WeChat Search

WeChat Search Technical Training01

Technical Training01

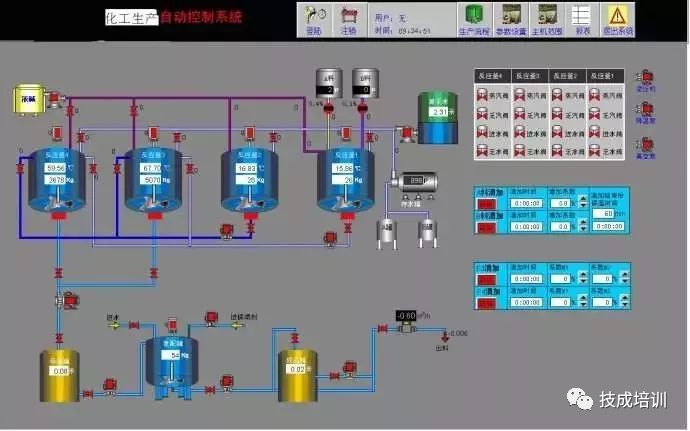

Configuration software generally has three English abbreviations: HMI/MMI/SCADA, corresponding to the full names Human and Machine Interface, Man and Machine Interface, and Supervisory Control and Data Acquisition, translated into Chinese as: 人机界面、监视控制和数据采集软件.

Currently, the development of configuration software is rapid, having expanded into enterprise information management systems, integrated management and control, remote diagnostics and maintenance, as well as a series of data integration on the Internet.

The application fields of configuration software are broad, applicable in data acquisition and monitoring control in power systems, water supply systems, oil, chemical industries, and many other areas. In power systems and electrified railways, it is also known as the remote terminal unit (RTU System).

02

The concept of “configuration” became widely known among automation technology personnel with the emergence of Distributed Control Systems (DCS).

With the continuous development and application of industrial control technology, the advantages of PCs (including industrial computers) over previous dedicated systems have become increasingly apparent.

These advantages mainly include: the rapid development of PC technology, the maturity of various related technologies; industrial control systems built on PCs have relatively low ownership costs; abundant software and hardware resources; strong interoperability between software; and PC-based control systems are easy to learn and use, with readily available technical support.

In the penetration of PC technology into the industrial control field, configuration software occupies a very special and important position.

Configuration software refers to specialized software for data acquisition and process control, which serves as a software platform and development environment at the monitoring layer of automatic control systems, using flexible configuration methods to provide users with general-purpose software tools for quickly building industrial automatic control system monitoring functions. Configuration software should support various industrial control devices and common communication protocols, and typically provide distributed data management and networking capabilities.

Corresponding to the original concept of HMI (Human Machine Interface) software, configuration software should be a tool or development environment that allows users to quickly establish their own HMI.

Before the emergence of configuration software, users in the industrial control field had to manually write HMI applications or commission third parties, which was time-consuming, inefficient, and unreliable; or purchase dedicated industrial control systems, which were often closed systems with limited options, unable to meet needs, and severely restricted in upgrading and adding functionalities.

The emergence of configuration software liberated users from these predicaments, allowing them to utilize the functionalities of configuration software to build the most suitable application systems for themselves. With its rapid development, real-time databases, real-time control, SCADA, communication and networking, open data interfaces, and extensive support for I/O devices have become its main components. As technology advances, monitoring configuration software will continuously be endowed with new content.

In simple terms, configuration is the process of using the tools and methods provided in application software to complete a specific task in a project.

In contrast to hardware production, configuration is similar to assembly. For example, to assemble a computer, various models of motherboards, cases, power supplies, CPUs, monitors, hard drives, and optical drives are provided, and our job is to piece together the components to create the computer we need. Of course, the configuration in software has a greater scope for flexibility than hardware assembly, as it generally has more “components” than hardware, and each “component” is very flexible, as software components have internal attributes that can change their specifications (such as size, characteristics, color, etc.).

Before the concept of configuration appeared, achieving a specific task was done by writing programs (using BASIC, C, FORTRAN, etc.). Writing programs not only required a large amount of work and time but also was prone to errors, making it difficult to guarantee deadlines. The emergence of configuration software solved this problem. Tasks that previously took months can now be completed in days through configuration.

Configuration software is specialized. A type of configuration software can only be suitable for applications in a specific field. The concept of configuration first appeared in industrial computer control, such as DCS configuration and PLC (Programmable Logic Controller) ladder diagram configuration. HMI generation software is called industrial control configuration software. In fact, the concept of configuration exists in other industries, but people just do not refer to it as such.

