For the manufacturing industry, under the backdrop of a new round of technological revolution and industrial transformation, intelligent manufacturing characterized by digitalization, networking, and intelligence has become a trend for future development. Cloud-based precise management of supply chains, continuous online monitoring, optimization of production equipment operation, energy data management, and industrial safety production in the industrial field will greatly enhance the development potential of enterprises. Industrial IoT platforms or industrial cloud platforms represent an important direction for future development in the industrial sector, and companies at home and abroad are engaged in fierce competition. SANY Heavy Industry Group, as a traditional manufacturing enterprise primarily producing concrete machinery, excavators, and other engineering machinery, strives to seize the current opportunities in intelligent manufacturing, accumulate new growth momentum, and provide reference experience for domestic enterprises.

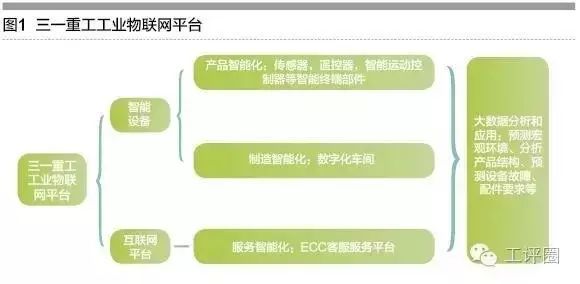

Building a Local Industrial IoT Open Platform

SANY Heavy Industry Group mainly engages in the production of concrete machinery, road machinery, pile machinery, and crawler cranes, holding the largest domestic market share in concrete delivery pumps and full-hydraulic road rollers, and ranking first in the world for pump truck production. As global manufacturing moves towards Industry 4.0, SANY Heavy Industry is also actively seeking to transform into intelligent manufacturing. The development of SANY Heavy Industry’s industrial IoT can be divided into three stages.

Early IoT Exploration Stage. Focus on the research and application of the “Internet of Things” with M2M as the main component, establishing the “M2M Remote Data Collection and Monitoring Platform”.

As early as 2005, SANY Heavy Industry recognized the increasingly important role of IoT in the engineering machinery industry and began research on core components and related technologies of engineering machinery IoT. SANY Heavy Industry became the first company in the domestic engineering machinery industry to apply GPS systems, enabling identification, positioning, tracking, monitoring, diagnostic processing, and enterprise production management of global equipment.

In 2007, China Mobile’s Changsha branch collaborated with SANY Heavy Industry on the “SANY Engineering Machinery Equipment Intelligent Service System” project to explore the establishment of an “M2M Remote Data Collection and Monitoring Platform” based on IoT technology. The platform consists of three parts: a data collection and reverse control subsystem based on the CAN bus, an intelligent channel subsystem, and an M2M application platform. By utilizing data collection devices installed on equipment, M2M terminals, and reverse control systems, the equipment status parameters are transmitted to the enterprise monitoring center through the China Mobile network.

Initially, it was a small-scale commercial application, implemented in a limited range of engineering equipment and vehicles, mainly addressing technical issues such as unstable information collection status, inadequate wireless network transmission bandwidth, and network interface renovation of the monitoring information platform. In 2009, SANY Heavy Industry’s “M2M Remote Data Collection and Monitoring Platform” achieved large-scale commercial use, establishing the first engineering machinery IoT enterprise control center in the country. The company further improved the onboard M2M system, which is standardized for engineering machinery, pre-installed before leaving the factory, and activated China Mobile’s M2M services.

Large-Scale Application Stage of IoT. Strengthen remote data collection and analysis, enhance product intelligence levels.

After 2010, SANY Heavy Industry strengthened the application of M2M in information collection, data analysis, information transmission, and solution operation, further subdividing the “M2M Remote Data Collection and Monitoring Platform” and gradually forming three sub-platforms.

The first is the equipment remote monitoring technology support platform. This includes the equipment remote monitoring technology support platform and the equipment data platform, providing reference data for the continuous improvement of main equipment quality and after-sales service.

The second is the fleet intelligent service system. Through real-time data interaction and sharing of concrete mixer truck location information, concrete delivery information, concrete consumption information, and the current operational status of pumping equipment and mixer trucks among various fleet devices at the mixing station, collaboration and operational guidance among fleet devices can be achieved. Based on this, users can adopt more scientific vehicle scheduling strategies and equipment operating modes, improving enterprise operational efficiency and equipment utilization while reducing overall operational costs.

