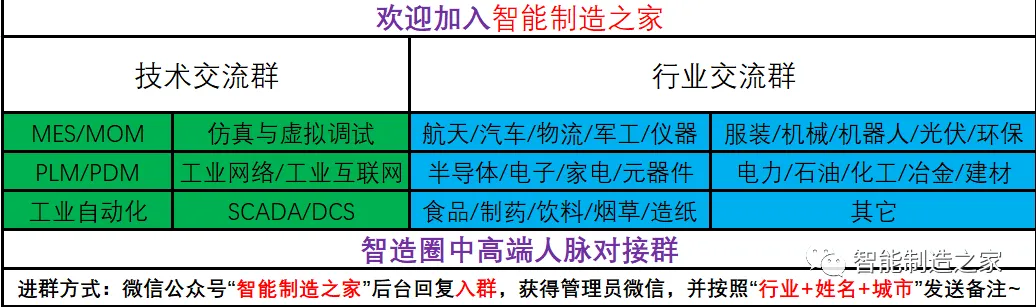

Virtual PLC Technology Maturity: Still in the Early Development Stage

According to the latest research by IoT Analytics, the overall technology maturity of Virtual PLCs (vPLCs) is currently low and does not yet meet all the technical requirements of traditional hardware PLCs. The research evaluates the maturity of vPLCs from four core technology dimensions: control task support, functional safety, control logic portability, and redundancy capability. The vPLC products currently available in the market generally exhibit the following technical limitations:

-

Control Task Support

: No vPLC can handle high-speed control tasks with execution times below 1 millisecond, while hardware PLCs have achieved microsecond-level response in this area.

-

Functional Safety Certification

: There is a lack of functional safety certification compliant with IEC 61508 standards, which is the global benchmark for the functional safety of electrical, electronic, and programmable electronic systems, and is indispensable in safety-critical applications.

-

Control Logic Portability

: Most vPLCs cannot seamlessly migrate between different vendors’ operating environments (e.g., between Vendor A and Vendor B’s runtime systems) without modifying code, making true hardware independence difficult to achieve.

-

Redundancy Capability

: Most vPLCs lack redundancy design; if the central server hosting multiple vPLCs fails, all control logic will fail simultaneously, severely impacting system reliability.

Despite this, the automotive industry has become an early adopter of vPLCs. Data from 2023 shows that the automotive sector accounts for nearly a quarter of the emerging vPLC market, demonstrating the potential application of this technology in specific scenarios.

Driving Forces and Practical Cases for Virtual PLC Applications

The research reveals eight core factors driving vPLC adoption, with three key drivers particularly prominent:

-

Improved Operational Efficiency vPLCs support management through a single centralized interface, simplifying tasks such as software updates and enabling centralized access to all PLC data. This feature significantly reduces operational complexity, especially for large factories with multiple PLCs.

-

Flexibility and Openness vPLCs decouple control logic from hardware, breaking vendor lock-in. Users can customize and deploy applications according to their needs without relying on proprietary tools. Additionally, multiple PLC runtimes can be deployed on the same hardware, meeting dynamic business demands without increasing hardware costs.

-

Significant Cost Benefits Multiple vPLCs can be integrated into a single hardware platform, reducing the need for physical PLC purchases. Furthermore, the hardware replacement costs for vPLCs are lower—since they run on general-purpose hardware, only software updates are needed during replacement, significantly lowering maintenance costs.

Typical Case: Audi’s Edge Cloud 4 Production (EC4P) Project

Audi is promoting factory automation upgrades through the EC4P project, with the core goal of enhancing production efficiency, scalability, and safety by integrating IT and OT systems. In this project, Audi uses vPLC technology to migrate the control logic of distributed industrial PCs (IPCs) to a central server cluster, successfully addressing three major pain points of traditional hardware PLCs:

-

Long Downtime

: Long downtimes caused by manual updates of hardware PLCs;

-

High Maintenance Costs

: High maintenance costs of distributed PLCs;

-

Difficult Expansion

: The complex process of reconfiguring the entire production line when introducing new vehicle models.

The project is supported by Cisco, CODESYS, Siemens, and VMware, connecting the central server with the workshop thin clients through Cisco’s network infrastructure. The VMware ESXi hypervisor runs Siemens SIMATIC S7-1500V vPLC and CODESYS Virtual Control SL, achieving centralized management of control logic. In July 2023, Audi announced the successful testing of EC4P, which has been deployed in the Böllinger Höfe factory to support the production of models such as the e-tron GT quattro.

Challenges and Evolution Path for the Popularization of Virtual PLCs

Despite the significant advantages of vPLCs, their widespread adoption still faces multiple challenges:

-

Ambiguity of Technical Support As vendors shift from proprietary hardware solutions to hardware-independent vPLCs, the technology stack involves components from multiple vendors. This openness, while providing flexibility, also increases the difficulty of technical support and troubleshooting. Addressing this issue requires vendors to strengthen collaboration, provide unified support across components, or integrate diagnostic tools capable of monitoring the entire technology stack.

-

Resistance to Change and Skills Gap The migration of control logic from traditional OT environments to IT infrastructure imposes new skill requirements on employees. OT personnel need to master modern IT skills such as DevOps practices, agile methodologies, and cloud infrastructure management. The commercial success of vPLCs will largely depend on whether vendors can effectively help customers address this change management challenge.

