The power domain controller is an intelligent powertrain management unit. It uses CAN/FLEXRAY for transmission management, battery management, and monitoring AC generator regulation, mainly for optimizing and controlling the powertrain, while also featuring electrical intelligent fault diagnosis, intelligent power saving, and bus communication functions.

(1) Working Requirements

The power domain control MCU can support major applications such as BMS, with the following requirements:

· High main frequency, main frequency of 600MHz~800MHz

· RAM 4MB

· High functional safety level requirements, capable of reaching ASIL-D level;

· Support for multi-channel CAN-FD;

· Support for 2G Ethernet;

· Reliability not lower than AEC-Q100 Grade 1;

· Support for firmware verification functions (national secret algorithm);

(2) Performance Requirements

High performance: The product integrates ARM Cortex R5 dual-core lock-step CPU and 4MB on-chip SRAM to support the growing demand for computing power and memory in automotive applications. The ARM Cortex-R5F CPU has a main frequency of up to 800MHz.

High safety: The automotive reliability standard AEC-Q100 reaches Grade 1 level, and the ISO26262 functional safety level reaches ASIL D. The dual-core lock-step CPU employed can achieve a diagnostic coverage rate of up to 99%. The built-in information security module integrates a true random number generator, AES, RSA, ECC, SHA, and hardware accelerators compliant with national secret commercial standards. These integrated information security features can meet the needs for secure boot, secure communication, and secure firmware updates.

4. Body Domain Control Chips

The body domain is mainly responsible for controlling various functions of the vehicle body. With the development of the whole vehicle, the number of body domain controllers is also increasing. To reduce controller costs and the overall vehicle weight, integration needs to unify all functional devices from the front, middle, and rear parts of the vehicle, such as the rear brake lights, rear position lights, tailgate locks, and even the dual support rods into a comprehensive controller.

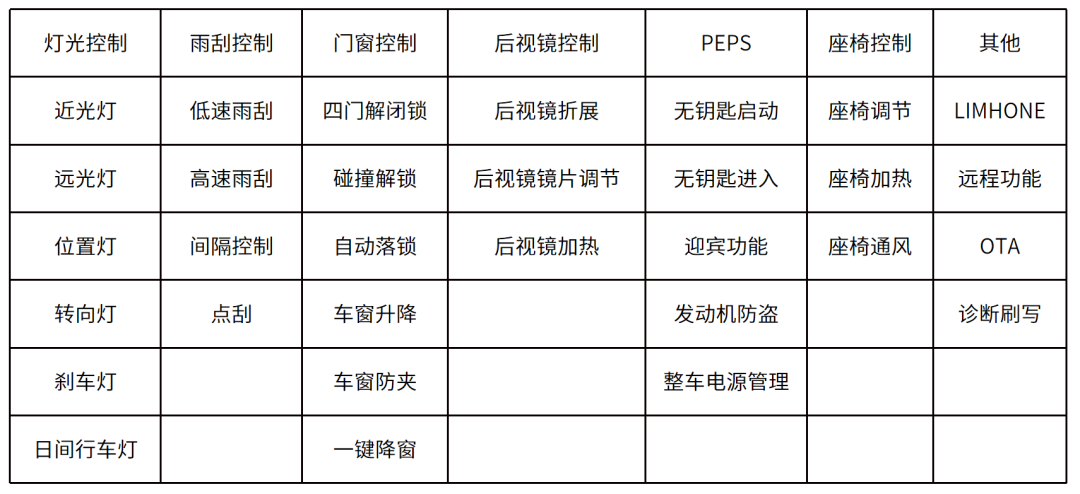

Body domain controllers generally integrate BCM, PEPS, TPMS, Gateway, etc. functions, and can also expand to include functions such as seat adjustment, mirror control, air conditioning control, etc., comprehensively and effectively managing various actuators and allocating system resources. The body domain controller has numerous functions, as shown in the figure below, but is not limited to the functions listed here.

Body Domain Controller Function Table

※Data Source: Public Data, Provided by the Writing Unit

The main demands of automotive electronics for MCU control chips are better stability, reliability, safety, and real-time technical characteristics, as well as higher computing performance, storage capacity, and lower power consumption indicators. The body domain controller has gradually transitioned from decentralized functional deployment to integrating all body electronics, basic driving functions, key functions, vehicle lights, doors, windows, etc. into a large controller. The design of the body domain control system integrates the control of lighting, wipers, central door locks, windows, etc., PEPS smart keys, power management, and various interfaces and modules such as CAN, expandable CANFD and FLEXRAY, LIN networks, Ethernet, etc.

Overall, the various control functions in the body domain place demands on the MCU’s main control chip, mainly reflected in computing processing performance, functional integration, communication interfaces, and reliability. Specific requirements vary significantly due to the functional differences of different application scenarios in the body domain. For example, applications like electric windows, automatic seats, and electric tailgates have high-efficiency motor control requirements, which require the MCU to integrate functions such as FOC electric control algorithms. In addition, different application scenarios in the body domain have varying interface configuration requirements for chips. Therefore, it is usually necessary to select body domain MCUs based on the specific functional and performance requirements of the application scenarios, while also comprehensively considering product cost-effectiveness, supply capacity, and technical service factors.

(2) Performance Requirements

The main reference indicators for body domain control MCUs are as follows:

· Performance: ARM Cortex-M4F @144MHz, 180DMIPS, built-in 8KB instruction cache, supports Flash acceleration unit execution with 0 wait.

· Large capacity encrypted memory: up to 512K Bytes eFlash, supporting encrypted storage, partition management, and data protection, supporting ECC verification, 100,000 erase cycles, and 10 years of data retention; 144K Bytes SRAM, supporting hardware parity check.

· Integration of rich communication interfaces: supporting multiple GPIOs, USART, UART, SPI, QSPI, I2C, SDIO, USB2.0, CAN 2.0B, EMAC, DVP, etc.

· Integration of high-performance analog devices: supporting 12-bit 5Msps high-speed ADC, rail-to-rail independent operational amplifiers, high-speed analog comparators, 12-bit 1Msps DAC; supporting external input independent reference voltage sources, multi-channel capacitive touch buttons; high-speed DMA controllers.

· Support for internal RC or external crystal clock input, high-reliability reset.

· Built-in calibratable RTC real-time clock, supporting leap year and ten-thousand-year calendar, alarm events, periodic wake-up.

· Support for high-precision timing counters.

· Hardware-level security features: cryptographic algorithm hardware acceleration engine, supporting AES, DES, TDES, SHA1/224/256, SM1, SM3, SM4, SM7, MD5 algorithms; Flash storage encryption, multi-user partition management (MMU), TRNG true random number generator, CRC16/32 computation; supporting write protection (WRP), various read protection (RDP) levels (L0/L1/L2); supporting secure boot, program encryption download, and secure updates.

