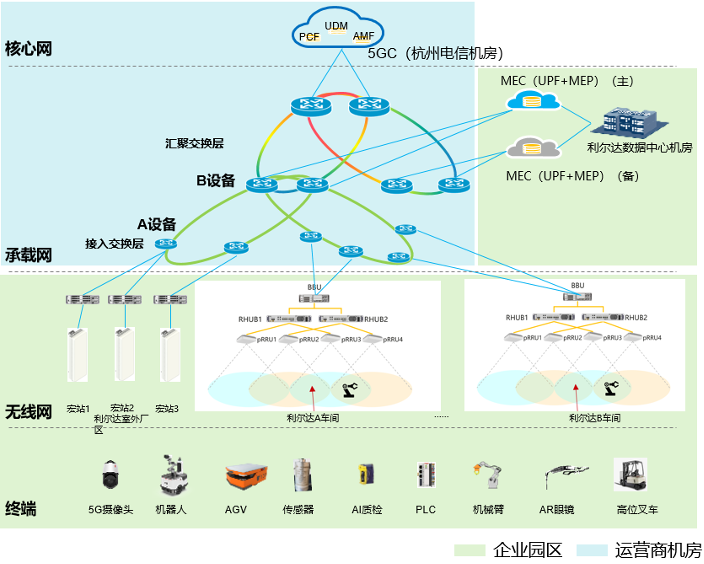

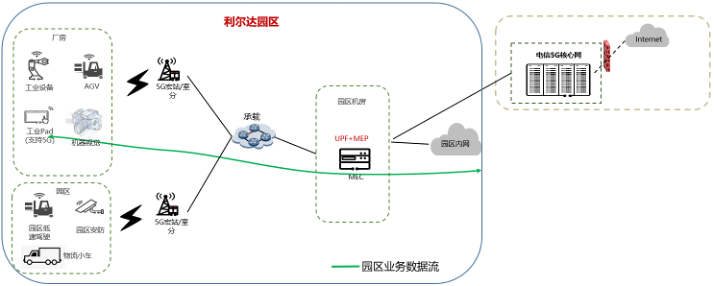

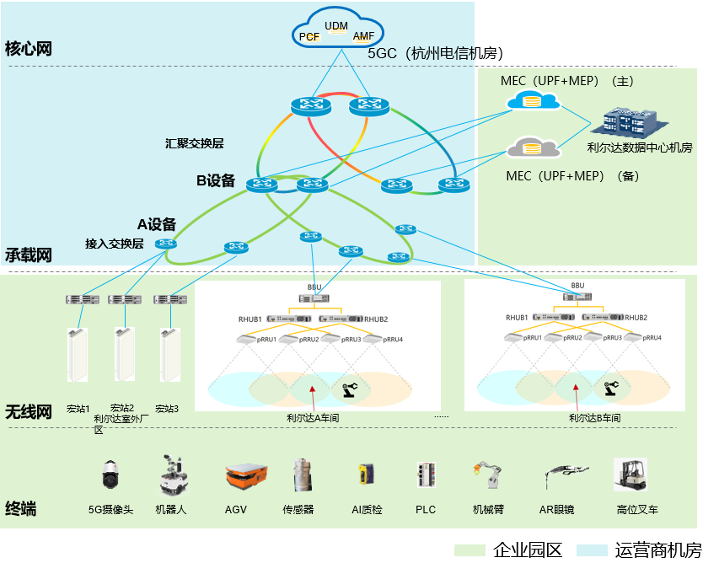

1. Lierda 5G Ultra-Converged Factory

Reported by: China Telecom Co., Ltd. Hangzhou Branch

Main Business: System integration, equipment sales, design and construction related to communication and information business; technical development, technical services, technical consulting, technical training; sales and maintenance of pagers, mobile phones, and their accessories; production and sales of telecom cards; customer service; house leasing; editing, publishing, and distributing telephone directories.

