Application Case

In a smart manufacturing enterprise’s production line upgrade project, faced with the stringent demands of processing a large amount of equipment status data daily and connecting multiple heterogeneous terminals, traditional industrial computers struggle to support real-time decision-making due to computational bottlenecks and communication delays.The Inconsi NIS-5130 industrial computer, with its edge computing architecture design, successfully established a closed-loop system for data collection, edge analysis, and control command issuance, achieving the following breakthroughs.

1. Creating a Data Core for Edge Computing

1

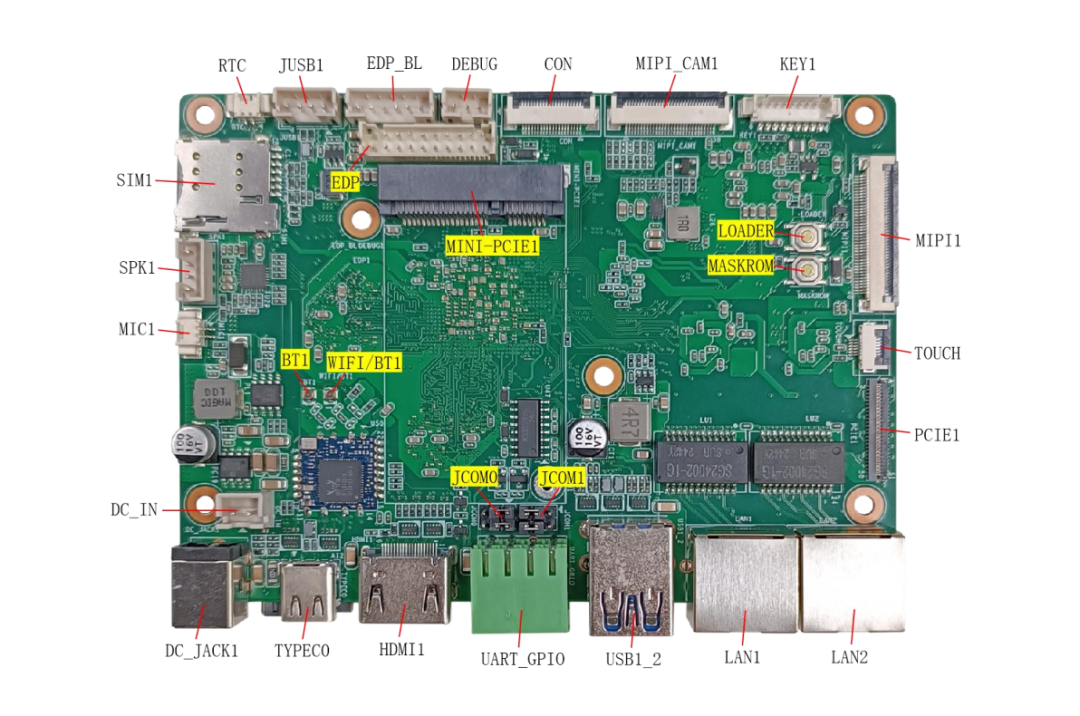

Unified Access to Multi-source Heterogeneous Data: Through dual Gigabit Ethernet ports, 2 configurable serial ports (RS232/RS485), and an optional CAN bus expansion board, it synchronously accesses industrial protocol devices such as Modbus TCP, Profinet, and EtherCAT, maximizing data collection completeness.

2

Millisecond-level Response Control: Based on the RK3588 processor (8nm process, 4×[email protected]) parallel computing capability, a single device completes the entire process of multi-channel sensor data parsing, AI anomaly detection model inference, and PLC control command generation with accelerated time consumption.

3

Industrial-grade Environmental Adaptability: Under harsh conditions of temperature fluctuations (-20℃~60℃) and strong electromagnetic interference, the device operates continuously without failure, with the CPU core temperature stably controlled below 68℃.

2. Main Advantages of the NIS-5130 Solution

High-precision Data Collection:

· Dual Gigabit Ethernet ports achieve physical isolation between the internal and external networks of the production line, ensuring data security;

· 4G/5G module + dual-band WiFi create a redundant transmission channel, automatically switching to wireless links in case of wired network failures, ensuring zero data loss;

· 2 configurable serial ports (RS232/RS485) are compatible with legacy device access, reducing renovation costs.

Remote Collaborative Management:

Users can additionally increase through optional expansion boards:

· 2×CAN bus interfaces: connect various mobile devices;

· PCIe 4X slot: expand high-speed data acquisition cards to meet future production capacity expansion needs;

· Memory LPDDR4X 4GB/8GB/16GB options, storage EMMC 64GB/128GB/256GB options, providing diverse choices.

3. Application Effectiveness and Value Enhancement

Increased Fault Warning Rate: By analyzing equipment vibration and temperature data in real-time on the edge, potential faults are identified in advance, reducing unplanned downtime.

Energy Consumption Optimization: Dynamically adjusting production line equipment operating parameters to reduce ineffective power consumption.

Reduced Operation and Maintenance Costs: Remote monitoring and diagnostic functions reduce the frequency of on-site inspections, improving operation and maintenance efficiency.

END

Long press to scan the QR code for more information

Long press to download the QR code for more products

Shenzhen Inconsi Industrial ControlPlanning & Editing: Xiao Ying (Click the image to see more application cases)★ Previous Application Cases ★

(Click the image to see more application cases)★ Previous Application Cases ★ ———————— TPC-983H Bridge Crane Automation Control Case ————————

———————— TPC-983H Bridge Crane Automation Control Case ———————— ———————— NIS-983H High-speed Rail Large Screen Display Case ————————

———————— NIS-983H High-speed Rail Large Screen Display Case ———————— ———————— FC-YS828 Energy Consumption Monitoring Case ————————

———————— FC-YS828 Energy Consumption Monitoring Case ————————

STEP BY STEP