· Support for clock failure monitoring and tamper monitoring.

· Equipped with 96-bit UID and 128-bit UCID.

· High reliability working environment: 1.8V~3.6V/-40℃~105℃.

The electronic systems in the body domain are still in the early stages of growth for both foreign and domestic companies. Foreign companies have a solid technical accumulation in single-function products such as BCM, PEPS, door and window, and seat controllers, while the product line coverage of major foreign companies lays a foundation for their system integration products. Domestic companies have certain advantages in the application of new energy vehicles in the body domain. Taking BYD as an example, the body domain of BYD’s new energy vehicles is divided into three domains: left, right, and rear, redefining the layout and integration of products. However, in the area of body domain control chips, the main suppliers of MCUs are still international chip manufacturers such as Infineon, NXP, Renesas, Microchip, and ST, with domestic chip manufacturers currently holding a low market share.

From a communication perspective, there is an evolutionary process from traditional architecture to hybrid architecture to the final Vehicle Computer Platform. The changes in communication speed and the reduction in prices of basic computing power with high functional safety are key factors. In the future, it may gradually be possible to achieve compatibility for different functions at the electronic level of basic controllers. For example, the body domain controller can integrate traditional BCM, PEPS, anti-pinch features, etc. Relatively speaking, the technical barriers for body domain control chips are lower than those for power domains, cockpit domains, etc., and domestic chips are expected to achieve significant breakthroughs in the body domain and gradually realize domestic substitution. In recent years, domestic MCUs have shown very good development momentum in the front and rear markets of the body domain.

5. Cockpit Domain Control Chips

The electrification, intelligence, and connectivity of vehicles accelerate the development of automotive electronic and electrical architectures towards domain control, and the cockpit domain is rapidly evolving from in-car audio and video entertainment systems to intelligent cockpits. The cockpit presents a human-machine interface, but whether it is the previous infotainment system or the current intelligent cockpit, it requires both a powerful SOC for computing speed and a real-time MCU to handle data interaction with the entire vehicle. The gradual popularization of software-defined vehicles, OTA, and Autosar in the intelligent cockpit domain has increased the resource requirements for cockpit domain MCUs. This is reflected in the increasing demands for FLASH and RAM capacity, an increasing number of PIN counts, and more complex functions requiring stronger program execution capabilities, as well as richer bus interfaces.

MCUs in the cockpit domain mainly implement system power management, power-on timing management, network management, diagnostics, vehicle data interaction, button management, backlight management, audio DSP/FM module management, and system time management.

MCU resource requirements:

· For main frequency and computing power, the requirements are not lower than 100MHz and 200DMIPS;

· Flash storage space not less than 1MB, with physical partitioning for code Flash and data Flash;

· RAM not less than 128KB;

· High functional safety level requirements, capable of reaching ASIL-B level;

· Support for multi-channel ADC;

· Support for multi-channel CAN-FD;

· Automotive-grade AEC-Q100 Grade 1;

· Support for over-the-air (OTA) updates, Flash supports dual Bank;

· Requires SHE/HSM-light level or higher information encryption engine, supporting secure boot;

· Pin Count not less than 100PIN;

(2) Performance Requirements

·IO supports wide voltage supply (5.5v~2.7v), IO ports support over-voltage use;

Many signal inputs fluctuate according to the power supply battery voltage, and supporting over-voltage use for IO ports can enhance system stability and reliability.

· Storage life:

The automotive lifecycle lasts up to 10 years, so the program storage and data storage of automotive MCUs need to have a longer lifespan. Program storage and data storage need to have separate physical partitions, where program storage has fewer erase cycles, so Endurance>10K is sufficient, while data storage requires frequent erasing and needs a higher erase count, referencing data flash indicators Endurance>100K, 15 years (<1K), 10 years (<100K).

· Communication bus interfaces;

As the communication load on automobiles increases, traditional CAN can no longer meet communication needs, and the demand for high-speed CAN-FD buses is increasing, making CAN-FD support gradually a standard for MCUs.

The current market share of domestic intelligent cockpit MCUs is still very low, with the main suppliers still being international MCU manufacturers such as NXP, Renesas, Infineon, ST, and Microchip. Several domestic MCU manufacturers are already in the layout, but market performance remains to be observed.

The automotive-grade and functional safety levels of intelligent cockpits are relatively not too high, mainly requiring accumulation of know-how, and continuous product iteration and improvement are needed. At the same time, due to the limited number of domestic wafer fabs with automotive-grade MCU production lines, the processes are relatively lagging. Achieving a fully domestic supply chain will require some time for adjustment, and there may also be higher costs, resulting in greater competitive pressure against international manufacturers.

