Without the automotive body control module, it is hard to imagine safe and comfortable driving. This module monitors and controls many things to keep critical electronic devices running smoothly. A well-positioned software solution for the body control module (BCM) can personalize the car for users and elevate safety and comfort to a new level.

Body Control Module: Functions, Advantages, and Challenges

The rapidly growing demand for driving comfort and safety inevitably leads to the need for cutting-edge vehicle electrical system architecture. The integrated body control module system is designed to transmit and integrate the operation of all electronic modules via the vehicle bus. Strictly speaking, the BCM is an embedded system that controls load drivers and coordinates the activation of automotive electronic units.

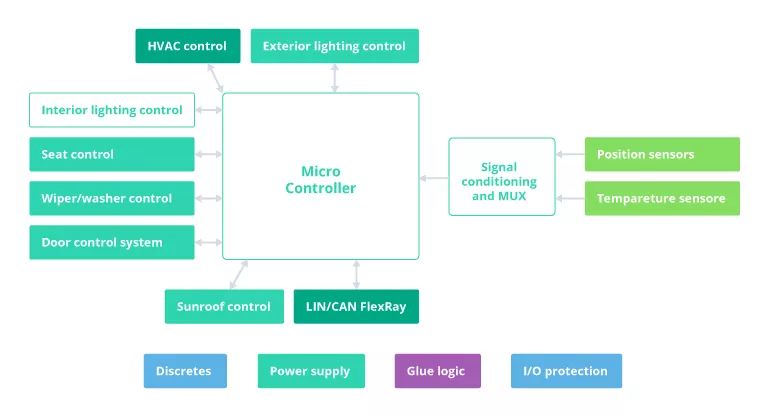

The microcontroller and connectors integrated into the BCM form the central structural unit of the system responsible for control. Operational data is transmitted to the control module through input devices. These may include sensors, vehicle performance metrics, and variable resistors.

After the module processes the data, response signals are generated through integrated output devices (including relays and solenoids). Through the output device system, the BCM coordinates the operation of various electronic systems. The body control module design diagram shows a custom circuit that acts as a gateway for connecting and integrating smaller circuits.

A general representation of the body control module:

What Are the Main Functions of BCM?

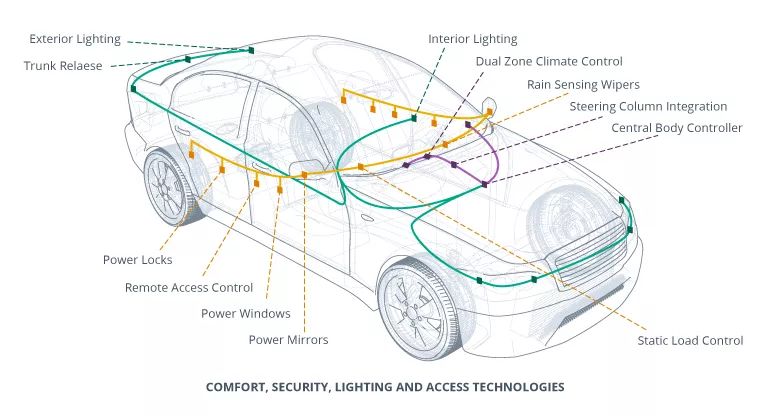

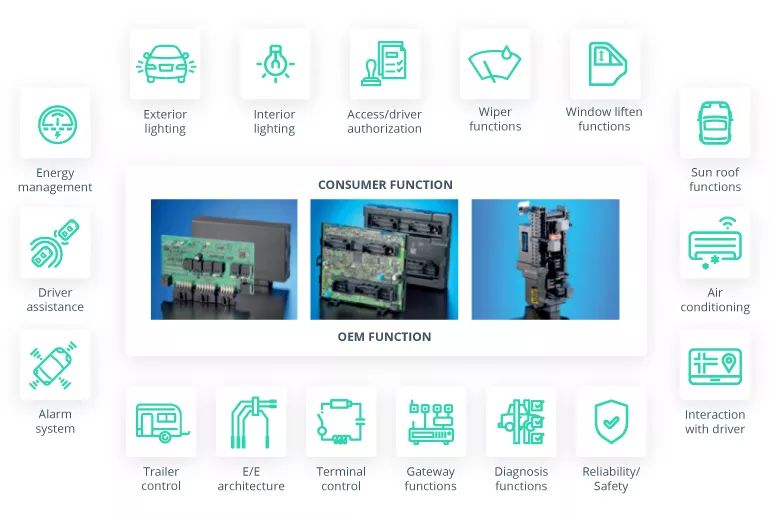

The BCM can perform a variety of functions. Output devices are managed based on data received from input devices through CAN (Controller Area Network), LIN (Local Interconnect Network), or Ethernet as a means of communication with the module and system. The electronic systems that can be integrated and controlled through the BCM include:

1. Energy management system

2. Alarm

3. Anti-theft

4. Access/driver authorization system

5. Advanced driver assistance systems

6. Electric windows

The BCM can perform multiple control-related operations simultaneously. One of the main objectives of the module is to detect faults in the operation of electrical system components. The overall functions of the body control module include:

1. Ensuring the safety, testing, and control of critical electrical loads, including lights, anti-theft devices, air conditioning systems, locking systems, and windshield wipers

