Skip to content

This article analyzes the smart manufacturing development of SANY Heavy Industry, a leading enterprise in the equipment manufacturing industry, focusing on its transformation process in smart manufacturing and the construction of the IoT platform. It explores the construction of smart manufacturing and industrial IoT platforms for Chinese manufacturing enterprises, providing reference for building industrial IoT platforms and implementing smart manufacturing.

01 / The Development Process of SANY Heavy Industry’s Smart Manufacturing

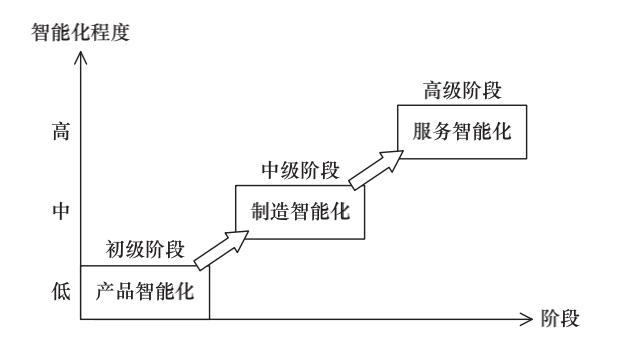

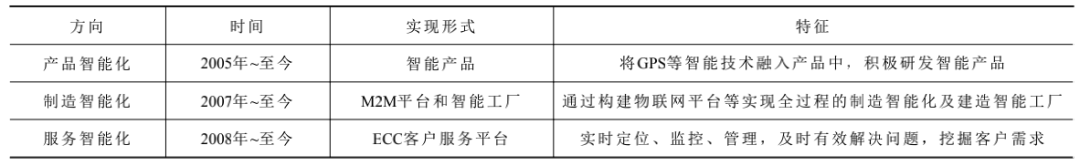

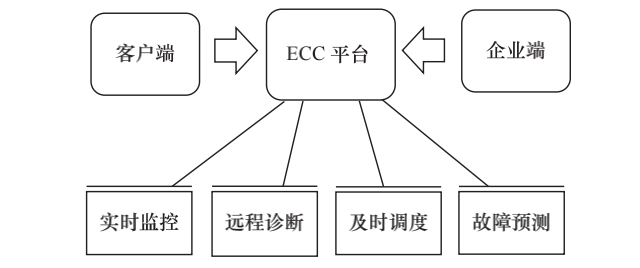

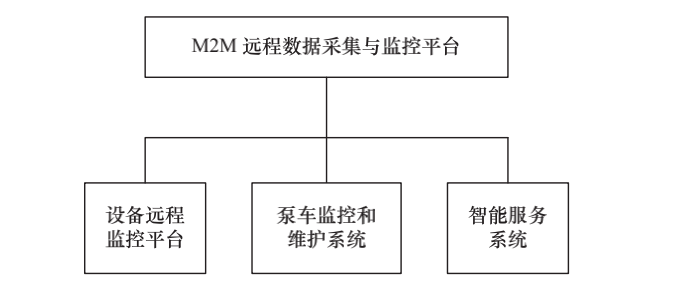

Analyzing the development of SANY Heavy Industry’s smart manufacturing, we identify the following three stages: product intelligence, manufacturing intelligence, and service intelligence. Among them, product intelligence is at the initial stage, manufacturing intelligence is at the intermediate stage, and service intelligence is at the advanced stage, with their levels of intelligence increasing from low to high, as shown in Figure 1.

