Cheng Xin

Global Partner at Bain & Company

Chairman of High-Tech Business in Greater China

Zhu Yonglei

Global Partner at Bain & Company

Chairman of Strategic Business in Greater China

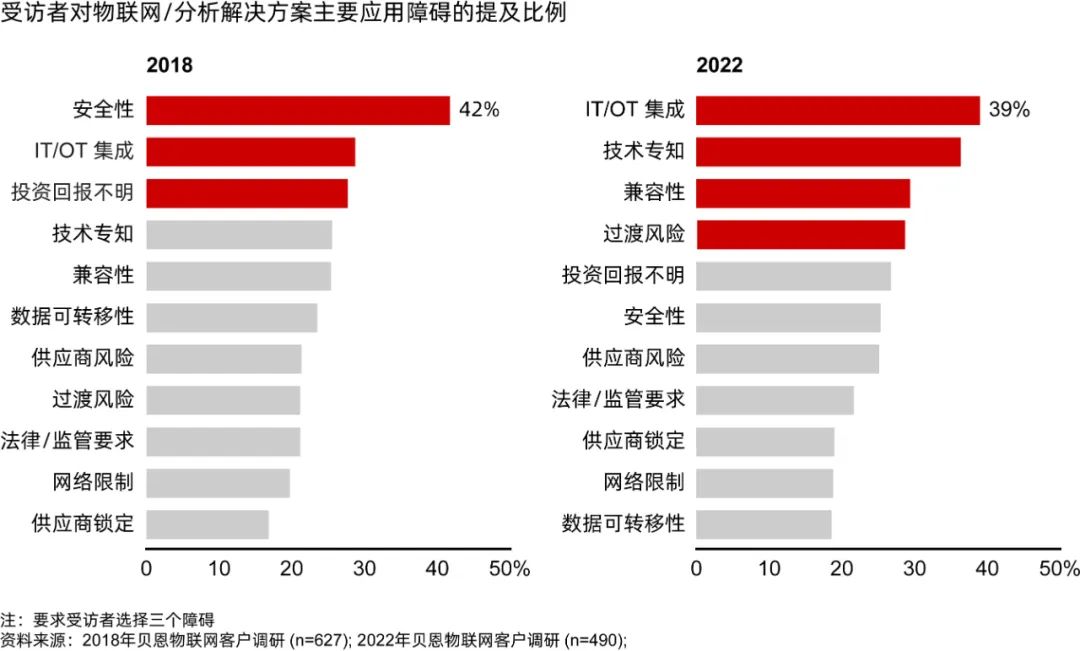

In the last issue, we explored how technology companies can win in the new AI era across three major areas. Beyond the next-generation AI technologies, the development of the Industrial Internet of Things (IoT) has been booming in recent years. Bain’s latest research shows that more and more companies are conducting technology pilots to reduce costs, increase efficiency, and improve revenue, yet they struggle to achieve large-scale applications. In this issue, we will share the current status, challenges, and solutions for the large-scale application of corporate industrial IoT.

Currently, the application of industrial IoT is significantly rising globally: according to Bain’s latest research, among 500 surveyed IoT decision-makers in Europe and the United States, the number of organizations conducting proof of concepts (POC) increased by nearly 20% from 2018 to 2022, and is expected to rise another 20% by 2026. Almost all respondents indicated that their deployment progress was in line with or exceeded expectations, with cost reductions and revenue increases of up to 30%-40%.

