platform, allowing for the direct creation of web-based simple HMI visualization interfaces within the PLC, accessible via the PLC’s built-in web server. In the toolbox area, you can find basic objects, elements, and controls for monitoring and interacting with the PLC program.

Now let’s start creating a dashboard control screen. Add three elements to interact with the PLC program:

-

A button to enable data sending

-

A slider to select input values

-

A gauge (dashboard) to display output

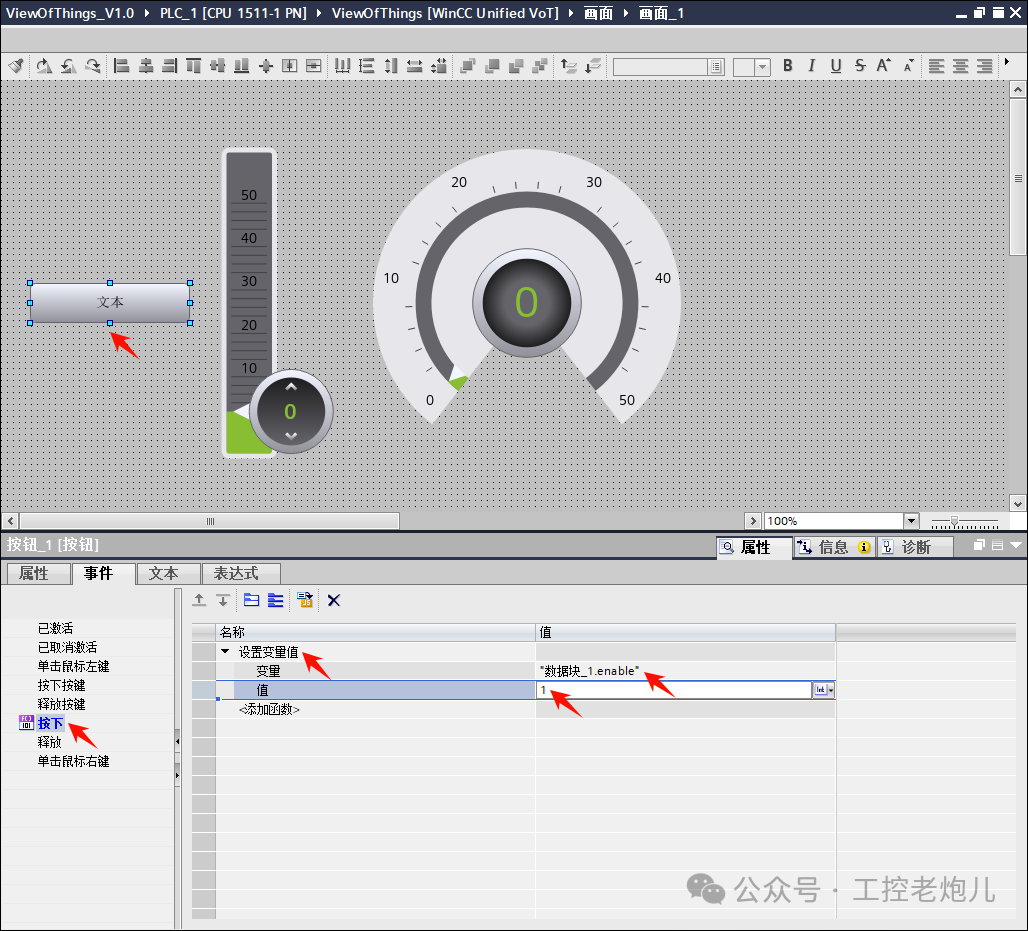

Add pressed event properties for the button:

