Beautiful Taihu, its beauty lies in the waters of Taihu.

The reeds by the water are lush, and the fish and shrimp beneath the water are abundant.

This well-known city song of Wuxi, “Beautiful Taihu,” expresses the stunning natural scenery of Taihu and the happy life of the people in the Jiangnan water town nourished by Taihu.

However, after the Taihu water crisis in 2007, the aquaculture industry that relied on the lake and the heavily polluting dyeing industry became important industries that Wuxi had to give up. A large number of farmers needed to come ashore, and many enterprises needed to shut down or relocate. Yet, 15 years later, the Internet of Things industry that developed after Wuxi’s “cutting off the wrist” has also entered a harvest period.

Not only has the scenery of Taihu become increasingly pleasant, but Wuxi has also become the world capital of the Internet of Things, with the entire industry gradually maturing and the commercialization process solidly taking root, revitalizing Wuxi with vibrant energy.

“From nothing to something, thriving development.” Numerous IoT companies have grown and expanded in Wuxi’s experimental field, already stepping out of Wuxi, out of China, and embracing the world. Regarding the future development direction, Wuxi’s Deputy Mayor Zhou Wendong believes that the integration and innovation of “Artificial Intelligence + Internet of Things (AIoT)” and the dual empowerment are the key paths for the rapid development and generational leap of the Internet of Things, while the sensing layer’s sensors and the application layer’s vehicle networking and industrial internet are the core tracks for Wuxi to promote the deep integration and wide application of AIoT.

Leading the Way, Cultivating a 300 Billion Industry

In the initial two to three decades of reform and opening up, the “Southern Jiangsu Model” was realized through the development of township enterprises in places like Suzhou, Wuxi, Changzhou, and Nantong, becoming an important growth point for local economic development. These enterprises not only contributed most of Wuxi’s GDP but also nurtured a batch of industry leaders.

However, the outbreak of the Taihu water crisis in 2007 posed ecological constraints on Wuxi’s industrial development, reaching a point where a choice had to be made, leading to painful decisions to “cut off” industrial enterprises around the lake.

In November 2009, the State Council approved Wuxi’s establishment of a national sensor network innovation demonstration zone, handing Wuxi the “key” to seize the development opportunities of the Internet of Things, marking the beginning of Wuxi’s journey as a pioneer and pilot for the national development of the Internet of Things.

Sensor Network Innovation Park

For thirteen years, as the only national sensor network innovation demonstration zone in the country, Wuxi has achieved significant transformations in the research and development of IoT technology, standard formulation, application promotion, and enterprise aggregation, realizing a major shift from the concept of the Internet of Things being “very” to “common,” from abstract to concrete, and from laboratory to real-world application. A large number of leading enterprises and unicorns in various niche markets are growing here, forming a relatively complete industrial chain that includes related chips, sensing devices, network communication, smart hardware, system integration, and application services.

The city has gathered over 3,000 IoT enterprises, including 79 listed companies and 33 national-level specialized and innovative “little giant” enterprises and manufacturing champions, establishing a differentiated industrial layout characterized by Xuelang Industrial Big Data, Nanshan Vehicle Networking, and Huanghai Bay Advanced Sensing.

Xuelang Town

In the past three years, the average growth rate of the IoT industry revenue has exceeded 20%, with the industry scale reaching 356.3 billion yuan in 2021, an increase of 26.8%. The Wuxi IoT cluster has successfully been selected as one of the first national advanced manufacturing industry clusters.

Chen Liming, Deputy Secretary-General of the Wuxi Semiconductor Association, said that at the beginning, everyone didn’t even know what the Internet of Things was, let alone how to use it, and many specific applications of the Internet of Things need to be integrated with industries.

For Wuxi, while providing policy support to IoT enterprises, it is more focused on helping enterprises find markets. By leveraging the construction of “smart cities,” Wuxi has handed over a large market share in smart transportation, smart environmental protection, smart tourism, and smart restaurants to upstream and downstream IoT enterprises, providing strong momentum for the industrialization of IoT technology locally.

Since 2010, Wuxi has introduced a series of policies, utilizing special financial funds to encourage enterprises to invest in research and development, design products that meet user needs, promote industrialization and market application, apply for invention patents, and formulate international and national industry standards. It also encourages non-governmental third-party organizations to establish public service platforms for the industry.

