CEO of Jiangsu Zhiku Intelligent Technology Co., Ltd., Cai Chuan Yu

CEO of Jiangsu Zhiku Intelligent Technology Co., Ltd., Cai Chuan Yu

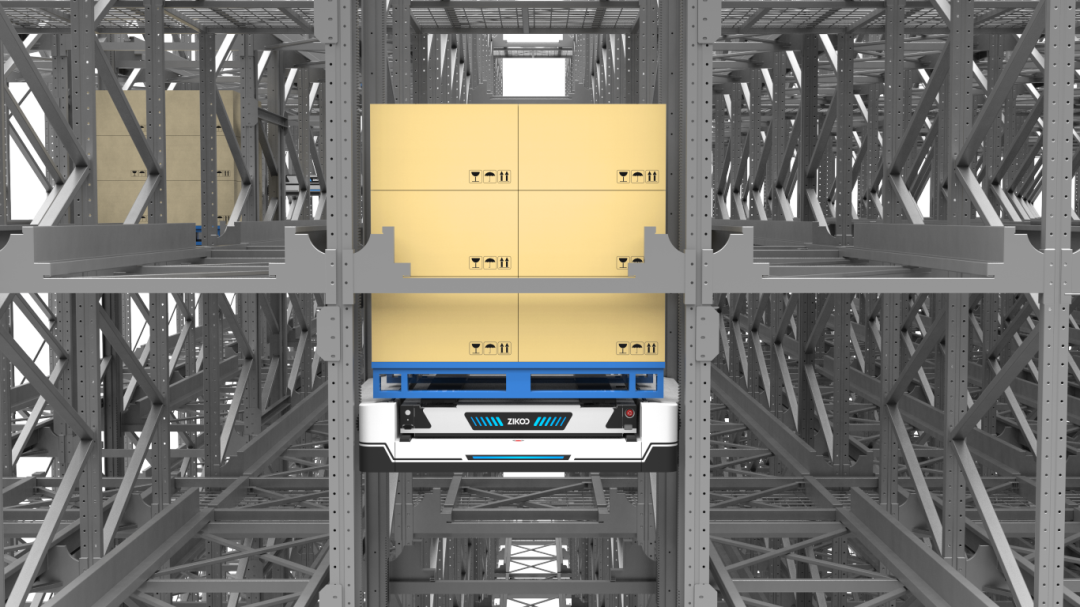

Zhiku Intelligent has launched a six-way shuttle vehicle, replacing traditional automation equipment with robots to provide more efficient and flexible solutions that meet the market’s demand for high flexibility and convenient delivery.

NEXT

Driven by the rapid development of artificial intelligence technology and the continuous advancement of China’s supply chain industry, the intelligent logistics storage sector is undergoing profound changes, with the pallet storage robot field showing enormous development potential and vast market space. The development in this area is not only related to improving the efficiency of the logistics storage industry but also closely linked to reducing costs and enhancing competitiveness for enterprises.

01»»»Zhiku IntelligentMarket Demand Insight: Seeking Better Solutions

Currently, the core demand in the pallet storage field focuses on providing solutions that offer higher density, greater flexibility, lower costs, and more convenient delivery and usage. Cai Chuan Yu, CEO of Jiangsu Zhiku Intelligent Technology Co., Ltd. (hereinafter referred to as Zhiku Intelligent), believes that despite the continuous market development, customers’ pursuit of core product elements has not changed.

Compared to traditional logistics automation equipment, intelligent storage robots demonstrate significant advancements in cost, delivery, density, efficiency, flexibility, and operation and maintenance. Pallets, as the most common storage container tools in warehouses, are widely used in storage and picking scenarios in manufacturing and distribution industries, where the demand for intelligent upgrades remains substantial. From the perspective of the existing market, the replacement of traditional automation equipment by intelligent storage robots has become an unstoppable trend.

It is worth noting that there are significant differences between pallet storage solutions and container storage solutions. Container storage solutions are mainly used for picking and are relatively concentrated in the distribution industry, while pallet solutions have a broader application range, covering various industries such as manufacturing and distribution, although the proportion of segmented demands in each industry is relatively dispersed. In the face of this fragmented market landscape, enterprises must focus on the versatility of products and the comprehensive capabilities of solutions, as the core of pallet storage lies in adapting to pallets and business needs rather than specific industries.

02»»»Zhiku Intelligent

02»»»Zhiku Intelligent

“Replacing Machines with Robots”

Innovative Six-Way Shuttle System

In response to the numerous issues faced by traditional stackers and four-way shuttle vehicles, Zhiku Intelligent actively conducts product and solution iterations, launching an innovative six-way shuttle solution.