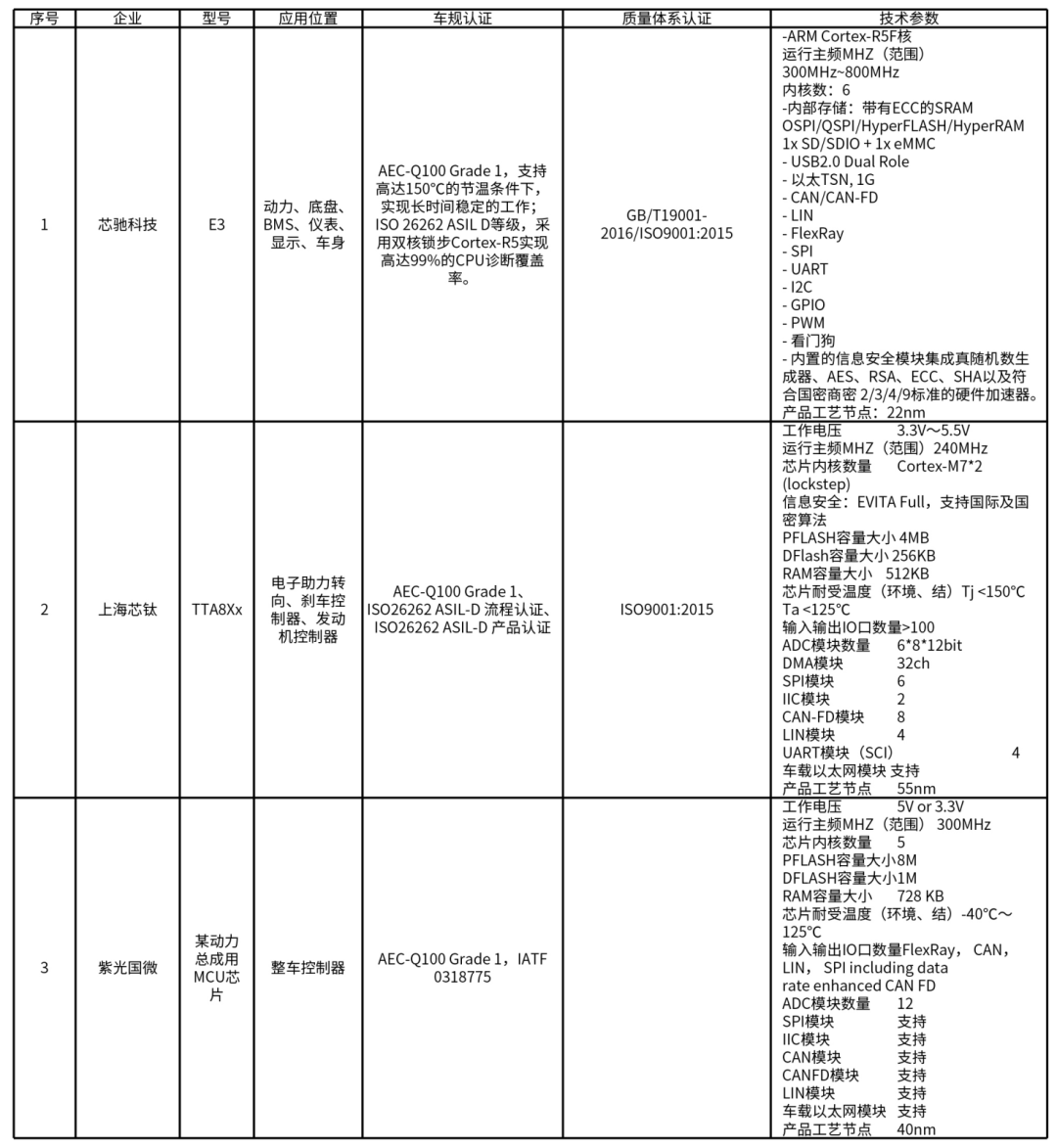

6. Application Status of Domestic Control Chips

Vehicle control chips mainly focus on automotive MCUs. Domestic leading enterprises such as Unisoc, Heda Semiconductor, Shanghai Xintai, GigaDevice, Jiefa Technology, Xinchip Technology, Beijing Junzheng, Shenzhen Xihua, Shanghai Qipuwei, and National Technology all have automotive-grade MCU product series, benchmarking against overseas giants’ products, mainly based on ARM architecture, with some companies also developing RISC-V architecture.

Currently, domestic vehicle control domain chips are mainly applied in the automotive front market, realizing applications in the body domain and infotainment domain, while in the chassis, power domain, and other fields, they are still dominated by overseas giants like STMicroelectronics, NXP, Texas Instruments, Microchip, and ST. Only a few domestic companies have achieved mass production applications. Currently, domestic chip manufacturer Xinchip launched the high-performance control chip E3 series based on ARM Cortex-R5F in April 2022, with functional safety levels reaching ASIL D, temperature levels supporting AEC-Q100 Grade 1, and CPU main frequency reaching 800MHz, with up to 6 CPU cores, making it the highest-performing product among existing mass-produced automotive-grade MCUs, filling the gap in the domestic high-end, high-safety-grade automotive MCU market. The Xinchip E3, with its high performance and reliability, can be used in core vehicle control areas such as BMS, ADAS, VCU, steer-by-wire chassis, instruments, HUD, and intelligent rearview mirrors. More than 100 customers have designed products using the E3, including GAC and Geely.