For example, AutoCAD, PhotoShop, and office software (PowerPoint) have similar operations, where users use the tools provided by the software to create their works and save them as data files, rather than executing programs. The data formed by configuration can only be recognized by its manufacturing tool or other specialized tools. However, the difference is that the configuration results formed in industrial control are used for real-time monitoring. The interpretation engine of the configuration tool must run based on these configuration results in real-time. On the surface, the operation program of the configuration tool executes its specific tasks.

Although configuration means that specific applications can be completed without writing programs, to provide some flexibility, configuration software also offers programming means, generally built-in compilation systems that provide BASIC-like languages, and some even support VB.

The emergence of configuration software liberated users from these predicaments, allowing them to utilize the functionalities of configuration software to build the most suitable application systems for themselves. With its rapid development, real-time databases, real-time control, SCADA, communication and networking, open data interfaces, and extensive support for I/O devices have become its main components. As technology advances, monitoring configuration software will continuously be endowed with new content.

03

Configuration software products appeared in the early 1980s and entered China in the late 1980s. However, before the mid-1990s, the application of configuration software in China was not widespread. The reasons for this are roughly as follows:

① Domestic users lacked awareness of configuration software, there was no budget for configuration software in projects, or they preferred to invest manpower and resources in lengthy and cumbersome programming development for specific projects rather than adopting configuration software.

② For a long time, domestic users had weak software awareness, and faced with the high prices of imported software (most early configuration software was developed by foreign manufacturers), very few users were willing to purchase genuine software.

③ At that time, the level of industrial automation and information technology application in China was not high, and the demand for configuration software to collect, monitor, and process large-scale applications and data, generating management-required data, had not fully formed.

With the deepening application of industrial control systems, configuration software has gradually become popular in China since 1995.

Below are introductions to several types of configuration software.

① InTouch: Wonderware’s InTouch software was one of the first configuration software to enter China. In the late 1980s and early 1990s, the Windows 3.1-based InTouch software was refreshing, providing a rich library of graphics. However, the early InTouch software communicated with drivers using DDE, which had poor performance. The latest InTouch 7.0 version is fully based on the 32-bit Windows platform and provides OPC support.

② Fix: Intellution started with Fix configuration software, which was acquired by Emerson in 1995 and is now a wholly-owned subsidiary of Emerson Group. Fix 6.x software provides familiar concepts and interfaces for industrial control personnel and offers complete driver programs (which need to be purchased separately). Intellution named its latest product series iFiX, which offers powerful configuration capabilities, but the new version is not fully compatible with the previous 6.x version. The original Script language has been changed to VBA (Visual Basic For Application), and the Microsoft VBA development environment is integrated internally. Unfortunately, Intellution did not provide a conversion tool from Script language to VBA for version 6.1. In iFiX, Intellution’s products are tightly integrated with Microsoft operating systems and networks. Intellution is also one of the founding members of the OPC (OLE for Process Control) organization. The OPC components and drivers for iFiX also need to be purchased separately.

③ Citech: CiT’s Citech was also one of the earlier products to enter the Chinese market. Citech has a simple operation method, but its operation is more programmer-oriented rather than industrial control user-oriented. Citech provides a C-like scripting language for secondary development, but unlike iFix, Citech’s scripting language is not object-oriented, which undoubtedly increases the difficulty for users in secondary development.

④ WinCC: Siemens’ WinCC is also a complete configuration development environment, providing C-like scripting, including a debugging environment. WinCC has embedded OPC support and can configure distributed systems. However, WinCC’s structure is complex, and users are advised to undergo Siemens training to master its application.

⑤ ForceControl: Beijing Sanwei ForceControl Technology Co., Ltd.’s ForceControl is also one of the earliest configuration software in China. However, it was not widely promoted as a formal product in its early days, so it is not well-known to most people. Around 1993, the first version was formed, but it was still based on DOS and VMS. Later, with the popularity of Windows 3.1, a 16-bit Windows version of ForceControl was developed. However, until the release of the Windows 95 version, it was mainly used for some internal projects. The 1.0 version under 32-bit architecture already had a relatively advanced structure, with one of its main features being a truly distributed real-time database three-layer structure, and its real-time database structure could be configured as a live structure. Between 1999 and 2000, ForceControl made significant progress, with the latest 2.0 version greatly improving functionality, usability, openness, and the number of I/O drivers. In many design aspects, ForceControl considers the practical needs of domestic users, emphasizing practicality while maintaining the standards of large software. Additionally, the company has invested significant manpower in product training and user technical support, believing that in a short time, ForceControl software products will create a significant impact in the industrial control software field.

Other common configuration software includes GE’s Cimplicity, Rockwell’s RsView, NI’s LookOut, PCSoft’s Wizcon, and some domestic configuration software companies’ MCGS, all of which have their own characteristics.