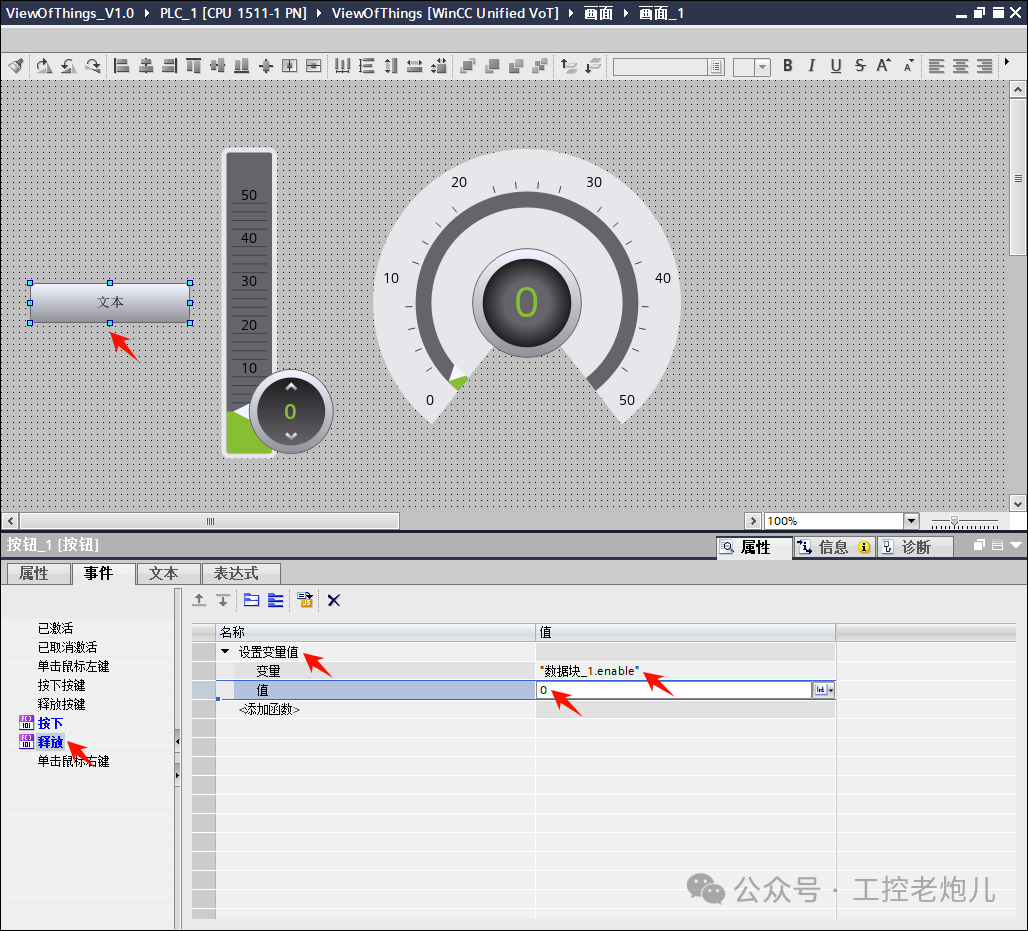

Add released event properties for the button:

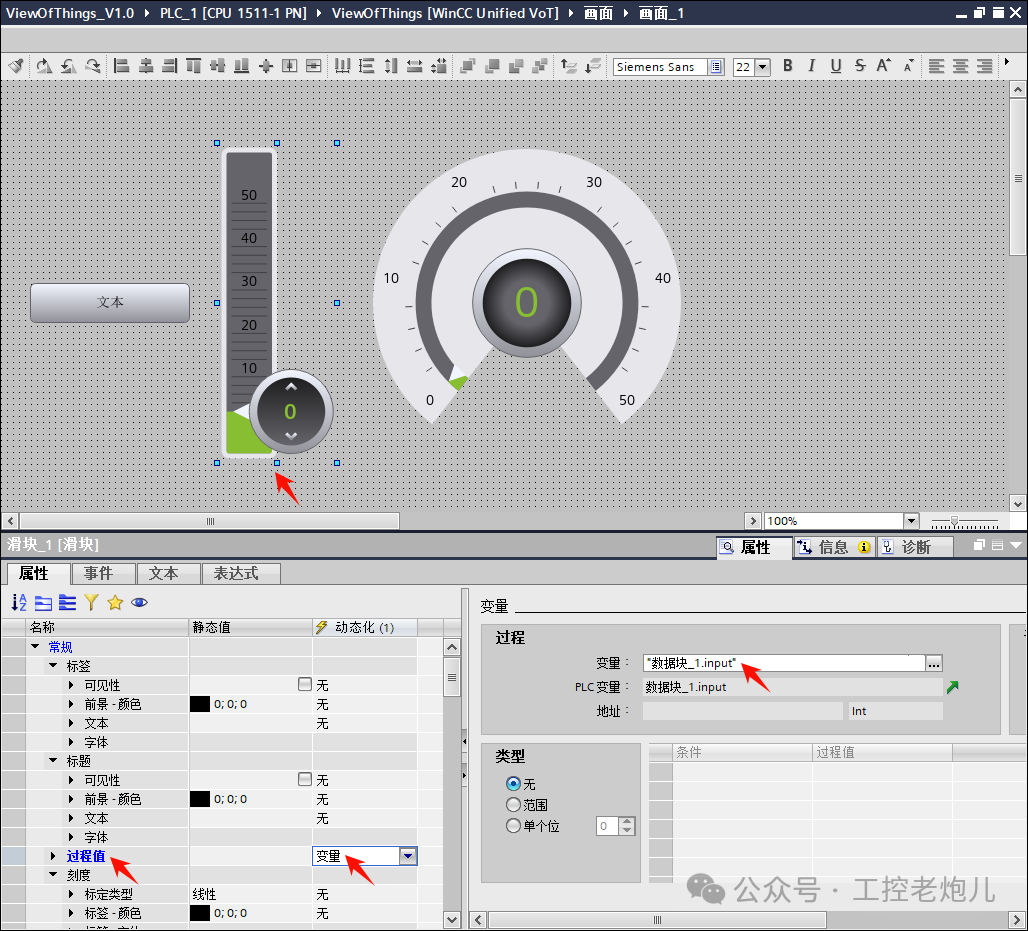

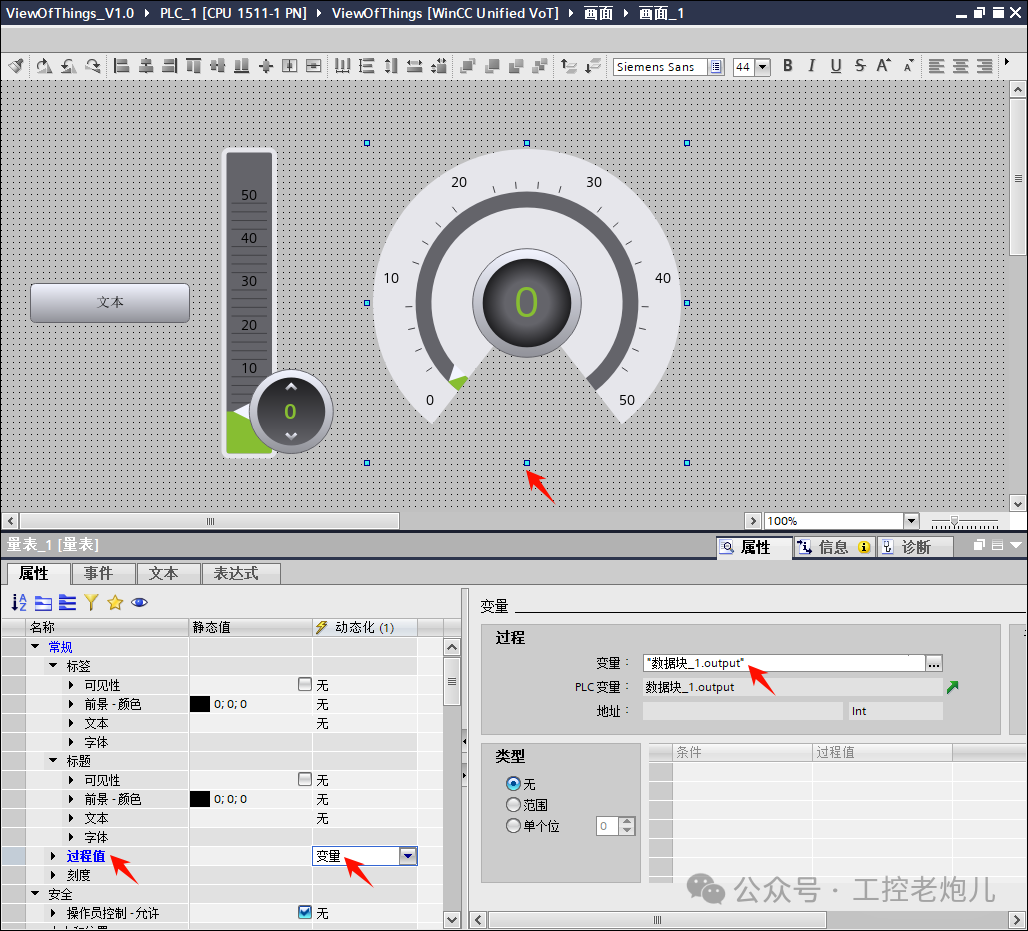

Add process value for the slider:

Add process value for the gauge (dashboard):

The VOT configuration is now complete. The VOT program needs to be compiled to generate the VOT code that will be sent to the PLC. When the VOT screen is active, click the compile button (note: the VOT screen must be recompiled after modifications).