By building a good ecological environment for the industry, many IoT enterprises have found application scenarios locally, breaking through technical paths and forming core products while exploring business models.

There are no limits to IoT applications; only imagination. Therefore, as a national demonstration zone, many enterprises have been able to pioneer and experiment in Wuxi, stimulating some demands for IoT, leading to the acceptance of certain products, thus enabling these enterprises to move towards industrialization.

Since pioneering and experimenting is allowed, there needs to be a fault tolerance mechanism and a tolerant mindset to ensure that enterprises can innovate and develop without worries.

Now, with a scale of hundreds of billions, Zhaosheng Microelectronics, founded by Xu Zhihan, returned to China to start a business in 2002 and began researching mobile TV (CMMB) chips in Wuxi in 2006. At one point, the company faced difficulties and could not pay salaries, and family members advised him to return home to run a clothing business. However, Wuxi provided him with an environment to hone his skills for ten years. By focusing on the research and development of RF chips for smartphones, Zhaosheng Microelectronics successfully entered the Samsung supply chain and seized the opportunity of the 5G era, becoming a leading enterprise in domestic RF switches and low-noise amplifiers for smartphones.

Regarding how to accompany enterprises in their growth, in 2017, then Deputy Mayor of Wuxi, Gao Yaguang, once said, “Since Wuxi has taken on the responsibility of being a national experimental field, it should have such a sentiment: it doesn’t matter if enterprises take some detours or face temporary failures; we are willing to wait for enterprises to grow their wings, expand their territories, and then soar high.”

In Wuxi, the application of IoT technology covers over 300 sub-industries in the city. Wuxi has taken the lead in 23 national-level major application demonstration projects in industries such as environmental protection, transportation, and healthcare. The IoT projects undertaken by Wuxi enterprises have spread to 78 countries and over 830 cities worldwide.

Currently, Wuxi enterprises have led or deeply participated in the formulation of multiple international and national IoT standards, representing that Chinese enterprises are gradually gaining greater international discourse power.

Building a Nest to Attract Phoenixes, Creating a Fertile Ground

In 2020, Sirun Tianlang Technology Co., Ltd. considered moving from Beijing to a more concentrated industrial area. Deputy General Manager Liu Zhijie conducted investigations in Shanghai, Suzhou, and Wuxi, spending over three months in each place. Since their decided development path was aimed at autonomous driving, represented by vehicle-road collaboration, assisting the digital transformation of the automotive industry, the service support and industrial atmosphere of the Yangtze River Delta were undoubtedly excellent.