04

All configuration software currently seen can perform similar functions: for example, almost all configuration software running on 32-bit Windows platforms adopt a similar resource browser window structure and configure and edit various resources (devices, tags, screens, etc.) in industrial control systems; they provide various data drivers; and they use scripting languages to provide secondary development functions, etc.

However, technically, the methods provided by various configuration software to achieve these functions differ. From these differences, as well as the trends in PC technology development, the future direction of configuration software can be seen.

05

Data Acquisition Methods:

Most configuration software provides various data acquisition programs that users can configure. However, in this case, the driver programs can only be provided by the configuration software developer or written by users according to the interface specifications of a certain configuration software, which places excessive demands on users.

The OPC specification proposed by the OPC Foundation is based on Microsoft’s OLE/DCOM technology, providing a complete solution for software component interaction and data sharing in distributed systems.

In systems that support OPC, the data provider acts as a server, while the data requester acts as a client, and communication between the server and client occurs through the DCOM interface without needing to know the internal implementation details of each other.

Since COM technology is implemented at the binary code level, servers and clients can be provided by different manufacturers. In practical applications, data acquisition programs acting as servers are often provided by hardware manufacturers along with the hardware, allowing full utilization of hardware capabilities, while configuration software as clients can seamlessly connect with drivers from various manufacturers through OPC, fundamentally solving the problem of dedicated format drivers lagging behind hardware updates.

At the same time, configuration software can also act as a server to provide data to other application systems (such as MIS, etc.). OPC is now supported by well-known foreign manufacturers including Intellution, Siemens, GE, and ABB. With the popularity of OPC-supporting configuration software and hardware devices, using OPC for data acquisition will undoubtedly become a more reasonable choice in configuration.

06

Functionality of Scripts:

Scripting languages are an important means to expand the functionality of configuration systems. Therefore, most configuration software provides support for scripting languages.

The specific implementation methods can be divided into three types:

First, built-in C/Basic-like languages;

Second, programming languages using Microsoft’s VBA;

Third, a few configuration software use object-oriented scripting languages.

C/Basic-like languages require users to write scripts using statements similar to high-level languages, combining system-provided function calls to complete various system functions. It should be noted that most domestic configuration software adopting this method do not provide complete support for scripts, with many only offering IF…THEN…ELSE statement structures and lacking loop control statements, which brings certain difficulties to script programming.

Microsoft’s VBA is a relatively complete development environment, and configuration software using VBA typically employs Microsoft’s VBA environment and component technology to implement objects in the configuration system as components, allowing access to these objects through VBA programs. Since Visual Basic is interpreted, some syntax errors in VBA programs may only be discovered during execution. Object-oriented scripting languages provide an object access mechanism, allowing access to objects in the system through their properties and methods, making them easier to learn, master, and extend, but their implementation is more complex.

07

Scalability of Configuration Environments:

Scalability provides users with the ability to add new functionalities to the system without changing the original system. These added functionalities may come from configuration software developers, third-party software providers, or users themselves. The most common means of adding functionality is through the application of ActiveX components, although only a few configuration software can provide complete ActiveX component import functionality and implement access to imported objects in scripting languages.

08

Openness of Configuration Software:

With the popularity of management information systems and computer-integrated manufacturing systems, the application of production site data is no longer limited to data acquisition and monitoring. In the production process, a large amount of data from the site is needed for process analysis and control to achieve adjustments and optimizations in production processes. Existing configuration software can only provide most of these demands in the form of reports or export data to external databases via ODBC for other business systems to call, and in most cases, redevelopment is still required to achieve this.

As the demand for information in production decision-making activities increases, it is foreseeable that the integration of configuration software with management information systems or executive information systems will become closer, and may likely appear in the form of modules that realize data analysis and decision-making functions within configuration software.

09

Degree of Support for the Internet:

Modern enterprises’ production has tended towards international and distributed production methods. The Internet will be the foundation for achieving distributed production. Whether configuration software can transition from the original local area network operation mode to supporting the Internet is an important issue facing all configuration software developers. Given the current network infrastructure and the level of industrial control applications in China, I believe that for a long time, monitoring industrial sites via the Internet in a browser mode will remain at the monitoring stage in most applications, while actual control functions should be completed through more stable technologies, such as dedicated remote clients, ActiveX controls provided by professional developers, or Java technologies.

10

Control Functions of Configuration Software:

With the continuous improvement of automatic control integrated system technology centered on industrial PCs and the increasing proficiency of engineering personnel in using configuration software, users’ requirements for configuration software are no longer primarily focused on graphics, but rather on substantive application functionalities, such as software and advanced process control strategies.