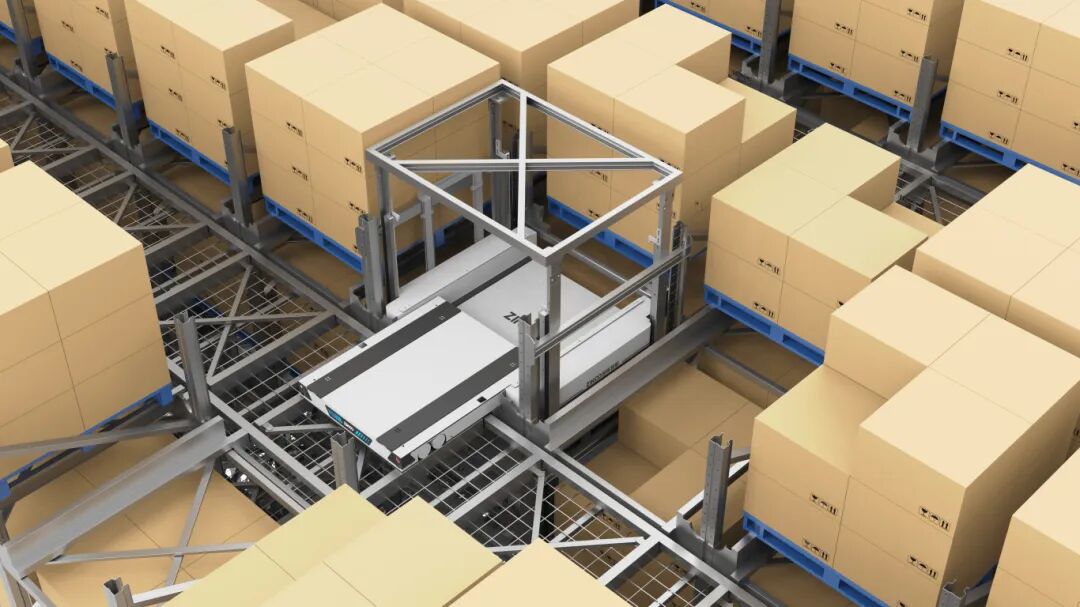

It consists of R-bot four-way shuttles and H-bot vertical two-way vehicles, which can be freely combined according to customer scenarios, efficiency, and layout requirements through cluster scheduling software, maximizing cost and benefits. It can adapt to both full pallet inbound and outbound or small quantity picking inbound and outbound scenarios, as well as high-density, high-throughput, multi-box picking scenarios.

In the past, while designing the four-way shuttle and collecting customer application feedback, Zhiku Intelligent found that the four-way shuttle was limited by the conveying and lifting equipment, resulting in efficiency bottlenecks, while the delivery cycle was long, and subsequent debugging faced many challenges, making it difficult to better meet customer needs.

“We believe that the flexibility of robots should not be limited by the supporting automation equipment, as this would make them very clumsy. Therefore, we have been thinking about whether we can create a product that achieves complete robotization and maximum flexibility. Based on the pursuit of robot flexibility, Zhiku Intelligent has discarded the constraints of traditional automation equipment, starting from the embedded lift deployed within the storage location. After more than two years of continuous product iteration, we successfully launched the six-way shuttle, which is the four-way shuttle plus the vertical two-way vehicle,” Cai Chuan Yu elaborated.

The most significant feature of the six-way shuttle is that it replaces traditional automation equipment with robots, using standardized products instead of integrated logistics equipment, thereby significantly enhancing the efficiency of storage centers. When discussing the challenges in product development, Cai Chuan Yu believes that the fundamental aspect of developing a new product is to break free from conventional thinking. “When we do many things, we may have some fixed mindsets. For example, when thinking of automated storage and retrieval equipment, everyone can think of lifts and conveyor lines. However, to achieve breakthroughs, we must break this fixed mindset and develop products based on a completely new thought framework.”

Solution Advantages: More Efficient and Flexible

During the research and development process, Zhiku Intelligent conducted a comprehensive comparison of the new product with traditional stackers, four-way shuttles, and shuttle board solutions across six key dimensions: cost, density, flexibility, efficiency, delivery, and operation and maintenance, showing that the six-way shuttle has significant advantages.

The six-way shuttle system solution can plan layouts similar to stacker systems, adopting long aisles and mother aisles facing outward. However, its path planning is more flexible than that of stackers; even if one vehicle stops operating, it will not affect the normal use of the entire system, and equipment scheduling is more flexible, with task distribution being more even, ensuring flexible operations at the inbound and outbound ports. Compared to stacker solutions, the delivery costs and cycles of the six-way shuttle solution are greatly reduced.

The six-way shuttle system solution uses the middle mother channel as the main aisle, avoiding the low efficiency issues caused by the frequent crossing of the mother channel by traditional four-way shuttles, while using four-way shuttles to replace conveyor lines, achieving installation and delivery upon setup, improving system stability and operational efficiency. This solution combines the flexibility of four-way shuttles with the efficiency of six-way shuttles, optimizing the overall performance of storage logistics.

In terms of system scheduling principles, the six-way shuttle also has advantages. It arranges four-way shuttles according to aisle layout, with each vertical two-way vehicle prioritizing the transportation and lifting of goods within its aisle. If cross-aisle operations are needed, it is done through the built-in four-way shuttle for planar scheduling, with internal logic being simple and clear.

