With the development of technology, the use of robots is becoming more and more prevalent. For those in the smart manufacturing industry, mastering common robot terminology can be a great help when using robots!

The operation of a robot’s arm or body is typically described by the number of axes or degrees of freedom. The number of joints is a good indicator of the number of axes, as more joints generally mean greater degrees of freedom. However, the ratio of axes to joints is not always 1:1, depending on how each joint moves and the design of the robot. Typically, each motor joint can provide two degrees of freedom.

Axes start with x, y, and z, and then add tilting and rotating capabilities. When selecting a robot for an application, degrees of freedom are a very important consideration and capability (or limitation).

More axes/degrees of freedom provide greater flexibility but also make programming more complex.

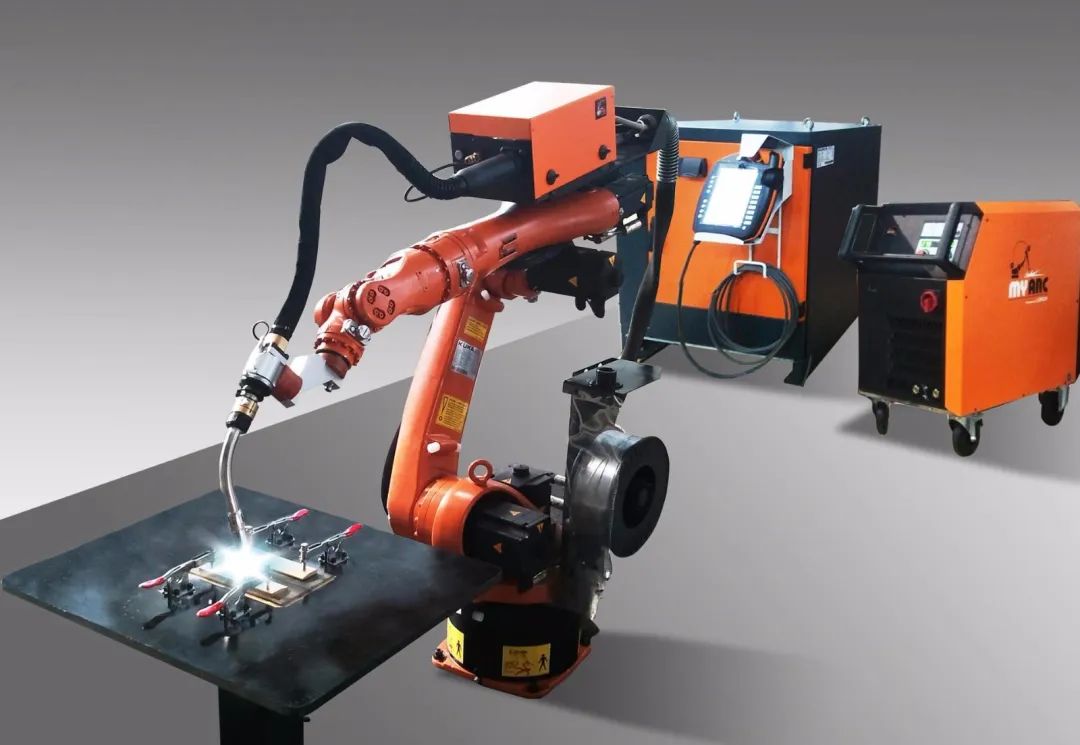

The end effector is the tool at the end of the robot’s arm, used to perform various tasks. Common end effectors include grippers, vacuum suction cups, and various specialized tools such as cutting, drilling, and deburring tools. To enhance the functionality of certain end effectors, auxiliary devices such as sensors or cameras can be added.

