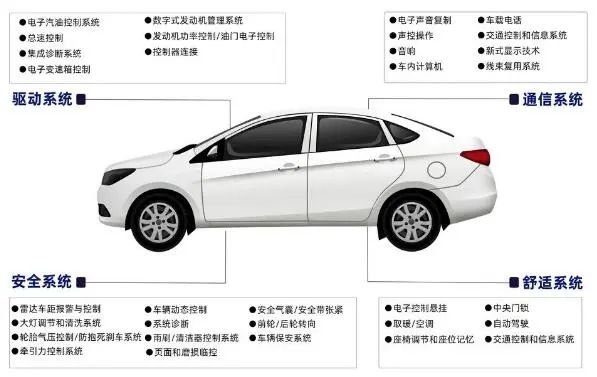

The ECU (Electronic Control Unit), as the brain of the car, controls the vehicle’s engine, airbags, anti-lock braking system, etc. In addition to the ECU located in the engine, there are also separate ECUs in other locations of the car, with approximately hundreds of ECUs in a single vehicle.

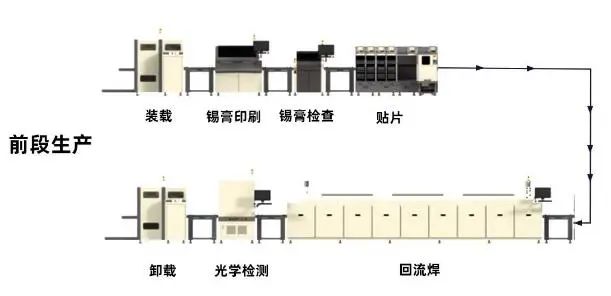

However, with the development of the automotive industry, ECUs are becoming more integrated, and the overall vehicle delivery cycle is gradually shortening, making production more complex and requiring high efficiency. In addition to the front-end PCB loading, silk screen printing, chip mounting, reflow soldering, and optical inspection, the back-end also requires complex testing systems such as ICT online testing, pin checks, aging tests, and functional tests.

(Image reference: Enai by your side)

With the shortening of vehicle delivery times, efficiency has become one of the important factors in the production of integrated ECUs. To improve efficiency, a large number of PXI/PXIe testing instruments are used in these testing systems, which we also refer to as virtual testing.

The integration of testing equipment has also posed new challenges for testing interfaces.

Tengfang Zhongke can provide targeted connection solutions to meet the special needs of ECU testing based on these requirements.

In the ICT testing phase, it is necessary to test the electrical performance of the components on the board and the connectivity of the circuit network. For this characteristic, the test fixture needs to be placed on a desktop for easy fixing and replacement of the PCB, while the test fixture should be simple and easy to switch for the ECU.

At this time, it is recommended to use Tengfang Zhongke’s VH series:

In the aging testing phase, to shorten testing time, the aging test cabinet must meet the requirements for mass ECU testing simultaneously while also accommodating quick switching for different ECU signal acquisition solutions.

At this time, it is recommended to use the V series:

In the functional testing phase, different ECU testing projects are completely different, and the interface must meet characteristics such as ease of plugging and unplugging and a rich variety of signal types. At this time, it is recommended to use the V series:

After adopting a universal interface, let’s take a look at the advantages:

One-time Installation, 20,000 Uses

By using Tengfang’s customized cables, the board signals are concentrated to a universal platform. The connector only needs to be locked during the first installation, and thereafter, there is no need for plugging and unplugging at the PXI board end, allowing for a testing lifespan of up to 20,000 times.

Each time when switching tests, pulling down or pushing up the lever by 90° completes the connection/disconnection, using a labor-saving lever mechanism to easily plug and unplug. Compared to traditional connections, at least 90% of the time is saved, greatly improving testing efficiency.

1) Using a combination of aluminum alloy frame + module pinhole, the signal contact points are concentrated on the module in a rectangular arrangement, with a maximum of 9600 signal channels supported per module, providing massive signals.

2) Additionally, the types of test signals are rich, which may include RF, fiber optic, high power, thermocouple, and ordinary signals. At this time, mixed modules can be selected, such as:

Ordinary Signal + High Power

Ordinary Signal + Coaxial

Ordinary Signal + Micro Power

and up to 14 combinations.

The receiver can be optionally equipped with a dust cover. When not in use, the cover can be placed on top, protecting against dust, water, and static electricity, effectively reducing the probability of pinhole damage and increasing product lifespan.