The third is the pump truck remote monitoring and maintenance system. By studying the theory of intelligent front-end for engineering machinery, leading industry products with independent intellectual property rights have been developed to enhance the operational capability and levels of engineering machinery, designing and constructing advanced remote monitoring systems to comprehensively improve the enterprise’s information service level and operational efficiency.

In 2011, SANY Heavy Industry built the largest M2M application platform in the domestic engineering machinery industry, capable of supporting 500,000 devices to connect in parallel and having dynamic expansion capabilities.

In terms of product intelligence, a complete system formed by a full set of intelligent terminal components including sensors, remote controllers, and intelligent motion controllers can collect data through this intelligent product, enabling the company to perform real-time remote monitoring and diagnostics on equipment. In 2009, SANY Intelligent Equipment Control Co., Ltd. was established to lay out products for sensing, communication, driving, control, human-machine interaction, remote maintenance, and diagnostics, providing intelligent products and systems for various industrial equipment, making SANY Heavy Industry the first engineering machinery enterprise in China to independently develop intelligent technology and products, establishing the company’s leading position in the field of intelligence. In 2011, SANY Heavy Industry Shanghai Huaxing Digital Technology Co., Ltd. was established, focusing on the research and development of engineering machinery instruments, hardware and software products, automatic control systems, and intelligent management systems.

Big Data and Cloud Platform Stage. Actively develop big data applications using the “ECC Customer Service Platform”.

Excavators have powerful functions, high production and sales volumes, and complex systems, currently showing trends of high efficiency and low energy consumption, intelligent precision, and better user experience. As a traditional manufacturing enterprise, the first step is to digitize all links of manufacturing, service, and production, and then use computer calculations, storage, and sharing for communication.

SANY Heavy Industry independently developed a big data storage and analysis platform called the “ECC Customer Service Platform”, which includes all hardware and software for underlying control of equipment, enabling bidirectional interaction and remote control of equipment, capable of transmitting real-time operational data from over 200,000 customer devices to the backend for analysis and optimization through sensors. Daily real-time monitoring of equipment operational information (such as location, working hours, speed, main pressure, oil consumption, etc.) is directed towards four main user categories: agents, operators, excavator owners, and R&D personnel. The design points of big data focus on the four aspects of agents, operators, excavator owners, and R&D personnel, using basic matrices to break down into basic vectors, further decomposing into feature values, which are then recombined to form custom vectors that combine into matrices such as equipment information and health, thereby providing value-added services throughout the entire lifecycle. Users can grasp the status of machines in various aspects anytime and anywhere through web pages or mobile apps. Based on big data analysis, precise control can be implemented for commonly used gears by region, load, and temperature, improving the powertrain efficiency of new products by 8% and reducing fuel consumption by 10%.

SANY Heavy Industry has formed over 5,000 dimensions, with 200 million data points per day, and over 40TB of big data resources. Based on this data, the main applications of big data are in the following aspects:

First, predicting the macro environment. SANY Heavy Industry collaborated with Tsinghua University to launch the “Excavator Index”, showing data such as equipment working hours and operating rates, predicting next month’s fixed asset investment increment based on operating rate data, which can reflect the macroeconomic trends in China to some extent. By analyzing data from each province, trends in fixed asset investment across provinces can be discovered, allowing for real-time analysis of regional market changes to guide marketing.

Second, analyzing product structure. Establishing a data analysis-based R&D model can reveal which product models are more popular, providing strong reference value for product R&D based on market positioning.

Third, predicting equipment failures. Maintenance can be performed in advance when signs of failure appear; currently, 50% of equipment failures can be predicted in advance, reducing losses for customers.

Fourth, predicting parts demand. By studying the relationship between equipment operating conditions and parts consumption, a predictive model can be established, significantly lowering production costs for enterprises.

Significant Achievements in Industrial IoT Platform Construction

Through the use of intelligent service systems and the intelligent analysis capabilities of system data, SANY Heavy Industry has developed energy-saving control technology for excavators, greatly improving fuel efficiency and reducing fuel costs during the use of excavators. By real-time monitoring of equipment operational conditions, key component wear, fuel consumption, and pressure conditions, early warnings can be issued before problems arise, achieving proactive maintenance, precise control of costs, and significantly improving user service quality. By overcoming the core technical bottlenecks of safety and controllability in engineering machinery, the development of financing leasing business has been promoted, enhancing service efficiency.