Soft PLC products are control devices based on the open structure of PCs, possessing the characteristics of hard PLCs in terms of functionality, reliability, speed, fault diagnosis, etc. Using software technology, standard industrial PCs can be transformed into fully functional PLC process controllers.

Soft PLC integrates the switching control, analog control, mathematical operations, numerical processing, communication networks, and other functions of computers and PLCs, providing a powerful instruction set, fast and accurate scanning cycles, reliable operation, and an open structure that can connect to various I/O systems and networks through a multitasking control kernel.

Thus, it can be said that soft PLC provides the same functionalities as hard PLCs while also possessing various advantages of the PC environment.

Currently, influential products internationally include: ISaGRAF software package from France’s CJ International, WinPLC from PCSoft International, Paradym-31 from Intellution, ProcessSuite from Moore Process Automation Solutions, InControl from Wonderware Controls, and SoftPLC from SoftPLC. There are currently no soft PLC products launched by domestic configuration software, and for domestic configuration software to comprehensively surpass foreign competitors, innovation must be pursued to launch similar functional products.

As enterprises demand high flexibility and high efficiency, control schemes based on classical control theory can no longer meet these needs. The introduction and successful application of advanced control strategies, represented by multivariable predictive control, have attracted widespread attention in the process industry.

Advanced Process Control (APC) refers to a class of operational and control strategies implemented in dynamic environments, based on models and fully leveraging computer capabilities to achieve maximum theoretical performance for factories.

Advanced control strategies mainly include: dual control and valve position control, pure dead time compensation control, decoupling control, adaptive control, differential control, state feedback control, multivariable predictive control, inference control and soft measurement technology, intelligent control (expert control, fuzzy control, and neural network control), etc. In particular, intelligent control has become a hot topic for development and application.

Currently, many large domestic enterprises are investing in implementing advanced control in their automation systems. Many foreign control software companies and DCS manufacturers are competing to develop advanced control and optimization control engineering software packages. According to reports, an investment of $1.63 million in an ethylene plant to implement advanced control is expected to yield benefits of $6 million per year. This indicates that configuration software capable of embedding advanced control and optimization control strategies will be greatly welcomed by users.

11

User demand drives technological progress, and this trend is particularly evident in configuration software. The future configuration software will provide more powerful configuration functionalities in distributed environments, fully support ActiveX, have strong scalability, support OPC and other industrial standards, possess strong control functionalities, and be an open system accessible via the Internet.

HMI is the abbreviation for Human Machine Interface.

HMI broadly refers to “the interface for communication, transmission, and reception of information between the user and the machine.”

For example, in a factory, we need to collect information such as temperature, humidity, and the status of machines in various areas of the factory, through a system that monitors and records these parameters, and can handle unexpected situations.

This is a typical application of SCADA/HMI. Generally, an HMI system must have several basic capabilities:

Real-time data trend display—immediately displaying captured data on the screen.

Automatic data recording—automatically storing data in a database for future reference.

Historical data trend display—visualizing data from the database.

Report generation and printing—converting data into report formats and being able to print them.

Graphical interface control—allowing operators to directly control machines and devices through a graphical interface.

Alarm generation and recording—users can define conditions for alarm generation, such as excessive temperature or pressure exceeding critical values, under which the system will generate alarms to notify operators for action.

Disclaimer: This article is reprinted from the internet, and the copyright belongs to the original author. If there are any copyright issues, please contact us promptly for deletion. Thank you!

HISTORY/Previous Recommendations

Complete question bank for the 2022 Electrician Junior Exam (including answers)

Three essential tools for electricians, easily accessible via WeChat!

【Collection】 The “path” of a ten-year veteran electrician, secrets to earning over ten thousand a month!

Five major electrical drawing software (CAD, Eplan, CADe_simu…), which one do you pick?

Latest electrical version CAD drawing software, with a super detailed installation tutorial!

Latest electrical drawing software EPLAN, with a super detailed installation tutorial!

Common issues for beginners using S7-200 SMART programming software (with download links)

Comprehensive electrical calculation EXCEL spreadsheets, generated automatically! No need to seek help for electrical calculations!

Bluetooth headsets, introductory books on electricians/PLC are available for free? Come and claim your electrical gifts!

Basic skills in PLC programming: Ladder diagrams and control circuits (with 1164 practical cases of Mitsubishi PLC)

If you still can’t understand electrical diagrams, take away the basics of electrician identification and simulation software, quickly get started with theory and practice!

12 free electrician video courses, 10GB of software/e-books, and 30 days of free live electrician courses are being given away!

Don’t forget to like and share!

Click “Read the original text” to learn PLC/electrician courses for free!

Click “Read the original text” to learn PLC/electrician courses for free!