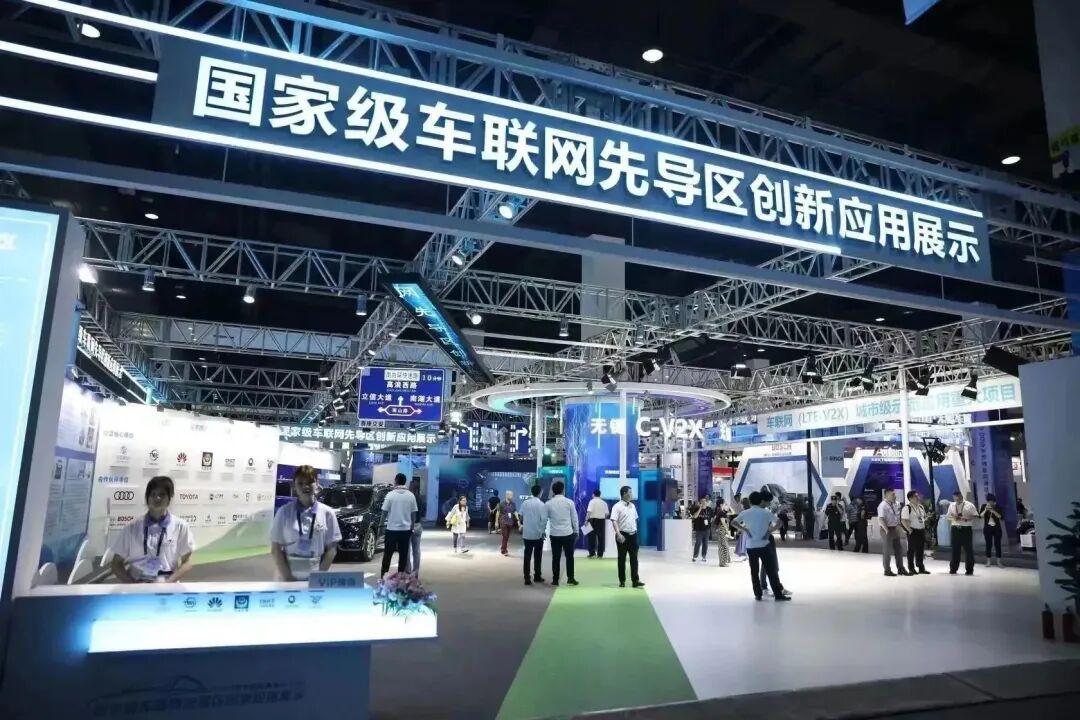

While the industrial environment in first-tier cities like Shanghai and Beijing is not much different, Suzhou is more focused on autonomous driving with a single vehicle intelligence approach. However, Wuxi, as the first national pilot area for vehicle networking, has a better atmosphere for V2X, leading to the decision to settle in Wuxi.

Nanshan Vehicle Networking Town

Another important reason is the concentration of the semiconductor and IoT industries in Wuxi, with a complete upstream and downstream industrial chain. Whether it is communication modules, chips, sensor networks, or various component enterprises, all suppliers needed to support automotive manufacturers can be found.

As a pre-installed vehicle networking communication terminal manufacturer serving OEMs, they began collaborating with Swedish vehicle networking company WirelessCar in 2012 to promote the implementation of the national vehicle networking standard “NGTP” in China, gradually iterating and upgrading to meet the localized needs of Chinese enterprises through five standardized technical systems (access, protocol, data, application, service) and a big data intelligent networking foundation to build over 200 modular services for car manufacturers, assisting them in achieving digital development in the automotive industry.

Thanks to the strong demand in the Chinese market and Wuxi’s complete industrial chain support capabilities, they can respond quickly to customer needs and deliver platforms in a SaaS manner. Currently, the system has undergone three iterations, better aligning with the needs of Chinese automotive manufacturers, with the number of models that can be integrated reaching over a hundred, and the scale of integration has reached over 5 million vehicles.

In fact, for many enterprises in the intelligent driving industry chain, Wuxi’s charm lies not only in the complete industrial chain support but also in being the first city in the country to deploy vehicle-road collaboration devices on a large scale throughout the city, not limited to a specific district. Most intersections and main roads have vehicle-road collaboration capabilities, while other places mainly focus on a few kilometers or dozens of kilometers of test roads.

National Intelligent Transportation Comprehensive Testing Base

According to a relevant person in charge of Wuxi’s Industry and Information Technology Bureau, Wuxi began laying out vehicle-road collaboration infrastructure many years ago. This year, they have further considered the installation of vehicle-road collaboration devices during the new construction and expansion of roads, including information control, radar-vision fusion integrated machines, edge computing units, etc.

Currently, among the more than 2,700 intersections in Wuxi’s urban area, most intersections in the main urban area have achieved coverage of basic vehicle-road collaboration facilities, with some intersections implementing “thickened” deployments. According to the “Management Regulations for Road Testing and Demonstration Applications of Intelligent Connected Vehicles in Wuxi” issued in September this year, unmanned vehicles can operate in four designated areas, while manned autonomous vehicles can operate throughout Wuxi, making it the first city in the country to open up the entire area for testing and demonstration of autonomous driving with a driver.

Since moving to Wuxi, Sirun Tianlang’s business has experienced rapid growth, with annual revenue doubling each year, and it is expected to reach 400-500 million yuan in 2022. They have planned three fully automated production lines with an annual capacity of 3.6 million units, ranking among the top in the domestic market for communication modules for new energy vehicles.

Liu Zhijie stated that Wuxi is focusing on areas with strong logistics demand, such as bonded zones, airports, and large enterprises, as well as points concentrated on public transport micro-circulation needs, accelerating the commercialization of autonomous driving applications and actively promoting the process of vehicle-road collaborative autonomous driving, where enterprises see the dawn of vehicle-road collaboration.

Starting from Wuxi, IoT enterprises have begun to reach the world. According to statistics, Wuxi has undertaken 23 national-level major application demonstration projects, and the IoT engineering projects undertaken by Wuxi enterprises have spread to 78 countries and regions, covering over 830 cities, providing a good “Wuxi model” for the large-scale application of IoT both nationally and globally.