01 Case Overview

Lierda is a national key high-tech enterprise in important fields, committed to the technology and market promotion of the IoT embedded industry for over a decade, with strong technical strength. Over 30% of the company’s employees are R&D personnel, possessing a solid background and rich practical experience in embedded microcontroller technology, RF hardware development, communication, and networking technology. In the field of wireless communication for the Internet of Things, the company has mature communication solutions including NB-IoT, Wi-Fi, BLE, ZigBee, RF, etc.; the systems launched, such as energy-saving lighting for underground parking lots, wireless four-meter collection, sub-room energy consumption monitoring and analysis, smart cold chain, smart electric vehicles, smart retail terminals, smart advertising placements, smart air monitoring and purification, smart shoes, etc., are widely used in smart homes, smart buildings, smart hotels, smart parks, smart health, smart security, and smart travel.

Currently, Lierda has a strong demand for digital transformation in product manufacturing and management processes, with the following needs:

1. The internal network of the enterprise is isolated and needs integration and upgrade.

2. Product manufacturing management urgently requires automation improvements.

3. Rapid business development requires full-process management.

02 Key Technologies

Edge computing, network slicing, positioning, big data, cloud computing, artificial intelligence, 5G LAN.

03 Application Effectiveness

2. Jinhui Hardware 5G Smart Factory “Smart Brain”

Reported by: China Mobile Communications Group Zhejiang Co., Ltd.

Main Business: System integration, equipment sales, design and construction related to communication and information business; technical development, technical services, technical consulting, technical training; sales and maintenance of pagers, mobile phones, and their accessories; production and sales of telecom cards; customer service; house leasing; editing, publishing, and distributing telephone directories.

01 Case Overview

With the rapid development of 5G vertical industries, the security of 5G networks needs to cover all aspects of the end-to-end 5G network. The security, reliability, and convenience of 5G infrastructure carrying technology applications are the key to success. Under the demand for industrial support in the new infrastructure sector, more new challenges have been raised for the security carrying capacity of 5G new technology application infrastructure and the differentiated scene security support capabilities of the industry.

Main construction functions are as follows:

1. 5G Security Smart Operation Brain: Provides unified analysis and display of 5GC, 5G MEC, and internet exposure surface node log data, security log auditing, monitoring and protection system collaborative operation, threat intelligence sharing, and operation and maintenance resource permission control.

2. 5GC Security Slice: Provides threat traffic monitoring for 5GC, industrial control traffic auditing capabilities; supports threat monitoring interception at the 5GC network boundary and provides security protection for the MES host.

3. 5G MEC Security Slice: Provides threat monitoring for workshop business traffic, MEC industrial control traffic auditing capabilities; supports threat monitoring interception at the MEC network boundary and provides security protection for the MEP host and its business systems.

4. Exposure Surface Security Slice: Provides threat traffic monitoring for the exposure surface and industrial control traffic auditing capabilities; builds a zero-trust access control system to achieve security protection for the exposure surface; supports security reinforcement for industrial control hosts of equipment such as AGV, lathes, and vertical warehouses within the workshop.

02 Key Technologies

5G industry virtual private network, edge computing, network slicing, big data, cloud computing, artificial intelligence.

03 Application Effectiveness

This project has been implemented in Jinhua Xinhui Hardware Smart Factory, covering the 5G smart manufacturing industry, focusing on three business scenarios: CNC, AGV scheduling, and intelligent warehouse management for security protection. The protected objects include 20 industrial control terminal devices within the workshop, the MEC edge cloud MEP server, and the three business systems deployed on it: CNC system, AGV scheduling system, and the core network’s MES server.