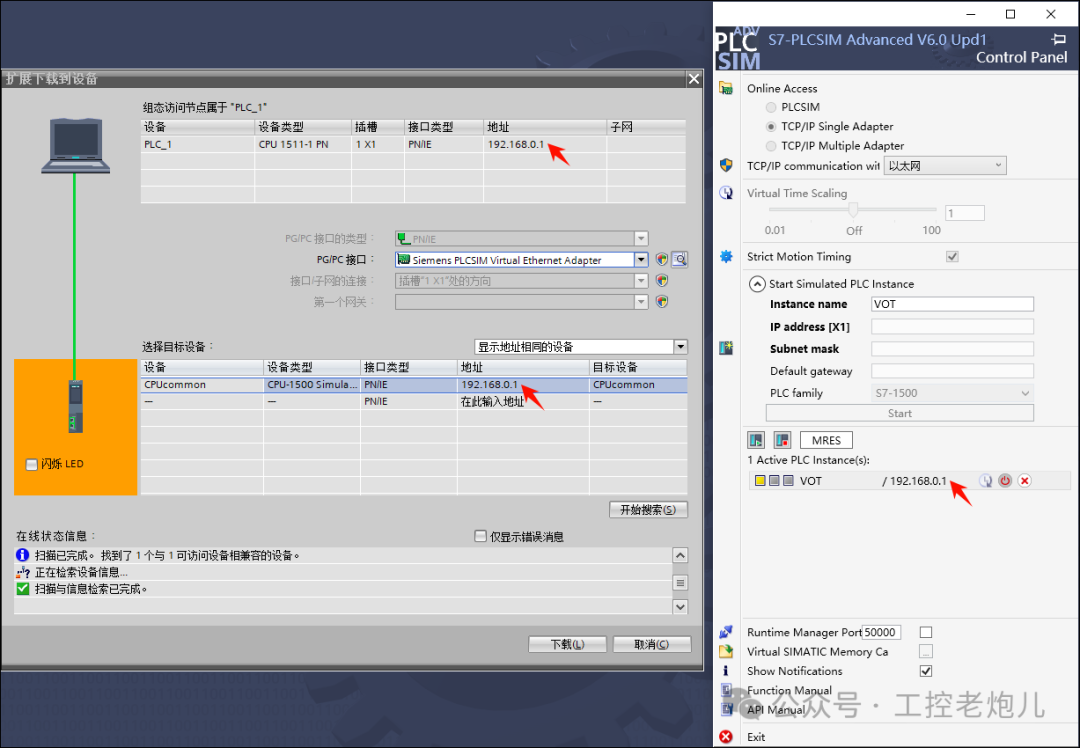

After compiling the VOT application, the project can be downloaded to the PLC. In this example, we will use the PLCSIM Advanced simulation instance, so please create the instance and download the program (note: ensure that the Ethernet virtual adapter is enabled).

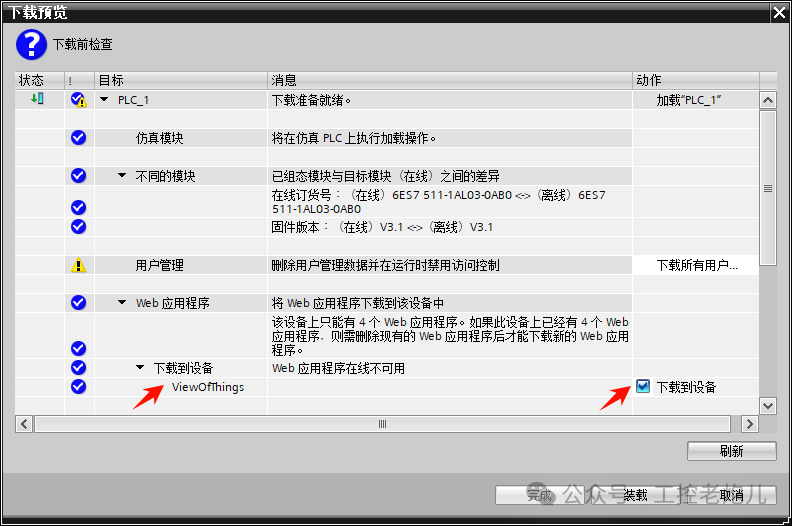

During the download process, check the “Download to Device” checkbox in the download preview window to allow the VOT application to be loaded.

