The competition among the new generation of display technologies has never ceased. Whether it is OLED, QLED technology, or Micro LED, Mini LED technology, all claim to be the future leaders in display technology. It can be seen that until the situation becomes completely clear, anyone can step forward to “declare sovereignty”.

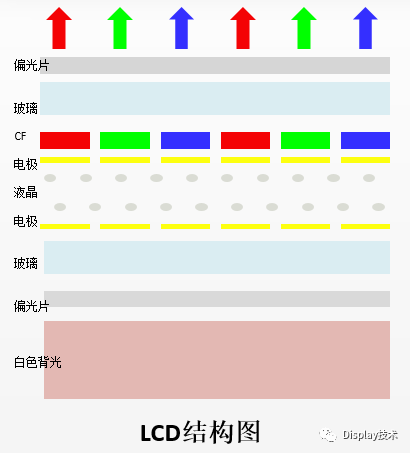

LCD: Backlight source + liquid crystal color display, the backlight source now uses LED white light, which is currently the mainstream LCD product in the market.

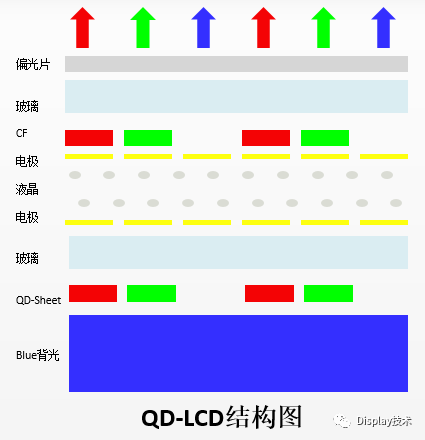

QD-LCD: The blue light emitted by QD-LCD LED hits the quantum dot film, producing better red and green light in terms of color gamut and brightness, which finally combines with blue light to display colors on the liquid crystal, resulting in better display effects for QD-LCD screens. This technology is currently applied to the mainstream quantum dot TVs on the market.

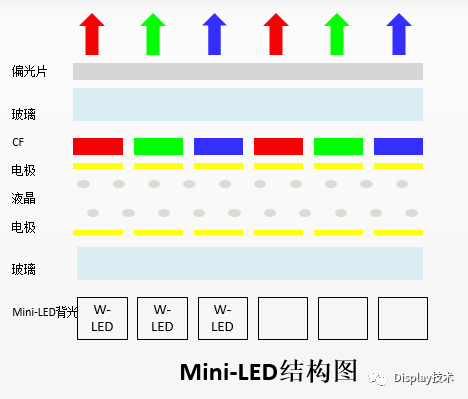

Mini-LED: This is an enhancement technology for the backlight of existing LCD display technology, using smaller LED lights as the backlight source. This allows for finer control of the image. Unlike traditional LED backlights, which only require a few high-brightness LEDs, Mini-LED requires tens of thousands of small LEDs. Through circuit design, tens of thousands of LEDs distributed in different areas can be precisely controlled to achieve high color contrast. Currently, the Starry Screen launched by CSOT adopts this structure, but TV manufacturers have not yet mass-produced it for sale. However, this technology is relatively mature and is not far from commercial availability.

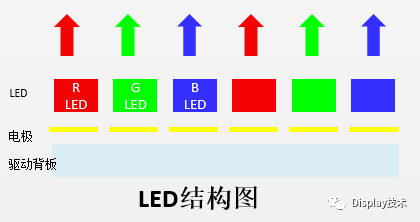

LED: Self-emitting and color displaying after power is applied, the light-emitting materials are GaAs (gallium arsenide), GaP (gallium phosphide), GaAsP (gallium arsenide phosphide), and other semiconductors. Most applications are in outdoor display boards.

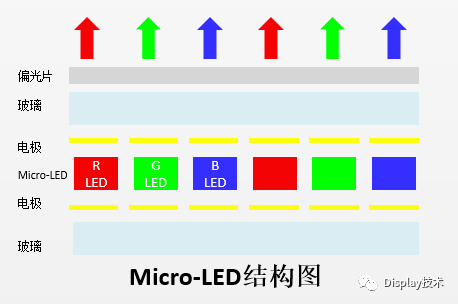

MicroLED: MicroLED is a very small light-emitting diode, with LED units smaller than 100 microns. Each light-emitting diode contains red, green, and blue subpixels. MicroLED technology uses inorganic materials to achieve the light-emitting effect. While LEDs can only be made into large screens outside stadiums and shopping malls, MicroLED can be made small enough to fit into TVs, watches, and other screens.

