IoT Think Tank Original

Please indicate the source and origin when reprinting

Introduction

With the development of the Internet of Things, the amount of data generated by industrial manufacturing equipment will continue to increase. If all this data is to be processed in the cloud, it will require endless spectrum resources, transmission bandwidth, and data processing capabilities; the “cloud” is bound to be overwhelmed, thus requiring edge computing to share the burden of cloud computing..

“90% of the data we collect is garbage,” lamented the owner of a factory in Kunshan, Jiangsu. “We collected data almost every moment of the 365 days last year, but we don’t know how to utilize the data. Compared to the various expenses incurred in data collection, I think it’s not worth it.”

A year of data collection experience has led this owner to lose the initial enthusiasm for the industrial internet, even raising the question: do we really need a lot of industrial data?

“If the problem can be solved by adding a few workers, why should I go through the trouble of collecting data and engaging in the industrial internet? It may not even be effective!”

Indeed, regardless of how splendidly concepts like industrial IoT, big data-driven, and digital twins are presented, in the actual industrial production process, if the core issues of the enterprise cannot be resolved—improving profits and reducing costs—it is bound to be mere talk. While data itself is important, services and applications that can directly solve problems are more valuable to enterprises. Currently, besides how to collect data, the key question most enterprises face is what data is worth collecting? In other words, how to use data to generate value!

We know that the collection and transmission of industrial data are basically in the “end-pipe-cloud” model. At the application site, the “end” is responsible for data collection and instruction execution, the “pipe” connects the data transmission path, while the “cloud” is responsible for all data analysis and control logic functions. Whether the entire process can be smoothly connected is crucial for data collection, analysis, and application capabilities.

However, with the development of the Internet of Things, the amount of data generated by industrial manufacturing equipment will continue to increase. If all this data is to be processed in the cloud, it will require endless spectrum resources, transmission bandwidth, and data processing capabilities; the “cloud” is bound to be overwhelmed, thus requiring edge computing to share the burden of cloud computing. For example, when a company is small, the board can manage the company down to the smallest detail, but as the company grows to a certain scale, it needs to give frontline employees the necessary autonomy.

Therefore, the edge computing gateway, which collects, processes, and transmits data on the edge of the industrial site, plays a crucial role in connecting industrial data transmission, integrating with cloud platforms—achieving edge-cloud integration, and ultimately utilizing big data analysis to empower production, thereby realizing the true value of industrial data.