In the field of engineering machinery, leveraging IoT and big data, SANY Heavy Industry provides scientific solutions and services, enhancing equipment performance and user experience, and for excavators, pump trucks, pavers, and other engineering machinery, has embarked on a path of intelligent differentiated development, achieving enterprise transformation.

Actively Exploring Innovations in Industrial IoT Business Models

SANY Heavy Industry has jointly established Mingzhao Capital with several domestic venture capital institutions. This fund focuses on investing in startups and small and medium-sized enterprises in the fields of Industry 4.0 or IoT. In March 2016, SANY Heavy Industry, together with Zhuhai Dahengqin Investment Co., Ltd., Zhuhai Huachuang Investment Management Co., Ltd., and 15 other shareholders, jointly initiated the establishment of China’s first IoT-based professional insurance company, Jiulong Insurance. Due to the diversity and complexity of risks in the equipment industry, very few insurance companies delve into this field, resulting in a clear mismatch between market professional demand and general supply. Leveraging SANY Heavy Industry’s extensive network of over 200 agents and a marketing service team of 9,000, the company embeds professional insurance products into relevant vertical internet platforms in equipment manufacturing, connecting with offline sales channels and service resources. Based on IoT and big data, Jiulong Insurance can more accurately identify risks and pricing, customizing insurance products and services based on customer risk characteristics, providing distinctive financial services for the global expansion of Chinese equipment manufacturing products.

In the future, SANY Heavy Industry plans to integrate domestic resources to build a local industrial IoT platform in China, further enhancing the intelligent manufacturing level of Chinese industry.

Future Development Trends of Industrial IoT from the Practice of SANY Heavy Industry

It is expected that by 2020, the global value of industrial IoT will reach $1.7 trillion. In today’s era of data explosion, how to acquire data, analyze data, and command production with data is the direction of industrial development, and industrial IoT is an important manifestation of industrial digitalization and networking, as well as the key to building core competitiveness for future enterprises.

Foreign companies are rushing into the industrial IoT market. In the field of industrial internet, developed countries are at the forefront. General Electric (GE) in the United States has developed predictive asset management tools such as Predix, Predictivity, and APM, which can connect various production equipment and suppliers to the cloud, providing asset performance management and operational optimization services. In 2014, the company earned over $1 billion through the Predictivity solution alone, and in 2015, it further opened the Predix industrial internet platform, allowing more machines worldwide to connect to the network platform. GE will also launch a dedicated cloud platform for application developers, Predix.io, to further expand GE’s industrial internet platform. Additionally, IBM has launched the Bluemix cloud platform, with over 30,000 cloud clients globally. Siemens in Germany uses SAP HANA cloud platform technology to officially provide data-based services such as predictive maintenance, asset analysis, and energy data management in 2014.

In the long term, the value of hardware manufacturing is continuously decreasing, while the value of intelligent products is continuously increasing. Big data and intelligent manufacturing have brought tremendous impacts on traditional industries; powerful industrial data analysis services will become an important part of the digital strategy of manufacturing enterprises, and industrial IoT will show greater strategic value.

The development of IoT big data platforms is very complex, and it is “unrealistic” for each enterprise to develop independently. The industrial IoT platform also faces issues such as insufficient equipment compatibility, the need for improved data collection technology, and concerns over network security. To establish a strong local industrial IoT big data platform, it is difficult to achieve this solely through the efforts of individual companies; independent approaches cannot achieve “interconnection”. It requires the joint efforts of machinery, hardware, and software companies to build an open platform based on big data from the entire industry to truly realize the platform’s value and achieve a greater impact.

The IoT promotes business process improvements and fosters business model innovation. The rising demand for services has become an important driving force for the ecological development of industrial IoT. In the context of IoT, equipment manufacturers can charge fees based on the customer’s usage of the equipment instead of selling the equipment. At the same time, the market competition model will shift from individual competition to ecological competition, and enterprises must actively participate in the construction of the ecological system with an open mindset. Equipment manufacturers should consider more collaboration with third-party software companies to achieve win-win cooperation.

(Source: China Industrial Review)