New Chapter in LCD Technology Evolution: Flexible Displays. Although Liquid Crystal Display (LCD) technology has been widely adopted in the industry for over twenty years, it still accounts for more than 90% of today’s display shipments. While various alternative display technologies continue to emerge, LCD has repeatedly proven its multifunctional adaptability and self-improvement capabilities. Over the past two decades, LCDs have become thinner, lighter, and larger; at the same time, their display performance continues to improve, including resolution, color, contrast, brightness, and refresh rate. The next chapter in LCD technology evolution will be flexible displays, bringing unprecedented advantages and flexibility to various applications and products.

Flexible OLCD

While flexible OLEDs are now widely used in flagship smartphones and smartwatches, there has yet to be a low-cost alternative display technology capable of providing curved displays for mainstream applications requiring large displays (such as smart home devices, automotive displays, and digital billboards). However, the latest developments in flexible Organic LCD (OLCD) technology open a new design dimension for a broader display market.

Unlike glass substrate LCDs, OLCD uses organic materials as substrates instead of amorphous silicon transistors. The temperatures required to produce these organic transistors are much lower, allowing the use of flexible bio-based substrates as thin as 40 microns—such as triacetyl cellulose (TAC)—to achieve lightweight OLCDs that are not only optically performant but also scalable like glass LCDs.

OLCD not only achieves a more aesthetic product appearance, but its flexibility can also fold the edges behind the display, allowing for ultra-narrow bezels. This brings significant advantages to applications like laptops and tablets, where a borderless design means larger display sizes for the same device dimensions. OLCD technology can also produce ultra-high contrast dual-cell displays with true pixel-level dimming capabilities, providing OLED-like performance at a significantly lower cost.

Compared to glass displays, the ultra-thin OLCD substrates have advantages in cost, viewing angles, and module thickness while retaining the flexibility required for various applications, such as surface-integrated automotive displays. This new technology represents a major advancement in the display industry, with OLCD already entering mass production in Asia and achieving the simultaneous manufacture of large and small screens on flexible substrates for the first time.

Figure 1: Organic LCD with a bending radius of 10mm.

(Image source: Provided by FlexEnable)

Low-Temperature Manufacturing

The transition from glass to flexible substrates will bring immeasurable benefits. Historically, the use of glass has many reasons, including its chemical inertness, optical transparency, and ability to withstand high temperatures of 300~500°C, all of which are essential for constructing silicon-based thin-film transistors (TFT).

Many processes involved in silicon TFT production—such as annealing, sputtering, reactive ion etching, ion implantation, and chemical vapor deposition (CVD)—require significant energy, making high-temperature processes very complex. Due to economic and environmental considerations, the industry needs more energy-efficient production methods, and OLCD offers an attractive alternative. This is due to its unprecedented low-temperature process (the entire OTFT process can be kept below 100°C) because it employs solution-processing organic TFTs.

In addition to lowering processing temperatures, the OTFT process also bypasses high-energy-consuming manufacturing processes associated with silicon. For example, simple solution coating processes can replace CVD. Industry experts estimate that transitioning from silicon TFT to evaporated OTFT can reduce process energy consumption by several orders of magnitude, and using solution-processing OTFT can further lower energy consumption.

Low-Cost Bio-Substrates

In fact, the OLCD process’s temperature is low enough to allow for various thin films to be selected as flexible substrates, including bio-based (non-oil-based) and biodegradable films. The OLCD process uses a transparent flexible film, triacetyl cellulose (TAC); as the name suggests, it is a cellulose typically made from wood pulp—in other words, TAC is made from the same natural materials as paper. In fact, the use of cellulose films as an environmentally friendly alternative to plastics in food packaging is becoming increasingly common.

TAC has been used in the display industry’s supply chain for decades, typically in the polarizers on either side of glass displays, and the device display you use to read documents might employ TAC. The reason for using TAC is its excellent optical performance and low manufacturing costs, with billions of square meters of TAC film produced annually.

During manufacturing, the TAC film is adhered to flat display glass. At the end of this process, TAC can be easily removed from the glass through a very simple “release” process without expensive equipment. This simple process is a key factor in OLCD’s low cost—not only is the yield high, but the flat glass carriers can be reused.

This TFT process developed by professional flexible display manufacturer FlexEnable is the lowest temperature transistor process that has been industrialized to date. Low temperatures not only save energy but also allow for the selection of various substrate materials, including environmentally friendly materials, thus reducing the cost of flexible displays.

High-Performance OTFT

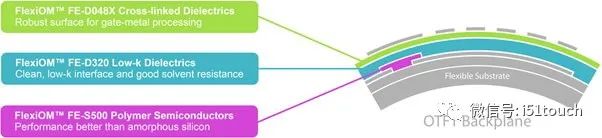

So far, LCDs have been using active matrix backplanes made from hard ceramic substrate materials on glass, which form the basis of transistor technology. The low-temperature manufacturing methods can replace hard ceramic materials with soft, flexible organic materials. The focus has always been on using high-performance, high-quality organic materials to develop OTFT display devices. The OTFT materials used to manufacture OLCD are known as FlexiOM, initially developed by Merck and later acquired by FlexEnable.

The active matrix backplane used for OLCD consists of at least three layers of FlexiOM: the first layer is FE-S500, a nearly amorphous semiconductor polymer with a low degree of energy disorder. The layer above it is FE-D320, a low-k dielectric material that serves as the original interface for the semiconductor. Finally, the organic layer is a cross-linkable dielectric material FE-D048X, which enhances electrical durability.

When they are processed together, it achieves state-of-the-art performance, including a threshold close to 0V and an on/off ratio greater than 106. Its field-effect mobility is greater than 1.5 cm2/Vs, which is higher than most amorphous silicon TFT technologies commonly used in TFT-LCD glass displays.

