In this series on “Engine Management”, we will explain some common issues and blind spots encountered by domestic players, aiming to help everyone understand how the ECU program controls the engine’s operation and what modifications should be made to the ECU program after changing the engine’s hardware.Mastering knowledge and scientifically modifying is the only way to ensure the vehicle’s lifespan and enjoy the fun of modification.We hope everyone can understand their vehicles better; no one wants to spend every day in a repair shop.Engine management is a very complex issue that cannot be thoroughly explained in just a few articles. Therefore, the content in this series is quite extensive but not too in-depth. If you have any points you would like to express, feel free to leave a message at the end, and we can discuss it together.

In this series on “Engine Management”, we will explain some common issues and blind spots encountered by domestic players, aiming to help everyone understand how the ECU program controls the engine’s operation and what modifications should be made to the ECU program after changing the engine’s hardware.Mastering knowledge and scientifically modifying is the only way to ensure the vehicle’s lifespan and enjoy the fun of modification.We hope everyone can understand their vehicles better; no one wants to spend every day in a repair shop.Engine management is a very complex issue that cannot be thoroughly explained in just a few articles. Therefore, the content in this series is quite extensive but not too in-depth. If you have any points you would like to express, feel free to leave a message at the end, and we can discuss it together. # Engine Management # Vol.01 # Practical Issues to Consider When Tuning ECU ## 1 #Modifying the ECU is not a one-time solutionTerms like “Stage 1”, “Stage 2”, and “Custom Tune” are very popular in the domestic market.

# Engine Management # Vol.01 # Practical Issues to Consider When Tuning ECU ## 1 #Modifying the ECU is not a one-time solutionTerms like “Stage 1”, “Stage 2”, and “Custom Tune” are very popular in the domestic market.

Without considering some merchants’ tricks, it can generally be understood thatStage 1 is a mass-produced program for factory hardware, Stage 2 requires some corresponding hardware modifications for a mass-produced program, and Custom Tune is a tailored program written for the specific conditions of a particular vehicle.At least in the domestic market, some brands of the same model may have significant differences in power when they leave the factory, mainly due to production tolerances of parts and assembly tolerances. Considering wear and maintenance issues during future use, we cannot guarantee that our vehicle will be very similar to another vehicle of the same model.

Without considering some merchants’ tricks, it can generally be understood thatStage 1 is a mass-produced program for factory hardware, Stage 2 requires some corresponding hardware modifications for a mass-produced program, and Custom Tune is a tailored program written for the specific conditions of a particular vehicle.At least in the domestic market, some brands of the same model may have significant differences in power when they leave the factory, mainly due to production tolerances of parts and assembly tolerances. Considering wear and maintenance issues during future use, we cannot guarantee that our vehicle will be very similar to another vehicle of the same model.

Therefore, some conservative ECU brands or merchants will tune the Stage 1 program conservatively to ensure that the hardware of each vehicle does not experience excessive wear under this program.

Therefore, some conservative ECU brands or merchants will tune the Stage 1 program conservatively to ensure that the hardware of each vehicle does not experience excessive wear under this program. On the other hand, some ECU brands or merchants may overly emphasize power, neglecting wear and the stability of the system.Even conservative programs may become too aggressive after several tens of thousands of kilometers as the vehicle condition deteriorates.A better approach to ECU tuning is to monitor data over the long term and adjust the custom tune with the merchant as needed, or the best approach is to write the program yourself and monitor it continuously for adjustments. Variations in winter and summer temperatures, different fuel types, hardware modifications, and changes in driving habits all require the ECU to adapt accordingly.

On the other hand, some ECU brands or merchants may overly emphasize power, neglecting wear and the stability of the system.Even conservative programs may become too aggressive after several tens of thousands of kilometers as the vehicle condition deteriorates.A better approach to ECU tuning is to monitor data over the long term and adjust the custom tune with the merchant as needed, or the best approach is to write the program yourself and monitor it continuously for adjustments. Variations in winter and summer temperatures, different fuel types, hardware modifications, and changes in driving habits all require the ECU to adapt accordingly. Regular testing and reprogramming of the ECU is essential.Only you know the condition of your vehicle and your usage habits, so try to write the program yourself or participate as much as possible in the merchant’s custom tuning process.