Wuxi is not only the first national pilot area for vehicle networking but also one of the first pilot cities for the coordinated development of smart city infrastructure and intelligent connected vehicles, and has been awarded the title of “Chinese Software Characteristic City” in the direction of IoT and platform software.

Chinese Academy of Sciences Internet of Things Research and Development Center

The ability to attract numerous enterprises to settle in Wuxi lies not only in application scenarios but also in supporting capabilities. Wei Shaojun, former president of Datang Telecom Technology Co., Ltd. and director of the Department of Micro-Nano Electronics at Tsinghua University, commented that Wuxi is one of the few cities in the country with a complete integrated circuit industry chain, covering chip design, wafer manufacturing, packaging and testing, supporting materials, and supporting services.

Wuxi has both integrated circuit design and manufacturing, as well as subsequent packaging and testing, with a very complete industrial chain. The comprehensive quality of talent is relatively high, and it can be said that no other city has such a complete industrial chain. The integrated circuit industry is a highly specific and closely interconnected field, which is a huge help to Wuxi’s IoT industry.

A relevant person in charge of Wuxi’s Industry and Information Technology Bureau stated that in Wuxi, there are companies like Zhonghuan Leading, Huahong, and Huaren for silicon wafer production, Changdian and Ansheng for packaging and testing, Longwei for devices, and Zhua Hai, which is close to going public, for second-hand equipment refurbishment. “Many semiconductor devices may seem inconspicuous, but among the ten suppliers for a product, five come from Wuxi. You can’t get around Wuxi.”

Proactive Upgrading, Rise of Leading Enterprises

Founded in 1957, Hongdou Group is a standard traditional manufacturing enterprise. Over 65 years, Hongdou has transformed from a small handmade workshop into a large multinational enterprise group covering textiles and clothing, rubber tires, health care with red cedar, and commercial real estate development.

After 2018, the gross profit in the garment processing industry has become very low, and operating costs have risen year by year. Many enterprises have shifted their production bases to Southeast Asia, and fierce competition has emerged in the domestic foreign trade processing industry, with personalized domestic demand gradually becoming prominent. Pan Jiaxiang, the factory manager of Hongdou’s suit factory, said that personalized demand poses significant challenges for production, making it difficult to streamline information flow and supply chains.

Therefore, they hope to combine their main clothing business with sensing technology and smart technology, applying IoT technology in the textile industry to create the first industrial internet platform for textiles and clothing in China.

The Hongdou Smart Suit Factory is the first 5G smart flexible factory in the clothing industry, created by Hongdou Group in collaboration with Wuxi Unicom. Through intelligent hanging systems, smart AGV delivery, intelligent sorting systems, smart cutting, and 5G AI intelligent decision-making systems, they have successfully achieved agile production and refined management. After the smart transformation and upgrade, the factory’s single consumption cost decreased by 10%, production efficiency increased by 20%, work-in-progress reduced by 30%, inventory decreased by 40%, and delivery time was cut by 50%.

Factory manager Pan said that previously, they would use manpower to replace equipment whenever possible, but now they use equipment to replace manpower whenever possible. In the past, they could only produce one or two styles a day, but now they can produce thousands of styles a day, achieving an annual capacity of over 2 million shirts and over 1 million suits. The profit margin for personalized customization can reach 30%, making it unnecessary to engage in cutthroat price competition.

After this model was established, Hongdou’s IoT division was spun off to form Hongdou Industrial Internet Co., Ltd., which operates independently. The general manager, Sun Jianming, stated that they now have a scale of about 100 people, can operate independently, and generate revenue of one to two billion yuan.

The Hongdou Industrial Internet platform has currently connected 200,000 devices and incorporated 600 ecological enterprises, serving as a benchmark industrial chain collaborative ecosystem solution, enhancing the overall collaboration and control level of the textile industry.

Currently, they have not only helped five factories of Hongdou Group complete their smart transformation but also provided external empowerment, such as helping Dongli Textile in Nantong establish a data center and helping Yueda Textile in Yancheng establish an industrial internet platform, covering the entire industrial chain from spinning and weaving to dyeing and garment making.

