The writing difficulty of this article on LCD screens, although it sounds a bit difficult, don’t worry, we have already cried and revised it N times…

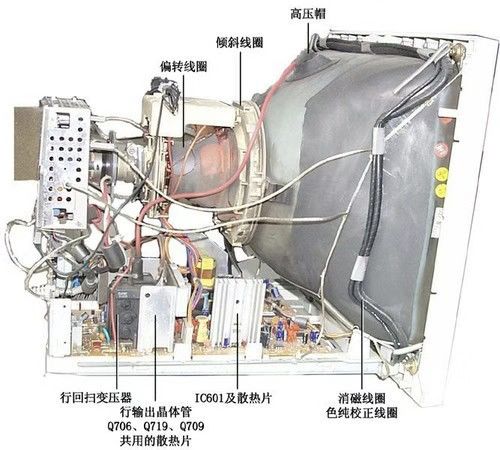

First let’s tackle a physics question from the past, “The commonly used CRT (Cathode Ray Tube)monitor works by using an electron gun to emit electrons, which bombard the fluorescent layer of the screen to display images.” So, what is the direction of the current?

The answer is: the direction from the screen to the electron gun. Because the direction of the electrons is opposite to the direction of the current. It’s just a hassle to look at a past CRT monitor, we won’t elaborate on this…

Well, this question is not meant to test everyone’s middle school physics knowledge, but to tell young people how huge the changes have been in the monitors I used when I was young! By the way, even if knowledge enters the brain, it can still fade away if not used… this is really a middle school physics question…

When I was in middle school, the home TV and computer monitors all had this heavy backside, of course, there were also stages of rear projection TVs and plasma TVs. But the one that has kept us laughing until now is the LCD screen, which, due to greatly reduced costs, has gradually become the most beautiful one on the market, widely used in various electronic devices, greatly reducing the size of screens, making laptops, pads, and phones more portable(at the same time making work encroach infinitely on life… sigh)。

Structure of LCD Screens

LCD stands for Liquid Crystal Display, and the mainstream technology now is TFT-LCD (Thin Film Transistor Liquid Crystal Display) technology. Looking at the disassembly in the image below, an LCD screen includes a backlight, polarizers, and most importantly, liquid crystals placed between two parallel glass substrates, with a TFT thin film transistor set on the lower substrate(you can understand it as a layout with many circuits), and a CF color filter set on the upper substrate(which has RGB red, green, and blue color filters)。

Color Rendering Principle

Because the CF color filter is printed with RGB color blocks, when the backlight of the screen passes through, let’s check the order in the image above: the light first passes through the transparent TFT thin film transistor substrate, then through the liquid crystal molecules, and then through the CF color filter. Due to the different transmittance of the liquid crystal molecules under each color block, the color blocks will emit different brightness levels of red, green, and blue, thereby mixing into the colors needed for display.

Of course, the premise is that these color blocks must be small enough, small enough to combine to form a rich color image, which we refer to as pixels!

What Is Liquid Crystal?

Now let’s introduce our main character—liquid crystal, which is a special state of matter. The states of matter we are most familiar with are gaseous (water vapor), liquid (water droplets), solid (ice), and another state we have heard of is plasma (fire). This time let’s familiarize ourselves with the state of liquid crystal, which has the anisotropy of crystals and the fluidity of liquids. Most liquid crystal molecules are “rod-shaped molecules”, originally oriented differently, but under different voltages, they exhibit different optical properties. Like metals in a magnetic field, when influenced by an external electric field, the liquid crystal molecules will produce a certain directionality.

So, as long as we properly control the arrangement of liquid crystal molecules, we can manipulate them to allow some light to pass through and block others, creating differences in light transmission~ Isn’t it brilliant, humanity!

