Every province and city has built comprehensive museums, along with many specialized museums. As the world enters the era of artificial intelligence and robotics, I believe that all museums should incorporate content related to computer applications to accelerate the progress of artificial intelligence and adapt to the pace of society.

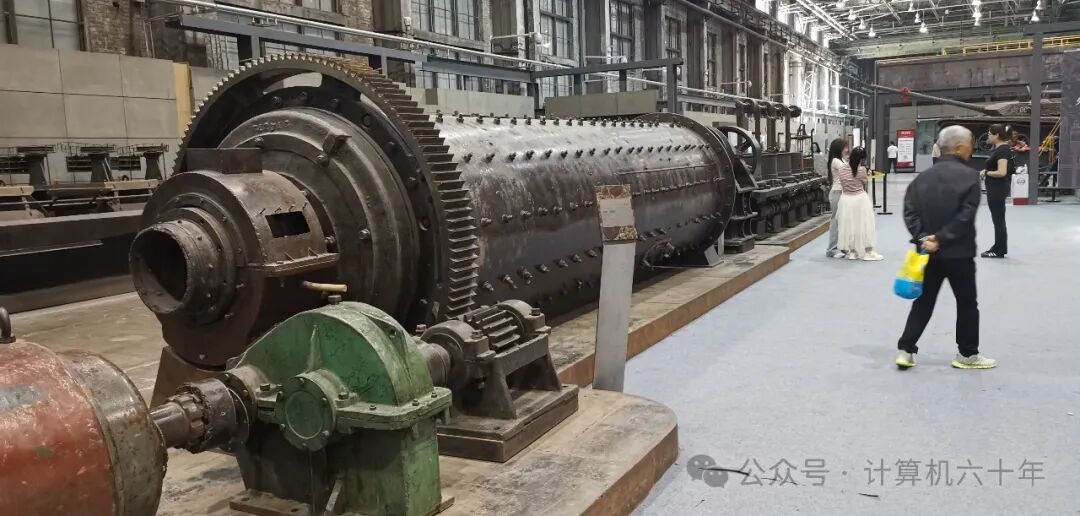

The “China Industrial Museum” in Shenyang has a rich collection, showcasing not only the origins and development of Chinese industry over the past century but also particularly emphasizing the industrial progress in Northeast China, especially in the Tiexi District of Shenyang. Although the museum primarily displays machine tools, casting, metallurgical machinery, and automobiles, it also touches upon some current developments in information technology.

Looking back at nearly seventy years of historical development in Northeast China, especially in Shenyang, although this region is not the focal point for the development of the computer industry, it has made significant contributions to the development of computers and electronic information. As a museum showcasing major industries, it should not overlook this aspect but should delve deeper into and exhibit the applications of computers, enriching and deepening the historical narrative of industry.

The General History Hall of the China Industrial Museum

The General History Hall of the Shenyang Industrial Museum features a corridor of information showcasing the achievements of world-renowned scientists, summarizing advancements in physics, electromagnetism, computers, and semiconductors over the past century. There are also several hand-cranked mechanical computers on display, where I saw a few elderly visitors discussing and recounting the steps of operating hand-cranked computers. However, there is no introduction to domestically produced electronic computers in the museum. In fact, the number of electronic computers in Northeast China is not small. According to a 1979 statistic from the Ministry of Machine Building, Liaoning had 148 units, ranking fourth in the country after Beijing, Shanghai, and Shaanxi; Heilongjiang had 102 units; and Jilin had over 50 units, ranking eighth and twelfth respectively. Computers are not only research achievements but also industrial products, and their application is a crucial part of the entire industrial system, warranting a significant position in industrial museums. Currently, as artificial intelligence and robotics become hot industries, facing a vigorous expansion across society, industrial museums should also reflect the foundational role of computers and their progress over the years.

Computer Research Institutes and Manufacturing Plants in Northeast China

In 1958, the Chinese Academy of Sciences established a computer research institute in Northeast China, which underwent several transformations, including the Liaoning Electronic Technology Research Institute’s Automation (903) specialty and the Automation Research of the Liaoning Branch of the Chinese Academy of Sciences. In August 1972, it was designated as the “Shenyang Automation Research Institute of the Chinese Academy of Sciences,” focusing on automation technology, computer applications, optoelectronic tracking systems, and numerical control technology from 1958 to 1978.