To address the limitations of hardware PLCs, vendors have adopted a progressive technology evolution strategy:

-

Soft PLC Transition Solutions Many vendors have introduced soft PLCs as a transitional solution. These products, while coupled with specific hardware, have partially broken through the limitations of traditional PLCs. For example, Beckhoff’s TwinCAT XAR runs on its embedded PC series, and Austria’s B&R Automation Runtime is compatible with its X20 controllers. CODESYS’s Runtime can adapt to various platforms through toolkits, demonstrating higher hardware compatibility.

-

Technical Breakthroughs in vPLCs Some vendors are pushing vPLCs towards the goal of “one-to-one replacement” with hardware PLCs:

-

Siemens

: The SIMATIC S7-1500V vPLC launched in April 2023, based on Docker container technology, can run on existing or general-purpose hardware, with functionality identical to that of the hardware PLC SIMATIC S7-1500.

-

CODESYS

: The Virtual Control SL, to be released in June 2024, achieves ISO 61508 SIL3 safety certification and supports dual-channel coding processing, marking a significant improvement in technology maturity.

-

Phoenix Contact

: The Virtual PLCnext Control, to be launched in November 2024, as an open container initiative (OCI) container, has the same functionality, operational capabilities, and programming options as the hardware PLCnext Control.

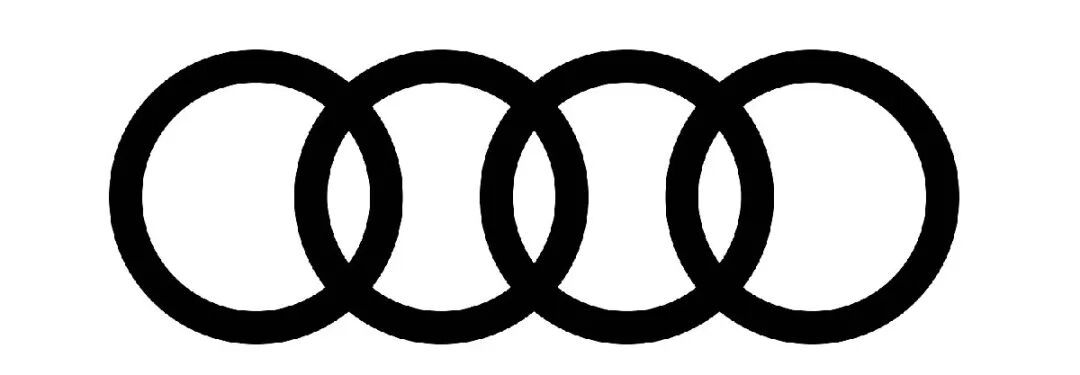

Market Prospects for Virtual PLCs and Analyst Perspectives

IoT Analytics predicts that by 2030, virtual or soft PLCs may account for a quarter of the new PLC market. Although the vPLC market currently represents only a single-digit percentage of the overall PLC market, advancements in technology, SIL3 safety certification, low-speed motion control support, and redundancy capabilities will enhance its attractiveness. However, some manufacturers still choose hardware PLCs due to the insufficient maturity of vPLCs, and the reliability and initial cost advantages of hardware PLCs will continue to exist.

Analysts believe that virtual PLCs are unlikely to become the industry norm before 2030, but their development has entered the fast lane. The development history of soft PLCs provides important reference: since their emergence in the 1990s, soft PLCs have not become mainstream, even for market leader Beckhoff, whose total revenue in 2020 was only $1 billion, accounting for a single-digit percentage of the overall PLC market. Virtual PLCs may experience a similar development cycle, but their scalability and cost-effectiveness may lead to faster market recognition.

From a market opportunity perspective, the “2024–2030 Virtual and Soft PLC Market Report” predicts that the industry will maintain strong growth. Although the sales margins of vPLC may be lower than traditional PLCs due to the stripping of hardware elements, their software-centric characteristics create new revenue streams for vendors, such as centralized data analytics, predictive maintenance, and AI applications as value-added services.

Conclusion: The Future Path of Virtual PLCs

The development of virtual PLCs marks a significant shift in industrial automation from hardware dominance to software-defined solutions. Despite challenges in technology maturity, market acceptance, and ecosystem building, their advantages in flexibility, cost-effectiveness, and centralized management have attracted the attention of many vendors and users. With continuous technological advancements and evolving industry demands, virtual PLCs are expected to gradually penetrate the market over the next decade, becoming an important component of the industrial automation field. However, to become the industry standard, technical bottlenecks must be resolved, ecosystems improved, and user inertia overcome, which will be a gradual and challenging process.

Previous Articles

These bizarre jump incidents are all true!

Mechanical repair misjudged motor faults, faced strong rebuttal from electricians

What was gifted to me by the power plant!

Why are metering CTs, protection CTs, and measurement CTs always confused? How to correctly choose the appropriate CT?

What is the UDT data type of SIMATIC S7-1200?

Learn about a communication protocol every day: OPC protocol

Have you encountered the “pits” of timers used in S7-1200?

Share, view, and like; at least I want to have one!