Liquid crystal display technology has been constantly evolving, from the most commonly heard LCD, LED, and OLED, to the industry’s hottest display technologies Micro LED, Mini LED, and Micro OLED. Have you ever thought about understanding them but found it confusing?

In this article, we will briefly introduce the characteristics of these new-generation display technologies and their differences from older technologies, allowing readers to quickly grasp the concepts.

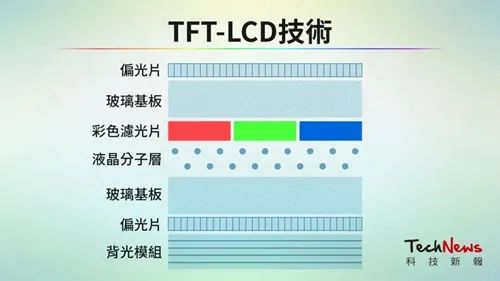

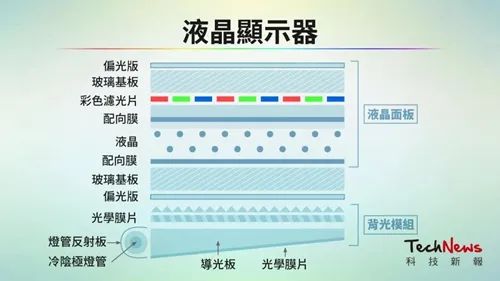

LCD stands for “Liquid Crystal Display”. Currently, the market mainly uses “Thin Film Transistor Liquid Crystal Display” (TFT-LCD) technology, which consists of two glass substrates sandwiching a layer of liquid crystal. The upper glass substrate is a color filter, while the lower glass substrate contains transistors. When current passes through the transistors, the electric field changes, causing the liquid crystal molecules to twist, thereby altering the rotation of light passing through and projecting different colors onto the color filter.

LCD panels commonly use TFT-LCD technology.

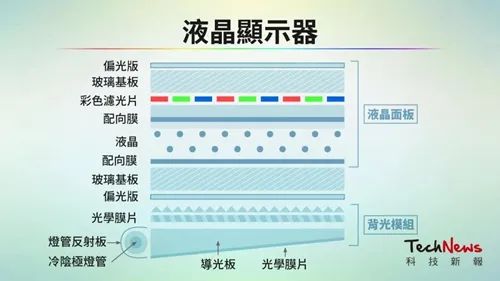

Currently, LCD technology is quite mature, used in general computer and television screens, and is cost-effective, making it a foundational technology for consumer products.

The imaging principle of a typical liquid crystal display.

After understanding LCD, let’s move on to LED and OLED.

LED stands for “Light-Emitting Diode”. It converts electrical energy into light energy. By applying voltage across its two terminals, when current flows, electrons combine with holes, and the remaining energy is released in the form of visible light. Depending on the materials used, the photon energy produces light of different wavelengths. Direct-view LEDs are commonly used in outdoor TV walls or traffic lights, while LED chips are currently the mainstream products for TV and screen backlighting and lighting.

LED technology converts electrical energy into light energy.

LED and OLED have similar driving concepts, but the materials used are entirely different. OLED stands for “Organic Light-Emitting Diode”. Its basic structure involves creating a layer of organic material on indium tin oxide (ITO) glass, followed by a layer of low work function metal electrode. When driven by external voltage, holes from the anode and electrons from the cathode combine in the light-emitting layer, producing energy and emitting light, resulting in the primary colors R, G, and B to form the basic color spectrum.

OLED technology.

The biggest difference between OLED and LCD is self-emission; LCD requires an LED backlight and filter, whereas OLED can self-emit light.

Although OLED displays vibrant images, consume less power, and can be bent, the organic materials oxidize, leading to a relatively shorter lifespan and color burn-in issues. Additionally, due to high costs and technical complexity, OLED is mostly used in small screens, such as smartphone displays.

Having understood the basic differences between LCD, LED, and OLED, let’s look at advanced display technologies Mini LED, Micro LED, and Micro OLED.

The most intuitive difference between Mini LED and Micro LED is the size of the LED chips, but conceptually there is a slight difference. Mini LED is officially known as “Sub-Millimeter Light-Emitting Diode”, while Micro LED refers to “Micro Light-Emitting Diode”. The crystal size of the two is basically distinguished by 100 micrometers, or about 0.1 millimeters.