A number of computer manufacturing plants were established in Northeast China, such as the Dalian Computer Factory, Shenyang Electronic Computer Factory, Harbin Electronic Computer Factory, Shenyang Electronic Computer External Equipment Factory, Jiamusi Radio Factory, Liao Yuan Radio Factory in Jilin Province, and Mudanjiang Electronic Equipment Factory, along with the Liaoning Electronic Technology Research Institute, Heilongjiang Electronic Technology Research Institute, and the 47th Research Institute of the Ministry of Electronics Industry, all of which are involved in the research and production of computers.

The Computer Numerical Control Machine Tools of Shenyang Third Machine Tool Factory

The 601 Institute of Shenyang Aviation Industry is one of the earliest research units in the country to set up computers, playing a significant role in aircraft design. In engineering design and industrial production, many projects have utilized electronic computers.

With special funding obtained from the Ministry of Machine Building, the CJ16 low-speed digital tape recorder produced by Mudanjiang Electric Factory became a standard accessory and a well-known brand for computers.

Under the leadership of Factory Director Zhao Rujin and colleagues such as Zou Guoqi, Li Defan, Zhang Xizhen, Zhang Zhitian, and Zhao Baoan, several external devices were successively produced. At 17 Baoshan Street, Xiaguan, Nanjing, and 1 Jingfu Street, Mudanjiang, these computer units gained national recognition, with delivery personnel continuously arriving to pick up goods, and workers smiling with pride amidst a bustling atmosphere.

In the early 1970s, due to the needs of the “Two Bombs, One Satellite” project, a base undertook a comprehensive renovation of a computer system. During the Cultural Revolution, the task was assigned to a radio factory in Jiamusi, where they braved the cold to take on all design, debugging, and installation tasks beyond production. They completed 18 communication interfaces, recording devices, remote control interfaces, and modifications and expansions to the computer’s mainframe interrupt system, adding two cabinets to each of the three computers. This was a round-the-clock effort over several months.

Northeast’s Computer Applications Show Great Potential

The design of the gravity arch dam at the Baishan Hydropower Station in Northeast China initially required manual calculations for a plan, estimating the concrete volume at 1.85 million cubic meters. Using computers, over 30 plans were calculated to find the optimal cross-section, reducing the concrete volume to 1.68 million cubic meters, saving 170,000 cubic meters of concrete and reducing investment by 10 million yuan.

The quality inspection and testing data of metallurgical production products are processed in real-time by computers. Beijing Steel Plant, Shanghai Steel Plant No. 5, and Daye Steel Plant use domestically produced small computers for automatic analysis of molten steel quality, reading spectrometer data in real-time, achieving good results, reducing processing time from 10 minutes to 1 minute while analyzing 15 elements, and reducing the number of analysts to one-fourth. Since its official production in 1974, it has operated continuously for 2044 hours without failure over five years.

Computers are widely used in enterprise management. The First Automobile Works in Changchun was one of the earliest to accumulate experience, using ABC computers to compile production schedules and statistics on output value and cost calculations, improving quality and efficiency. Previously, compiling a plan for one factory took 20 days to a month; now, using computers, the quarterly plans for all 21 branches of the factory can be compiled in just 5 days, and calculating the output value and costs for over 3000 types of parts produced by seven branches only takes 2.5 hours, significantly reducing repetitive labor and heavy manual calculations. Additionally, it also calculates wages for the factory’s 20,000 employees.

The 410 Factory of the Ministry of Machine Building uses the 736 (DJS-130) computer for collective parts warehouse inquiries and management, incorporating a total of 761 types of parts and components into computer management, allowing for inquiries about inventory status, ordering compatible quantities, missing parts status, and the shortest missing parts, as well as printing ledgers and monthly warehouse reports.

Computers have demonstrated remarkable capabilities in industrial automation process control. The application of computers in production process control, especially in small and microcomputers, is a significant area. Computer control is a major indicator of the transition from partial automation to comprehensive automation in production. Various industrial sectors in China, including petrochemicals, electric power metallurgy, light industry machinery, and textiles, have begun to show the advantages of computer control compared to conventional instrument regulation, with computer scheduling control and management being the main means to achieve high quality, high yield, and low consumption. In the 1980s, most control was achieved by single machines, with a few workshops implementing two-level computer supervisory control. The Northeast power system is also working on using computers for grid monitoring and scheduling, achieving offline computing and partial online safety monitoring.