The PLC program and VOT application are now running normally. Now try to access the dashboard screen created in the above steps.

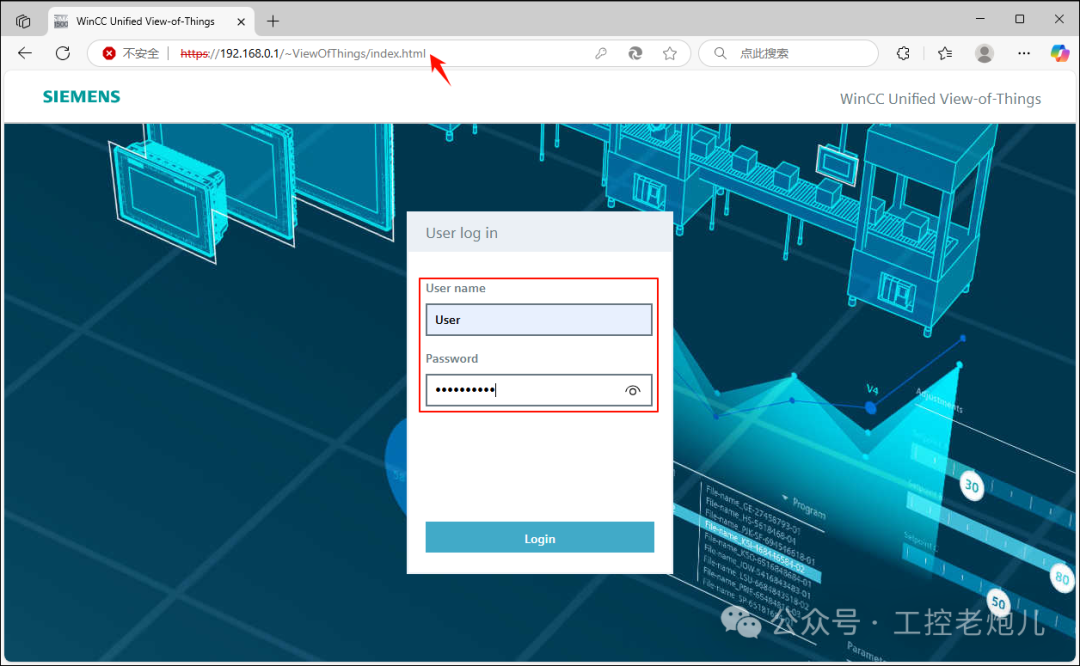

Please enter the following URL in any browser:

https://192.168.0.1/~ViewOfThings/index.html

Or directly access:

https://192.168.0.1/

Then select the customer page.

After opening the page, you will see the user login interface, where you can enter the login credentials created in the previous steps.

The dashboard screen is now displayed in the web browser, allowing direct interaction with the created program.

Conclusion

Through this tutorial, you have learned how to utilize the View Of Things feature in TIA Portal to directly integrate web-based HMI visualization interfaces into PLC systems.

The specific operational process includes:

- First, configure the CPU and create a basic PLC program as the carrier for the VOT application;

- Then, build an interactive operation screen, adding buttons, sliders, and gauges, and configure their communication connections with the PLC program;

- Compile the PLC and VOT code and deploy it to the PLCSIM simulation environment, testing the dashboard interaction functionality through a web browser.

The advantages of quick access to HMI visualization brought by the View Of Things feature are significant:

- Eliminates the need for dedicated HMI panels and complex network configurations, greatly improving operational efficiency;

- Enables direct integration through the PLC’s built-in web server, allowing engineers and operators to monitor and adjust key process parameters in real-time from any location;

- The real-time interaction capability of the HMI dashboard effectively enhances decision-making, troubleshooting, and system response speed.

You will see the roles of generators, steam turbines, condensers, feedwater pumps, boilers, etc., throughout the entire working cycle!

Previous Issues · Recommendations

Electrician’s Repair Diary: Fixing Motor Faults in Two Hours, Workers Urged to Avoid Anger

What Should a 38-Year-Old Electrician Do Next?

Learning Circuits, Animated Graphics are Invincible!

Learn About an Information System Every Day: MES System

Why Does Shielded Wire Have Such a Big Effect? But Remember to Ground One End!

Share, View, and Like, at least I want to have one!