Click above  “Electric Knowledge Home” can be subscribed to

“Electric Knowledge Home” can be subscribed to

“Save our planet, keep it free from pollution!” This is the unified call from scientists and visionaries around the world to reduce greenhouse gas emissions. Cars powered by fossil fuel engines are the main culprits. Although there are many alternative technologies to propel vehicles, the only feasible solution at present is — electricity.

The electric propulsion technology requires the integration of a completely new architecture powertrain system in vehicles. This newly added component requires in-depth multidisciplinary research on corresponding system components. The electric vehicle system consists of electric motors, power converters, and energy storage devices such as lithium-ion batteries. This new architectural system must be optimized to maximize system efficiency, allowing vehicles to achieve the longest driving distance on a single charge. The development of electronic technology provides important momentum for reducing gas emissions in transportation.

Electric Vehicles (EV) and Hybrid Electric Vehicles (HEV)

Electric vehicles run on batteries, and hybrid electric vehicles do too, but they also utilize a fossil fuel ignition engine as an auxiliary. For the technology powering these vehicles to succeed and have a bright future, energy efficiency is key. Therefore, intelligent power management mechanisms are needed to maximize the efficiency of converting battery energy into mechanical drive force for the wheels, thus increasing the driving distance per charge while not increasing carbon emissions, ideally significantly reducing carbon emissions.

Silicon Carbide (SiC) Power in Electric Vehicles

The weight, volume, and cost of electric vehicles, as well as the driving distance per charge, are directly related to the efficiency of the power conversion system. SiC power components are very suitable for operation in the common high-temperature environments of vehicles. Let’s take a closer look at how SiC power components improve system efficiency.

Lighter weight means extended mileage. One typical way to reduce the weight, cost, and size of the power conversion system is to increase the switching frequency of the switching regulator. We all know that when operating at higher frequency points, the size and weight of active components such as inductors, capacitors, and transformers can be reduced. Therefore, let’s quickly adopt SiC solutions.

Although silicon (Si) power components can also operate at high frequencies, the advantage of SiC is its ability to handle much higher voltages than Si. SiC is a wide bandgap (WBG) semiconductor component, and a wider bandgap means a higher critical electric field (the blocking voltage in the off state). The high voltage capability of wide bandgap SiC components allows them to have lower conduction resistance, enabling faster switching speeds and unipolar operating states. Part of the principle is that its carrier frequency needs to be accelerated to higher speeds (higher kinetic energy) to overcome the wider bandgap.

Although gallium arsenide (GaA) and gallium nitride (GaN) also have high critical electric fields and are improved components for high-power solutions, SiC has other advantages. Such as higher maximum operating temperatures, high Debye temperature, high thermal conductivity (in polycrystalline SiC), fast switching in electric fields, and high carrier saturation velocity with low resistivity, facilitating the production of silicon dioxide (SiO2) which leads to lower production costs, and high threshold energy resulting in stronger radiation hardening.

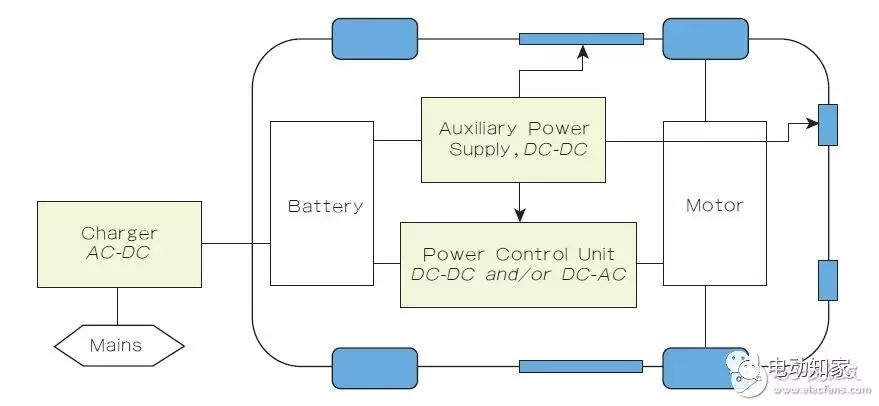

SiC components have many key applications in electric vehicles. Existing electric traction drive devices can convert 85% of electrical energy into mechanical energy to drive the wheels, which is quite efficient, but SiC can also assist in improving efficiency. Power converters can benefit from efficiency improvements because they transfer battery energy to the engine and can be used in battery charger circuits and any required auxiliary power (Figure 1).