The first model of electronic tube computer also made its way to Northeast China, where it was used effectively.

On December 22, 1961, the 19th 103-type computer’s “production sample trial identification meeting” was held at Beijing’s 738 Factory. The machine that passed the identification was renamed the DJS-1 and was transported to the Dalian Institute of Chemical Physics of the Chinese Academy of Sciences, where it began normal operation after a few days of preparation, achieving an average monthly computing time of 600 hours, setting a national record at the time.

After modification, the computer at the Chemical Physics Institute achieved a speed of 1500 calculations per second, calculating rocket fuel formulas, quantum chemistry topics, and ship propeller surfaces. This machine was also provided for teaching and research use at Dalian Institute of Technology and Changchun Institute of Physics, training a group of professional teachers and graduate students. Vice Premier Chen Yi praised the good working condition of this computer during his inspection in Dalian.

Computers have made significant contributions in product design and tooling allocation.

The engineering optics program at Beijing Industrial University (now Beijing Institute of Technology) is nationally renowned, with optical projects requiring substantial calculations. Previously, hand-cranked computers and trigonometric tables were used. Professor Song Hantao developed a “general optical system design calculation program” that can calculate not only camera and telescope lenses but also microscope lenses, accommodating various aberrations for near-axis light and wide beams, achieving a leading level in optical design. Optical teachers were thus freed from manual calculations, improving efficiency and accuracy.

In 1971, the optics department at Beijing Industrial University held a training course on optical design, attracting participants from the national weapons industry and optical factories, where experienced technicians expressed strong curiosity about computers.

Previously, design changes to lens radius, thickness, distance, and glass material parameters were all done manually, requiring tedious input on paper tape for adjustments. Song Hantao modified the program to allow real-time parameter modifications via human-computer interaction on the console. Later, an automatic design program was developed to optimize design structural parameters, a stark contrast to manual operations! This significantly elevated the design level across the entire optical industry.

Beijing Industrial University was the first to offer paid external services with the 441-B computer, charging by the hour. Optical instrument factories in Beijing, Dalian, Henan, Jiangsu, and other regions adopted this program for product calculations, revolutionizing the design approach across the industry.

Gong Xingyi from a factory in Harbin, with the help of Professor Song Hantao from Beijing Institute of Technology, used the 441-B machine to calculate parameters for machine tool drive wheels, publishing the “Drive Wheel Manual” for use by factories nationwide.

National Backbone: The Journey of Computer Applications in the Oil Sector

China’s oil exploration sector includes three major groups: China Petroleum & Chemical Corporation, China National Offshore Oil Corporation, and China National Petroleum Corporation, along with the China Petroleum Exploration and Development Research Institute and various oilfield research institutes, all of which are the backbone of computer applications.

