Application of Dam Safety Monitoring System in Water Conservancy

Dam safety monitoring is a core aspect of water conservancy project management. Traditional methods have significant shortcomings in real-time performance, data coverage, and intelligent analysis. This paper proposes a dam safety monitoring system that integrates LORA wireless communication technology and digital twin technology. It achieves low-power, wide-area data transmission through LORA, combined with digital twin technology to construct high-precision dynamic models for monitoring and predicting the entire lifecycle of dam structures. The system has been deployed in multiple water conservancy projects, validating its effectiveness in improving monitoring efficiency, reducing operational costs, and enhancing early warning capabilities. The research results provide an innovative solution for the construction of smart water conservancy.

The dam, as a core facility of water conservancy projects, directly relates to the realization of functions such as flood control, power generation, and irrigation. Traditional monitoring methods rely on wired sensors and manual inspections, which have drawbacks such as complex wiring, delayed responses, and isolated data. In recent years, the rapid development of the Internet of Things (IoT) and digital twin technology has provided new ideas for intelligent monitoring of water conservancy projects.

LORA Technology: Supports long-distance (3-15 km), low-power wireless communication, suitable for the complex terrain of dams.

Digital Twin: Real-time mapping of the physical dam state through virtual models, combined with historical data and machine learning for fault prediction. The combination of the two can construct a new monitoring system with wide coverage, strong real-time performance, and intelligent analysis, significantly enhancing dam safety management levels.

1. Overall Design1.1 System Architecture Design

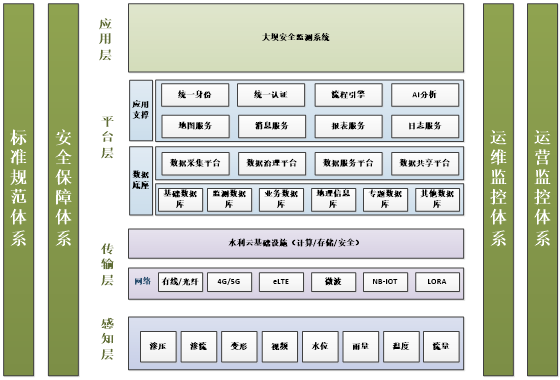

In accordance with the construction requirements of digital twin technology and the development needs of modern water conservancy, a dam safety monitoring system architecture based on LORA and digital twin technology is designed. The overall architecture is divided into perception layer, transmission layer, platform layer, application layer, network security system, and operation and maintenance support system. The detailed overall architecture diagram is as follows:

Figure 1 System Architecture Diagram

The perception layer: mainly collects various data information during the operation of the project, including seepage pressure, seepage flow, deformation, video, water level, rainfall, temperature, flow rate, etc.

The transmission layer: uploads the data information collected by the perception layer to the cloud platform through network facilities such as LORA, 4G/5G, or optical fiber.

The platform layer: The platform layer is the “central” of the LORA and digital twin-based dam safety monitoring system, serving as the system foundation for processing monitoring data and business applications. The construction content includes a data base platform and an application support platform, which can achieve data cleaning, storage, analysis, and calculation of the monitoring data from the perception layer to construct the digital twin model.

The application layer: integrates monitoring data with basic information of the reservoir to construct a visual interface for management personnel, while also providing early warning and decision support based on monitoring data.

1.2 Hardware Design

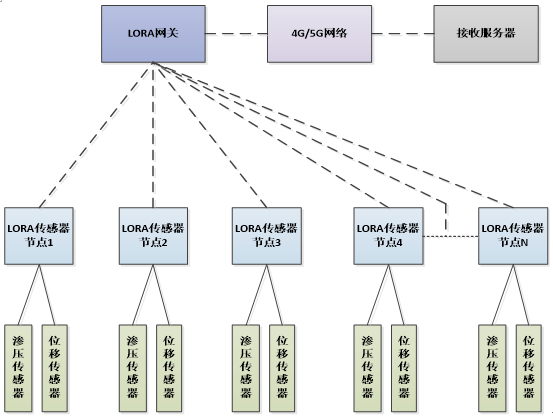

The hardware devices mainly include LORA sensor nodes and LORA gateways: the overall hardware working structure diagram is as follows.

