Photonic sensors are known for their fast response times, enabling non-contact measurements with high accuracy, high resolution, and good reliability. Additionally, photonic sensors are compact, lightweight, energy-efficient, and easy to integrate, making them one of the most widely produced and applied sensors today. They are extensively used in various fields including military, aerospace, communications, smart homes, intelligent transportation, security, LED lighting, toys, detection, and industrial automation control.

Monitoring Smoke Dust Turbidity with Photonic Sensors

Preventing industrial smoke dust pollution is one of the important tasks of environmental protection. To eliminate industrial smoke dust pollution, it is essential to know the amount of smoke dust emissions; therefore, monitoring, automatic display, and exceeding standard alarms for smoke dust sources are necessary. The turbidity of smoke in the flue is detected by measuring the changes in light transmission through the smoke. If the turbidity increases, the light emitted by the light source is absorbed and refracted by the dust particles, resulting in a decrease in the light reaching the light detector. Consequently, the strength of the output signal from the light detector reflects the changes in smoke turbidity.

Smoke detectors also use photonic sensors as core components to measure smoke concentration. They consist of infrared light-emitting diodes and phototransistors, but the two are not in the same plane (there is a certain angle). In the absence of smoke, the phototransistor does not receive infrared light; when smoke enters the sensing chamber, the smoke particles scatter some of the light beams to the phototransistor. As the concentration of smoke increases, more light beams are scattered to the sensor, and when the light reaching the sensor reaches a certain level, the buzzer will emit an alarm signal.

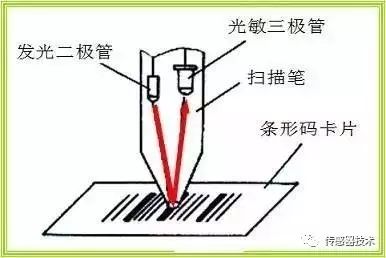

Photonic Sensors in Barcode Scanners

When the scanner head moves over the barcode, if it encounters a black line, the light from the light-emitting diode is absorbed by the black line, and the phototransistor does not receive reflected light, presenting a high impedance and being in a cutoff state. When it encounters a white space, the light emitted by the light-emitting diode is reflected to the base of the phototransistor, causing it to generate a photocurrent and turn on. After scanning the entire barcode, the phototransistor converts the barcode into a series of electrical pulse signals, which are amplified and shaped to form a pulse train, and then processed by a computer to complete the recognition of the barcode information.

Counting Function of Photonic Sensors in Bill Counters

One of the essential components of a bill counter is the photonic sensor. The counter uses non-contact infrared photonic detection technology, which has advantages such as simple structure, high accuracy, and fast response speed.

The bill counter uses two sets of infrared photonic sensors. Each sensor consists of an infrared light-emitting diode and a phototransistor receiving infrared light, with an appropriate distance between them.

When there are no banknotes passing through, the receiving tube is illuminated and conducts, outputting 0. When a banknote passes through, it blocks the infrared light, resulting in insufficient light flux to the receiving tube, outputting 1. After the banknote passes, the receiving tube receives infrared light again and conducts. This generates a pulse signal at the output of this part of the circuit. These signals are shaped and amplified by subsequent circuits and input to the microcontroller, which drives the execution motor and completes counting and display accordingly. The reason the bill counter uses two sets of photonic sensors is to detect the integrity of banknotes and avoid counting damaged notes.

By using photonic sensors to detect the counting of banknotes, the total count can be accumulated, and finally displayed visually to the user through a liquid crystal display and an external display. An automatic alarm can also be triggered in case of anomalies.

Photonic Sensors in Automatic Meter Reading Systems

With the development of microelectronics, sensor technology, computer technology, and modern communication technology, photonic sensors can be used to develop automatic meter reading systems. The aluminum disk of the energy meter rotates under the action of eddy currents and magnetic fields. Using photonic sensors, the number of rotations of the aluminum disk can be converted into pulse numbers. For example, by partially painting the rotating aluminum disk black and using reflective photonic emitter-receiver pairs, when the aluminum disk rotates, pulses are generated at the blackened areas. The number of rotations of the aluminum disk can be sampled and converted into corresponding pulse counts, which are sent to the CPU’s T0 port for counting processing via an optocoupler isolation circuit. The use of optocoupler isolation can effectively prevent interference signals from entering the microcomputer. Combined with other transmission methods, an automatic meter reading system can be formed.

Photonic Sensors in Automated Production Lines

Photonic detection methods have high precision, fast response, and non-contact advantages, widely used in light industry automation machines.

Photonic Material Deviation Detector

The material deviation detector is used to detect the extent and direction of deviation of strip materials during processing, thereby providing correction signals for the correction control circuit, mainly used in printing, dyeing, paper feeding, film, and tape production processes.

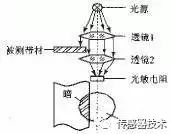

The principle of the photonic material deviation detector is shown in Figure 1. The light emitted by the light source is focused into a parallel beam through lens 1, directed to lens 2, and then focused onto the photoconductive resistor. Some of the light is blocked by the material being measured, reducing the light flux reaching the photoconductive resistor.

Figure 1: Working Principle of Material Deviation Detector

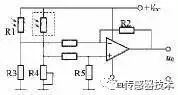

Figure 2 is a schematic diagram of the measurement circuit. R1 and R2 are photoconductive resistors of the same model. R1 is installed under the material, while R2 is covered with a light shield for temperature compensation. When the material is in the correct position (center position), the bridge formed by R1, R2, R3, and R4 is balanced, resulting in an output voltage U0 of 0. When the material deviates to the left, the shaded area decreases, reducing the resistance of photoconductive resistor R1, causing the bridge to lose balance. The differential amplifier amplifies this unbalanced voltage, and the output voltage is negative, reflecting the direction and extent of the material deviation. Conversely, when the material deviates to the right, U0 is positive. The output signal U0 is displayed by a display device and sent to the actuator, providing correction signals for the correction control system.

