Introduction

On May 12, 2025, the “Battle of Industrial Robots” reported by the Reference News revealed a silent yet profound global industrial transformation:

China, with a stock of 2 million industrial robots, occupies 43% of the global market, with a localization rate exceeding 58%, transitioning from a “follower” to a “rule-definer”.

Behind this competition lies the struggle between European and American companies accelerating localization and Chinese technology breakthroughs—from the domestic substitution of reducers and servo systems to AI collaborative robots reshaping global pricing power, the industrial robot industry has transcended traditional manufacturing categories, becoming a strategic fulcrum in great power games.

However, concerns about technological redundancy, price wars, and international standard disputes cast a shadow over this “intelligent revolution”.

This article, based on authoritative data from the International Federation of Robotics (IFR), the GGII Robotics Industry Research Institute, and other sources, combines industry cases and policy analysis to deeply analyze the driving forces, challenges, and global industrial chain restructuring logic behind China’s rise in industrial robots.

1. Global Landscape: China Leads, Europe and America Diverge

China Dominates the Global Market

Market Size and Stock: By 2025, China’s stock of industrial robots is expected to exceed 2 million units, accounting for 43% of the global total, maintaining the world’s leading position for 12 consecutive years.

In 2024, China’s industrial robot production is projected to reach 556,000 units, a year-on-year increase of 14.2%, with the localization rate rising to 58.65% and the self-research rate of core components exceeding 45%.

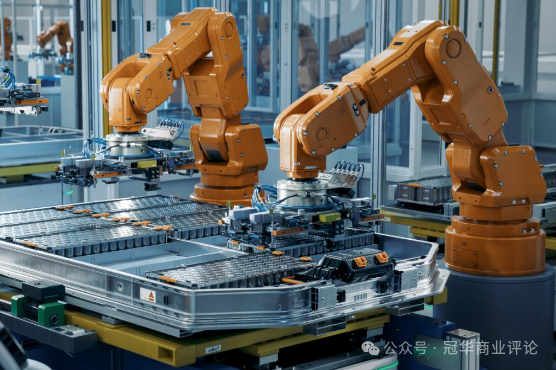

Deepening Application Scenarios: The three core application areas are automotive manufacturing (35% share), 3C electronics (fastest growth), and new energy (lithium batteries and photovoltaics with a 40% annual growth in demand), with welding robots achieving precision of ±0.02mm, surpassing some international standards.

Localization and Divergence of European and American Companies

International Manufacturers’ Strategic Adjustments: Giants like Fanuc and ABB are accelerating localized production, for example, KUKA (owned by Midea) is expanding its production capacity in China, while Fanuc is building a new factory in Shanghai, but market share has still declined to 30%-40%.

Technological Lag in the United States: The value of industrial robots imported by the U.S. is twice that of its exports, with a market share of only 4.7%. The tariff policies of the Trump administration have been criticized for falling into the “Luddite trap,” hindering technological innovation and global supply chain integration.

2. Technological Breakthroughs: Accelerated Domestic Substitution, AI and Collaborative Robots as Focus

Breakthroughs in Core Component Localization

Reducers: Lide Harmonic has achieved mass production of RV reducers with precision of ±1 arc minute and a lifespan exceeding 30,000 hours, breaking Japan’s monopoly.

Servo Systems: Inovance Technology has launched a 200kHz high-speed response servo with positioning accuracy of ±0.01mm; Huawei’s Ascend AI controller achieves ultra-short cycle control of 2ms, supporting 256-axis linkage.

Controllers: Companies like Efort have achieved 100% localization of core components such as reducers and servo motors, with the domestic share of heavy-duty robots increasing from less than 3% to 15%.

Upgrades in Intelligence and Collaboration Technology

AI Integration: Deep learning algorithms have enabled robots to achieve a defect detection accuracy of 99.99%, with AI vision systems improving response speed by 50%.

Collaborative Robots (Cobots): By 2025, the global market size for collaborative robots is expected to reach 10 billion yuan, with domestic share exceeding 90%, and export share increasing to 24.57%. Companies like AUBO and Dazhong are challenging Universal Robots through “low-cost hardware + open ecosystem”.

3. Market Drivers: Policy Dividends and Industrial Upgrades

Strong Policy Support

China’s 14th Five-Year Plan raises the robot density target to 500 units per 10,000 people, with an expected 400 units per 10,000 people by 2025; the “Robot + Application Action Implementation Plan” aims to double the density of robots in manufacturing compared to 2020.

Local governments, such as Zibo City, are investing 500 million yuan to build intelligent production lines, improving production efficiency by 20% and reducing defect rates by 40%.

Economic Drivers for “Machine Replacement”

Labor Cost Pressure: The production of industrial robots in Guangdong is expected to grow by 31.2% in 2024, with exports increasing by 44% against the trend, accelerating the replacement of repetitive and dangerous jobs while creating 7 million new jobs.

Manufacturing Cost Reduction: The price of domestic robots is 30%-50% lower than that of imported products, boosting the purchasing willingness of small and medium-sized enterprises by 20%, while modular design reduces deployment costs by 15%.

4. Challenges and Risks: Technological Redundancy and Intensified Global Competition

Technological Barriers and Price Wars

High-end reducers and high-precision sensors still rely on imports, and the actual utilization rate of some AI functions in production lines is less than 30%.

Intense competition in the mid-to-low-end market has led to a phenomenon of “increment without revenue” in the collaborative robot sector, with some manufacturers’ profit margins below 5%.

International Games and Supply Chain Security

The U.S. export controls on key raw materials (such as rare earths) and technologies are forcing China to accelerate domestic substitution; the EU’s “Digital Twin Factory” plan competes with China’s “Robot +” initiative in terms of technical standards.

The rise of the Southeast Asian market, with Vietnam’s industrial robot imports increasing by 45% annually, has led Chinese companies to export at an average price decrease of 22% through a “technology licensing + localized service” model, while profit margins have increased by 5 percentage points.

5. Future Trends: Ecological Restructuring and Global Layout

Technological Integration and Commercialization of Humanoid Robots

Humanoid Robots: Xiaomi and Tesla have reduced the production cost of their models to below $50,000, and brain-machine interface technology will enhance response speed by 10 times, with the global market size potentially reaching trillions by 2035.

Green Intelligent Manufacturing: The application of lightweight materials reduces energy consumption by 30%, and the usage rate of recycled plastics increases to 40%, promoting sustainable development.

Industry Chain Collaboration and Global Expansion

The Yangtze River Delta and Pearl River Delta are forming industrial clusters of “core components – body manufacturing – system integration,” with a scale expected to exceed 200 billion yuan by 2025.

China’s collaborative robot exports to Southeast Asia and Central and Eastern Europe have surpassed 25%, with technology going from “low-price dumping” to “high-value-added services”.

Conclusion: Insights from the Chinese Model and Global Impact

The rise of China’s industrial robots is essentially a triple resonance of policy guidance, market demand, and technological iteration. Through domestic substitution and ecological restructuring, China has not only changed the global supply chain landscape but also defined new standards in AI and human-robot collaboration.

However, technological redundancy, international competition, and industry involution remain long-term challenges.

In the next decade, whether China can shift from a lead in “quantity” to a lead in “quality” will determine its ultimate position in global intelligent manufacturing.

Thank you for your patience in reading. If you found this article helpful, feel free to bookmark, follow, and share!