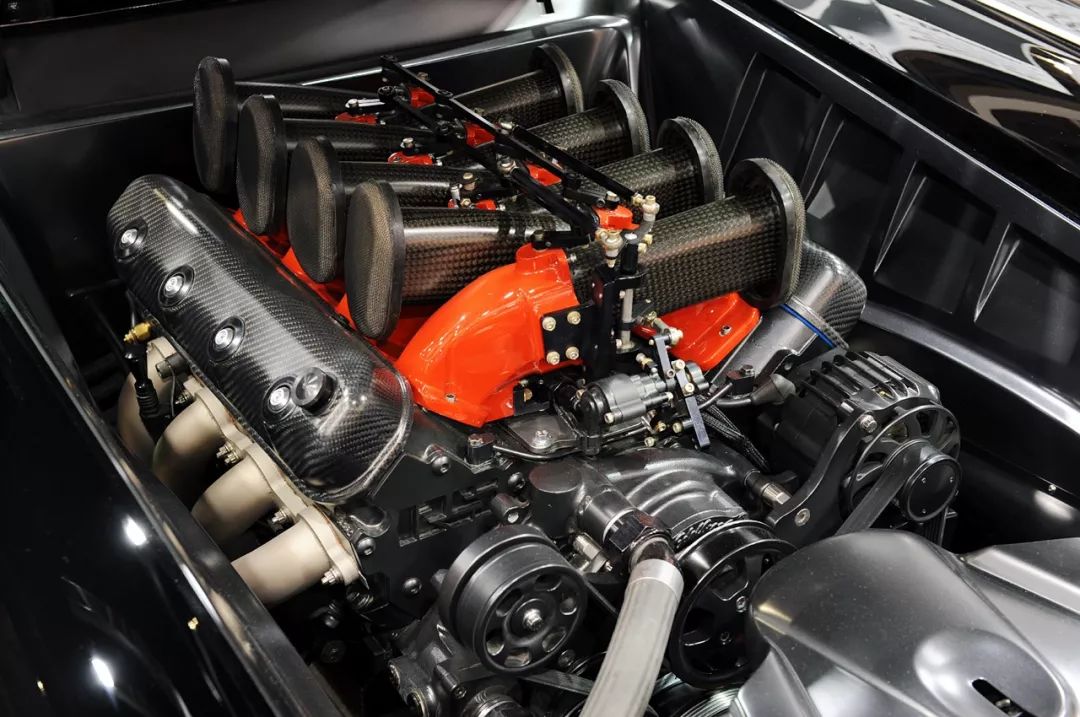

Regular testing and reprogramming of the ECU is essential.Only you know the condition of your vehicle and your usage habits, so try to write the program yourself or participate as much as possible in the merchant’s custom tuning process. Almost all hardware modifications to the power system require reprogramming the ECU to work effectively or to compensate for issues brought by new hardware.Although some factory programs or ECU rewrite programs can adapt to certain hardware changes to some extent, this adaptation is often insufficient.For example

Almost all hardware modifications to the power system require reprogramming the ECU to work effectively or to compensate for issues brought by new hardware.Although some factory programs or ECU rewrite programs can adapt to certain hardware changes to some extent, this adaptation is often insufficient.For example

- Some cells in the fuel map and ignition map are often considered to be in an unused range, and their values may not have been well tested. However, after using new hardware, these cells may become relevant, and untested values will directly participate in calculations, leading to unpredictable results.

- After replacing the factory back pressure exhaust with a straight pipe, the exhaust flow becomes smoother, the exhaust temperature lowers, and the tendency for knock decreases. The allowable ignition angle and boost values may exceed the maximum execution values in the original program, and the air-fuel ratio may not be maintained at the target value, even triggering the factory’s protection program.

- To maximize the effect of the new exhaust system, it is necessary to retest and rewrite the target values for ignition angle and boost in the program.

# 2 #Selecting the Right BrandSome ECU software allows users to input not the actual execution values for controls like fuel injection and ignition, but rather the ideal values desired by the user. The computer will determine the target values for actual operation based on the user’s ideal values and the actual conditions.If the computer’s evaluation is absent, directly executing according to the user’s ideal values may cause component damage due to some hardware not meeting the requirements.

The computer’s evaluation process mainly includes some experimental models from car manufacturers or ECU manufacturers and some protective limit functions. It is recommended that ordinary individual players choose such ECU products.Some ECU software or hardware opens up more permissions.

The computer’s evaluation process mainly includes some experimental models from car manufacturers or ECU manufacturers and some protective limit functions. It is recommended that ordinary individual players choose such ECU products.Some ECU software or hardware opens up more permissions. Some even allow complete control of engine management according to user-input data. This allows for more freedom in controlling engine operation but loses some of the models and critical protective functions calibrated by the manufacturer. Such brands are more suitable for experienced racing teams or highly experienced players.# 3 #Issues to Consider Before Tuning ECUEnsure No Faults Before TuningBefore testing or modifying any power system hardware, you shouldensure that there are no clearly existing faults in the power system or potential faults that may arise during testing.Issues like a dirty MAF sensor or existing fault codes can affect the accuracy of the tests.