Figure 1: The Transformation Process of Intelligent Manufacturing in Enterprises

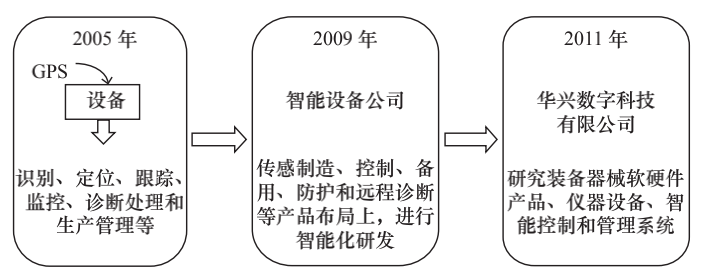

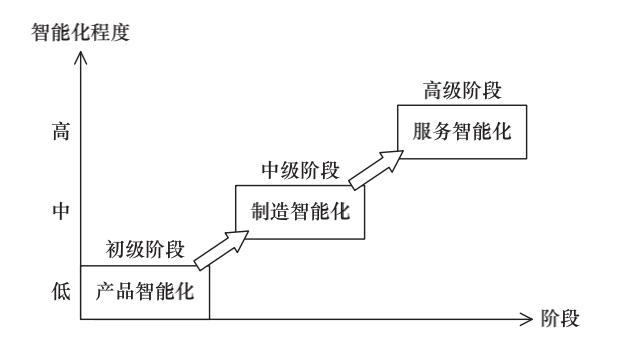

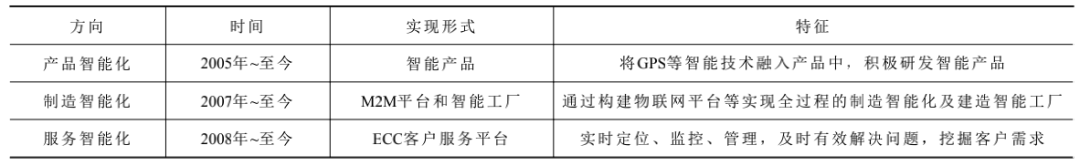

To achieve the transformation to smart manufacturing, SANY Heavy Industry actively engages in the research and development of intelligent products. With the development of the IoT, SANY Heavy Industry keenly recognizes the significant role that the IoT will play in the equipment manufacturing industry. In 2005, SANY Heavy Industry was the first to begin researching core components and technologies in equipment manufacturing based on the IoT, and began applying GPS in the equipment manufacturing industry, achieving the ability to locate, track, monitor, identify, diagnose, and manage production using GPS technology. This made it the first company in the country to realize this functionality.

In 2009, SANY Heavy Industry established a smart equipment company, implementing intelligent product R&D in various types of industrial equipment including sensing manufacturing, control, backup, protection, and remote diagnostics, becoming the first company in China’s industrial manufacturing sector to develop intelligent technologies and mechanical products, and a leader in the field of smart manufacturing. In 2011, SANY Heavy Industry established Huaxing Digital Technology Co., Ltd. in Shanghai, primarily researching and developing hardware and software products for equipment, instruments, and intelligent management systems, forming a complete set of intelligent terminal devices that facilitate real-time remote monitoring and maintenance of equipment. The process of SANY Heavy Industry’s product intelligence R&D is shown in Figure 2.

Figure 2: The Process of Product Intelligence R&D

SANY Heavy Industry utilizes big data analysis to monitor equipment operation data more precisely, improving product power efficiency and reducing fuel consumption. Additionally, big data applications can help R&D personnel analyze product structures, using data-based development models to identify which models are more popular and market-oriented, providing high reference value for product design.

In summary, SANY Heavy Industry’s product intelligence process has gone through three stages: initial use of GPS, establishment of a smart equipment company, and establishment of a digital technology company, while actively applying big data analysis to gradually realize product intelligence. Product intelligence is the initial stage of the enterprise’s smart manufacturing transformation, where the focus is on the application of intelligent technologies and big data in the product R&D process, dedicated to developing intelligent products.