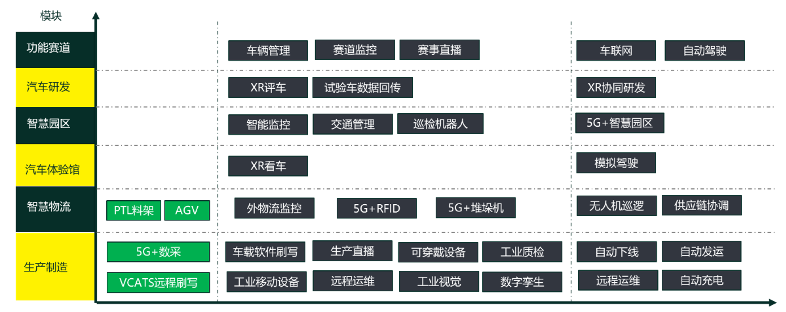

3. 5G+ Cloud Helps Geely Enter the “Future Factory” Fast Lane

Reported by: China Telecom Co., Ltd. Ningbo Branch

Main Business: System integration, equipment sales, design and construction related to communication and information business; technical development, technical services, technical consulting, technical training; sales and maintenance of pagers, mobile phones, and their accessories; production and sales of telecom cards; customer service; house leasing; editing, publishing, and distributing telephone directories.

01 Case Overview

Geely Holding Group has established Geely Automobile Research Institute (Ningbo) Co., Ltd., covering an area of 415 acres, possessing the largest and most advanced R&D center, vehicle testing and trial production center in the country, and has won the National Science and Technology Progress Award multiple times. The center is structured into the Vehicle Research Institute, Automotive Powertrain Research Institute, New Energy Vehicle Research Institute, and Automotive Creative Design Center, with R&D technology, vehicle testing, powertrain testing, and vehicle trial production centers, integrating design and R&D, testing and trial production, quality control, and supplier collaborative development, with independent R&D capabilities for complete vehicles, engines, transmissions, and electronics, and can conduct key component testing and assembly testing, performance testing for new energy motors, chassis durability testing, complete vehicle analysis and evaluation, structure research, and measurement, making it Geely’s “strongest brain” for design and R&D, testing and trial production, quality control, and supplier collaborative development.

Through the construction of a 5G + MEC private network, a highly reliable, efficient, and maintainable smart industrial system is established to promote the informationization and automation of the park; by applying 5G LAN, technical support is provided for specific scenarios in industrial manufacturing, decoupling the operator’s network from the enterprise, simplifying network architecture, and solving deployment costs through 5G + HPC exclusive cloud deployment, helping Geely’s R&D informationization and digital transformation, providing a testing environment guarantee for various simulation simulations; through the deployment of a 5G private network smart management platform, integrated management of all devices and terminals is achieved, enabling customer-level 5G self-service.

The project has completed more than 30 tests of 5G application scenarios, among which eight core applications have replicable promotion capabilities, including a 5G welding group control system, 5G Vcats vehicle-mounted software remote rewriting, 5G stacker/shuttle, 5G AGV system, 5G smart PTL material rack, 5G EMS aerial delivery, 5G SCADA & VR real-time monitoring system, and 5G digital twin. At the same time, a high-bandwidth high-speed cloud dedicated line connects Tianyi Cloud with Geely’s R&D base, using high-frequency CPUs, independent infrastructure resource pools, and IB networks to meet Geely’s massive computing power needs. The following are the project features:

1. Provides a benchmark model for 5G fully connected factories: Achieves full coverage of the 5G future factory, innovatively providing 5G application models for multiple links such as R&D, production, and logistics, confirming that the network architecture for 5G applications in the industrial field has redundancy reliability.

2. Innovative application of 5G LAN technology: Achieves pilot application of 5G LAN technology in real factory environments, with application scenarios spanning the entire manufacturing process of Geely automobiles, providing technical support for building Geely’s future factory system.

3. Cloud-network integration provides the strongest computing support: 5G + HPC provides a high-reliability testing environment and massive data support for various simulations in automotive manufacturing.

4. Achieves integrated management of 5G: Achieves full-scope management from 5G devices to terminal access devices, providing self-service capabilities for 5G private network and application management, comprehensively improving operational efficiency.

5. Cross-domain scenario applications of 5G: Achieves 5G implementation from Ningbo Research Institute to Wuhan Lotus Factory, validating the feasibility and practicality of implementation from testing to commercial landing.

02 Key Technologies

5G industry virtual private network, edge computing, network slicing, big data, cloud computing, artificial intelligence, 5G LAN.