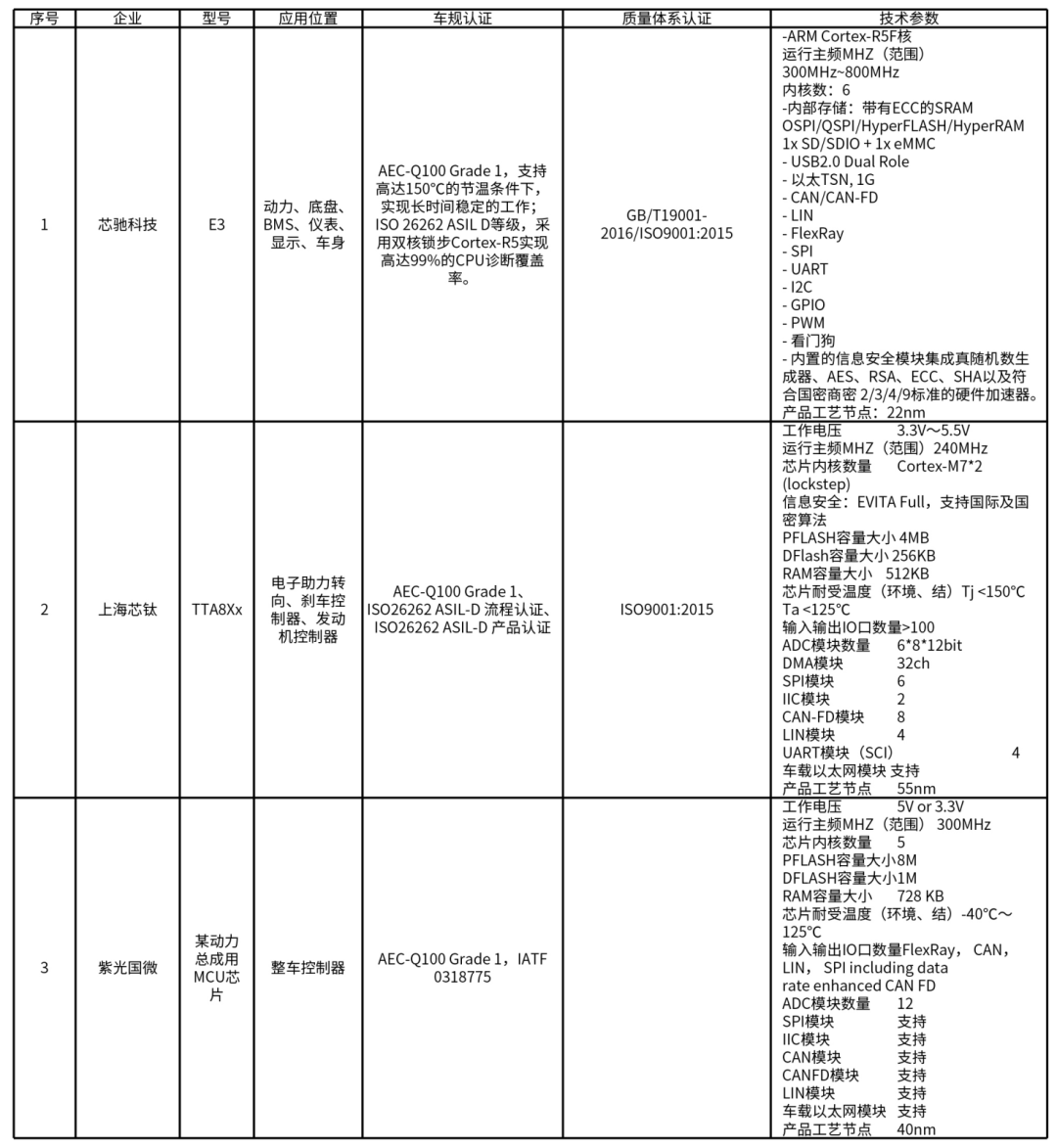

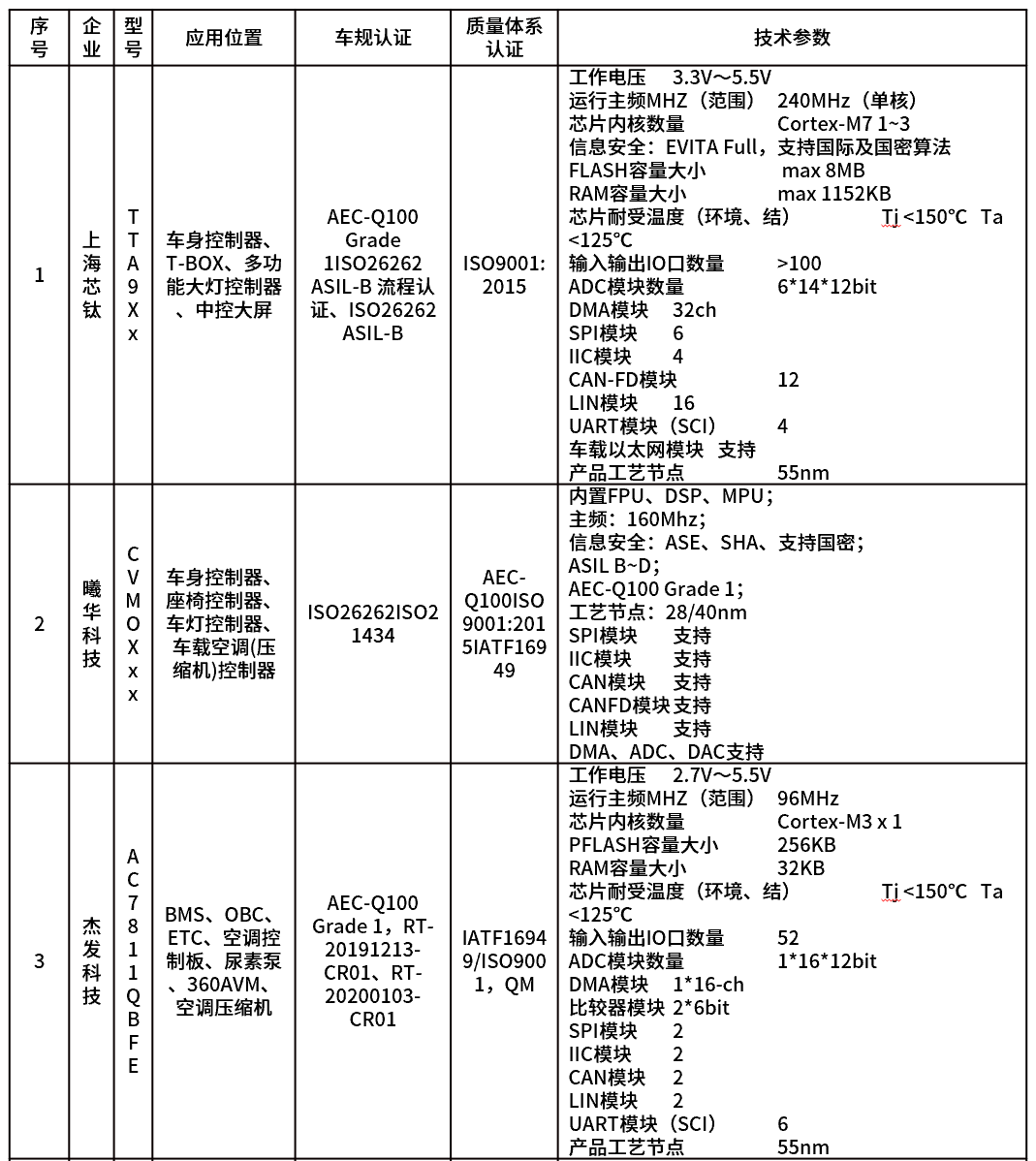

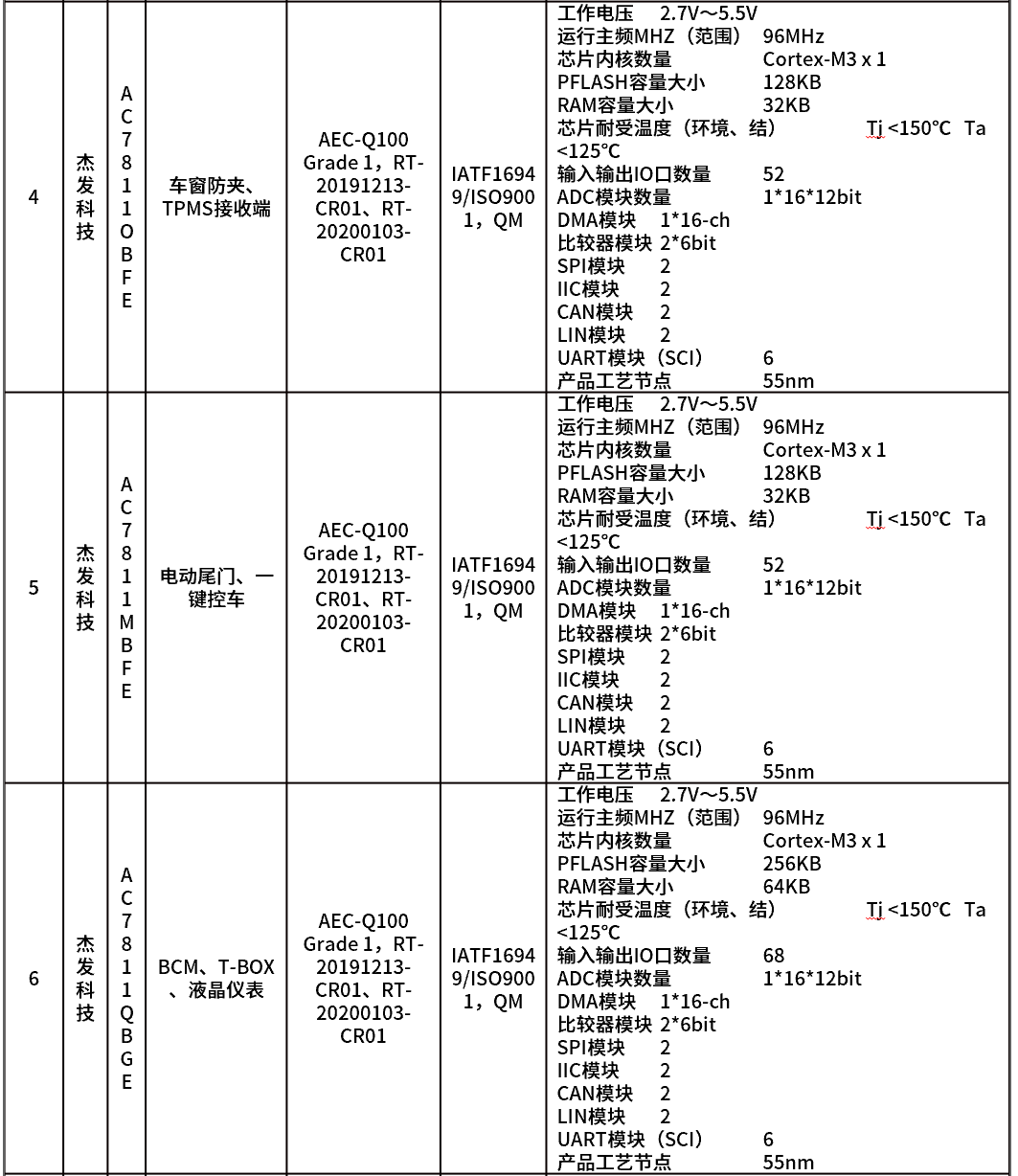

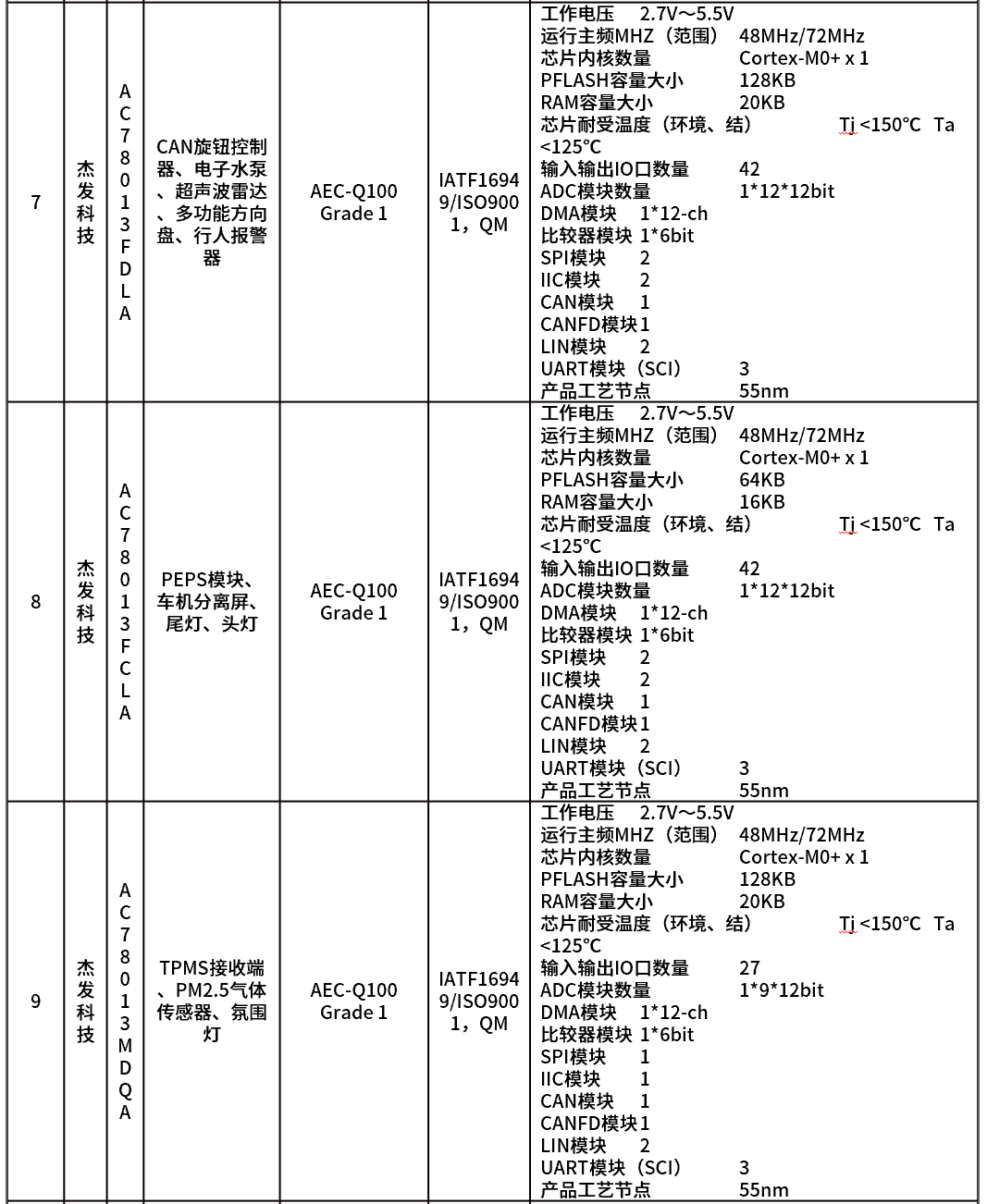

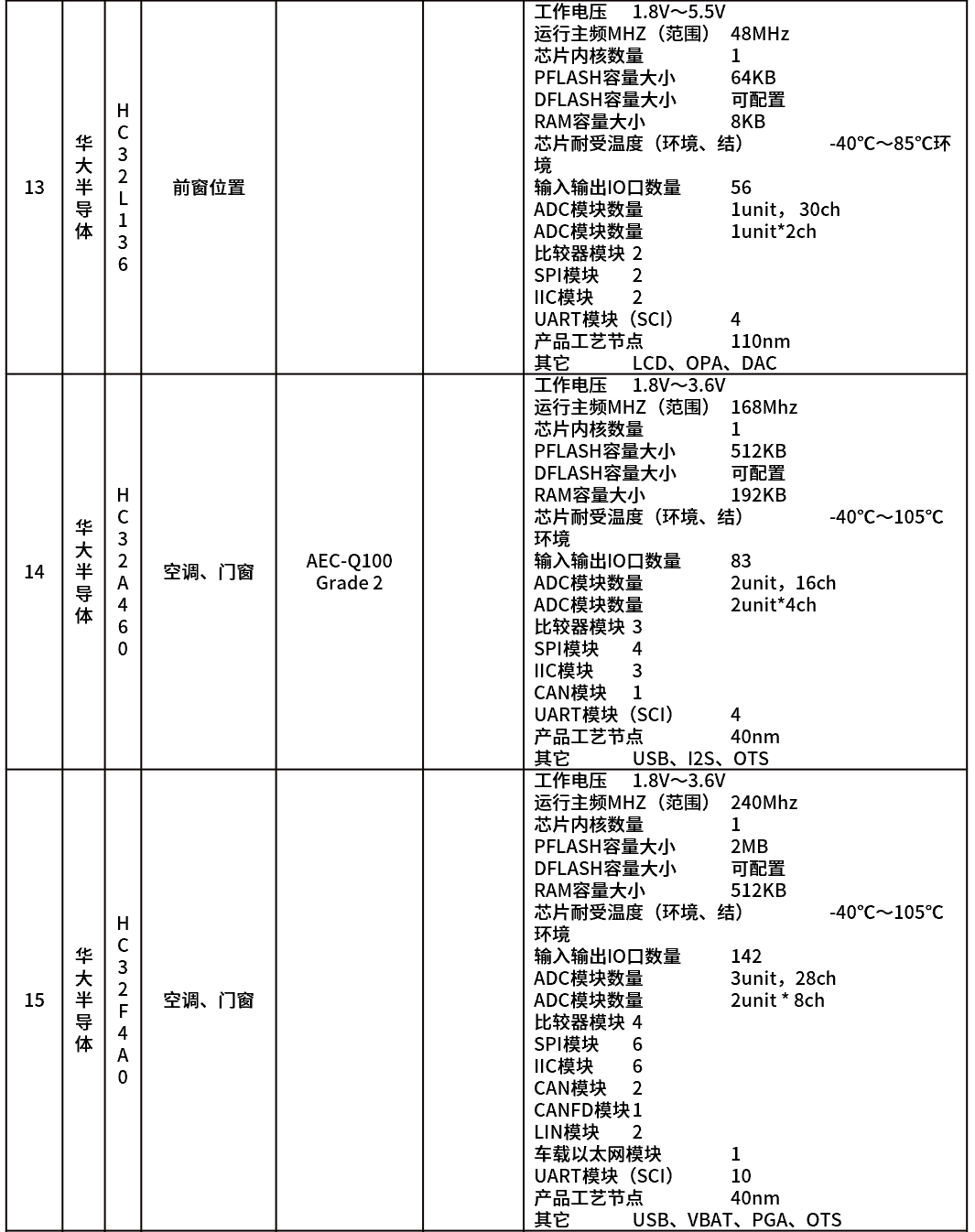

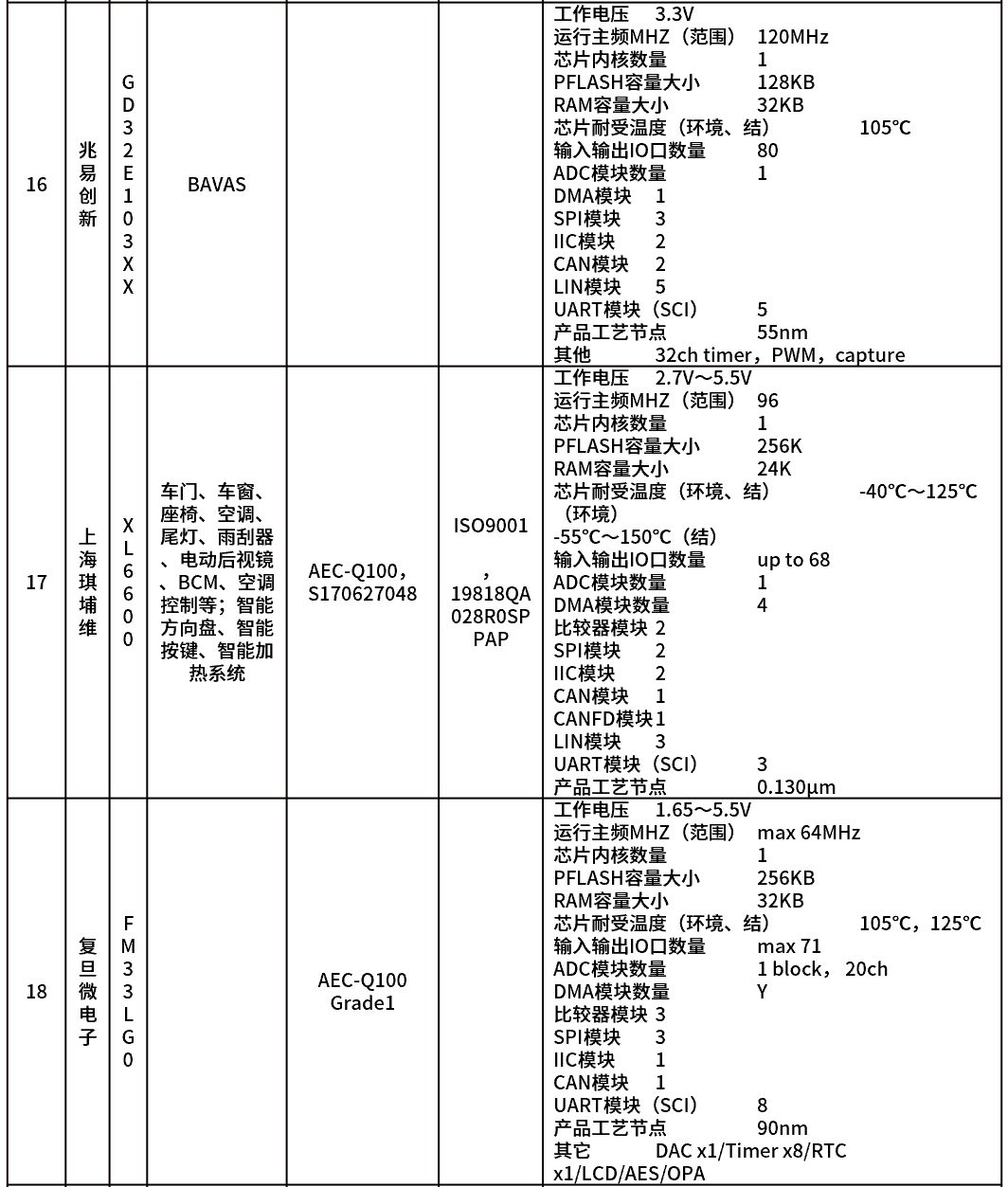

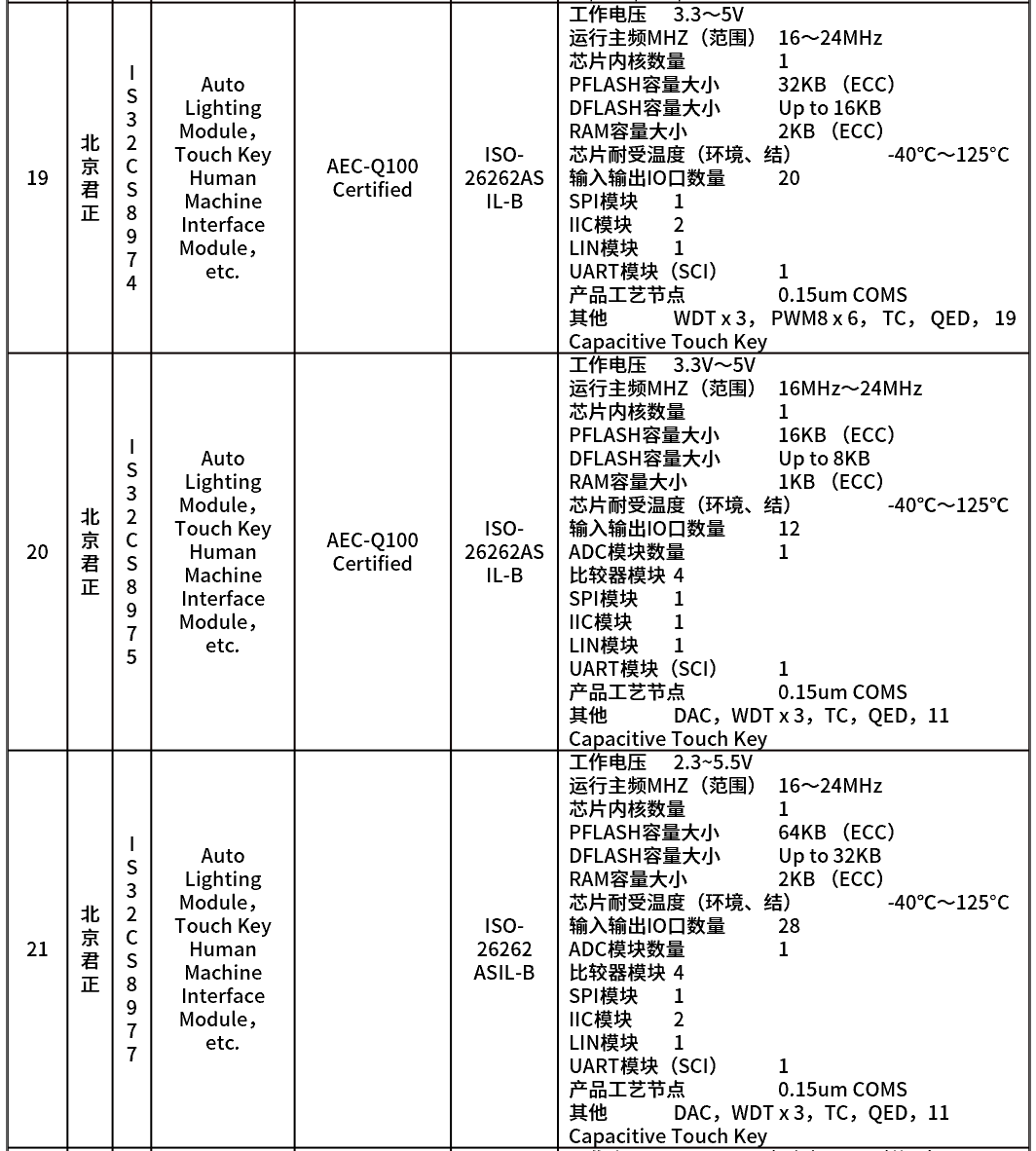

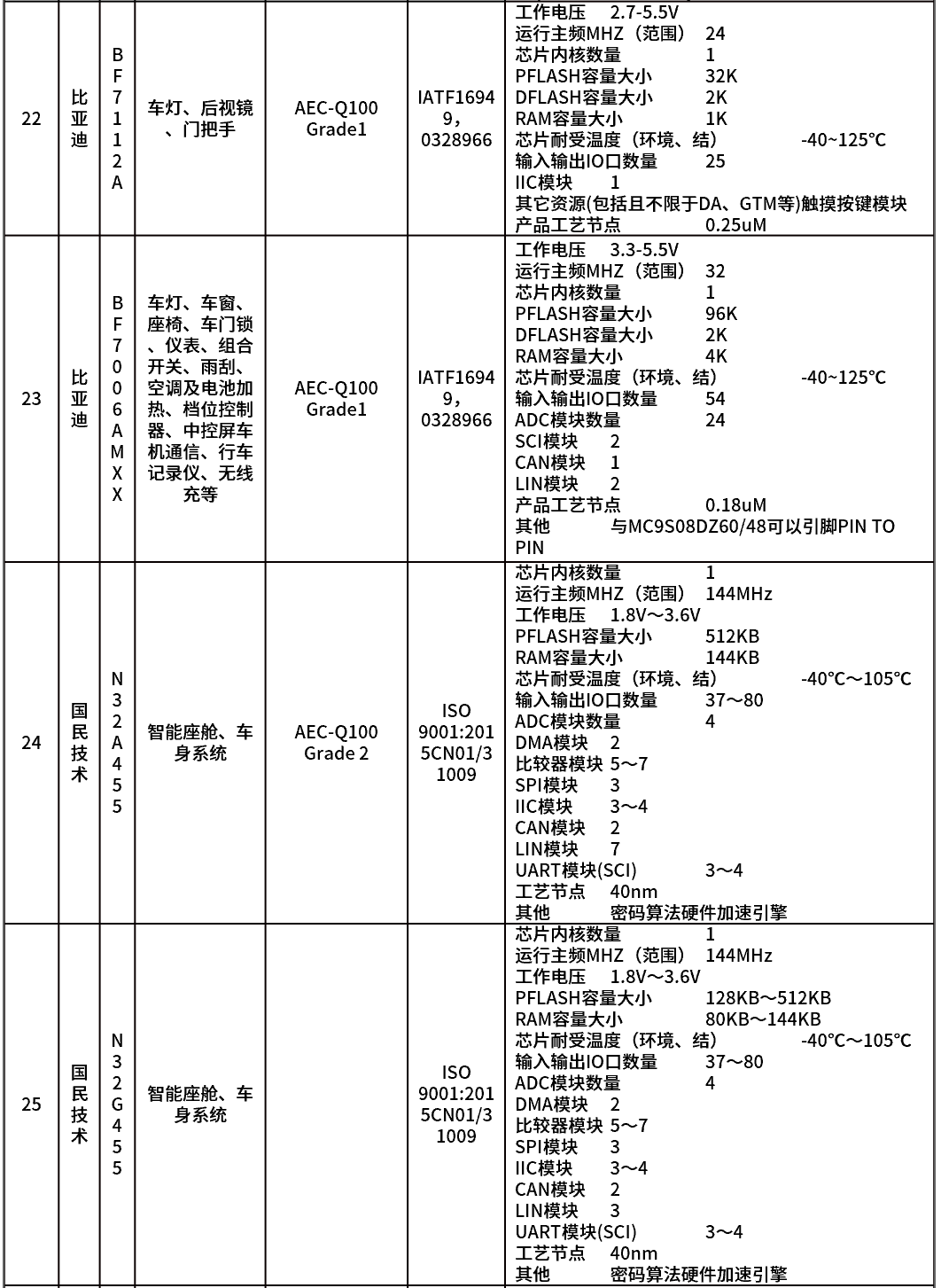

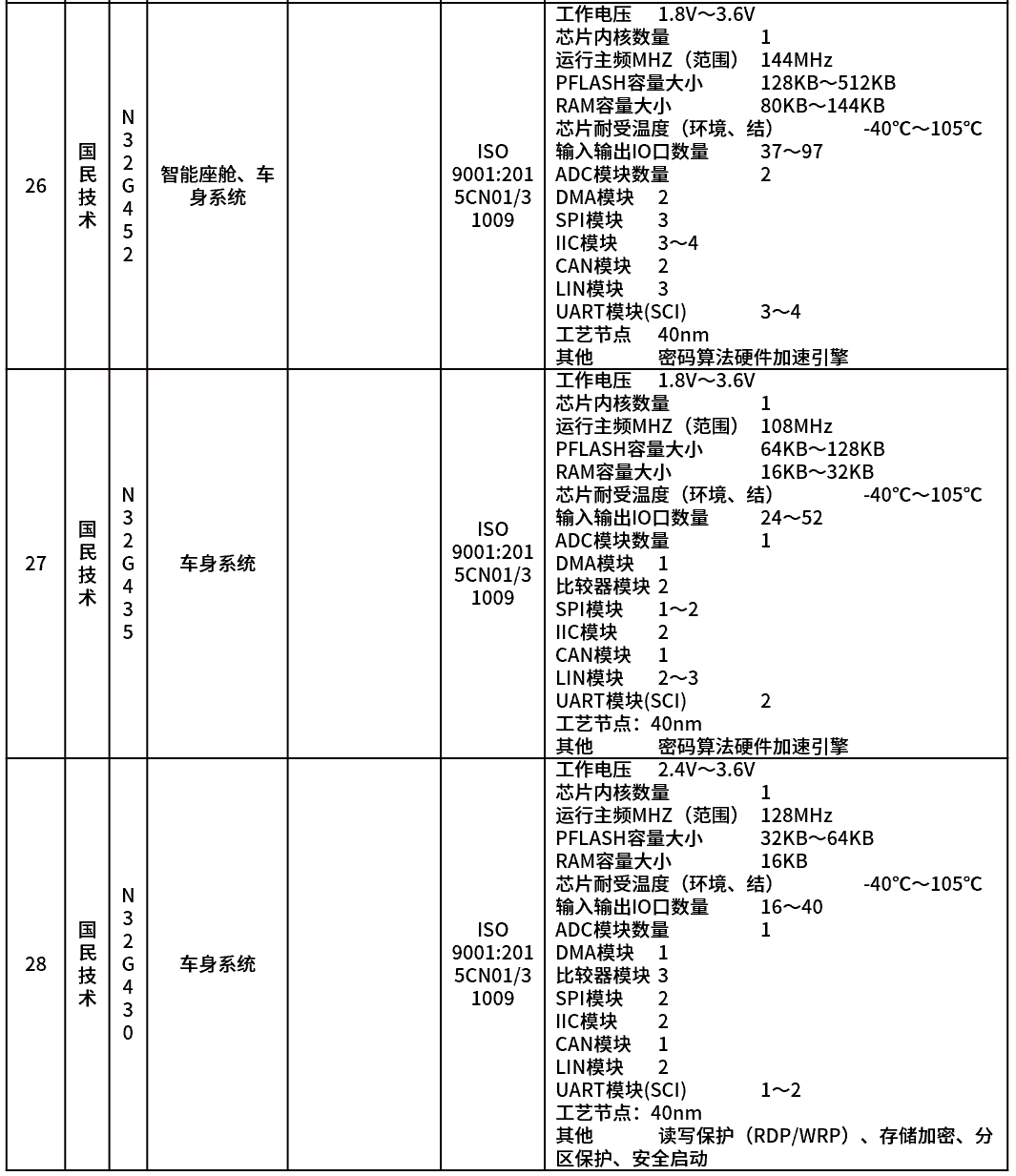

Application Status of Domestic Controller Chip Products

