As the number of IoT devices increases, connectivity becomes the biggest barrier. Open Platform Communications (OPC) and Data Distribution Service (DDS) provide two methods for seamless integration of systems, and the choice of which method to use depends on the installed systems and terminal devices, as well as the integration methods offered by each solution.

Integrating the Internet of Things (IoT) with existing systems is somewhat analogous to broadcasting and television. Both broadcasting and television use radio waves to transmit signals, utilizing hardware devices on both ends to encode and decode, converting signals into audio and images respectively. Although the overall concept is the same, the results can be drastically different.

This is like: a manufacturer produces equipment using one communication protocol, while another manufacturer produces a different system using a different communication protocol, and now it is necessary to configure both to communicate with each other. Unless there is a dedicated protocol conversion, these two devices will not be able to communicate effectively. This is why connection software like Open Platform Communications (OPC) and Data Distribution Service (DDS) have come to the forefront.

Complexity Continues to Decrease

Despite the different technical details, the ultimate goal of OPC and DDS is similar: to connect devices using any protocol by implementing standard software interfaces. This not only simplifies the daily operations of industrial automation companies, as they are responsible for supporting these protocols and providing the hardware and software for control systems; it also makes it easier for new device and instrument companies to integrate systems that existed before the concept of IoT.

An example of integrating new technology with existing systems is the concept of geofencing and beacons. Geofencing is software that uses designated locations on a map to track and confirm whether people are in a specific area; beacons are similar, using hardware integrated with location-aware devices to track how far a person is from the beacon. This technology has been widely applied in consumer retail applications, where relevant coupons or notifications can be sent to customers when they are detected near a store or restaurant. This concept can be applied in industries such as security and emergency alert systems.

For example, within an industrial facility, if a geofencing system is configured to track the location of operational personnel, once personnel are detected entering a specific area of the factory, an alert can be sent to the Human-Machine Interface (HMI) in the control room. In case of an emergency, this information can easily locate everyone within the facility. When using mobile devices for data collection, this data can also be integrated with control systems. As operational personnel need to move throughout the facility, when moving to different process areas, their devices can automatically load the correct data onto the input screen, allowing readings to be collected.

Taking geofencing as an example, integrating a nascent technology within the industrial sector requires significant effort, development work, and integration testing with numerous system architectures. In contrast, if the geofencing vendor adopts OPC or DDS to design their system’s integration with control systems, only one or two integration functions need to be developed, with open interfaces allowing OPC or DDS to communicate with any control system. This can immediately increase the vendor’s potential market share without adding any extra work.