Some even allow complete control of engine management according to user-input data. This allows for more freedom in controlling engine operation but loses some of the models and critical protective functions calibrated by the manufacturer. Such brands are more suitable for experienced racing teams or highly experienced players.# 3 #Issues to Consider Before Tuning ECUEnsure No Faults Before TuningBefore testing or modifying any power system hardware, you shouldensure that there are no clearly existing faults in the power system or potential faults that may arise during testing.Issues like a dirty MAF sensor or existing fault codes can affect the accuracy of the tests.

Issues like aging hoses after the turbo, severe spark plug contamination, and poor radiator coolingthat were previously acceptable may cause larger problems during extreme testing or after using new hardware.Retain Original Data Before TuningBefore making any modifications or replacements to power system hardware, you shouldconduct as many tests as possible and retain the original hardware data for comparative analysis with the new components.This should include sensor logs, acceleration test data, as well as repair manuals, component data sheets, and any issues encountered during disassembly and their solutions.

Issues like aging hoses after the turbo, severe spark plug contamination, and poor radiator coolingthat were previously acceptable may cause larger problems during extreme testing or after using new hardware.Retain Original Data Before TuningBefore making any modifications or replacements to power system hardware, you shouldconduct as many tests as possible and retain the original hardware data for comparative analysis with the new components.This should include sensor logs, acceleration test data, as well as repair manuals, component data sheets, and any issues encountered during disassembly and their solutions. For example: Before modifying the high-flow intake piping or air filter, you should first test several sets of turbo pressure boost curves and MAF curves during full-load acceleration with the old hardware.After installing the new piping or air filter, conduct several sets of the same tests, ensuring that the environmental conditions such as ambient temperature, intake temperature (IAT), and water temperature (ECT) that may affect power are as consistent as possible.

For example: Before modifying the high-flow intake piping or air filter, you should first test several sets of turbo pressure boost curves and MAF curves during full-load acceleration with the old hardware.After installing the new piping or air filter, conduct several sets of the same tests, ensuring that the environmental conditions such as ambient temperature, intake temperature (IAT), and water temperature (ECT) that may affect power are as consistent as possible. In the final comparative analysis, if we find that the turbo pressure curve rises earlier (relative to RPM) and is higher with the new piping or air filter, we can conclude that the new components effectively enhance power.It is important to note: when analyzing, consider other factors that may affect the test items or results, such as strong winds.

In the final comparative analysis, if we find that the turbo pressure curve rises earlier (relative to RPM) and is higher with the new piping or air filter, we can conclude that the new components effectively enhance power.It is important to note: when analyzing, consider other factors that may affect the test items or results, such as strong winds. The purpose of testing several sets before and after is twofold —

The purpose of testing several sets before and after is twofold —

- If you cannot ensure the consistency of testing conditions before and after (for example, changes in ambient temperature and pressure after several hours of disassembly), having more data sets can provide mutual reference.

- Some vehicle ECU control logic and protection logic can be quite complex, making it difficult to identify or control all factors affecting turbo pressure, valves, and exhaust valves. More tests can bring the final data analysis closer to the truth.

For exampleCan the newly designed boost piping or intercooler reduce internal airflow pressure loss?

- This can be judged under full load conditions by the opening degree of the turbo wastegate. With the same actual boost (or manifold pressure), a larger wastegate opening indicates lower internal losses in the intake piping.

- Considering that some control logic may limit target turbo pressure, leading to tests before and after the replacement not achieving the same actual turbo (or manifold pressure), having only one set of pre-replacement data would not be helpful for reference and judgment, necessitating multiple disassemblies for comparison.

# 4 #Post-Tuning IssuesAfter inputting the new program, acceleration and deceleration should be gentle at first.On one hand, you need to adapt to the new program’s pedal response and power characteristics. On the other hand, we cannot be sure that the new program will perfectly match the hardware without issues. After confirming that there are no serious problems, log data to check if various parameters are normal under full load conditions. To avoid future worries, logging should be done deliberately under extreme conditions.For example: deliberately allowing the intake temperature to rise, deliberately loading the vehicle, deliberately using high gears, and deliberately testing on uphill sections.Some vehicles may require throttle pedal and/or throttle body reset after a new program is flashed, while others may not.