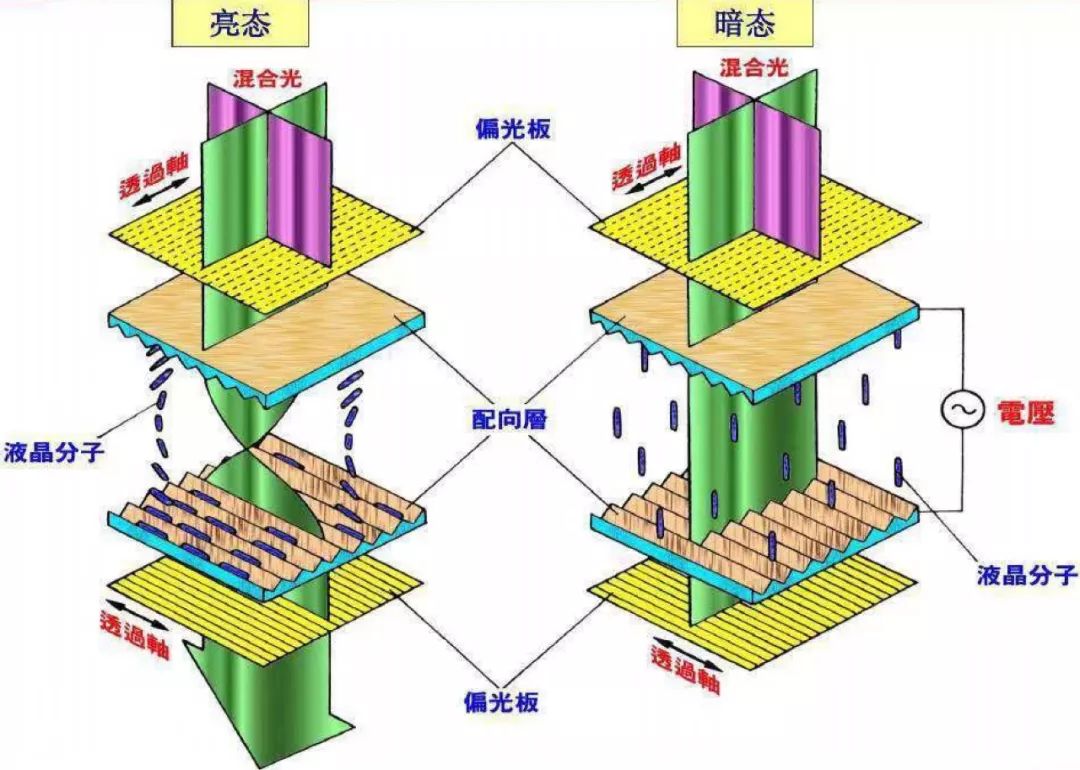

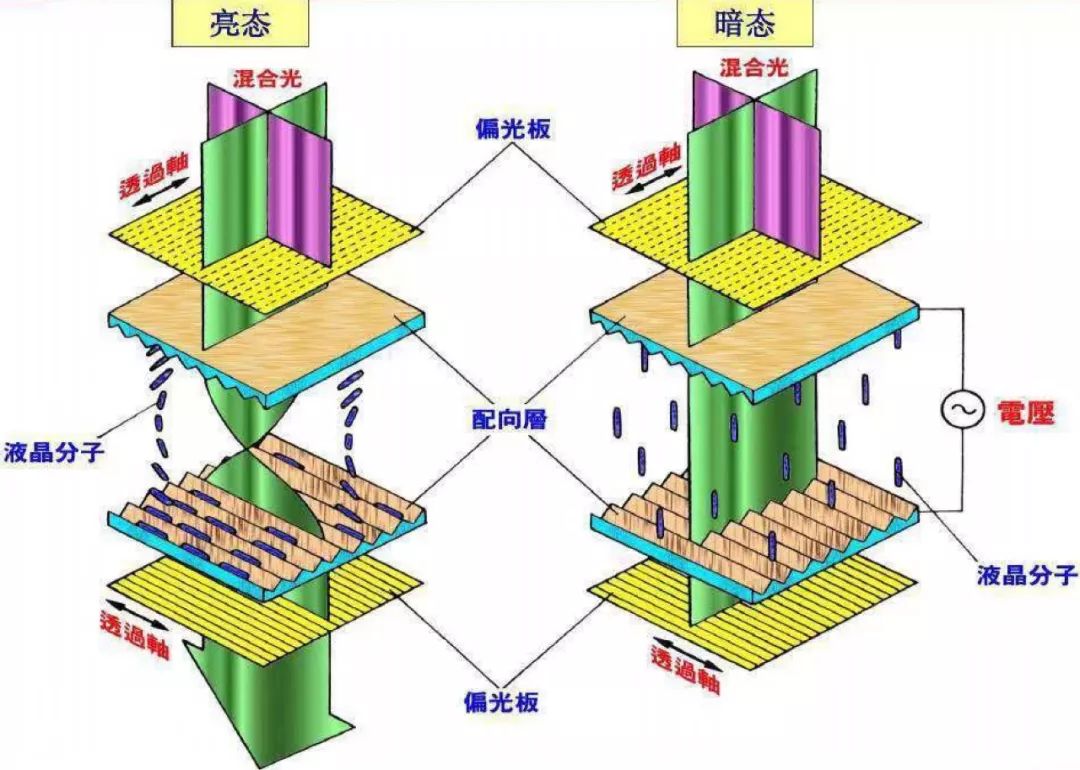

Application of Polarizers

Now let’s look at the two polarizers of the LCD screen, which are oriented perpendicular to each other and generally cannot pass light. But! We have liquid crystals! In the left image below, the arrangement of liquid crystal molecules forms a spiral, thereby rotating the light, allowing it to pass through the second layer of the polarizer and appear in front of the screen.

The above is a microscopic pure principle explanation, and when it comes to a large visible LCD screen, operating different areas to turn on or off the electricity, allowing light to pass or not, ultimately macroscopically combines to display an image.

All principles have been explained, don’t get a headache!Next, let’s look at the interesting manufacturing~

Manufacturing Liquid Crystals

First, let’s take a look at the manufacturing of liquid crystals that have caused a tremendous change in electronic devices over the past half-century! Generally, our domestic LCD manufacturing plants directly purchase liquid crystal raw materials, but since I found the video… I can’t let it go to waste. Workers pour chemical raw materials into a tank, and after a series of reactions, a liquid substance is finally obtained.

Heating and rotating in the bottle is the liquid crystal, and it is currently undergoing purification.

Next, the liquid crystal solution is sent for purification, then poured out to dry.

As the liquid crystal solution slowly crystallizes, it will form a white crystalline substance. Different liquid crystals will present different states, like milk or ice…

Finally, it is crushed into powder. The liquid crystal used in LCD screens is composed of many of these monomers mixed together, such as IPS, PSVA, VA-TFT, and other types of liquid crystal materials. As for the Chinese names… it’s not that we are showing off, it’s just that when we learned, we really didn’t know what they were called, I remember they were all in English…