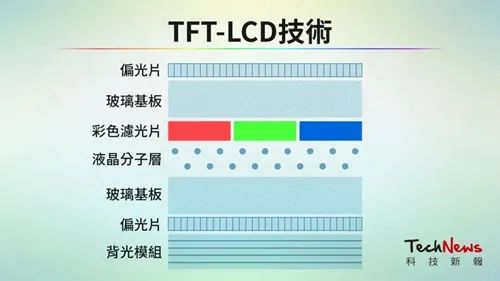

Micro LED technology no longer requires filters and liquid crystal layers.

Mini LED is seen as a transitional phase to Micro LED, an improved version based on traditional LED backlight, used as a backlight source for LCD panels. Micro LED, on the other hand, is a new generation display technology that miniaturizes and matrices LED backlighting, aiming to individually drive inorganic self-emitting (self-emission) pixels, extending product lifespan and potentially outperforming OLED, thus being regarded by the industry as the next-generation display technology.

Currently, Mini LED technology is mainly used in “Multi-Zone Backlit Displays” and “Large RGB Small Pitch Displays”. The “Multi-Zone Backlight Control” feature in Mini LED technology allows for zoned dimming, enhancing the high contrast and resolution of images to achieve HDR effects, comparable to OLED displays. Another technology uses Mini LED chips to create large screens with pixel spacing below Pitch 1.0 mm, improving the resolution of LED displays and creating new mainstream specifications for display screens.

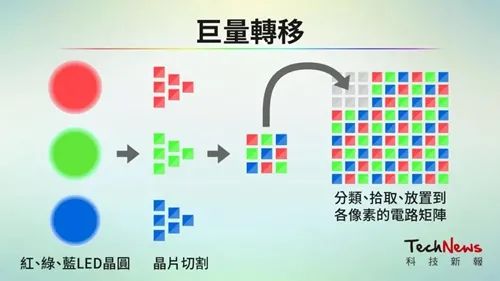

Micro LED, however, brings new technological breakthroughs, not limited to backlighting. Since the chips of Micro LED reach a level indistinguishable to the naked eye, they can directly combine R, G, and B chips into a single pixel, creating the concept of “one pixel”, eliminating the need for filters and liquid crystal layers. This technological characteristic, completely different from the light-emitting structure of past LCD screens, will revolutionize the LCD industry.

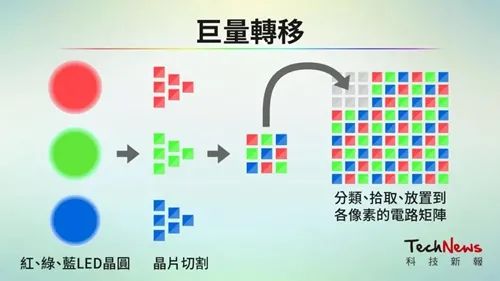

Mass transfer needs to place the chips completely onto the circuit matrix, which is very difficult to achieve.

In addition to potentially creating a new landscape for the LCD industry, the future applications of Micro LED are broad, including AR/VR devices, automotive screens, and high-resolution wearable products. However, there are many challenges to overcome with Micro LED technology, from early-stage epitaxial technology bottlenecks, mass transfer yield issues, packaging and testing challenges, to subsequent detection and maintenance, which all significantly impact the mass production feasibility of Micro LED.

Micro OLED has been a hot topic this year, as Apple has partnered with TSMC to develop Micro OLED panels. The biggest feature of Micro OLED is that, unlike traditional TVs and high-end smartphones that build screens on glass substrates, it is directly mounted on wafers.

Micro OLED uses single crystal silicon wafers as the backing, offering advantages such as lighter weight, smaller size, lower power consumption, self-emission, and high luminous efficiency, making it particularly suitable for AR, VR, and other display wearable devices.

It is reported that Apple’s Micro OLED under development measures less than 1 inch (2.54 cm) and will be used for Apple’s latest augmented reality (AR) products. However, the Micro OLED project is currently in the trial production stage and will take several more years to reach mass production.

Currently, Sony, Samsung, and BOE are all developing Micro OLED display technology, planning to mass-produce and use it in future wearable devices and AR devices. (News source: TechNews, Cover image source: Paixin Network)

For more in-depth information on Mini LED, click to learn about TrendForce’s “2021 Mini LED New Backlight Display Market Analysis Report”.

> Samsung 2021 The Wall Micro LED Commercial Display Officially Launched

> Raising 1 Billion Yuan! Longli Technology Focuses on Medium and Large Size Mini LED Display Modules

> Aiming for 10x Growth! Leyard Plans to Achieve Nearly 300 Million Yuan in Micro LED Revenue This Year

> LG’s First 42-Inch OLED TV Postponed to Next Year