03 Application Effectiveness

1. Enhances the level of unmanned operation, remote management reduces operational costs. 2. Optimizes work processes through 5G, comprehensively improving production efficiency. 3. Achieves refined logistics management, comprehensively improving logistics efficiency. 4. Achieves full touchpoint control of 5G devices and terminals, enhancing self-service capabilities. 5. HPC exclusive cloud provides the strongest computational brain for Geely’s automotive R&D.

4. 5G+PON Dual Gigabit Builds Aoyun De Auto Parts Manufacturing “Future Factory”

Reported by: China Telecom Co., Ltd. Cixi Branch

Main Business: System integration, equipment sales, design and construction related to communication and information business; technical development, technical services, technical consulting, technical training; sales and maintenance of pagers, mobile phones, and their accessories; production and sales of telecom cards; customer service; house leasing; editing, publishing, and distributing telephone directories.

01 Case Overview

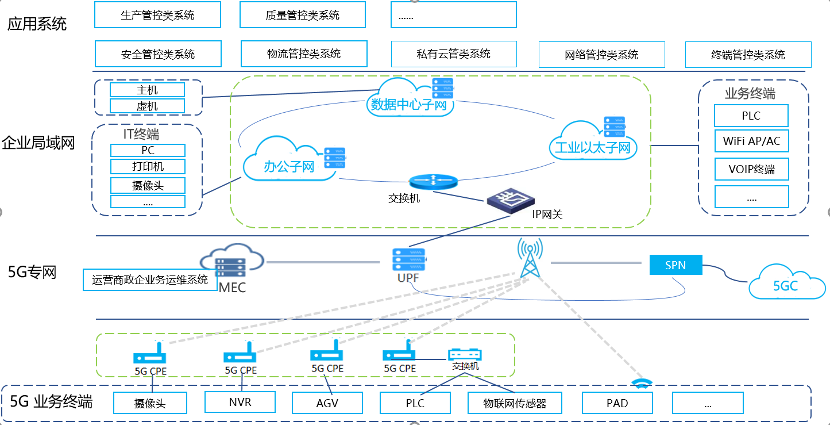

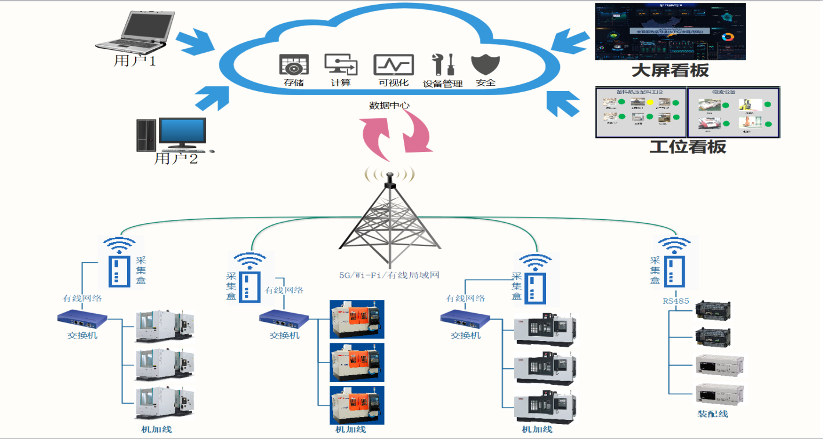

This project is a digital workshop (factory) construction project, guided by Aoyun De’s transformation and upgrading to a “future factory”, using 5G + industrial PON + MEC to build a dual-gigabit smart optical network for the factory (as shown in the overall architecture in Figure 2), deploying networks for smart parks, office scenarios, and production scenarios. The PON network achieves coverage of wired scenarios, while 5G + industrial Wi-Fi achieves coverage of wireless scenarios. By building an MEC platform and Aoyun De’s private cloud, MEC edge computing is realized, with core data uploaded to the private cloud for cloud-edge collaboration.

According to the demand for upgrading the internal network of the factory and the park, the design concept of this project is as follows:

Following the principles of “multiple nodes, multiple plants, extensive coverage”, flexible and unified network deployment is achieved, realizing comprehensive multi-business access and full scene coverage; meeting the requirements of operations for business capacity performance, environmental adaptability, and safety reliability, therefore, the equipment must work in high-difficulty ranges, with strong corrosion resistance and electromagnetic interference resistance; complying with the economic requirements of network investment, energy-saving and environmentally friendly, while the network has good compatibility and continuous evolution capability, allowing for smooth upgrades.

