Follow+Star Public Account Number, don’t miss out on exciting contentThe boss requires the project to be completed in three months, but after half a year, the project is still not finished.Is this a situation you often encounter?Recently, I saw friends in the group discussing similar issues, so let’s talk about:Why Are Embedded Projects Always Delayed?

Unclear Requirements

When starting a project, the first step is the requirements.If the requirements are not clear, 99% of projects will be delayed.The first issue comes from ambiguous requirements from the client, where the client asks for a product similar to a certain product’s functionality.If you do not communicate the details thoroughly and immediately start the project, there is an 80-90% chance that the product will not satisfy the client. The second issue comes from the client’s changing requirements, for example: the client wants to create a temperature sensor that displays on an LED screen. After a while, the client says to add a humidity and wind speed sensor. After another while, the client requests to view the sensor data on both mobile and computer.…… With such project management, it will never be completed and will never be done well.

The second issue comes from the client’s changing requirements, for example: the client wants to create a temperature sensor that displays on an LED screen. After a while, the client says to add a humidity and wind speed sensor. After another while, the client requests to view the sensor data on both mobile and computer.…… With such project management, it will never be completed and will never be done well.

Underestimating Project Difficulty

When we receive a project, we first conduct a comprehensive assessment based on the requirements, including technical details, development cycle, etc. However, some people like to boast, and do not follow the usual path, thinking they can just start without much thought, believing that since the project is similar, it won’t take long to complete. For example: some people think that because they have made a small car in school, making a robot is very simple. The project keeps dragging on, and in the end, they barely deliver a product that is not very complete.

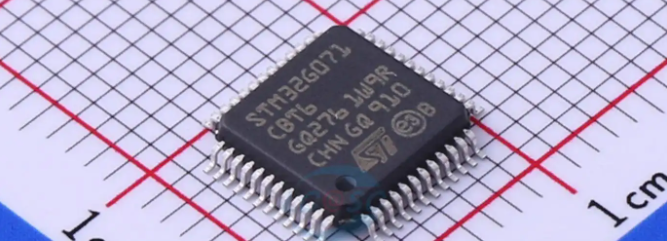

Cost and Procurement Control Issues

Embedded projects are tangible products, not virtual products; a chip or even a resistor can affect the overall project cost. Compared to the chip price surge we all experienced in the past two years, not only did prices rise, but it was also difficult to purchase components. In such a price increase and component shortage (chips), do you think the project will be delayed?

In such a price increase and component shortage (chips), do you think the project will be delayed?

Poor Project Management

Large companies usually have a complete management system, but many small companies have almost no management at all. As a result, projects can be very chaotic. For example, unreasonable planning, resource management issues, or poor communication can all lead to delays in electronic product development. In embedded development, there is often the issue of “passing the buck”; is there a problem with the circuit? Is there a problem with the program? Of course, since management requires significant human and material resources, it is normal for small companies to lack such management.

Other Reasons

Developing a product is very different from playing around in a lab; there are many factors to consider. Here are some factors that may affect delays.Regulatory Compliance: Electronic products must comply with various regulations and standards. If these regulatory requirements are not met in a timely manner during development, additional time may be needed for adjustments and reviews, leading to delays.Supplier Issues: If the suppliers we rely on encounter problems, such as delivery delays, quality issues, or bankruptcy, it can negatively impact project progress.Human Resource Issues: A lack of skilled and experienced personnel can affect development progress. Staff turnover, training needs, or insufficient personnel can all lead to delays.Testing and Validation: Electronic products require rigorous testing and validation processes to ensure their performance and stability. If testing reveals design flaws or performance issues, additional time will be needed to resolve these issues, extending development time...……In the end, how many projects have you messed up? Finally, we welcome all hardware team leaders, hardware managers, and hardware directors to purchase our curated high-quality hardware design materials: High-quality hardware design treasure materials, 7G high-quality hardware design USB drive materials

Statement:

This account maintains neutrality regarding all original and reprinted articles’ statements and viewpoints, and the articles pushed are for readers’ learning and communication only. The copyright of articles, images, etc., belongs to the original authors. If there is any infringement, please contact us for deletion.

—— The End ——Recommended ReadingFour Methods of BLDC Current Sampling and Their Advantages and Disadvantages ComparisonDebugging Case of Exceeding Radiation Emission Test Standards in Ethernet Mode of an Industrial Control ProductSummary of Four Common RS-485 Isolation Solutions

Share💬Like👍Read❤️

Support quality content with a “three-click” action!