It relies on the single-crystal silicon substrate to drive the circuit, and the steps to transfer LEDs from sapphire substrates to silicon substrates mean that making a screen requires at least two sets of substrates and independent processes. This leads to increased costs, especially when applied to larger areas, facing huge challenges in yield and cost.

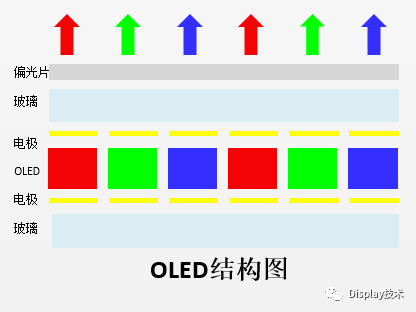

OLED: Self-emitting and color displaying after power is applied, the light-emitting and displaying RGB color materials are organic molecular polymers. The OLED screens used in current smartphones are of this structural type. This technology mainly uses the evaporation (FMM) method for mass production. Due to the limitations of FMM characteristics (previously discussed in inkjet printing), it is currently not applicable to large sizes, with the largest production line being the 6th generation line.

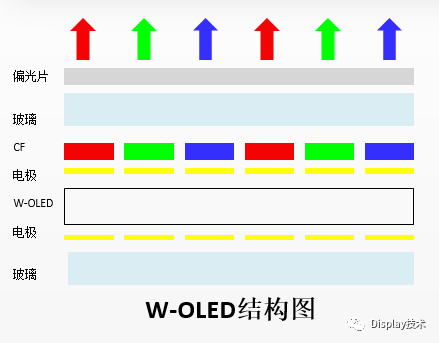

W-OLED: After applying power, the white (W) OLED material self-emits light, which then passes through a color film CF to emit RGB colors. The advantage of this technology is that it eliminates the need for a white backlight module and does not require high precision in the evaporation (FMM) of white OLED materials, making it suitable for large-size production. Currently, LG’s OLED production line uses this structure, which is also the structure of large-size OLED TVs on the market.

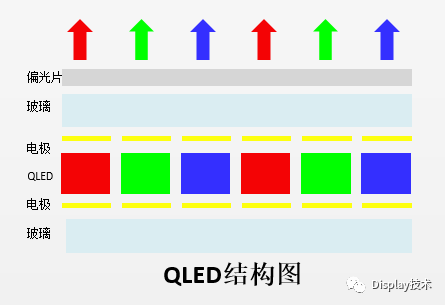

QLED: Self-emitting and color displaying after power is applied, the light-emitting material is quantum dots, which are inorganic semiconductor nanocrystals typically composed of zinc, cadmium, selenium, and sulfur atoms. Currently, it is in the laboratory research and development stage, focusing on material lifespan and the development of cadmium-free quantum dots.

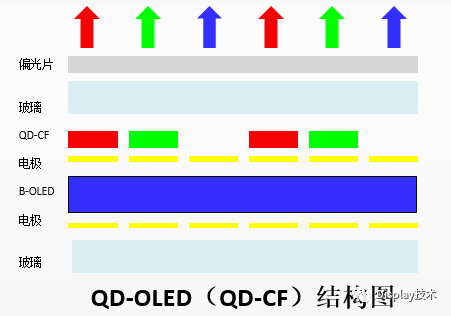

QD-OLED (QD-CF): After self-emitting (electroluminescence) and color displaying, the light-emitting material is blue (B) OLED material, while the color film CF contains light-emitting (photoluminescence) red (R) quantum dot materials and green (G) quantum dot materials. Through the color film CF, colors are reproduced with high color gamut and high contrast. Some quantum dot TVs on the market currently use this structure, and Samsung is building an inkjet printing line to manufacture QD-CF films.

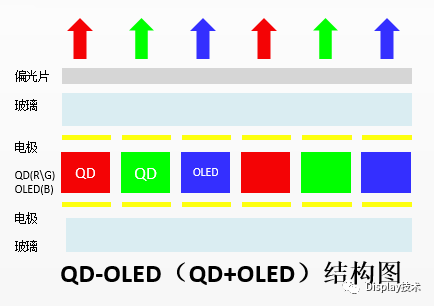

QD-OLED (QD+OLED): After self-emitting and color displaying, the light-emitting material is blue (B) OLED material, along with self-emitting red (R) quantum dot materials and green (G) quantum dot materials. This is currently in the laboratory research and development stage.

The above is a summary of the various display types’ structures. Of course, their internal structures also have different subdivisions, including the shape of internal pixels and how pixels are arranged, all of which are considered to achieve high resolution, high color gamut, and to cover various issues such as immature processes and material lifespan. I will explain these in detail later.

If you like it, please follow the “Display Technology” public account. If there is any content you want to know, please feel free to leave a message!