Figure 2: Measurement Circuit of Material Deviation Detector

Height Detection of Packaged Filling Materials

Using the volumetric method to measure packaged products, in addition to having a certain error range for weight, there are generally also requirements for filling height to ensure the external quality of the product. Products that do not meet the filling height requirements will not be allowed to leave the factory. Figure 3 illustrates the principle of controlling filling height using photonic detection technology. When the filling height h deviates too much, the photonic joint does not produce an electrical signal, prompting the actuator to push the packaged item out for processing.

Figure 3: Controlling Filling Height Using Photonic Detection Technology

Photonic Color Quality Detection

Figure 4 illustrates the principle of photonic color quality detection for packaging materials. If the specified base color of the packaged item is white, due to poor quality, some may appear yellowish. Before product packaging, the color quality is first detected by photonic means; when the item appears yellowish, a voltage difference is output, activating the electromagnetic valve to blow out the yellowed items.

Figure 4: Photonic Color Quality Detection Principle for Packaging Materials

Plastic Film Position Control in Plastic Packaging Bag Production

Figure 5 illustrates the principle of the plastic film position control system in packaging machines. The rolled plastic film is printed with trademarks and text, with positioning color marks. During packaging, the trademarks and text must be accurately positioned, and the patterns must not be cut in half. The position of the trademark on the film is detected by the photonic system, amplified, and used to control the electromagnetic clutch. When the color mark on the film (a small area that is opaque, usually black) has not reached the positioning color mark position, the photonic system allows the electromagnetic clutch to be energized and engaged, allowing the film to continue moving. When the color mark reaches the positioning color mark position, the light from the projector is blocked by the color mark, sending a signal indicating that the position is correct. This signal is converted and amplified by photonic means, causing the electromagnetic clutch to disengage, accurately stopping the film at that position, ready for cutting before continuing to move.

Figure 5: Schematic of Film Position Control System

When the color mark on the film has not reached the photonic tube, the photonic relay coil has no current flowing through it, causing the servo motor to rotate and drive the film to continue moving. When the color mark reaches the position of the photonic tube, the photonic relay coil receives current, and the servo motor immediately stops, thus the film stops at that position. After the cutting action is completed, the servo motor continues to rotate.

Other Applications

Photonic switches can also be used for production line output statistics, detecting whether assembly parts are in place and the quality of assembly, such as whether bottle caps are pressed on during filling, whether trademarks are missing (see Figure 7), and whether feeding mechanisms are out of material (see Figure 8).

Figure 7: Bottle Filling Detection Schematic

Figure 8: Feeding Mechanism Detection Schematic

Additionally, reflective photonic sensors can detect the presence and width of fabrics. Using obstructive photonic sensors to detect the droop of fabrics can help adjust the tension of the fabric during transmission, and reflective photonic sensors installed on frames can detect empty boxes from missing products and use hydraulic cylinders to push out the empty boxes.

Applications of Photonic Sensors in Automobiles

In-vehicle entertainment/navigation/DVD system backlight control enables ideal backlight brightness under all ambient light conditions; backlight control for rear-seat entertainment displays; instrument cluster backlight control (speedometer/tachometer); automatic rearview mirror brightness control (usually requires two sensors, one front-facing and one rear-facing); automatic headlight and rain sensing control (specialized, changes according to demand); rearview camera control (specialized, changes according to demand).

This has become one of the most effective solutions for providing better display quality, as it has characteristics similar to the human eye, which is crucial for automotive applications that require full backlight effectiveness under all ambient light conditions.

For example, during the day, users need maximum brightness for optimal visibility, but this brightness is too bright for nighttime conditions, so photonic sensors with good spectral response (good IR attenuation), appropriate dynamic range, and overall good output signal regulation can easily automate these applications. End users can set several threshold levels (such as low, medium, bright), or dynamically change the sensor’s backlight brightness.

This also applies to automatic rearview mirror brightness control, where intelligent brightness management is needed when the mirror darkens and/or brightens, which can be accomplished using ambient light sensors.

Applications of Photonic Sensors in Consumer Electronics

Recent advances in semiconductor-like sensors and packaging development have given end users a broader choice in light sensors. Small packaging, low power consumption, high integration, and ease of use are reasons why designers increasingly adopt light sensors, applying them more widely in consumer electronics.

For portable applications, if users do not change system settings (usually brightness control), a display always consumes the same amount of energy. In particularly bright areas, such as outdoors, users tend to increase the brightness of the display, which increases the system’s power consumption. When conditions change, such as entering a building, most users do not change the settings, so the system power consumption remains high. However, by using a light sensor, the system can automatically detect changes in conditions and adjust settings to ensure the display is at optimal brightness, thereby reducing overall power consumption.

In general consumer applications, this can also extend battery life. For mobile phones, laptops, tablets, and digital cameras, using feedback from ambient light sensors can automatically control brightness, thus extending battery life.

Photonic sensors have extensive applications utilizing the variables of photonics, such as escalators, automatic doors, anti-theft guards, automatic lighting, material level control, and so on. In the future, with the development and popularization of Internet of Things technology, the applications of photonic sensors will penetrate all aspects of human life.

– END –

Source: Sensor Technology

Editor: Ctrl