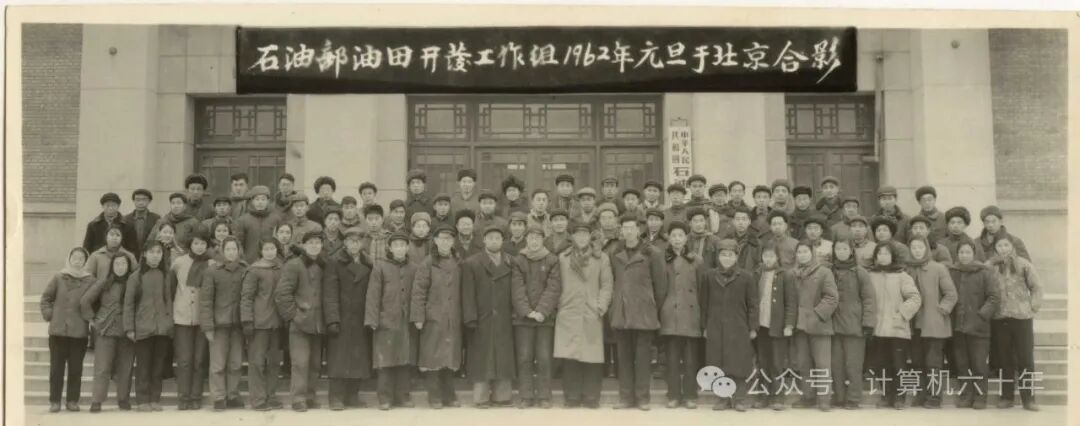

On New Year’s Day 1962, the “Oilfield Development Working Group” of the Ministry of Petroleum held a mobilization meeting, with then Deputy Commander of the Daqing Oilfield Battle Fan Yuanshou, Deputy Commander of the Geological Command Li Desheng, and oilfield personnel posing for a group photo, with the first computer group in line. This was during a well-known difficult period, with people looking thin and their clothes worn. Despite the New Year and the trip to Beijing, the women’s clothing was wrinkled. However, the entire team displayed a brave and determined spirit, shouldering heavy responsibilities as they prepared to venture into the icy wilderness to extract the urgently needed oil for the country from the barren land of Daqing.

The first batch of computer personnel: Li Guozhi (2nd from left, 3rd), Gan Yuguang (2nd from right, 4th), Diao Wenju (3rd from right, 2nd), Jin Yuming (3rd from right, 6th), Huang Wenji (3rd from left, 11th), Li Shilu (4th from left, 5th), Qiang Weifang (4th from left, 7th);

The first batch of electrical simulation personnel: Shi Wanzhao (2nd from right, 2nd), Gu Kejin (2nd from right, 6th), Zhang Jingcun (2nd from left, 6th), Ling Shengcai (2nd from left, 10th), Su Wei (3rd from left, 8th), Li Zhaoming (4th from left, 11th);

Leaders of the computing room: Tan Wenbin (1st from left, 9th), Xiang Dexin (2nd from left, 4th), Qi Qingxiang (4th from left, 10th).

Front row: From right, Deputy Commander Li Desheng, Deputy Director Fan Yuanshou, Professor Qin Tongluo from the Petroleum Institute, Chief Engineer Tong Xianzhang, and Deputy Director Tan Wenbin from the Daqing Oilfield Development Research Institute.

In 1975, 71 electronic computers were installed in the petrochemical sector. By 1979, this number increased to 191, including several imported computers. The Geophysical Bureau of the Ministry of Petrochemical Industry used the 150 machine to process over 400,000 records, playing a prominent role in locating oil resources and developing oilfields; the Daqing Oilfield Computing Station used the DJS-6 machine for selecting oilfield development plans, processing static and dynamic data to provide scientific basis for the construction and management of thousands of wells in Daqing, ensuring stable and high production. Among over 2000 oilfield development plans, the best plan was selected, saving 50% in steel and cement, and completing the oil extraction area a year ahead of schedule. The following computers and units were used:

In 1964, the 103 machine was used in Daqing Oilfield;

In 1970, the 441-C machine was used in the Geophysical Institute of Daqing Development Research Institute;

In 1971, the 121 machine (DJS-21) was used by the electronic team of the Qianjiang Geological Survey in Jianghan Oilfield; it completed the first horizontal superimposed seismic geological profile and offset superimposed profile.

In September 1970, the DJS-6 (108-B machine) was used in Daqing Oilfield;

On October 10, 1973, the 150 machine passed acceptance, with a total of nine types of 22 external devices;

In 1976, the array machine’s offline input and offline display device were used by the electronic team of Jianghan Oilfield;

In 1976, the TQ-6 machine was used in Daqing Oilfield, developing a data management system (1980);

In February 1987, the Galaxy seismic data processing system passed “national-level technical identification” and won the first prize for national scientific and technological progress in July 1987;

From 1985, Daqing introduced three sets of American CYBER-830 machines, one set of CYBER-855, one set of French and American PE-3210, and one set each of Japanese M220-D and M-150 machines. By the early 1990s, the computing station entered a period of brilliant development, with members of the electronic class becoming the backbone.

“The Glorious Years” records two events during the 50 years of construction of Daqing Oilfield: On March 6, 1971, the computing room of the Oilfield Development Research Institute completed the input paper tape compression technology for the DJS-6 (108-B) computer, used by over 30 units; in July 1977, the institute successfully developed the TQ-16 machine and the DJS-6 machine with a shared tape interface and profile display interface, forming a geological data processing production line.