The LORA sensor node is responsible for responding to inquiries from the LORA gateway, collecting data from connected sensors, and reporting the collected data to the LORA gateway.

The LORA gateway is responsible for periodically querying the LORA sensor nodes and receiving the data reported by the LORA sensor nodes, then processing and converting the data before reporting it to the cloud server, while also responding to information sent from the cloud server.

Figure 2 Hardware Structure Working Diagram

1.3 Software Design01 Digital Twin Model Construction

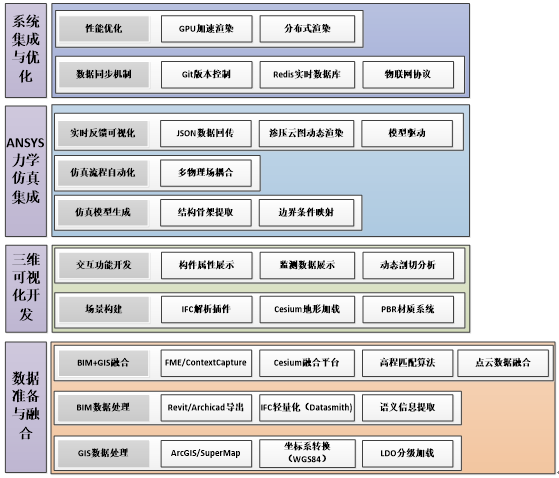

Based on BIM (Building Information Modeling) and GIS data, 3D visualization is achieved using Unity3D, integrated with ANSYS for mechanical simulation, and the simulation results are reflected in real-time on the model. The entire digital twin model architecture framework is shown in the following diagram.

Figure 3 Digital Twin Model Architecture Diagram

1) Data Preparation and Fusion: First, BIM data processing is performed by generating a construction model of the reservoir dam using BIM software, exporting it in IFC (Industry Foundation Classes) format, which includes geometry, materials, component attributes, etc.; using FBX Exporter (Unity) to optimize the model’s polygon count and materials to avoid rendering pressure on the engine; parsing metadata in BIM (component ID, functional classification) to provide logical associations for subsequent simulations and interactions; secondly, GIS data processing is performed using software such as ArcGIS and SuperMap to obtain terrain data of the reservoir dam, in formats including Shapefile, GeoTIFF, point cloud, etc.; then converting the local coordinate system of BIM to the global coordinate system of GIS; LOD (Level of Detail) processing: dynamically loading GIS data based on the visualization range, switching to high-precision point clouds around the reservoir dam. Finally, BIM+GIS fusion is achieved using FME, Bentley ContextCapture, or Cesium platform to ensure accurate embedding of the BIM building model into the GIS terrain scene, ensuring elevation matching (the base of the reservoir dam fits the terrain surface).

2) 3D Visualization Development: First, scene construction is performed by importing the BIM model into the engine through the IFC parsing plugin; GIS terrain is dynamically loaded using Cesium for Unreal/Unity plugin for global or local maps; physically based rendering (PBR) materials are applied to give the reservoir dam a realistic texture; dynamic global illumination (such as Unreal’s Lumen) simulates natural light changes. Secondly, interactive functionality is developed, allowing users to click on the model to obtain BIM attributes (including the location of on-site monitoring facilities, monitoring data, and reporting dates); dynamically slicing the model allows viewing of internal structures.

3) ANSYS Mechanical Simulation Integration: Extracting the structural skeleton from BIM and importing it into ANSYS Mechanical, converting it into a finite element mesh; defining simulation constraints based on GIS environmental data (temperature, humidity, atmospheric pressure, etc.); writing parameterized simulation scripts; coupling ANSYS Fluent (fluid) with Mechanical (structure) for wind vibration analysis; exporting simulation results (displacement data) in JSON format, transmitted to the visualization engine via WebSocket; parsing data in Unity to drive model deformation and color mapping.

4) System Integration and Optimization: Using Git to manage updates of BIM/GIS data, ensuring consistency in multi-team collaboration; deploying Redis to handle real-time data streams from sensors; utilizing Unity’s Burst Compiler to enhance particle effect computation efficiency; adopting Unity Render Streaming for cloud rendering and access from low-end devices.