Advantages of Integration

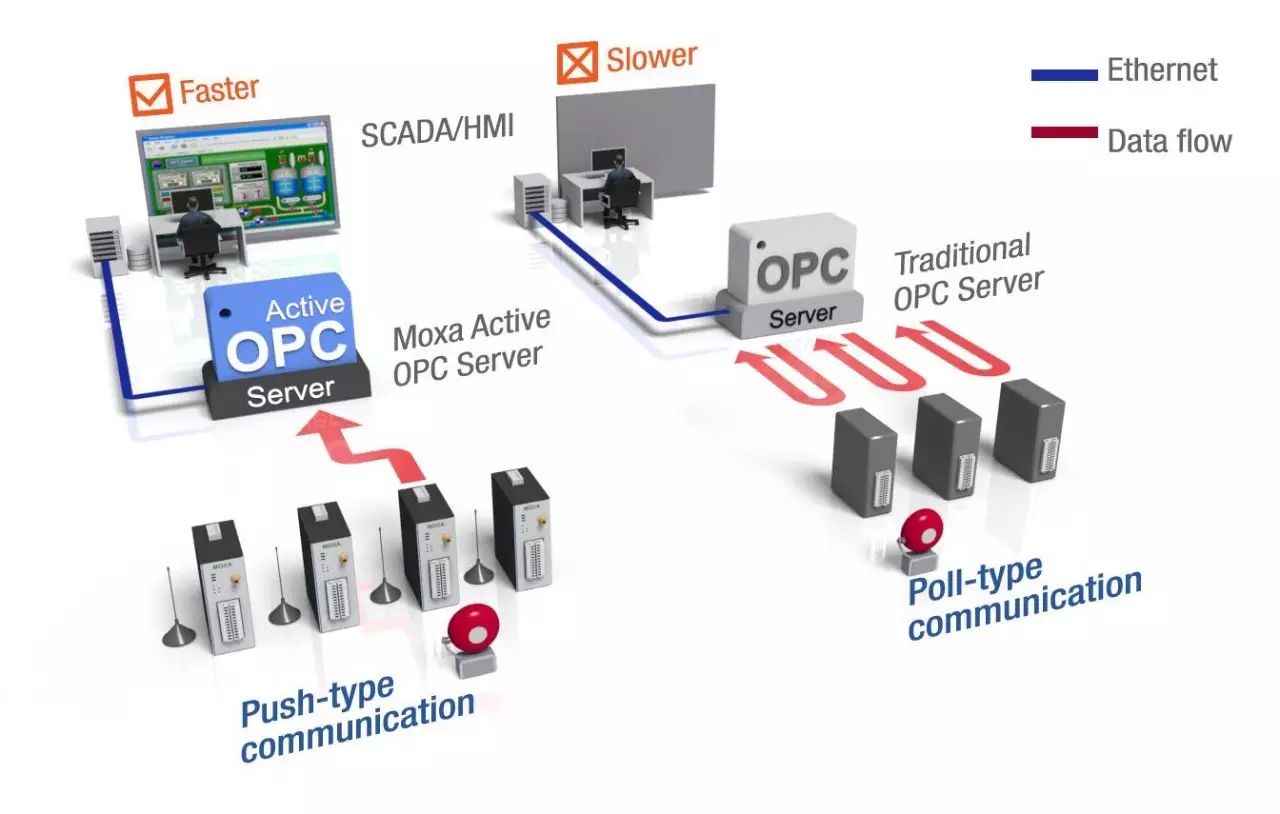

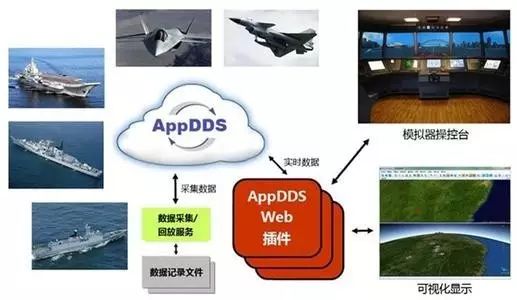

Although OPC and DDS are conceptually similar, their technical backgrounds differ. OPC is based on a client-server architecture, where OPC servers communicate with clients, with the most typical application being industrial control systems. DDS uses a decentralized architecture between devices, creating peer-to-peer networks to publish information.

OPC has a long history of development in the industrial field. Different OPC solutions provide various communication protocols as well as database integration, serial device communication, and integration with network-based devices. On the other hand, DDS was originally developed for IT-centric applications to simplify communication across the entire network; as the boundaries of technology expanded, it was gradually absorbed into control system architectures.

OPC and DDS act as middleware between terminal devices or entire systems and other systems, standardizing communication configurations and delivering data to the requester. The choice between the two solutions depends on the installed systems and terminal devices, as well as the integration methods offered by each solution. As IoT becomes increasingly popular in the manufacturing sector, it is likely that both will be present in the final system design.

In enhancing the overall functionality of Industrial Control Systems (ICS), both OPC and DDS are excellent tools. They can help integrate new devices into factory facilities, provide more information and process-related content, and enable operators and employees to make more informed operational decisions.

The key questions to ask are: What information is most useful? Where does this information come from? What is the simplest way to deliver it to where it is needed? This may mean using a combination of different standard protocols within the control system to integrate OPC and DDS with non-standard devices.

One of the main advantages of IoT is the ability to integrate with any number of new technologies, some of which may have never been imagined. This makes it easier to integrate new technologies into the industrial sector, thus accelerating the return on investment for such technologies and creating more benefits for manufacturers.