In conjunction with the three-year action plan for intelligent transformation and digital transformation across the province, Hongdou Industrial Internet has also provided diagnostic services for digital transformation to over 300 enterprises.

Not only Hongdou, but also enterprises from Wuxi such as Hailan Home, Weifu High-Technology, and Baotong Belt Industry have upgraded their own digitalization and then served their respective industries, becoming excellent industrial internet solution providers. Specialized service institutions such as Xuelang Smart, Hanyun Industrial Internet Platform, and Yangsheng Technology’s E-Smart energy management system have also emerged.

In December 2021, the Ministry of Industry and Information Technology released the “14th Five-Year Plan for Intelligent Manufacturing Development,” pointing out the need to accelerate system innovation, enhance new momentum for integrated development, strengthen key core technology breakthroughs, and accelerate the promotion and application of intelligent manufacturing equipment and systems. By 2025, digitalization will be basically popularized among large-scale manufacturing enterprises; by 2035, digitalization will be fully popularized among large-scale manufacturing enterprises.

According to Wuxi’s plan, it aims to help 7,000 large-scale enterprises complete digital diagnostics and conduct assessments of intelligent manufacturing maturity within a few years. Based on the standards achieved, corresponding subsidies for fixed asset investments will be provided.

Accumulating Strength, Seizing International High Ground

In 1999, Dr. Zhao Yang, who had lived in the United States for many years, returned to China to start a business. He graduated from Peking University with a degree in physics and studied for a Ph.D. in physics at Princeton University under Nobel laureate Cui Qi. After graduation, Dr. Zhao worked for seven years in a well-known multinational semiconductor company in the United States.

After investigating the entire micro-electromechanical systems industry in China, he found that Wuxi, Jiangsu, had a talent advantage in this area. Thus, he and four partners decided to establish Meixin Semiconductor (Wuxi) Co., Ltd. “It was Wuxi’s complete IC industry chain, first-class talent environment, and the various supports provided by the government that attracted me, especially Wuxi’s support for enterprises is almost always responsive to requests,” said Zhao Yang.

Since its establishment, Meixin has been dedicated to the research and development of MEMS sensors, being the first to launch a CMOS single-chip accelerometer and the first pure MEMS sensor company to be listed in the United States.

In 2006, Meixin entered the consumer electronics market, including mobile phones, digital cameras, and MP3 players, and successfully went public on NASDAQ at the end of 2007, achieving sales of 100 million yuan in 2008.

As the consumer electronics market became saturated, Dr. Zhao sold the traditional business to the listed company Huacan Optoelectronics and shifted his focus to the newly spun-off company, Xinna Sensor Systems Co., Ltd., established in 2017, which specializes in developing automotive-grade and industrial-grade MEMS sensor solutions. Their product line includes high-performance code-open inertial measurement units (IMUs), automotive-grade high-precision real-time dynamic INS positioning systems, and current sensors.

According to Lu Wei, Senior Vice President of Xinna, autonomous vehicles need to know their precise location under various conditions, including which lane they are in. Relying solely on GNSS signals is insufficient; IMUs are also needed, and they must achieve very high precision because the position of the vehicle is derived from double integration of acceleration, requiring measurements 100-200 times per second. Even small errors can accumulate significantly.

Currently, their precision has improved from a zero-bias instability of 10 degrees per hour to 1.5 degrees, with the next generation aiming for under 0.5 degrees. This equipment has wide applications in passenger vehicles, commercial vehicles, unmanned vehicles, and logistics vehicles.

Currently, Xinna has secured multiple model designations from leading domestic passenger vehicle manufacturers and achieved mass production, supporting the commercial operation of leading autonomous driving logistics heavy trucks for over 10 million kilometers. Internationally, they supply core equipment for large agricultural machinery such as autonomous driving combine harvesters and seeders to John Deere, a major American agricultural machinery company.

Lu Wei stated, “In this field, Analog Devices (ADI) was originally the industry leader. However, we respond more quickly, are more flexible, and our performance meets the requirements, with excellent delivery records and very low failure rates.”

In his view, Wuxi has a very solid semiconductor foundation, with important suppliers located locally. This year, after receiving a new request for inertial measurement units from a leading new energy vehicle manufacturer, it took them only a month and a half from receiving the request to producing a sample, which is half the usual industry cycle.