In the summer of 1972, the Jianghan Oilfield connected the seismic exploration data input device produced by Xi’an Petroleum Instrument Factory and the seismic profile playback device, achieving the first output of seismic geological profiles and completing the digitization of exploration data processing.

Daqing Holds Computer Professional Training

In September 1970, the computing room of Daqing Oilfield installed the 108-B machine, supporting nearly 40 personnel from brother oilfields and geophysical bureaus, along with over 10 graduates from the old fifth class who were transferred to train in the oilfield.

In 1976, the TQ-6 computer was put into operation, marking the beginning of seismic data processing applications, and talent became a pressing issue again. Daqing leaders, including Li Yugen, decided to inherit the tradition of the Iron Man School and set up their own computer training class, which opened in August 1978 and graduated in November 1979. The deputy chief engineer of Daqing Oilfield Research Institute, Niu Chaoqun, was responsible for the training class. After mobilizing the entire oilfield for recruitment, 110 young workers were selected to study both hardware and software specialties. The students studied hard in tent classrooms, and all passed the exams.

Graduation photo of the Daqing Oilfield Electronic Computer Training Class (Software) [Among those marked with an underline, 22 were assigned to the Daqing Oilfield Computing Room] (From left): Row 5: Zhang Qingtong, Chen Yuping, Qin Zhijun, Zhao Yongsheng, Bai Huiqing, Jin Hui, Song Zhenhong; Row 4: Zhang Hongyi, Ye Senlin, Shi Changxu, Yang Huabin, Yan Hanyie, Pan Gengxie, Zhou Jianguo, Zhao Wenlong; Row 3: He Yufang, Zhao Shengyu, Zhang Qiaoling, Wu Shu, Ji Sufang, Wang Yu, Song Lin, Ke Guilan; Row 2: Liu Yong, Zhao Shuren (teacher), Liu Jingrui (teacher), Niu Chaoqun (responsible person), Wu Futang (teacher), Li Kairui, Gong Lihua, Wang Baoxia; Row 1: Dou Aihua, Song Yumei, Ma Chunhua, Chen Li, Song Ning, Li Jin, Cheng Yingmei. (Student Wang Yanzhi was absent for the photo, provided by Zhao Shifa)

After graduation, 22 software and 38 hardware students were assigned to the computing room of Daqing Scientific Research and Design Institute, while the remaining 50 returned to their original units. The computing room expanded to include hardware, software, seismic processing, and research preparation rooms, responsible for the maintenance and application of the TQ-6 machine, DJS-6 (108-B) machine, and 131 machine, installing various peripherals and developing oilfield databases.

Although the training of students was not recognized as a formal qualification, they worked diligently and many were promoted to intermediate and senior engineers, taking on leadership roles and contributing to the application of computers in the oil sector.

By 1992, the computing station had surpassed the annual processing of seismic data by 100,000 standard kilometers, maintaining this for five years. From 1980 to 1993, nearly a hundred projects involving training class members received departmental and bureau-level awards.

In 1958, CNC machine tools began in China.

In the China Industrial Museum, CNC machine tools are an important area, featuring dozens of various CNC machine tools. However, there is a lack of information on the inception of CNC machine tools, which should be highlighted as the innovative period when CNC machine tools took their first steps.

In 1958, Tsinghua University and South China Institute of Technology, one in the north and one in the south, coincidentally developed a program-controlled milling machine, marking the first step in computing technology in China’s education sector and the first step in CNC machine tools in China.

The CNC milling machine developed by Tsinghua University was led by the Precision Instrument Department, with nearly a hundred participating teachers, students, and workers, under the overall responsibility of Professor Zou Zhiqi from the Precision Instrument Department, expected to be completed within six months.

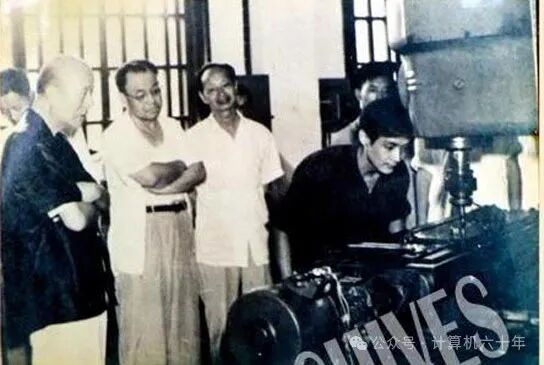

In 1959, Professor Zou Zhiqi (right) and students tested the CNC milling machine.