2. Maintaining communication between integrated control units via the vehicle bus system (CAN, LIN, or Ethernet)

3. Acting as an integrated gateway

4. Providing a user-friendly interface for complex data management

5. BCM is challenging. But it is also very beneficial

You may have heard that writing BCM can cost a lot of money, but that is only part of the problem. Developing body control module software is indeed a very challenging and complex process. Here are the main challenges associated with BCM programming:

1. Increased performance requirements

2. Increased number of input/output processors and channels

3. Need to develop cycles for more complex modules

4. Power consumption issues in run and sleep modes

Controlling in-vehicle electronics through BCM

However, the benefits associated with BCM far outweigh these challenges and drawbacks. Once the automotive electronic units are integrated and controlled through the body control module system, you can forget about the traditional replacement and repair of automotive electronic devices. Here are the outcomes of BCM:

Fewer electronic modules and fewer cables

Reduced vehicle weight

Improved fuel efficiency

Lower manufacturing costs

Lower total cost of ownership

BCM Development: Achieving Efficiency Through Integration

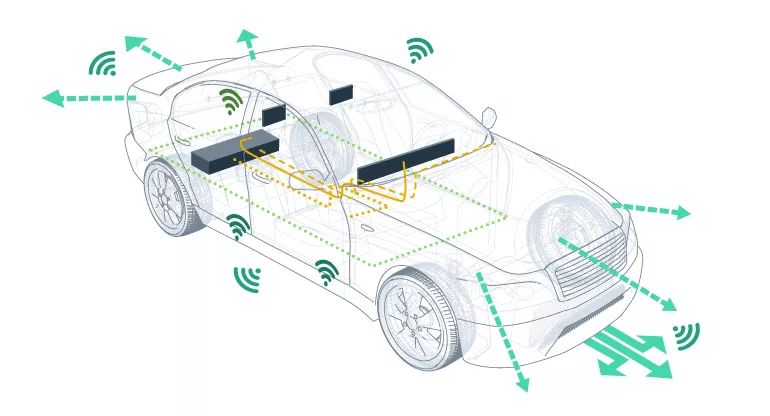

The electronic control units (ECUs) in vehicles are becoming increasingly complex and numerous. A typical modern car has about 100 ECUs designed to enhance overall performance through improved human-machine interfaces, remote information processing, engine functionality, battery life, and more. The complexity of ECUs is a major factor in developing integrated body control module software.

About 100 ECUs in modern cars help improve human-machine interfaces, remote information processing, engine functionality, and battery life.

OEMs should consider the requirements of BCM programming for their developers. Custom body control module software must be developed for each specific case. However, the general requirements for the software remain the same:

Cost-effective performance

Focus on reliability and safety

Energy efficiency

Scalability, cross-model solutions, mastering complexity

Diversified and rapid product cycles

Support for global OEM platforms and growth in new markets

Integrate advanced data management capabilities

Comply with ISO 26262, SPICE, and AUTOSAR 4.0 standards

Improved consumer and OEM capabilities using BCM

Embedded BCM Solutions

The increasingly important role of embedded software is one of the main trends defining automotive development. The demand for complex embedded automotive solutions primarily comes from the small size of these systems. By 2021, the embedded software development market is expected to reach $233 billion. Advanced embedded electronic devices enable automakers to implement new positioning navigators, diagnose potential faults, and avoid premature replacement of mechanical parts.

By 2021, the embedded software development market is expected to reach $233 billion.

Embedded solutions and the Internet of Things (IoT) are also widely used in body control module design. Today, embedded software is used to develop two main architectures for BCM: centralized and distributed. Compared to distributed architecture, centralized architecture requires fewer high-function modules, while distributed architecture builds with fewer modules and more communication interfaces. Distributed BCM architecture is more flexible but cannot achieve the ECU optimization level of centralized structures.

In the ECU network of modern vehicles

Overcoming the Challenges of BCM Development

The four major challenges faced in developing body control module software are increased performance demands, increased numbers of input/output processors and channels, the need to develop cycles for more complex modules, and power consumption issues in run and sleep modes. Several practical solutions can be applied to overcome these challenges.

Separate input/output processors can be used to offload interrupt handling. Higher performance demands can also be met by applying complex software architectures like AUTOSAR. To avoid issues related to the increased number of input/output processors and channels, eSwitch with Serial Peripheral Interface (SPI) can save Pulse Width Modulation (PWM) channels. Cost-effective Quad Flat Package (QFP) can also help address power consumption issues in run and sleep modes. Finally, to develop cycles for more complex modules, rapid prototyping services can be applied.

The increasing number of electronic control units in vehicles enhances the demand for complex software solutions that integrate, manage, and control automotive electronics through a single gateway. The automotive central body control module is an indispensable solution to meet the growing market demands of OEMs, tier-one suppliers, and end-users. BCM allows cars to use fewer electronic modules and fewer cables, thus reducing vehicle weight, improving fuel consumption and power efficiency, lowering manufacturing costs, and overall ownership costs.

Most importantly, BCM enhances safety and comfort, providing new opportunities for the development of autonomous driving technology. BCM programming is based on complex embedded software solutions that require deep expertise and advanced programming skills.

Source: Qingyan Che Lian