Figure 2: Cross-section of OTFT backplane using FlexiOM materials.

(Image source: Provided by FlexEnable)

Multiple Design Possibilities

LCD displays are widely adopted, but their purely flat limitations constrain engineers from the start of product design. Electronic products often have to conform to the flat characteristics of displays, which is somewhat counterproductive. Because flexible substrates are easy to cut, replacing glass with these substrates eliminates this design constraint and provides many opportunities to create unique display shapes and curved displays.

Smart Home Devices

Glass-free OLCDs can easily be processed into convex or concave shapes, with a down-bending radius of up to 10mm without affecting the display’s toughness. For example, high-end smart speaker products on the market now come equipped with displays, but these flat glass screens are a compromise between integrating displays and making them blend into the overall product design. Using OLCD allows the display to be designed to “wrap around” the speaker shape, creating a brand new audiovisual user case effect.

Automotive Displays

Automotive applications provide significant opportunities for flexible OLCDs. Modern automotive interior designs often feature curved streamline styles, and a flat display would affect the overall aesthetics; in fact, the display is often the only flat part inside the car. There is a high demand for curved displays in such applications, but currently, there is no viable display technology that fully meets the requirements.

LCDs have been successfully used in the automotive field for many years, despite stringent requirements (the LCD industry has established quality standards suitable for automotive display components to meet these requirements), but the LCD industry has overcome challenges and become the default choice for in-car display applications. Any flexible OLCD implementation scheme can build on this supply chain foundation, making it easier to introduce new display technologies into the automotive market using existing components.

Figure 3: Automotive component supplier Novares integrated a curved OLCD display into Nova Car #2 in 2019.

(Image source: Provided by Novares)

Laptops and Tablets

The cost structure of flexible OLCD is similar to that of glass LCDs—except for glass, it uses many of the same low-cost components, reducing the weight of laptop displays by 100g and thickness by 0.5mm. In addition, OLCD can achieve borderless displays, giving laptops and tablets larger displays without increasing weight.

Televisions and Monitors

Liquid crystal televisions are low-cost and dominate the television market, but they cannot achieve the ultra-high contrast performance of OLED televisions. The latest development in glass LCD technology is to stack two LCDs together to form a dual-cell LCD to improve LCD contrast. Although this method significantly enhances the contrast of the display, it requires four glass plates, increasing the thickness of the display, raising module costs, and requiring brighter backlighting, and it cannot provide true pixel-level dimming functionality.

Using dual-cell OLCD technology can overcome the issues of increased thickness and lack of true pixel-level local dimming. The TAC film used to construct OLCD is ten times thinner than glass, meaning that these two display units can cluster together at a much smaller distance than the pixel pitch of televisions. Moreover, the display architecture becomes thinner and can be manufactured in a simpler manner (compared to dual-cell glass LCDs or OLEDs), at a lower cost, and with higher optical performance.

Digital Billboards

When screens are made of glass, weight becomes a significant consideration for large display devices, as large displays often require sturdy supports or frames, limiting the locations and methods for installing glass displays on buildings and atop objects. OLCD technology possesses all the benefits of LCD technology as advertising selling points in terms of brightness, color performance, video transmission rates, and costs, while its significant advantage is being glass-free, lightweight, and fit for integration. OLCD technology can extend to large displays, even allowing large digital billboard displays to merge with pillars, street decorations, vehicle exterior designs, and retail store interiors.

Comparison with OLED

In recent years, significant investments have been made in flexible OLED technology, particularly in Asia, leading the industry to consider whether OLCD and OLED can coexist to address the flexible display application needs.

By carefully studying the manufacturing and performance attributes of each technology, it can be found that they actually target different market areas. Flexible OLED displays provide excellent performance in contrast, color, and response speed, but have limitations in lifespan, cost, and size scalability. The lifespan of OLED screens is inversely proportional to brightness, making them less suitable for applications that require both high brightness and long lifespan.

OLED also has complex processes, resulting in higher capital expenditures and material costs, leading to very high overall manufacturing costs. Most importantly, several process steps make flexible OLEDs difficult to scale to large sizes, so their applications are currently almost entirely focused on flagship smartphones and smartwatches.

On the other hand, the production process of OLCD is simpler, with complexity similar to that of amorphous silicon LCDs, and it can scale to the same large sizes. Therefore, existing TFT/LCD production lines can be used to manufacture OLCD, producing plastic LCDs with pixel densities, contrasts, colors, and response speeds comparable to similar glass products. The manufacturing costs of OLCD are also close to those of glass LCDs because OLCD can use many components from the existing supply chain, such as polarizers and backlight modules.

Finally, like any LCD, OLCD will not affect its lifespan even if brightness is set to very high levels. Collectively, these characteristics make qualified OLCDs very suitable for applications requiring larger sizes and/or longer lifespans, such as smart appliances and consumer electronics, automotive, laptops, tablets, and even televisions and digital billboards. Thus, OLCD and flexible OLED are complementary technologies that can work together to provide flexibility for all major market segments in the display market.

Displays Moving Towards a “Flexible” Future

By leveraging existing LCD manufacturing technologies, current display manufacturers can quickly transition to OLCD production. Better aesthetic effects have always been a primary purchasing motivation for early adopters of electronic products, driving many designers to shift from flat to bendable new display technologies to achieve novel screen shapes and designs.

From the perspective of display manufacturers, as more 10.5-generation panel production lines come online, the pressure to close or repurpose old small LCD production equipment will grow. OLCD is specifically designed to allow for a quick shift to flexible OLCD manufacturing using existing display production lines while retaining optimized cost segments in the existing supply chain.