The CNC milling machine consists of four parts: the hydraulic system managed by the Precision Instrument Department; the digital control part managed by the Automatic Control Department; the stepper motor and its drive part managed by the Motor Department; and the Beijing First Machine Tool Factory, as the external cooperation and production unit, was responsible for providing the milling machine and maintenance. Fifty years ago, this was a challenging pioneering project.

In the days leading up to May 1, 1959, the CNC milling machine was assembled and debugged on the first floor of the old aviation museum. On the night of September 29, the second secretary of the Beijing Municipal Committee, Liu Ren, and secretary Zheng Tianxiang visited the machine tool trial, along with President Jiang Nanxiang, Director Zhong Shimo, and Wang Zhenhuan to watch the demonstration of the milling machine cutting. Two small programs were compiled: one for milling a five-pointed star and the other for milling the Chinese characters “Welcome.” Professor Liu Zhengyi.

The People’s Daily prominently published the news of “China’s First CNC Milling Machine Successfully Developed” on the front page, detailing the development process and photos. The CNC milling machine often became a highlight during visits from foreign leaders to the school. Premier Zhou Enlai and Marshal Chen Yi accompanied foreign guests to visit multiple times.

On September 5, 1959, the Yangcheng Evening News headlined “Electronic Computer Controls Machine Tool Successfully,” completed by lecturers, assistants from the Mechanical Factory of South China Institute of Technology, and the Guangdong Automation Research Institute in less than a year, achieving group control functionality through self-manufactured stepper motors controlling the milling machine.

In December 1958, an eight-member project team was established at South China Institute of Technology, consisting of seven teachers: Zhou Qijie (founder of the automation major at the school, specializing in electronic technology), Zou Shimin, Su Shushan, Li Jingxi, Chen Tongjian, Zhong Muliang, Lin Dehao, and one student, Liu Zhengyi. The electronic circuits in the project framework included binary addition and subtraction calculation principles and circuits; linear and circular interpolation principles and calculators; and circuits for the stepper motor’s ring pulse distributor.

After seven to eight months of intense work, the program-controlled vertical milling machine was finally developed, capable of processing complex parts and even engraving Chinese characters. Vice Governor of Guangdong Province Li Jiaran visited the school, and teachers and students worked overtime for several days to prepare the programming perforated tape for engraving the three characters “Li Jiaran.” The first group of names was processed using copper plates, taking half a month; the second group was processed using stainless steel, taking only two hours.

In 1959, Dean Zhang Jin of South China Institute of Technology (third from left) accompanied Governor Chen Yu of Guangdong Province (first from left) to visit the CNC machine tool.

In late August 1959, the Ministry of Machine Building held an exchange meeting at the Beijing Machine Tool Research Institute, where Liu Zhengyi and Lin Dehao represented South China Institute of Technology to report, and it was generally recognized that Tsinghua, Xi’an University, and South China Institute of Technology were at a high level.

In the 1980s, wire-cutting machine tools became popular in China, with the Shanghai Post and Telecommunications Department’s 519 Factory providing social services for converting processing parts into CNC paper tapes, available for immediate pickup. Although there were computers for programming wire-cutting machine tool paper tapes, not every unit could afford to purchase them.

From manual processing operations to the realization of digital processing technology and the intelligentization of programming, the application of computers has rapidly developed and advanced year by year. In May 1978, the Dalian Locomotive and Rolling Stock Factory built 59 automatic lines over seven years, with all 15 workshops equipped with self-manufactured CNC machine tools and other equipment, including an eight-station boring and milling machine controlled by an electronic computer, which was photographed by Xinhua News Agency reporter Jiang Keyun.

Computer machine tool processing control is a major category, with the Shanghai Machine Tool Institute, Shanghai Fourth Machine Tool Factory, Shanghai University of Technology, and Shanghai Yangtze River Machinery Factory forming a machine tool group management system task force, which began in 1976. After four years of work, they achieved simultaneous control of three machine tools, two three-coordinate milling machines, and a plotting device using a DJS-130 machine manufactured in Shanghai.