By the way, the process of manufacturing liquid crystals has a bit of a breaking bad vibe, does it remind you of Walter White and Jesse Pinkman…

Manufacturing Steps

Having “liquid crystal” material alone is not enough. In addition to light, we also need to control the “brightness” and “color” of the light. Roughly dividing it, the production line process of LCD is: first ARRAY array manufacturing, then CELL panel manufacturing, and finally MODULE assembly.

Photolithography Technology

In the ARRAY factory, the most core part of the TFT thin film transistor substrate is the “photolithography process”. Photolithography means using light as a knife to engrave the photosensitive protective layer, and this photosensitive material is called photoresist. Ahem, Jiu Mo Zhi’s flame knife might have a lot to say…

Speaking of which, although Japan is no longer the king of LCDs, the engraved carrier “photoresist” is still firmly in hand, so once export restrictions are imposed, Samsung and LG, who make LCD screens in South Korea, will jump up and complain…

Array Manufacturing

Do you remember what we mentioned at the beginning? TFT thin film transistors can be considered as the production of circuit boards. You may have seen the circuit board when you were kids playing with the Little Tyrant game console~

During production, a “mask” with patterns is first covered over the photoresist material and exposed to ultraviolet light. The areas exposed to light will undergo a “photo-curing reaction”, dissolving in the “photoresist developer” and thus we obtain the desired image. After developing, heating can etch the thin film layer that is not protected by the photoresist, then strip the film, and drop the photoresist solution, preserving the part protected by the photoresist, completing the manufacturing of a layer of thin film transistors.