To avoid future worries, logging should be done deliberately under extreme conditions.For example: deliberately allowing the intake temperature to rise, deliberately loading the vehicle, deliberately using high gears, and deliberately testing on uphill sections.Some vehicles may require throttle pedal and/or throttle body reset after a new program is flashed, while others may not. For some vehicles, long-term fuel trim values may be reset, while others may not. Regardless of whether they are reset, it will take some time for the long-term fuel trim values to stabilize correctly. If the circuit board is disassembled for flashing, pay attention to the waterproof sealing of the ECU housing and the integrity of the connectors.Variables Recommended for Monitoring During Power System Testing

For some vehicles, long-term fuel trim values may be reset, while others may not. Regardless of whether they are reset, it will take some time for the long-term fuel trim values to stabilize correctly. If the circuit board is disassembled for flashing, pay attention to the waterproof sealing of the ECU housing and the integrity of the connectors.Variables Recommended for Monitoring During Power System Testing

- Atmospheric Data:Temperature, pressure, oxygen content, wind direction, wind speed

- Ground Data:Ground slope, ground friction coefficient, ground flatness

- Tire Data:Model, size, tire pressure, friction surface temperature

- Vehicle Data:Weight, center of gravity, external changes (spoilers, chassis height, chassis flatness, etc.)

- Fuel Data:Fuel type, fuel temperature (small bubbles in the fuel line can affect injection quantity)

- Power System:Oil temperature, oil pressure, water temperature, intake temperature, exhaust temperature, knock conditions, clutch slippage, etc.

- Brake System:Brake disc temperature, brake disc wear, brake fluid temperature, integrity of steel lines

- Suspension System:Shock oil temperature (weight transfer can affect wind angle and acceleration performance)

ConclusionEngine management is a very complex issue that cannot be thoroughly explained in just a few articles. More

More

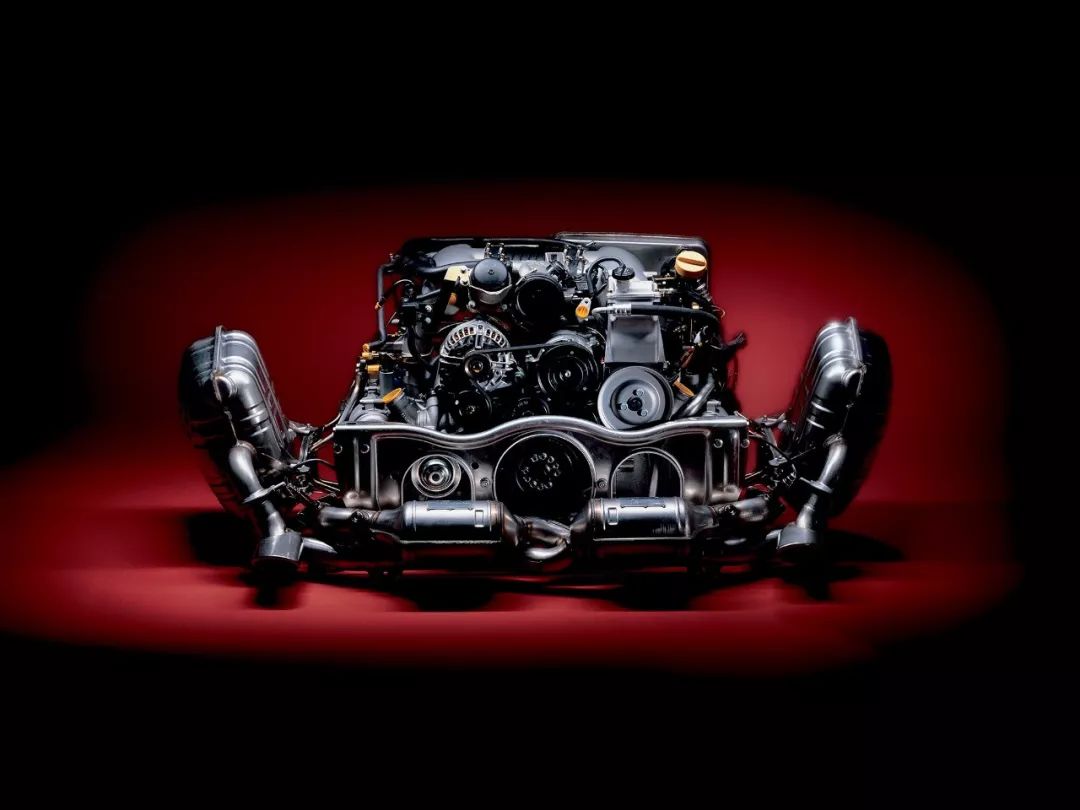

- Owning a Honda NSX NA1 is perfection

- 1355Nm diesel Cummins Mustang, a sexy mix of violence

- Old cars are not loose, new cars are tighter — “Suspension Bushings” Guide to Improved Handling

- Transplanting a Volkswagen R32 engine into a 1000hp Audi RS4, this is the true essence of play

Today’s Signature