Figure 1 SiC power components have many uses in electric vehicles.

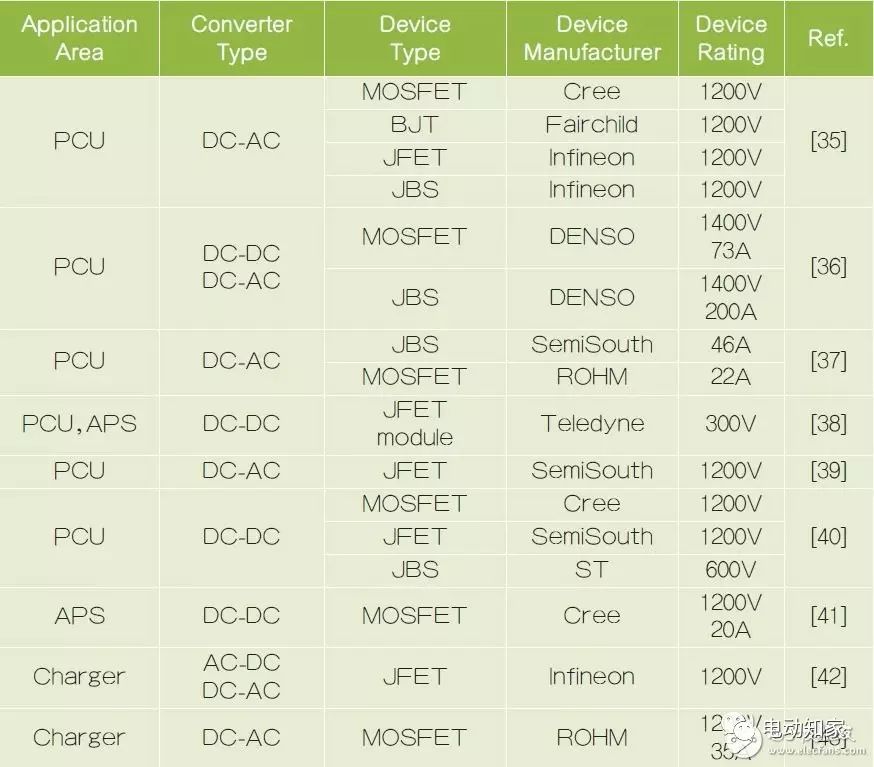

The SiC power supply that converts 750V to 27V for low-voltage electric vehicles is a great example of using SiC power components to improve electric vehicle efficiency. This architecture improved efficiency from 88% to an astonishing 96%, reduced size and weight by 25%, and did not require a fan for cooling excess heat compared to Si solutions. Table 1 shows some important applications of electric vehicle SiC power components.

Table 1 Some SiC applications in the electronic architecture of electric vehicles. (PCU refers to power control unit; APS refers to auxiliary power) (Table source: 2015 Tenth International Conference on Ecological Vehicles and Renewable Energies)

GaN Power in Electric Vehicles

GaN has also made significant contributions to power improvements in electric vehicles. Insulated gate bipolar transistors (IGBTs), which are widely used in motor drives and DC/DC control, have traditionally been based on Si products. The switching times for these designs typically range from 10k to 100kHz, while GaN components can achieve switching times in the nanosecond (ns) range and can easily operate in automotive environments at 200℃.

Like SiC, GaN components can reduce the size of inductors, capacitors, and transformers in the power architecture due to their higher switching speeds, and can also reduce overall volume and weight due to the reduction in the sizes of passive components.

We will analyze their effectiveness based on the chemical composition of electric vehicle batteries, such as lithium-based compositions and high energy density nickel-metal hydride (NiMH) batteries. As previously mentioned regarding SiC components, improving the efficiency of the power conversion architecture is also necessary to enable longer driving distances on a single charge.

The switching speed and minimum conduction resistance of Si components have reached their maximum limits, and GaN seems to be a viable solution to surpass these limits. Experiments have shown that if the switching frequency can be increased by five times, the size of inductors and capacitors can be reduced to one-fifth. Today’s GaN technology can support very high speeds.

GaN power components excel in four key areas: high-temperature operation, higher breakdown voltage, low conduction resistance, and nanosecond switching speeds suitable for higher operating frequencies. These advantages are similar to SiC, but their differences are twofold: LEDs and RF transistors have always used GaN; many Si processes are compatible with GaN processes, reducing wafer and process costs compared to the higher substrate costs of SiC.