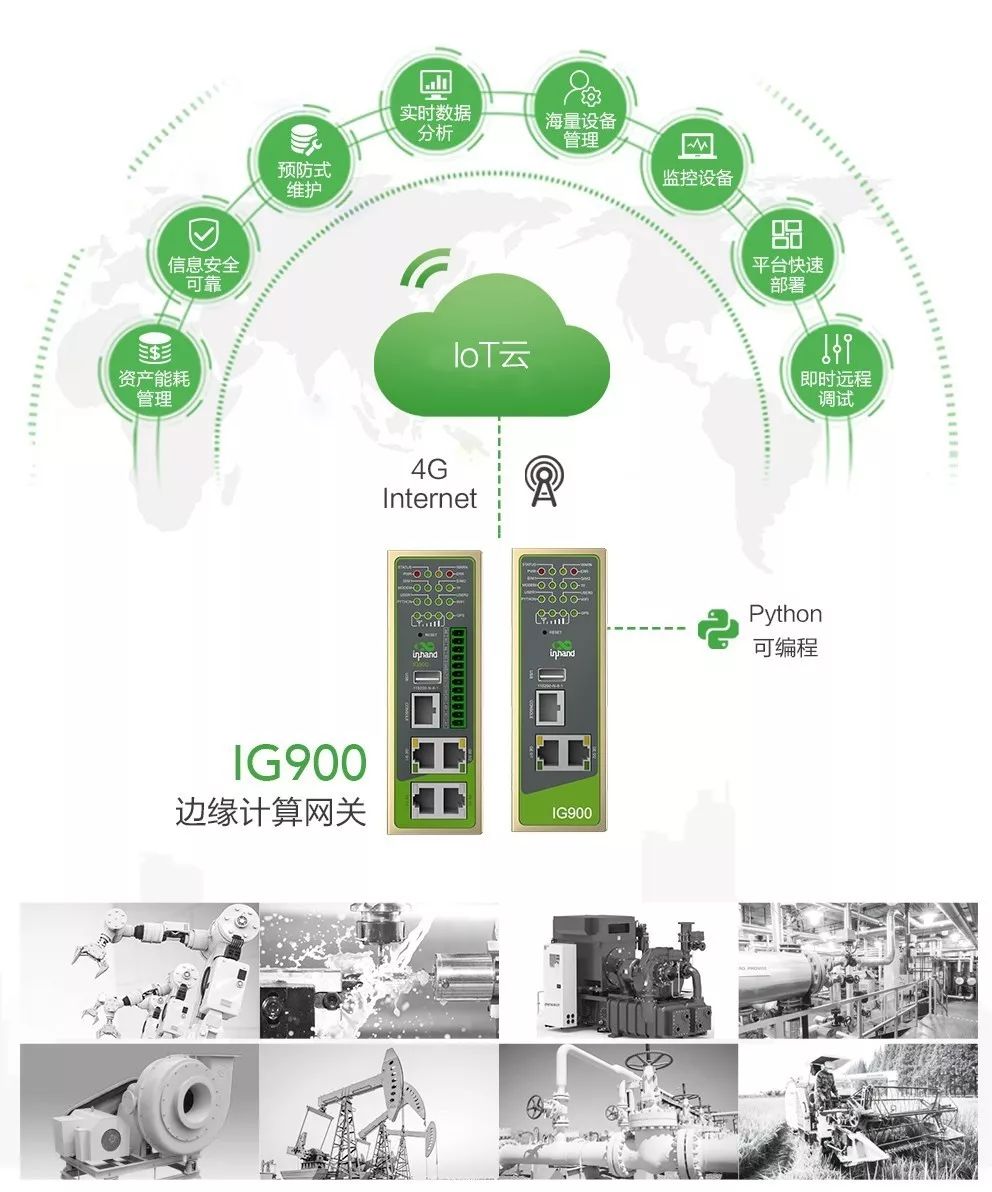

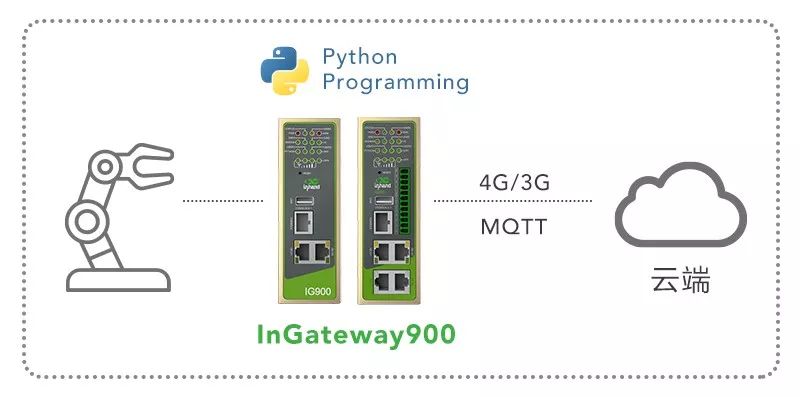

Figure: Edge-Cloud Collaboration

Two key questions arise that we must face:

1. How can we ensure the validity of data in the context of a large amount of industrial data being generated?

2. What value can “edge-cloud” integration bring to industrial IoT?

“Outsiders watch the excitement, insiders look at the details.” Regarding the answers to these two questions, InHand Networks, which has been cultivating the industrial IoT field for 17 years, has a strong voice.

Enhancing Edge Computing to Address Data Downward Pressure

According to Gartner’s report on the top ten strategic technology trends for 2018: From Cloud to Edge, by 2022, as digital business continues to evolve, 75% of data generated by enterprises will be created and processed outside traditional centralized data centers or the cloud.

With the development of industrial IoT, there will inevitably be more local near-control and on-site data. How can we process this gradually increasing on-site data to ensure its effectiveness while reducing the pressure on cloud computing?

Any small improvement in the industrial world can bring significant advantages; any small fault can also lead to substantial losses—many data on the industrial site have a short “shelf life.” Once processing is delayed, the data value drops sharply, and processing industrial data can be described as “walking on a tightrope.” At this point, “edge computing” plays an irreplaceable role.

If we compare the brain to the cloud, then edge computing is the nerve endings, processing simple stimuli and feeding the processed feature information back to the cloud brain. Therefore, industrial IoT entrants, including InHand Networks, are focusing on laying out edge computing.

InHand Networks was established in 2001 and listed on the New Third Board in 2014. It is one of the earliest enterprises in China to independently develop and manufacture IoT communication equipment products. Currently, the company’s main business has expanded from the initial M2M products to the industrial IoT solution field, providing M2M devices and IoT solutions for clients in various industries such as industrial automation, power, new retail, smart cities, smart business, energy, vehicle networking, security, transportation, agriculture, and municipal services.

From the development process of industrial IoT, InHand Networks’ empowerment of industrial IoT has coincided with several key stages of development: from not collecting data from industrial devices to collecting data over the network; from primarily processing data in the cloud to achieving edge-cloud integration.

Figure: Data Collection on Industrial Sites

Although the core issue that industrial enterprises currently pursue is how to empower production with data and generate value, we cannot ignore the common problems that have troubled industrial enterprises for many years, the key link in data processing—how to collect data? For any industrial enterprise, the first step to mining the data gold mine is data collection; discussing big data analysis without data is like building castles in the air, and an industrial cloud platform without data is like a tree without roots.