Repeating the steps of depositing thin films, coating photoresists, exposing, and developing multiple times completes the photolithography of the TFT thin film transistors~

Panel Manufacturing

First, clean the substrate thoroughly, then evenly coat the alignment liquid on the large cylinder on the right, and transfer it to the glass substrate. After heating and curing, an “alignment film” is formed. Next, using a grooved alignment rubbing cloth on the alignment film, grooves are rolled out to orderly arrange the liquid crystals on the substrate, forming a certain pre-tilt angle. Without the alignment film, the liquid crystals would be scattered on the substrate, and we would not be able to control the direction of light.

The CF color filter also needs to undergo the same alignment process.

One point to mention is the “frame glue coating”. The purpose is to better bond the TFT and CF, ensuring the gap height between the two, while also preventing liquid crystal leakage. Those who have experienced leaking liquid crystals feel quite distressed…

Next, a spacer is sprayed to control the thickness of the liquid crystal layer and support the space between the two substrates.

Then, in a vacuum environment, liquid crystal is dropped in, and the TFT and CF are aligned and pressed together to form the master board of the liquid crystal panel. The process of exposing with ultraviolet light and heating then hardens the frame glue. Finally, the liquid crystal panel is cut and pasted.

Let’s take a close-up look at an actual manufacturing process! On the TFT thin film transistor substrate, the liquid crystal is precisely applied~ Undoubtedly, this work can only be performed by machines, without the hands of grandpas and grandmas, precisely controlling the amount of liquid crystal dropped and the position it lands.

The brown bottle contains the liquid crystal, which is extracted with a tube and dripped onto the substrate.

Covering Polarizers

Now we need to attach the polarizers to both sides of the liquid crystal panel in a certain direction. First, let’s see an animated demonstration.

Dangdangdang~ The actual process is shown in the image below, and the liquid crystal panel you want is completed like this.

Module Assembly

We’re at the last stage! The liquid crystal panel is assembled with backlight and other components into a module, and then tested together before shipment. The image below shows the LCD finished panel (Cell), anisotropic conductive film (ACF), driver IC, flexible circuit board (FPC), and PCB circuit board being pressed together by machinery.

Next, it needs to be assembled with the backlight, light source, and iron frame to produce the finished product.

Finally, there is aging testing and quality inspection. After confirming that everything is fine, a fragile warning sticker is applied, and it’s over~ The production line of modules is not as automated as that of panels and arrays, but this precision processing is also completed by machines, with only “inspection” and “gluing” done manually.

Everyone sees that most of the article consists of animated demonstrations because each manufacturing step is extremely precise and almost all are closed processing。

Proofread by: Cast + Jiang Xiaosang

Screenshots by: Yang Ge

The GIFs in the article are sourced from YouTube creators How To Asia’s “Understanding the Manufacturing Process of TFT-LCD”, Media VR Lab’s “Color Filter Array of the LCD Display”, the channel of “The World of Wonders”‘s “Scientific Animation – How LCD Screens are Made”, CCTV’s official channel “CCTV Close to Science”‘s “Where Do Things Come From – Liquid Crystal: Is There Liquid in Liquid Crystal Displays? 20181010 | CCTV Close to Science” and the 97 version of the TV series “Demi-Gods and Semi-Devils” – Jiu Mo Zhi beating Murong Fu.

Source: Interesting Manufacturing Editor: Tuoba Monkey