Under the above premise, this project strives to achieve:

1. Network Intelligence. Meet basic network data transmission, achieve data interconnectivity, and enable seamless roaming of data returned through 5G base stations. The capacity for massive access of multiple business types, low network latency, high bandwidth, video transmission, and industrial control signal transmission meets the production needs of enterprises. Deploy edge clouds nearby, allowing intelligent computing to sink to the park edge, timely invoking cloud network resources, achieving low-cost cloud migration for enterprises.

2. Detection Intelligence. Through the collaboration of terminal + 5G network + MEC edge cloud + cloud services, achieve real-time monitoring, automatic problem discovery, and proactive warning.

3. Production Intelligence. Based on PON + 5G C2C control, achieve flexible production, improve production efficiency, and reduce production costs.

4. Transportation Intelligence. The 5G network helps AGV vehicles achieve automated and intelligent transportation. AGVs can save 100% of manpower in circulation, and along with the construction of a lean logistics system in the supply chain, significantly reduce production costs and enhance the efficiency of goods turnover in the factory.

5. Collection Intelligence. Using 5G + industrial PON combined with new edge computing-enabled PLCs to achieve real-time control of industry and direct cloud mode machine networking and data collection through the 5G + PON network.

MEC fusion achieves the fixed-mobile fusion application of the 5G private network: by building the MEC platform and Aoyun De’s private cloud, MEC edge computing is realized, where 5G traffic, through the internal diversion capability of the MEC, returns data to Aoyun De’s internal network and the AI video analysis system, AR remote assistance system, AGV scheduling system, data collection SCADA platform, and C2C control center deployed within the MEC computing resources, ensuring that data does not leave the park while computing resources sink to the edge.

02 Key Technologies

5G industry virtual private network, edge computing, network slicing, cloud computing.

03 Application Effectiveness

This project has practical applicability, having signed a 5G custom network agreement, industrial PON, and industrial Wi-Fi protocols in 2022, and the project plan is fully operational.

The project is implemented in two phases, with the specific implementation plan as follows:

Phase One: Coverage of the 5G network in the southern factory area, construction of the industrial PON network, achieving data collection in the workshop, AGV, visual analysis, and mobile office scenarios.

Phase Two: Coverage of the 5G network in the northern factory area, construction of the industrial PON network, achieving data collection in the workshop, AGV, visual analysis, and mobile office scenarios.

Currently, Aoyun De has signed a business contract for industrial 5G + PON with China Telecom Co., Ltd. Cixi Branch, and the project is an important part of Aoyun De’s 2021 Zhejiang Province “Future Factory” demonstration project.

5. Huafeng Group Chemical Industry 5G+ Fully Connected Factory

Reported by: China Telecom Co., Ltd. Wenzhou Branch

Main Business: System integration, equipment sales, design and construction related to communication and information business; technical development, technical services, technical consulting, technical training; sales and maintenance of pagers, mobile phones, and their accessories; production and sales of telecom cards; customer service; house leasing; editing, publishing, and distributing telephone directories.

01 Case Overview

The Huafeng Group 5G+ Smart Factory project officially launched in 2021, planning to deploy MES systems in batches and gradually across more than 50 wholly-owned and holding companies within the Huafeng Group over three years.

02 Key Technologies

5G industry virtual private network, edge computing, network slicing, cloud computing, artificial intelligence.

03 Application Effectiveness

6. SANY Equipment Industrial Multi-Network Management Platform and 5G Time-Sensitive Optimization Applications

Reported by: China Telecom Co., Ltd. Huzhou Branch

Main Business: System integration, equipment sales, design and construction related to communication and information business; technical development, technical services, technical consulting, technical training; sales and maintenance of pagers, mobile phones, and their accessories; production and sales of telecom cards; customer service; house leasing; editing, publishing, and distributing telephone directories.