2. Manufacturing Intelligence

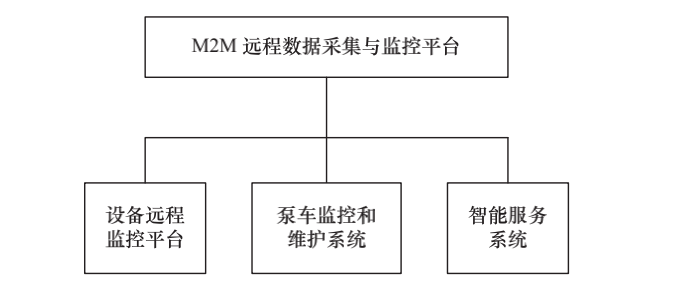

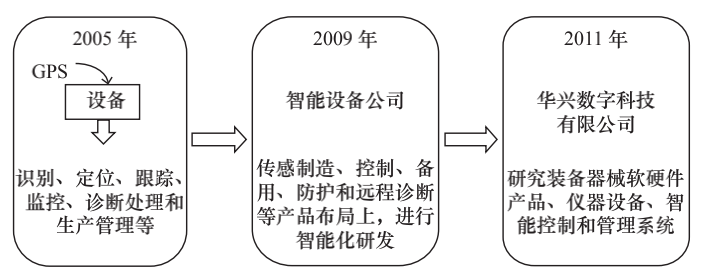

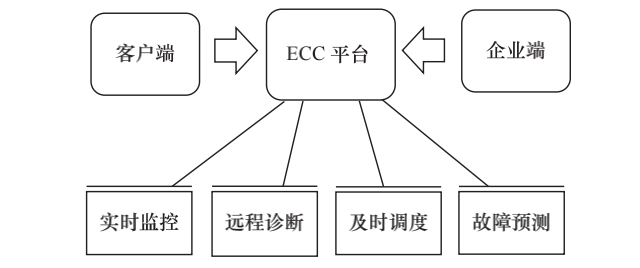

While conducting product intelligence R&D, SANY Heavy Industry is also actively transforming the manufacturing process to intelligence. In 2007, SANY Heavy Industry began exploring the development of an M2M platform, collaborating with China Mobile’s Changsha branch on the “SANY Construction Machinery Intelligent Service System” project, establishing an “M2M Remote Data Collection and Monitoring Platform.” This platform consists of three subsystems: data collection and reverse control system, smart channel system, and M2M application system.

After 2010, SANY Heavy Industry strengthened the application of the M2M system in information collection and transportation, and developed solutions, subdividing the “M2M Remote Data Collection and Monitoring Platform” into three sub-platforms: the first is the remote monitoring platform for equipment, which includes a monitoring technology support platform and an equipment data statistics platform, capable of providing information such as improving equipment quality, tracking and servicing equipment, and other parameter information; the second is the pump truck monitoring and maintenance system, which utilizes advanced theories of machinery intelligence in the equipment manufacturing industry to develop intelligent products with independent intellectual property rights, enhancing monitoring and maintenance capabilities, optimizing the efficiency of the enterprise; the third is the intelligent service system, which achieves collaborative effects and work between on-site machines by real-time sharing of information regarding site conditions, concrete delivery consumption, vehicle usage, and actual operation information of pumps and mixing facilities.

After years of development, by 2011, SANY Heavy Industry successfully established the largest M2M system available nationwide, capable of dynamic expansion based on 500,000 terminals. The subsystems of the M2M remote data collection and monitoring platform are shown in Figure 3.

Figure 3: Subsystems of the M2M Remote Data Collection and Monitoring Platform

With the continuous development of SANY Heavy Industry’s manufacturing intelligence and the application of the IoT platform, in 2012, SANY Heavy Industry built Factory No. 18 located in Changsha Industrial Park, becoming a demonstration workshop for intelligent manufacturing in China. Before the construction of the workshop, information simulation design was used to model the factory, planning the entire design of the workshop in advance through logistics simulation and production process reasoning to prevent potential issues during construction and save costs. The entire workshop implements flexible production, allowing machines and production lines to assemble different parts and products, and can be modified at any time according to demand. Intelligent terminals are installed at employee workstations to assist employees in querying standard operating procedures and installation methods.