In different industrial production processes, due to the numerous brands of automation products, the diversification of industrial interfaces, and the lack of unification in industrial protocols, seemingly simple data collection is not that easy. Moreover, with the increasing speed of industrial data generation, the demand for edge-cloud integration is becoming increasingly urgent, which undoubtedly presents a huge development opportunity for InHand Networks, which focuses on “edge-cloud integration solutions.” Thus, this is the core reason why InHand Networks launched the IG900 series of edge computing gateways.

Figure: IG900 Edge Computing Gateway

This series of gateways primarily addresses three major pain points of data collection from the perspective of edge computing: first, they have rich industrial interfaces and are compatible with various mainstream industrial bus protocols, including Modbus TCP/RTU, Profinet, Profibus, EtherNet/IP, EtherCAT, OPC UA, CC-LINK, PPI, etc., allowing for rapid integration into complex industrial sites; second, based on the edge computing architecture, they provide a development environment for edge applications in industrial sites; third, in collaboration with various mainstream industrial clouds, as partners of giants like Microsoft, Amazon, and Alibaba, the IG900 series of edge computing gateways support platforms such as Microsoft Azure, Amazon AWS, Alibaba Cloud, Schneider EcoStruxure, Siemens MindSphere, providing comprehensive ecological solutions for the IoT industry.

Figure: Some Clouds Supported by IG900 Edge Computing Gateway

In addition to data collection, in terms of data processing and application, due to the short “shelf life” of data on industrial sites and the problem that a large amount of “garbage” data does not need to be transmitted to the cloud, InHand Networks’ IG900 series edge computing gateways can not only quickly achieve data collection and address the “shelf life” issue but also filter and preprocess the collected data, thereby alleviating the pressure on cloud computing.

So, based on this edge computing gateway, how does InHand Networks’ edge-cloud collaboration empower industrial IoT?

Integrated IoT Solutions for Edge-Cloud Collaboration

Although from an industrial perspective, edge computing is developing rapidly, from an application perspective, it is still in the early stages of implementation. The integration of edge computing with cloud computing is what truly reflects the value of industrial data.

In fact, the industry has recognized the importance of edge-cloud collaboration and has begun active exploration. For example, Huawei’s intelligent edge platform IEF released at its HC2018 conference explicitly proposes the concept of integrated services for edge and cloud collaboration; Siemens introduced the concept of Industrial Edge in 2018, which roughly aims to achieve coordination between edge computing and cloud computing through cloud deployment of Industrial Edge Management. InHand Networks showcased its “InHand Device Networks Cloud + Edge Computing Gateway” at this year’s Hannover Industrial Fair, achieving edge-cloud collaboration.

Figure: InHand Networks’ “Edge-Cloud Collaboration” Display at Hannover Industrial Fair

Since edge-cloud collaboration is so important for industrial data, how do we understand edge-cloud collaboration? The key to processing data in edge-cloud collaboration is data integration.

In industrial scenarios, on one hand, real-time analysis algorithms are run directly through edge computing, while on the other hand, through the collaboration of edge and cloud, models are continuously improved and optimized, thereby enhancing the platform’s real-time analysis capabilities with edge analysis technologies. Of course, the capabilities and connotations of edge-cloud collaboration will vary when applied to different scenarios, because each type of edge computing business form has different business needs for collaboration with cloud computing.

For example, in the process of flexible manufacturing, the application of modern industrial robots is becoming increasingly widespread. The stability and reliability of robots and mechanical arms on the production line are of great significance to ensuring the economic benefits of enterprises. The large-scale deployment of industrial robots, with their complex structures and high maintenance costs, poses significant requirements on the maintenance capabilities of production enterprise technicians. This is primarily reflected in the need to detect abnormalities in robot components and control devices before failures occur, and to alert users to perform targeted maintenance before downtime occurs, thus reducing downtime to zero and achieving continuous production.

Figure: Industrial Robot

The core point here is to achieve preventive maintenance through edge-cloud collaboration, ensuring continuous and effective production. InHand Networks provides a “cloud” + “edge” industrial robot remote management ecosystem solution, allowing industrial robots and other intelligent devices on the production site to connect to the IG900 series edge computing gateway for instant data collection, filtering, processing, etc., through various industrial buses or high-speed Ethernet…

In the cloud, the InHand Device Cloud can aggregate real-time production data from the industrial site for centralized storage, analysis, processing, and prediction. From network management, field exploration to perception and response, it can significantly improve operational and maintenance efficiency.