The Controversy Over the Return of the DJS-220 Machine in Harbin

The Shanghai Astronomical Observatory, after investigating several computer production plants and users of the DJS-6 type machine from Harbin No. 3 Factory, signed a purchase agreement with Harbin No. 3 Factory on October 26, 1978, determining delivery for acceptance in the fourth quarter of 1980.

The DJS-220 mainframe and 35 external devices totaled 5.5 million yuan, with a prepayment of 2.5 million yuan before the end of 1978, a further payment of 2 million yuan in the third quarter of 1979, and the remaining amount to be paid upon acceptance after the machine was delivered in 1980, with the final actual price set at 4.685 million yuan.

From September to November 1981, the observatory and Harbin No. 3 Factory proposed machine testing plans, each holding firm to their views. Harbin No. 3 Factory made six trips to Shanghai and two round trips to Beijing, arguing their case and even requesting mediation from the Chinese Academy of Sciences. In October 1982, both parties reached a compromise, signing a supplementary agreement on the 19th, requiring a one-time startup operation of 150 hours without failure and completing seven major and 54 minor assessment tasks within a month.

On January 4, 1982, a delegation from the Shanghai Astronomical Observatory, led by Director Wei Baishan, visited Harbin for machine testing. The test results showed that the machine’s stability achieved 200 hours and 5 minutes of continuous operation, after which it was manually shut down without any adjustments or maintenance. Following this, a series of project assessments were completed in just two days, with all assessment items passing on the first attempt and exceeding various indicators.

During the testing period, the machine and external devices operated for a total of 971 hours, with the read-only memory operating for 871 hours, the central processing unit running continuously for 869 hours, and the memory running continuously for 323 hours without failure. The actual assessments far exceeded the 150-hour requirement, and the personnel from the purchasing side unanimously agreed that the machine was indeed in optimal condition, comparable to similar foreign machines, and accepted the computer based on the agreed testing plan.

Harbin No. 3 Factory produced such high-quality and high-level computers due to a strong technical team that worked hard for three years, a rigorous scientific attitude with over 700,000 components carefully screened, and a collective that encouraged talent and allowed scientific personnel to focus on their work. They successfully completed the production and testing tasks. After the machine was delivered to Shanghai, it underwent 50 hours of stability testing and various ISO example calculations for acceptance, entering the business operations of the observatory.

Due to the strong impact of imported computers, Harbin No. 3 Factory only produced this one DJS-220 machine.

Temperature Control in Production at Anshan

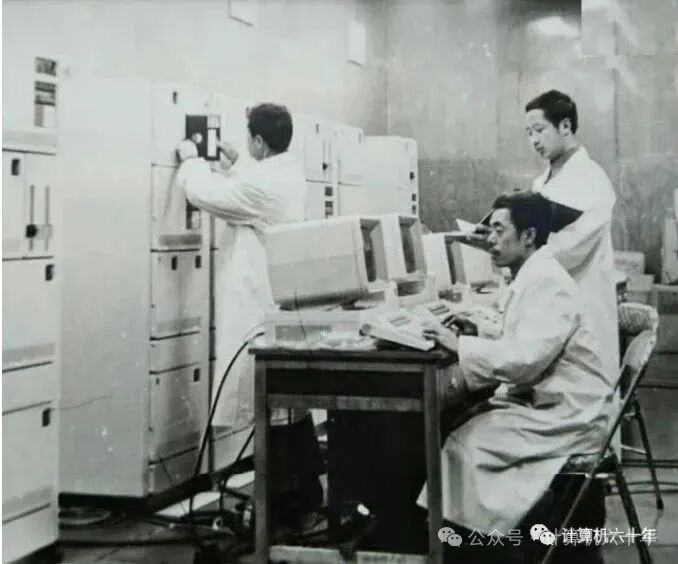

In the K-351 machine room, Lü Chuanyou operates at the control console (left). The workshop’s “Double Reform” leaders and K-351 staff engage in political study in the instrument room.

Computer kiln temperature control is another major application area, with the first cold-rolled industrial control computer from Anshan Steel, a fruitful application spanning nearly forty years, creating happy memories for the two units involved in its development and application.

