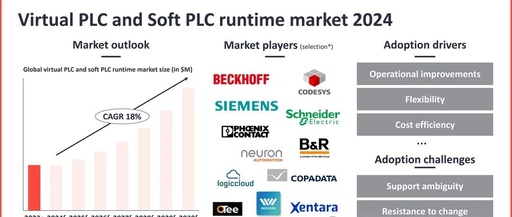

Virtual PLC vs Traditional Hardware PLC: Who Will Dominate Industrial Control in the Next Decade?

Virtual PLC Technology Maturity: Still in the Early Development Stage According to the latest research by IoT Analytics, the overall technology maturity of Virtual PLCs (vPLCs) is currently low and does not yet meet all the technical requirements of traditional hardware PLCs. The research evaluates the maturity of vPLCs from four core technology dimensions: control … Read more