-

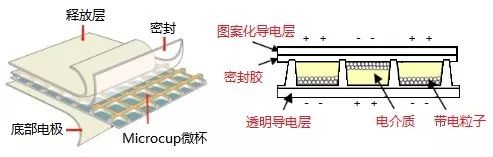

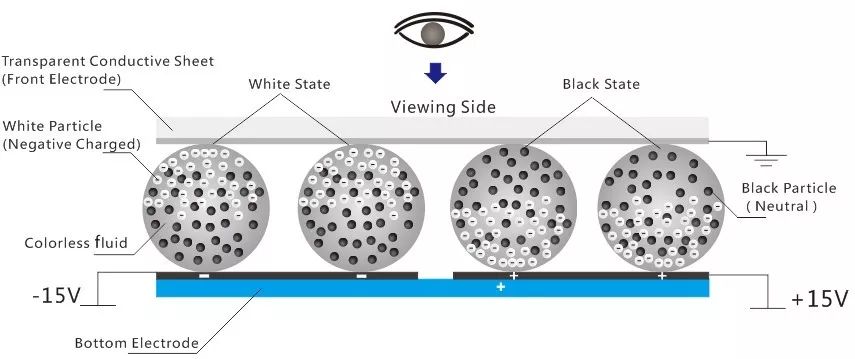

Electrophoretic Display Technology (EPD)

-

Cholesteric Liquid Crystal Display Technology (Ch-LCD)

-

Bi-stable Nematic Liquid Crystal Technology (Bi-TNLCD)

-

Electrowetting Display Technology (EWD)

-

Electrofluidic Display Technology (EFD)

-

Interference Modulation Technology (iMod)

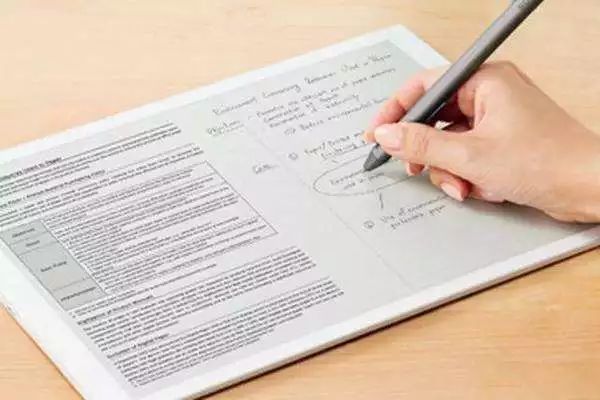

◤ Microencapsulated Electrophoretic Display

◤ Electrowetting Display (E-WET)

-

Liquavista Bright: black and white screen with high contrast, refresh speed sufficient for video viewing. Similar to ink screens, mainly used for e-books.

-

Liquavista Color: color screen suitable for video playback, reading, magazines, etc.

-

Liquavista Vivid: combines black and white and color screens, with a black and white mode (more suitable for reading) and a color mode (more suitable for video and image viewing).

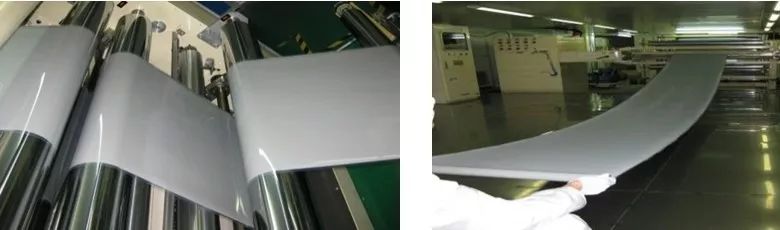

◤ Printing Technology in E-Paper Production

◤ Future Prospects

News is not just the news itself; Display Times takes you deep into the stories behind the news!