After 1975, the DJS-154 machine produced by the 738 Factory entered the Anshan cold-rolled plant.

In the 1960s, the K-351 industrial control system from the Central South Institute successfully controlled the production of 75 hood-type annealing furnaces simultaneously. This was a transistor computer with 4K memory, paper tape input, and machine instruction coding. It controlled over fifty process curves, reducing the labor intensity of workers in high-temperature and harmful gas environments, improving product quality, and increasing the steel pass rate by 1-2%. Based on an annual production of 150,000 tons, this equates to at least 1.5 million yuan, while the computer system cost 500,000 yuan.

In the autumn of 1965, at the invitation of the Automation Command of Anshan Cold Rolling, a survey team from the Central South Institute and over ten other units visited Anshan to participate in the planning of the automation of the reversible cold rolling mill, which was a national key project. The Central South Institute unexpectedly discovered that the conditions for applying computer control to the annealing of cold-rolled steel coils were preliminarily met, and proactively proposed to use computer control for the heat treatment process in the hood furnace workshop, receiving approval and support. This task was launched under the guise of “training for cold rolling control.”

The K-351 control system was the first process control computer developed during the “Third Five-Year Plan,” located on the first floor of the Anshan Cold Rolling Plant’s administrative building, adjacent to the instrument room of Workshop 3 (75 hood-type annealing furnaces). In May 1969, the K-351 system passed industrial testing, controlling the production of 15 furnace bases simultaneously, achieving the set goals, and receiving praise from the factory for the temperature curve and measured heat treatment quality. On September 1, both parties signed the handover documents.

On March 22, 1970, the K-351 was put into closed-loop operation, commemorating the tenth anniversary of the “Anshan Constitution.” The use of electronic computers to control hood-type annealing furnaces represented a domestic advanced level. A germanium tube computer operated continuously for nearly ten years in the heat treatment workshop, creating a miracle.

In the 1970s, the K-351 machine, installed in a 30-square-meter machine room, stood out in China’s industrial process control field, becoming a typical representative of computer applications. In 1973 and 1974, hundreds of batches of leaders and technical personnel visited for inspection. Wuhan University and the Central South Institute of Mining and Metallurgy included the K-351 machine in their computer and automatic control professional textbooks.

After 1975, with equipment updates and expansions, the DJS-154 machine produced by the 738 Factory entered the Anshan cold-rolled plant, equipped with a real-time multitasking operating system, the first generation of operating systems used for process control. In 1983, the hood-type annealing furnaces at Anshan Steel Company adopted electronic computers for steel control, receiving commendation at the National Science Conference.

“Tracing the Origins of Chinese Computers” was published by Sanlian Bookstore in 2015.

Selected readings from the “Sixty Years of Computers” public account:

National Honor: From Telegraph Automation to Computer Networks

Early Requirements for Shoe Changes in Computer Rooms

Memories of Tiexi: China Industrial Museum

To the Sky: Shen Rongjun Talks About Missile Test RangesFrom the Popularization of Program-Controlled Telephones to Artificial Intelligence

Zhu Pengju Safeguards Satellite Flight

Professor Kang Jichang: Dual Virtues, Eternal Spirit

Memories and Current Status of the College Entrance Examination Data Processing System

The Past and Present of the University of Posts and Telecommunications

The “Heavenly Thunder Disaster” Asteroid and the Monte Carlo Method

Deeply Mourning the Chairman of the Jiangxi Computer Society, Ni Guoxi

The Development History of China’s First Microcomputer (DJS-050)

The Lhasa Satellite Observation Station—Vanguard Satellite Launch and Recovery (3)

The Lhasa Satellite Observation Station—Locking the Meridian Instrument, Capturing the Sky Laboratory (2)

Computers and Quality Rectification in National Military Enterprises

The Establishment of the Computer Major at Peking University and the Student List (1956-1976) Draft Three

My Admission to Tsinghua University and the Official Establishment of the Computer Department

CCTV: Willing to Dedicate a Lifetime to Great Plans, Yu Min!

The Four Computers of Peking University Computing Center

Zhou Xingming: Starting from Harbin Military Engineering, Climbing to New Heights | “Incalculable Contributions” Interview

Returning to the Influential Harbin Military Engineering