02 Data Analysis Algorithms

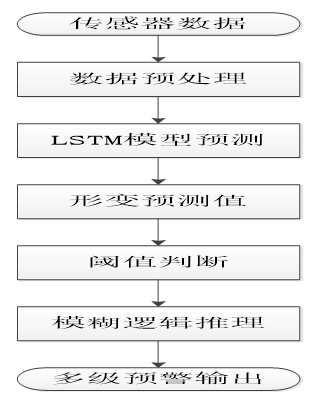

Using LSTM (Long Short-Term Memory) networks to predict structural deformation trends, triggering preliminary warnings based on threshold methods, and employing fuzzy logic for multi-level risk assessment in complex scenarios, ultimately generating dynamic warning signals. The entire data analysis algorithm framework is shown in the following diagram.

Figure 4 Data Analysis Algorithm Flowchart

1) Sensor Data: Obtained from the front-end LORA devices, the structural deformation time series data (seepage pressure, seepage flow, displacement, tilt angle, strain, etc.); external factors data such as temperature, humidity, wind load, etc.

2) Data Preprocessing: Using sliding average filtering to eliminate high-frequency random noise (such as electromagnetic interference), combined with wavelet transform to separate signal characteristic frequency bands to cope with non-stationary noise; addressing data missing issues through interpolation based on the spatial-temporal correlation of sensors, and introducing Generative Adversarial Networks (GAN) to synthesize physically plausible virtual data; finally, standardizing multi-source data dimensions through Z-score normalization (converting displacement units from mm to standardized values), while achieving millisecond-level precision timestamp synchronization, ensuring accurate alignment of multi-sensor data streams on a unified timeline, providing high-quality input for subsequent analysis.

3) LSTM Model Prediction: The LSTM prediction model adopts a time-series-driven architecture: the input layer constructs time-series feature vectors using time window slices (all monitoring data within the past 24 hours); the hidden layer captures long-range dependencies in both forward and backward directions through bidirectional LSTM, embedding attention mechanisms to dynamically focus on key event nodes (such as seepage pressure values during increased rainfall); the output layer generates predictions for seepage pressure values over the next 6 hours, and outputs confidence intervals using Monte Carlo Dropout techniques for uncertainty quantification. The model training employs Huber Loss to balance prediction accuracy and robustness against outliers, combined with spatial-temporal cross-validation strategies (partitioning training/validation sets by spatial regions) to prevent overfitting, ensuring generalization capabilities in complex environments.

4) Deformation Prediction Values: Based on the core warning indicators output by the LSTM deep learning model, the input layer (all monitoring data within the past 24 hours) extracts spatial-temporal features through bidirectional LSTM and attention mechanisms, generating predictions for seepage pressure values over the next 6 hours, and quantifying prediction uncertainty using Monte Carlo Dropout techniques, outputting confidence intervals (displacement range at 85% confidence level). This prediction not only reflects structural deformation trends but also assesses reliability through error boundaries, providing key inputs with both numerical precision and credibility for subsequent threshold judgments and fuzzy logic reasoning, directly driving multi-level warning decisions.

5) Threshold Judgments: Dynamic threshold settings adopt a static-dynamic combination strategy: the static part sets safety thresholds based on design specifications (dam displacement limit of 10mm) and a warning buffer threshold of 60% of the historical maximum; the dynamic part achieves adaptive adjustments through sliding window statistics (recent data mean ± 3σ), coupled with ANSYS physical simulation results (stress-displacement relationships) for threshold corrections, forming multi-dimensional warning baselines.

6) Fuzzy Logic Reasoning: The fuzzy logic reasoning module fuzzifies input variables (deformation values {“slight/moderate/severe”}, change rates {“gentle/accelerated/sudden”}) using triangular/Gaussian membership functions, and implements multi-level warning decisions based on an expert rule base (e.g., “moderate deformation and acceleration → orange warning, severe deformation or water level exceeding limit → red warning”).