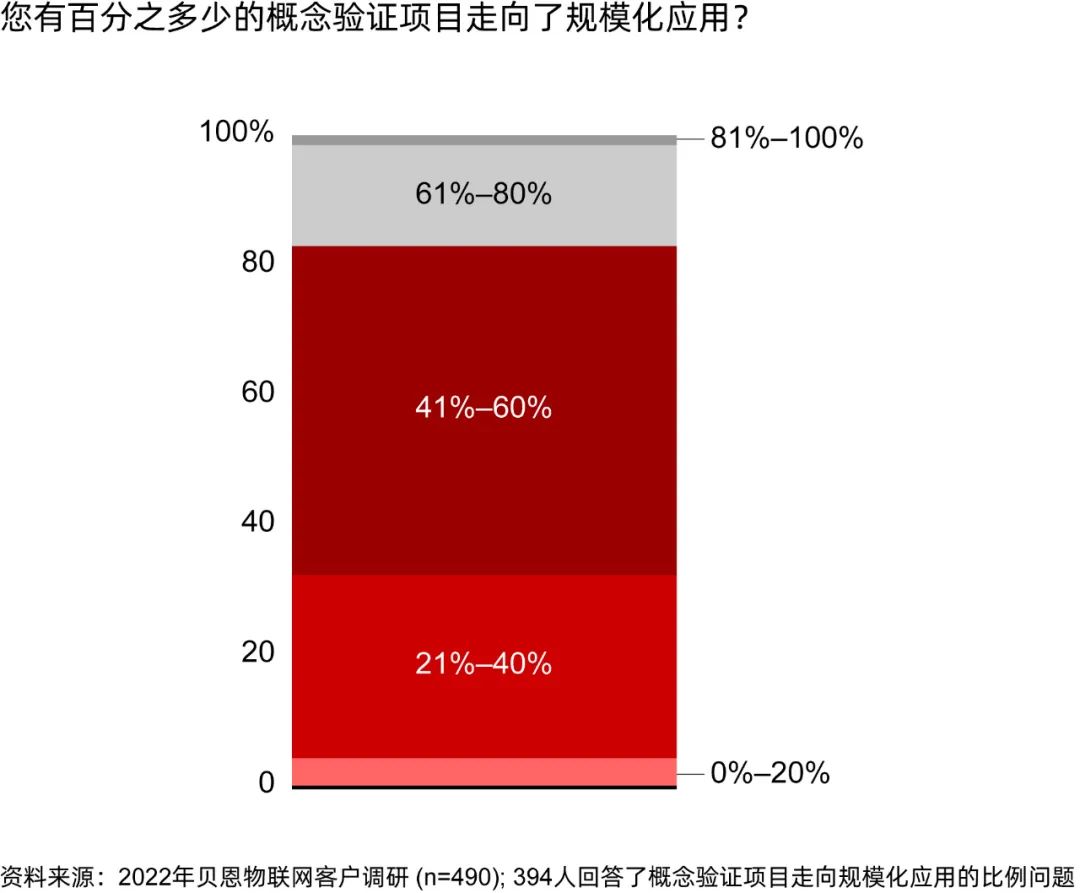

Figure 1: In 4 out of 5 surveyed companies, less than 60% of

proof of concept (pilot) projects progressed to large-scale applications

-

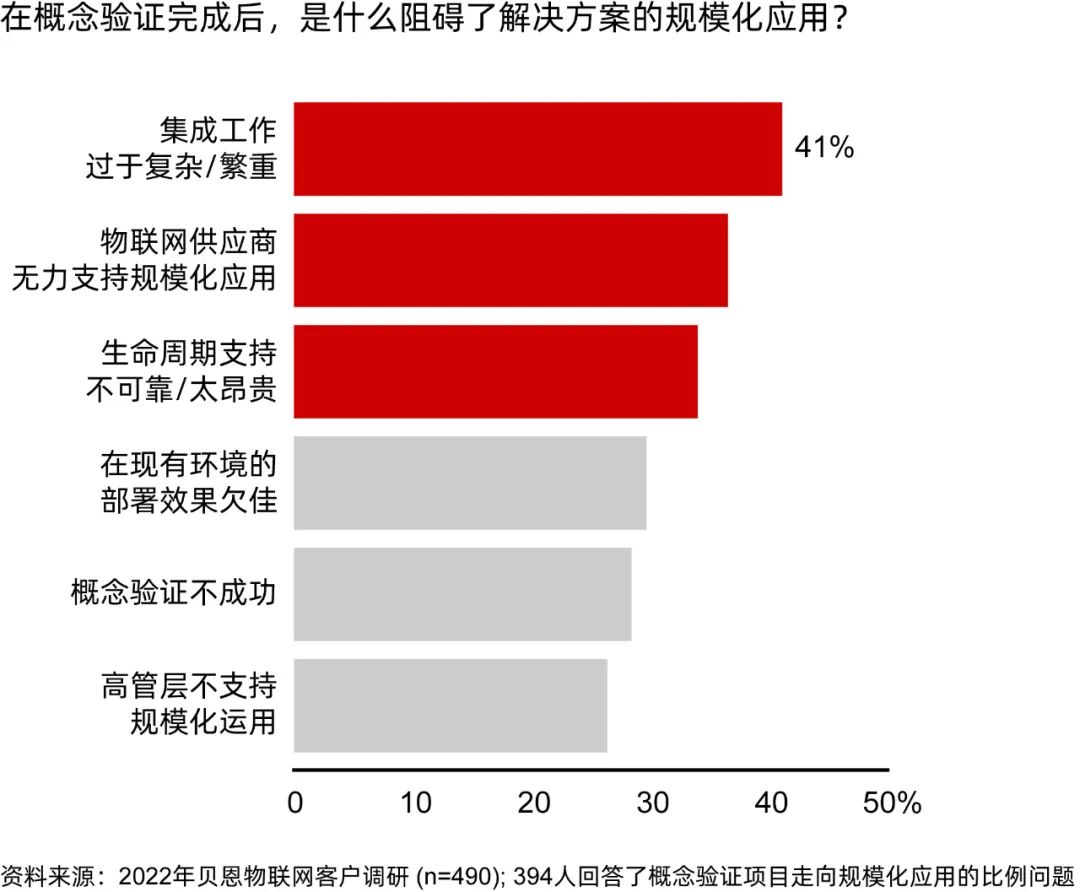

Challenge 1: High Integration Complexity, is the most widespread challenge faced by the surveyed companies (Figure 2);

-

Challenge 2: Difficulty of suppliers to support large-scale applications;

-

Challenge 3: Insufficient lifecycle support for IoT solutions.

The Three Advantages of Hardware Providers

-

Advantage 1: Rich industry knowledge, talent pool, and implementation experience

Case Study 1

Krones is a company that provides packaging and bottling production lines for the food and beverage industry. The company has been laying out its strategy for the past decade, focusing on maintaining food safety and quality, enhancing production line operations, and performance by developing digital solutions based on industrial IoT: through internal development and external acquisitions, expanding from its core hardware business to provide software and system integration solutions. In 2021, Krones achieved a gross profit margin of approximately 51%, exceeding competitors by 15 percentage points, largely due to its IoT-focused Syskron division.

-

Advantage 2: Strong customer channels and market entry capabilities

Case Study 2

Hilti is a manufacturer of high-performance tools, fastening, and protective equipment, which, through its direct sales model, over 20,000 field engineers, strong brand recognition, and customer loyalty, has stimulated customer interest in its industrial IoT solutions, including the ON!TRACK management system, one of the more important solutions in construction technology. In recent years, Hilti has also added solution consultants and system integration engineers to further enhance its market entry and system integration capabilities.

-

Advantage 3: Important complementary advantages with cloud services, software, and analytics tool suppliers

Case Study 3

In the construction industry, Hilti’s experience demonstrates that traditional mature enterprises can also develop IoT-focused businesses. In the packaging industry, Tetra Pak has improved production line performance stability by 30% and halved product defects and waste by deploying connected devices, mobile apps, and remote support to predict maintenance needs and identify performance deviations. Hardware companies and industrial equipment manufacturers possess industry expertise, integration experience, and partnerships, which can provide relevant services and support, driving industrial IoT from a series of successful pilot projects to large-scale applications, achieving true transformation and upgrading.

In the next issue, we will present the latest trends in investment and financing in the technology industry, stay tuned.