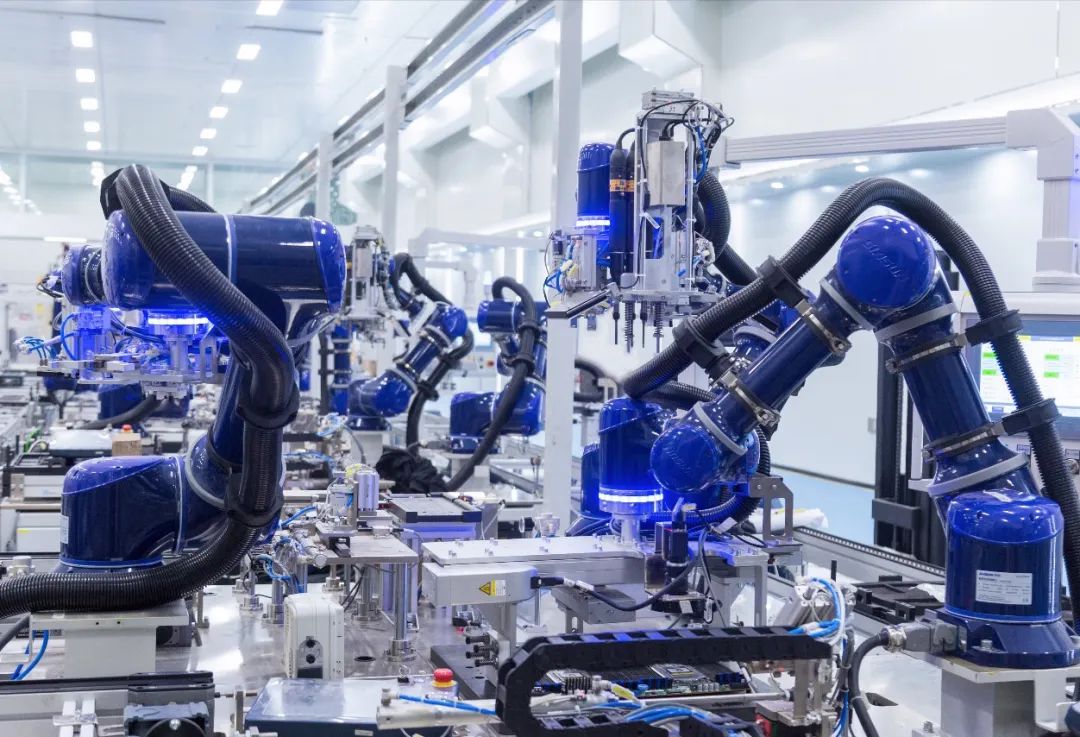

In collaborative robots, manual guidance is often used to help “teach” the robot how to perform tasks. Manual guidance allows the operator to manually move the robot to different positions or waypoints to complete tasks. Manual guidance plays an important role in the programming of collaborative robots.

Repeatability is the ability of a robot to perform the same task over and over again. Although there may be some deviations, if the deviations are minimal when executing tasks repeatedly at the same position, it can be considered to have high repeatability. Therefore, when considering a robot’s performance, repeatability is an important consideration alongside accuracy.

A tool changer simplifies the process when multiple different end effectors need to be used on the same robot by providing an “easy-to-change” interface between the end of the robot arm and the different tools.

Payload refers to the weight that a robot can carry. Additionally, the payload of the end effector is also a factor to consider. If multiple end effectors are planned to be changed on the robot, then the payload is not only a consideration at the initial implementation stage. If the payload is too small, it may not be able to complete tasks ranging from picking up light circuit boards to lifting a stack of shelves. Lighter robots usually have smaller payloads, making them easier to move and redeploy, but appropriate payload must be considered in any case. When calculating payload, the weight of attachments like cameras and end effectors mounted on the robot must be considered.

Grip strength is the force applied by the end effector to an object while moving. Unlike payload, grip strength is more akin to the hand strength required by a tennis player or rock climber.

While a person can lift very heavy objects (payload), their grip strength also plays a crucial role in certain activities. Therefore, when selecting an end effector, it is important to consider not only its payload and strength but also how tightly it can grip an object and how much grip strength needs to be applied.

When discussing collaborative robots, it is generally considered that force-limited robots have built-in safety features that allow them to work safely alongside human workers. However, some force-limited robots may not be capable of performing certain tasks, even without human intervention. Additionally, there are also force-unlimited robots that have other safety features that allow them to be used safely near human workers.

Copyright Notice:Thanks to every author for their hard work and creativity. Except for many articles that cannot be traced, we have noted the sources in the articles.If copyright issues arise from reprints, please contact us for deletion, thank you very much!

Recently Everyone is Watching

1. The Physics World is Exploding! American Scientists Announce Breakthrough in “Room Temperature Superconductivity” Technology

2. How Should Chinese Companies Navigate the Path of Large Models?

3. From “Feature Phones” to “Smart Phones”: Robots Call for RobotGPT

4. Latest Trends and Outlook in Future Industries

5. Ministry of Industry and Information Technology Expert: What is the Biggest Problem with Chinese Sensors? How to Solve It? (Latest Viewpoint)

6. Academician Chu Junhao: Sensors Make Our Sensitive Nerves More Sensitive

7. Collection of Common Machine Learning Terms, Bilingual!

8. Research Finds: New Targets for Destroying Cancer Cells →

9. AGV Robots: The Theoretical Basis for Vision-Based Obstacle Avoidance

10. OpenAI Valuation Reaches $29 Billion: New Round of Financing Announced Complete