In the fields of smart vehicles, autonomous driving, and precision agriculture, the accuracy requirements for inertial navigation devices are much higher than those for consumer electronics, which is precisely Xinna’s core capability. Since officially operating independently in 2017, they have been growing at nearly double the rate each year, and they have begun shipping in the pre-installed mass production of vehicles. Xinna’s inertial navigation positioning products have an annual shipment volume of over 100,000 units, totaling over 1 million units.

Focusing on application scenarios and connecting the industrial chain, many enterprises in Wuxi have grown along this path.

Founded in April 2010, Jiangsu Tianan Smart Link Technology Co., Ltd. originally focused on smart rearview mirrors. As a participant in Wuxi’s vehicle networking phase one project, they initially operated on a self-sustaining basis. However, simply inputting traffic signal data into rearview mirrors was insufficient for the enterprise to find a profitable model. They later began developing a vehicle networking platform, aiming to become a system integrator and service provider that integrates terminal R&D, platform establishment, and operation and maintenance.

As they became more involved in the construction of Wuxi’s vehicle networking, coupled with the Ministry of Industry and Information Technology’s nationwide promotion, they have participated in the construction of three of the four national vehicle networking pilot areas and are currently applying for the national vehicle networking pilot area in Hubei (Xiangyang). The company has over 700 million yuan in orders on hand, becoming a pioneer in the 2.0 era of vehicle networking. Wuxi’s vehicle networking enterprises have successfully upgraded from product output to model output.

According to Zhang Fan, Director of the IoT Industry Development Department of Wuxi’s Industry and Information Technology Bureau, “The characteristics of IoT enterprises being ‘specialized, refined, distinctive, and innovative’ are very evident. The market is fragmented, and applications are long-tailed. Even if the market share is relatively high, it is not easy to scale up. Many enterprises in Wuxi are leading in many niche fields and are among the top in their respective areas.”

For example, in the logistics field, Zhongke Weizhi Manufacturing Technology Jiangsu Co., Ltd. has achieved the collection of equipment, core components, and key devices for Chinese intelligent manufacturing, breaking the long-standing monopoly of foreign manufacturers on high-end logistics equipment.

Wuxi Xinjie Electric Co., Ltd. ranks among the top in the Chinese small PLC market. Aerospace New Meteorology Technology Co., Ltd. is the only domestic provider of integrated meteorological detection instruments and services covering “air, land, sea, and space.” The tilt sensors produced by Wuxi Beimi Sensor Technology Co., Ltd. are used in the domestically produced large aircraft C919, with their products’ high precision and stability ensuring a fivefold increase in testing efficiency.

Wuxi has built a total of 178 national-level platform carriers, among which the National Integrated Circuit Characteristic Process and Packaging Testing Innovation Center is the first national-level manufacturing innovation center in the new generation information technology field in the province, and the Wuxi National “Chip Fire” Innovation and Entrepreneurship Base is the first national “Chip Fire” platform to settle in a prefecture-level city.

In the past three years, Wuxi’s IoT has received 14 national science and technology progress awards or above, with an average of over 2,000 invention patents granted annually. A large number of innovative achievements in high-performance MEMS sensors, heterogeneous perception fusion, and IoT terminal security protection have reached the international forefront.

Perception China Center

Since the beginning of this year, Wuxi has made systematic considerations, overall planning, and comprehensive promotion around the development of the Internet of Things and digital economy, proposing future development ideas for Wuxi’s IoT.

In the next step, Wuxi will rely on its own advantages, focusing on the era’s propositions of “a manufacturing powerhouse, a network powerhouse, and a digital China,” seizing new opportunities for digital development, and endowing new connotations to the construction of the national sensor network innovation demonstration zone in the new stage. The focus will be on the integration and innovation of “Artificial Intelligence + Internet of Things (AIoT)” as the main line, with intelligent sensors, vehicle networking, and industrial internet (one perception, two networks) as the main attack directions, accelerating the development of Wuxi’s IoT into a world-class advanced manufacturing industry cluster. On June 27 of this year, Wuxi’s Deputy Mayor Zhou Wendong stated during a research visit to the Wuxi IoT Innovation Promotion Center that as we enter the digital age, we need to inject new connotations into the development of IoT in the city, solidly promote the integrated innovation and application of IoT and artificial intelligence, strengthen and optimize the AIoT industry, and continuously contribute to the evolution of IoT technology and industrial upgrading.