01 Case Overview

02 Key Technologies

Edge computing, uplink enhancement, timing, 5G TSN.

03 Application Effectiveness

1. 5G uplink enhancement technology, based on time-sensitive 5G uplink wireless resource allocation technology. Refines 5G uplink 5QI services, improving uplink capacity for time-sensitive 5QI services by 10% compared to existing systems. Provides a solid foundation for SANY Equipment’s 5G + machine vision’s high uplink bandwidth requirements, facilitating implementation for weld seam detection and coating inspection.

2. Low latency jitter-sensitive communication technology. Utilizes slicing, UPF sinking, and other architectures to reduce time jitter, achieving 5% less time jitter compared to existing technologies.

3. Key technology for high-precision clock synchronization based on Beidou, integrating 5G and TSN. Supports both 5G network and industrial Internet clock domains, adjusting domain clock baselines as needed, and aligning two time domains. Improvements in latency and clock synchronization technology play an important role in the coordinated operation of SANY Equipment’s AGV vehicles.

4. Industrial Internet 5G fusion terminals. Supports high-precision timing from Beidou, and supports various field operating systems such as LC, CNC machine tools, industrial robots, and other industrial data interfaces.

5. Lightweight 5GC core network products. Supports TSN network deployment functions. Supports access for 2000 terminals. Supports high-precision timing and synchronization control from Beidou.

6. 5G TSN hybrid networking system. Achieves mixed scheduling of time-sensitive business flows and other business flows, supporting applications in various industrial Internet scenarios such as design, manufacturing, inspection and monitoring, and logistics transportation.

7. Quanxing Precision 5G+ Smart Factory Project

Reported by: China Mobile Communications Group Zhejiang Co., Ltd. Shaoxing Branch

Main Business: System integration, equipment sales, design and construction related to communication and information business; technical development, technical services, technical consulting, technical training; sales and maintenance of pagers, mobile phones, and their accessories; production and sales of telecom cards; customer service; house leasing; editing, publishing, and distributing telephone directories.

01 Case Overview

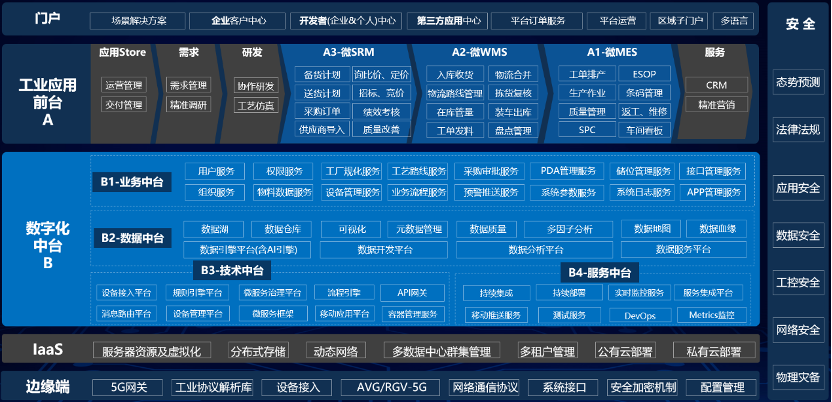

The Quanxing Precision Group is very urgent in its demand for 5G and intelligent transformation, mainly focusing on data collection, equipment management platforms, graphical displays, and MES system development.

The Quanxing Precision Group, after analyzing its information technology foundation, builds an MES software and hardware platform, integrates with other information management systems, and applies lean management concepts to create a smart factory, enhancing the enterprise’s operational control capabilities. The project construction content is as follows:

2. Multi-system software integration. Integrates MES with the following software: Product Lifecycle Management Platform (PLM), Enterprise Resource Planning Platform (ERP), Warehouse Management System (WMS), Automation Office System (OA);

3. Build an MES software platform. Main functions include: process management, planning and work order management, production management, quality management, equipment management, environment and energy management, material management, event management, report management, etc.;

02 Key Technologies

5G industry virtual private network, edge computing, network slicing, cloud computing.

03 Application Effectiveness