Figure: “Cloud” + “Edge” Industrial Robot Remote Management Ecosystem Solution

Conclusion: Nowadays, it is not an exaggeration to compare data to oil; oil needs to be collected, transported, processed, and refined to be used, and industrial data is no different. Edge computing provides stronger insights and analysis capabilities for collected data, and the application of edge computing and the deployment of edge computing gateways will make the benefits of data clear, dispelling factory owners’ doubts about industrial data, allowing the industrial internet to truly be implemented at the “frontline.”

Edge-cloud collaboration brings immeasurable value to ICT manufacturers, OT manufacturers, OTT manufacturers, and telecom operators, promoting business innovation and commercial model innovation through deep data mining, accelerating digital transformation.

In the era of smart manufacturing, all aspects of production need to be interconnected and able to interact in real-time; for instance, production data and equipment data from production, warehousing, logistics, etc. need to be monitored and tracked in real-time, and then processed through big data to make intelligent predictions, including pre-stocking, safety precautions, etc. InHand Networks’ layout in industrial IoT is precisely following the footsteps of Industry 4.0, based on “edge computing gateway + InHand Device Cloud + big data analysis,” using edge-cloud collaboration to connect the channels of data collection, transmission, and processing, and conducting big data analysis to fully leverage the value of data, ultimately empowering industrial IoT from all directions.

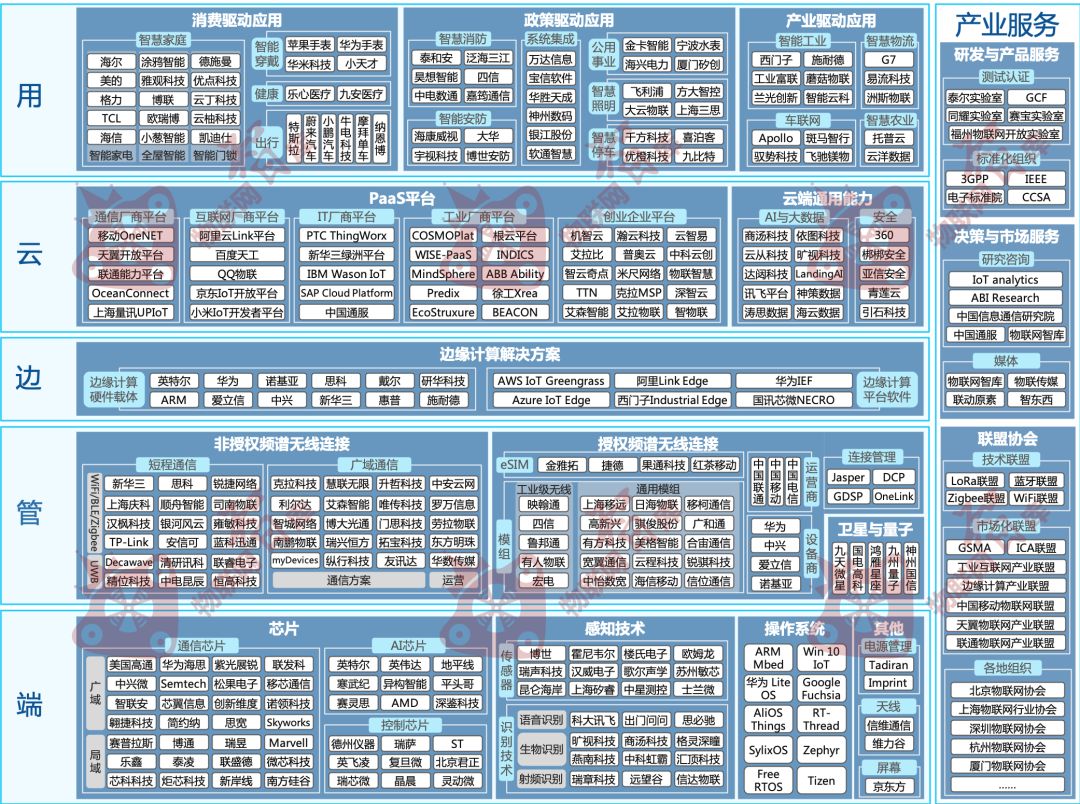

IoT Think Tank “2019-2020 China IoT Industry Panorama”

Previous Hot Articles (Click on the article title to read directly):

-

“How Difficult Is It to Make a Smart Lock on Shared Bicycles?”

-

“Cognitive Computing, Blockchain IoT, IoT Security… Those Who Understand Will Control the Future”

-

“[Heavy Release] 2017-2018 China IoT Industry Panorama Report—The Deep Transformation of IoT to Industries Has Begun”

-

“[Heavyweight] IoT Industry Panorama Report, First to Open the Domestic IoT Industry Two-Dimensional Perspective Panorama”

-

“A Cartoon Explains: Besides WiFi, What Can the Recently Popular NB-IoT Do?”

-

“A Cartoon Explains: What Is LoRa, Which Everyone Is Talking About Behind NB-IoT?”