7) Multi-Level Warning Output: Based on deformation prediction values and dynamic threshold judgment results, multi-level alerts are generated through fuzzy logic reasoning: the system sets five warning levels: green, blue, yellow, orange, and red, where green does not trigger a warning, requiring seepage pressure values to be below 10% of the safety threshold; blue warning triggers when seepage pressure values exceed 10% of the safety threshold but are below 20% (only logging); yellow warning triggers when seepage pressure values exceed 20% of the safety threshold but are below 40% (initiating high-frequency monitoring); orange warning triggers when seepage pressure values exceed 40% of the safety threshold but are below 60% (manual intervention for verification); red warning triggers when seepage pressure values exceed 60% of the safety threshold (triggering emergency and equipment linkage). The warning results are synchronized with the three-dimensional BIM model, highlighting the warning areas in real-time.

2. Key Technology Implementation1. LORA Network Optimization

Data verification mechanism: Communication between LORA sensor nodes and LORA gateways combines device address verification and CRC data verification to avoid co-frequency data interference, enhancing communication stability.

Dynamic wake-up mechanism: The MCU and communication module of the LORA sensor node are configured to external wake-up mode (the standby power consumption of the entire LORA sensor node can be controlled within 1mA (12V). When the collection time arrives, the LORA gateway can issue commands to wake up the LORA sensor node for data collection and reporting, ensuring that the LORA sensor node can still operate normally in low-power working mode.

2. Digital Twin Model Driven

Real-time data mapping: Sensor data is synchronized to the twin model via network protocols, with the fastest update frequency reaching once per second.

Multi-physical field coupling analysis: Combining seepage field-stress field coupling models to assess the long-term stability of the dam.

3. Safety Warning Strategy

The platform has established a four-level warning mechanism:

Normal display (green): Data values have not exceeded 10% of the safety threshold.

Level 1 warning (blue): Data values exceed 10% of the safety threshold but have not exceeded 20%.

Level 2 warning (yellow): Data values exceed 20% of the safety threshold but have not exceeded 40%.

Level 3 warning (orange): Data values exceed 40% of the safety threshold but have not exceeded 60%.

Level 4 warning (red): Data values exceed 60% of the safety threshold.

4. Application Cases and Effect AnalysisCase Background

A certain earth-rock dam is 85m high and 320m long, deploying 20 LORA nodes and a set of LORA gateways, monitoring coverage of the dam body and foundation, with monitoring data including seepage, seepage pressure, displacement, water level, rainfall, wind speed, wind direction, and atmospheric pressure data.

Implementation Effects

This paper uses the case reservoir as a background to compare various situations between traditional methods (manual measurement), wired systems, and LORA systems, as shown in the table below:

Table 1 Comparison of Implementation Effects of Three Systems

| Traditional Method | Wired System | LORA System | |

| Management and Construction Costs | High | Medium | Low |

| Technical Requirements for Management Personnel | High | Low | Low |

| Line Interference During Signal Acquisition | Low | High | Low |

| Efficiency of Data Collection and Reporting | Low | High | High |

| Operation and Maintenance Difficulty | Low | Medium | Low |

| Degree of Damage to the Dam Body from Installation Facilities | Low | High | Low |

| Environmental Requirements for the Dam Body | Medium | Low | High |

| Ability to Respond to Extreme Weather | Medium | High | Medium |

Overall comparison shows that using the LORA system as a dam safety monitoring facility solution on conventional flat reservoirs has significant advantages: low management and construction costs, low technical requirements for management personnel, minimal line interference during signal acquisition, high data collection and reporting efficiency, low operation and maintenance difficulty, and low degree of damage to the dam body from installation facilities.

5. Conclusion

The “LORA + Digital Twin” dam safety monitoring system proposed in this paper achieves real-time perception, intelligent analysis, and precise early warning of dam status through the collaboration of wireless sensor networks and high-precision virtual models. Practical applications indicate that this system can significantly enhance the safety management level of water conservancy projects and provide a technical paradigm for the promotion of smart water conservancy. Future research will focus on: first, enhancing the anti-interference capability of LORA in extreme environments to ensure effective application of LORA communication under extreme weather; second, improving model accuracy and data quality to enhance the reliability of twin model data to meet more complex engineering demands.

Provided by: China Railway Water Conservancy Information Technology Co., Ltd.