※Data Source: Public Data, Provided by the Writing Unit

The above content is organized from the China Automotive Chip Alliance public account.

Welcome to all angel round and A round enterprises in the entire automotive industry chain (including the power battery industry chain) to join the group(will recommend to 800 automotive investment institutions including top institutions);There are communication groups for leaders of technology innovation companies, with dozens of groups covering the entire automotive industry, automotive semiconductors, key parts, new energy vehicles, intelligent connected vehicles, aftermarket, automotive investment, autonomous driving, vehicle networking, etc. To join the group, please scan the administrator’s WeChat (Please indicate your company name)

※Data Source: Public Data, Provided by the Writing Unit

The above content is organized from the China Automotive Chip Alliance public account.

Welcome to all angel round and A round enterprises in the entire automotive industry chain (including the power battery industry chain) to join the group(will recommend to 800 automotive investment institutions including top institutions);There are communication groups for leaders of technology innovation companies, with dozens of groups covering the entire automotive industry, automotive semiconductors, key parts, new energy vehicles, intelligent connected vehicles, aftermarket, automotive investment, autonomous driving, vehicle networking, etc. To join the group, please scan the administrator’s WeChat (Please indicate your company name)

※Data Source: Public Data, Provided by the Writing Unit

※Data Source: Public Data, Provided by the Writing Unit