“The six-way shuttle is launched as a standardized product in the pallet storage field, which is an important innovation. The project only requires shelves, pallets, and six-way shuttles to be installed and delivered directly for use. This is a result of industry development, and Zhiku Intelligent has transformed the pallet storage scenario from product integration to integrated productization, fully reflecting the innovative advantages of robot manufacturers,” Cai Chuan Yu added.

03»»»Zhiku IntelligentCustomer-Centric Innovation Philosophy

In terms of corporate innovation, Cai Chuan Yu emphasized that the most core element of innovation is “customer-centricity,” meeting the fundamental needs of customers.

Currently, the market for mobile robots is booming, with some companies even launching new products every month. These products vary widely, including some disruptive products with high technical difficulty and others that are merely iterative products with minor innovations. Cai Chuan Yu stated, “Some of these products are just technical stacking, and their starting point does not benefit market and industry development. Innovation should not be driven by the desire to ‘innovate’ but should be based on meeting the most fundamental needs of customers, solving practical problems in specific scenarios and customer demands.”

Since its establishment eight years ago, Zhiku Intelligent has positioned itself as a “leader in pallet storage robots,” dividing pallet storage space into two types: above and below 10 meters, and launching multiple compatible products for different spaces, building a complete product system.

From the perspective of traditional automation products, storage spaces above 10 meters mainly use stacker systems, while those below 10 meters mainly use forklifts. Based on this division of labor, Zhiku Intelligent has launched multiple products targeting both above and below 10 meters, creating its own product system. For example, to address storage spaces below 10 meters, Zhiku Intelligent has developed an omnidirectional high-lift AMR, achieving higher efficiency, narrower aisles, and safer operational solutions.

Similarly, for storage spaces above 10 meters, Zhiku Intelligent has developed the six-way shuttle, achieving a more cost-effective, flexible, and easily deliverable product solution. The core product, the four-way shuttle, adopts an innovative technical solution with a full gearbox in its mechanical structure, and uses a fusion positioning method of “RFID + magnetic induction + odometer” to solve the pain points of traditional QR code or single photoelectric positioning, better meeting customer needs.

Cai Chuan Yu stated: “In recent years, we have continuously gained widespread market recognition for our self-innovative products, which not only provide strong support for the company’s development but also make significant contributions to industry progress. We have never been content to be followers in the industry but have always maintained a keen perspective on customer needs, combining advanced technology and supply chain advantages to continuously launch innovative products and lead the development trend of the industry.”

In terms of market layout, Zhiku Intelligent has established a complete market system, achieving extensive coverage both domestically and internationally; in organizational management, it has created a complete system driven by efficiency and resilience, from product development to marketing and delivery, with all projects achieving 100% delivery, earning high recognition from customers.

04»»»Zhiku IntelligentTrends: Moving Towards Productization and Intelligence

In the pallet storage field, high-quality leading enterprises have traditionally been system integrators, with project delivery primarily customized. However, in other storage scenarios, more and more robots are achieving product solutions that do not require system integration through combinations. Cai Chuan Yu predicts that the pallet storage field will also develop towards productization, as standardized products help better control quality and costs, facilitating global delivery and deployment.

The pallet storage field will move towards productization and intelligence in the future, with both mobile robot hardware and software scheduling, business management, etc., achieving higher levels of intelligence. Zhiku Intelligent has independently developed a storage robot controller, investing significant energy and costs to enhance product control precision and operational stability; at the same time, in the product scheduling phase, it continues to research multi-vehicle scheduling, storage strategies, etc., continuously iterating on technology.

Since the launch of the six-way shuttle, it has not only gained favor from domestic customers but has also received enthusiastic positive feedback in overseas markets. Currently, the six-way shuttle has been implemented in various industries, including pharmaceuticals, industrial manufacturing, food cold chain, clothing and textiles, and 3PL (third-party logistics), with projects underway in countries such as Italy, Egypt, and Kazakhstan, where the largest project has deployed nearly 50 units of the six-way shuttle product.

As a global product, Zhiku Intelligent has used the six-way shuttle as a starting point to establish extensive cooperation with enterprises in multiple countries. Currently, for the overseas market, Zhiku Intelligent is particularly optimistic about developed markets such as Europe, America, Japan, and South Korea, which have higher requirements for products and technology, helping to test the core technologies of enterprises and promote long-term development; at the same time, the Southeast Asian market, due to its growing storage demand, is also one of its key focus areas.

Cai Chuan Yu stated that the future trend of the entire industry is that automation equipment will be replaced by robots, which is also the core concept behind Zhiku Intelligent’s development of the six-way shuttle—”robots replacing machines.” Today, the intelligent logistics storage field has moved from the stage of “machines replacing humans” to the new era of “robots replacing machines.” Zhiku Intelligent will continue to observe customer needs, combine advanced technology and supply chain advantages, and launch more innovative products to lead the trend of industry development.

END