In 2019, SANY Heavy Industry decided to transform Factory No. 18 into a lighthouse factory benchmark in the machinery manufacturing industry. After a year of development, Factory No. 18 achieved a higher level of intelligence, with technical workers able to respond to material requirements at all workstations using a single device, and the use of intelligent robots became more proficient, improving per capita efficiency, per capita output value, and resource utilization.

From the above analysis, it is evident that SANY Heavy Industry has transformed its production processes to intelligence through the construction of the IoT platform—M2M Remote Data Collection and Monitoring Platform, actively applying big data analysis, ultimately establishing intelligent factories, achieving manufacturing intelligence. Manufacturing intelligence is the intermediate stage of the enterprise’s smart manufacturing transformation, where the focus shifts from single product intelligence to applying intelligent technologies throughout the entire manufacturing process, constructing IoT platforms and utilizing big data to achieve intelligent manufacturing throughout the process.

With the manufacturing of intelligent products by SANY Heavy Industry, to better address post-sales service issues and product maintenance, SANY Heavy Industry pioneered the development of the ECC system (Enterprise Control Center) in 2008 to avoid losses caused by equipment downtime for customers. This system can accurately locate service personnel and vehicles in real-time. When equipment issues occur, customers can call the 24-hour service hotline, and the ECC can dispatch personnel quickly and effectively, guiding customers in troubleshooting or arranging for maintenance personnel to provide on-site service. Additionally, this system can provide other value-added services, such as automatically triggering alarms when equipment leaves the designated work area.

