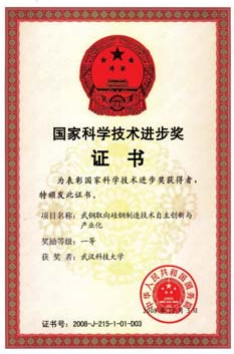

National Awards

Compilation of Achievements from Wuhan University of Science and Technology

Independent Innovation and Industrialization of Manufacturing Technology for Oriented Silicon Steel by Wuhan Iron and Steel Corporation

Oriented silicon steel is a type of steel material with excellent soft magnetic properties, primarily used in the electromechanical and energy industries. It is a major raw material for electrical appliances and is one of the most complex steel products in terms of production processes, with the longest production flow, highest technical content, and greatest technical difficulty. In China’s manufacturing technology for oriented silicon steel, six national technical standards and two industry technical standards have been led by Wuhan Iron and Steel Corporation. This project has applied for 68 patents, including 30 inventions, and possesses over 200 technical know-how.

Based on the comprehensive digestion, absorption, and innovation of introduced technologies, Wuhan Iron and Steel Corporation has formed a series of proprietary technologies for controlling composition, degree, thickness, and grain orientation. They have independently developed four major series of oriented silicon steel products and manufacturing technologies, represented by QRD low-oriented silicon steel, significantly reducing the heating temperature of oriented silicon steel. The unit furnace output of the hot rolling process has increased from 8,000 tons to 100,000 tons, fundamentally changing the situation where the production of oriented silicon steel at Wuhan Iron and Steel Corporation was constrained by introduced patent technologies.

In addition, Wuhan Iron and Steel Corporation has independently integrated and constructed supporting projects for secondary silicon steel, four steelmaking projects, and three hot rolling projects, achieving a localization rate of over 90% for equipment, resulting in a leap in the technological capabilities and production capacity of oriented silicon steel. The product quality has reached world advanced levels and has been awarded the title of “China Famous Brand Product.” The annual output has increased from 120,000 tons in 2004 to 310,000 tons in 2008, with the output of high-end HiB steel increasing from several thousand tons before 2007 to 150,000 tons in 2010, and reaching 300,000 tons in 2013. Since 2007, the domestic market share has exceeded 50%. This has resolved the long-standing market demand for oriented silicon steel production in China, changing the situation where product resources were dependent on imports. Previously, all products used domestically, except those produced by Wuhan Iron and Steel Corporation, relied entirely on imports, with the highest dependency reaching 70%, while high-end Hi-B silicon steel was almost 100% dependent on imports.

This project has formed a series of proprietary control technologies, applied for 68 patents, including 30 inventions, and possesses over 200 technical know-how. In the national standards for oriented silicon steel manufacturing technology in China, six national standards and two industry standards have been led by Wuhan Iron and Steel Corporation. This technology has significantly reduced the heating temperature of oriented silicon steel, fundamentally changing the situation where the production of oriented silicon steel at Wuhan Iron and Steel Corporation was constrained by introduced patent technologies.

Contact Information

Technical Service Contact Phone:

Deng Meng 13007135600

Zhang Kai 13871540110