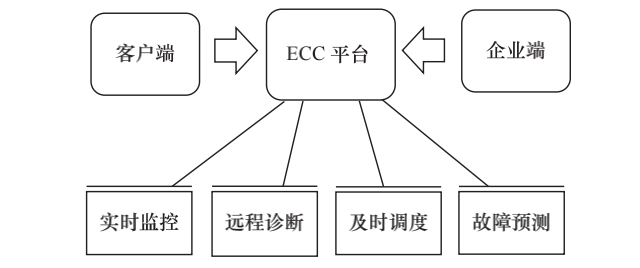

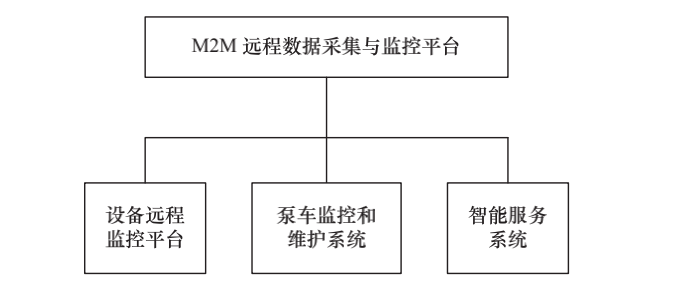

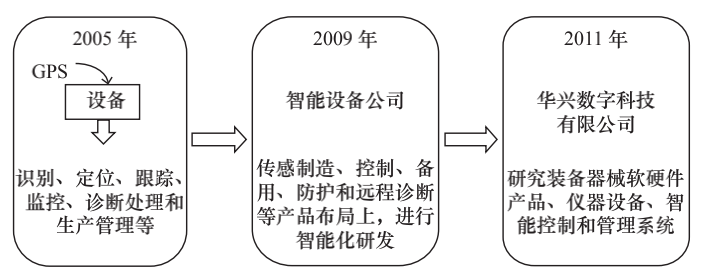

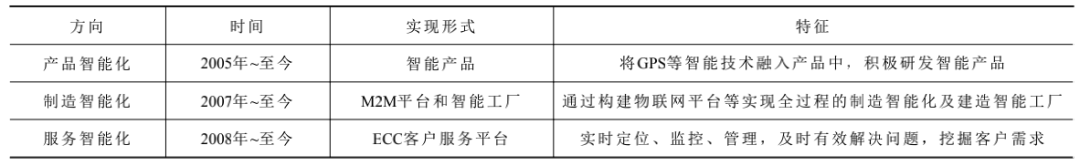

In 2014, the advent of the “Industrial Big Data” era prompted SANY Heavy Industry to recognize the greater value of the early customer after-sales service equipment monitoring and control system. SANY Heavy Industry optimized and improved the early ECC system and developed a new ECC platform—Customer Service Platform, for storing and analyzing big data. Through the “ECC platform,” SANY Heavy Industry actively conducts big data applications, digitally transforming the entire process of production, manufacturing, and service, and facilitating communication through computer storage analysis and sharing. The ECC platform can perform bidirectional control and remote monitoring of all hardware and software controlled by equipment, sending real-time operational data from over 200,000 customer devices to the backend system for optimization analysis. The main users of the ECC platform are agents, operators, customers, and R&D personnel. The functions of the ECC platform are shown in Figure 4.

Figure 4: Functionality of the ECC Platform

Through the ECC platform, SANY Heavy Industry has made customer service more intelligent. Customers using the ECC platform can monitor their equipment operations in real-time, receiving information from the system about their equipment, making it more convenient for customers. When equipment fails, the ECC platform can achieve faster troubleshooting based on real-time detection results, changing the previous “passive” service situation, better enhancing customer service levels and managing financial risks. Even before failures occur, SANY Heavy Industry can predict potential issues through data diagnostics of equipment operation, informing customers of possible failures, allowing them to address issues before they arise, extending equipment lifespan and health, reducing customer losses, and leveraging big data to mine customer service needs to design products that better meet customer demands, as well as optimizing the service process through big data analysis.

In summary, SANY Heavy Industry has monitored customer equipment operational status through the establishment of the ECC customer service platform, helping customers resolve issues more quickly, and by applying big data technology to mine customer needs, providing better service. Service intelligence is the advanced stage of the enterprise’s smart manufacturing transformation, where the enterprise manages the entire lifecycle of products, deeply integrating products, manufacturing, and services, achieving an intelligent product service system.

02 / Comparison of the Three Stages

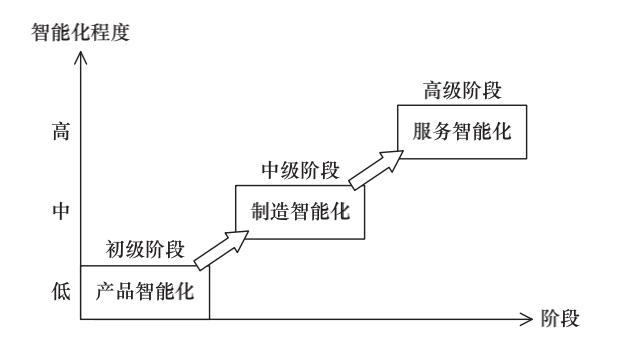

SANY Heavy Industry’s transformation to smart manufacturing is carried out from three aspects: product intelligence, manufacturing intelligence, and service intelligence, with comparisons shown in Table 1.

Table 1: Comparison of Intelligent Manufacturing Development Stages

SANY Heavy Industry simultaneously began the transformation process of product intelligence and manufacturing intelligence. After achieving scale in intelligent product R&D, it proceeded with the transformation of service intelligence. In all three processes mentioned above, big data analysis and application were integrated. Through the collaborative development of these three aspects, SANY Heavy Industry achieved its smart manufacturing transformation. Product intelligence focuses on how to integrate SANY Heavy Industry’s products with intelligent technologies, enhancing product functionality; manufacturing intelligence, from a production perspective, utilizes the IoT platform to achieve intelligence throughout the entire production process, precisely controlling equipment through mining and analyzing extensive operational data, ultimately establishing intelligent factories; service intelligence builds the ECC platform to manage the entire lifecycle of equipment, increasing equipment lifespan and health, reducing customer losses, and providing manufacturing services centered around customer value.

In conclusion, through the collaborative development of these three stages, SANY Heavy Industry promotes its intelligent transformation, enhancing product R&D capabilities, realizing the value of equipment across its lifecycle, and providing better service to customers.

Based on the case analysis of SANY Heavy Industry, it can be seen that manufacturing enterprises leveraging industrial IoT for intelligent transformation generally experience three stages: product intelligence, manufacturing intelligence, and service intelligence. Through the collaborative development and mutual influence of these three stages, intelligent manufacturing is gradually realized.

Manufacturing enterprises, during their intelligent transformation process, need to implement product intelligence upgrades to provide customers with intelligent products. Intelligent products are the foundation of smart manufacturing. Enterprises should focus on applying emerging technologies such as digital technology to the product layout of industrial equipment, developing intelligent terminal devices such as machinery instruments and intelligent management control systems, collaborating with intelligent software companies, and collecting and analyzing the intelligent needs of downstream customers in the supply chain for intelligent R&D, making product control and production processes more convenient, thereby improving enterprise efficiency and producing higher quality products for customers. At the same time, enterprises should pay attention to the introduction of intelligent talent and manage the refined processes of intelligent products, establishing a product knowledge base.

2. Manufacturing Intelligence

On the basis of intelligent products, manufacturing enterprises can construct industrial IoT platforms for timely control and data collection of production processes, making the manufacturing process more precise and effectively managing the manufacturing site, keeping real-time track of progress. Enterprises can collaborate with intelligent technology companies, actively engage in intelligent product R&D while introducing intelligent equipment, emphasize resource sharing in the manufacturing process, apply production information management systems such as MES, and focus on training intelligent talent in the production process. Therefore, manufacturing enterprises should strengthen their transformation towards manufacturing intelligence, build intelligent factories, and emphasize flexible manufacturing to effectively utilize resources and improve production efficiency.

Manufacturing enterprises should focus on both ends of the smile curve, emphasizing both product design and customer service. By mining customer demand information, manufacturing enterprises can design products that better meet customer needs; simultaneously, through real-time monitoring of equipment operation data and key component wear, they can provide early warnings before issues arise, achieving proactive maintenance and precise cost control, significantly enhancing the quality of customer service. Through service intelligence transformation, manufacturing enterprises change traditional manufacturing models, gradually completing control over the entire lifecycle of products and enhancing customer value. Enterprises should also consider introducing senior service talents, intelligent service facilities, and developing intelligent service software to optimize service processes intelligently.

From the perspective of the supply chain, it is essential to incentivize upstream and downstream enterprises to share information and study customer-oriented service operation platforms. Service intelligence runs through the entire process of product intelligence and manufacturing intelligence, representing a deep integration of products, manufacturing processes, and services, achieving collaborative product intelligence and service intelligence, ultimately forming an intelligent product service system.

In the context of the “Industry 4.0” revolution and the era of big data, how to successfully undergo intelligent transformation is an urgent issue for manufacturing enterprises. This article employs a descriptive single-case study method, taking SANY Heavy Industry as a case study, exploring its construction of an IoT platform and the process of intelligent manufacturing transformation. SANY Heavy Industry’s approach to smart manufacturing transformation through product intelligence, manufacturing intelligence, and service intelligence provides valuable experience for Chinese manufacturing enterprises in implementing smart manufacturing and developing industrial IoT.

In the long run, the value of intelligent products and equipment across their entire lifecycle will continue to rise, and industrial IoT and smart manufacturing will have a significant impact on traditional manufacturing models. To respond to the challenges and impacts brought by smart manufacturing models, manufacturing enterprises should establish good partnerships with upstream and downstream supply chain enterprises, collaboratively build a big data platform serving the entire industry, leverage platform value, and achieve intelligent transformation and win-win cooperation.

The original text was published in “Manufacturing Technology and Machine Tools”, Issue 7, 2022

Authors: School of Management, Xi’an University of Engineering, He Zheng, Li Yanni, Yang Xiaohong