Since reliability issues were resolved as early as 2003, today’s technology has successfully brought the first GaN high electron mobility transistor (HEMT) components into production. These are normally-on components, so a gate voltage of 0V will create an on state, while any voltage below 0V will turn off the component. Early versions used SiC substrates, and once Si substrates can be perfectly integrated with GaN, production costs can be significantly reduced. In 2014, a new cascade architecture was implemented to convert normally-on components to normally-off components.

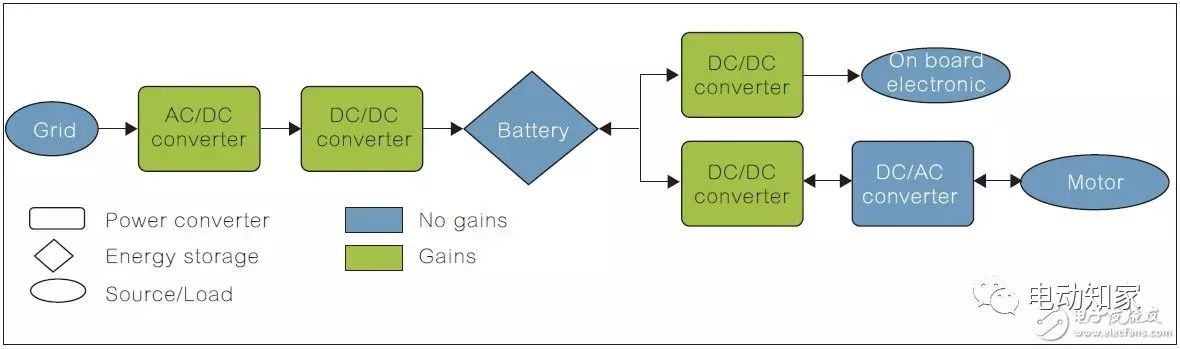

Since then, driving technology has made significant progress, with increasing integration and significant improvements in power inverters. GaN components also perform remarkably well in electric vehicle battery chargers, which are composed of AC/DC converters plus DC/DC converters. This combination acts as a power factor controller (PFC) (Figure 2).

Figure 2 Typical power architecture in electric vehicles.

Using GaN, along with higher switching speed GaN HEMTs, can achieve smaller passive components. The increased frequency leads to lower ripple current through smaller inductors, thus improving power factor and resulting in smaller, lower-cost capacitors. Lower ripple current also puts less stress on capacitors, thereby enhancing their reliability and lifespan.

In recent years, the reliability of GaN has been raised to a high standard, which is critical for its use in vehicles.

Improving the efficiency of hybrid vehicle powertrains to reduce greenhouse gas emissions

Currently, about 72% of traffic emissions are produced by cars on the road. Improving the design of hybrid vehicle powertrain systems to enhance their efficiency is a primary means of reducing emissions. One approach is to enhance the efficiency of the DC-link voltage control architecture, which means first improving the efficiency of the power converters in series hybrid vehicle powertrains.

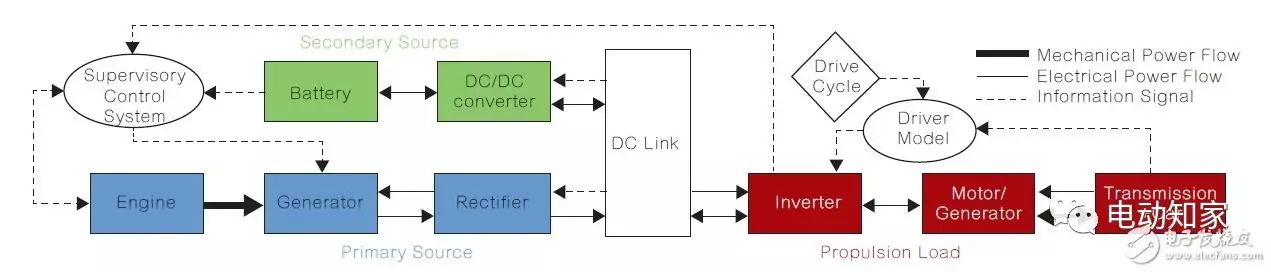

The DC-link typically connects three powertrains: a primary power source composed of three-phase rectifiers; a secondary power source composed of a dual active bridge (DAB) DC/DC converter; and a propulsion load composed of three-phase inverters (Figure 3), which are associated with series hybrid vehicles.

Figure 3 Block diagram of the powertrain in hybrid vehicles.

In designs where the DC-link and battery voltages are unequal, an intermediate solution in the DC/DC converter is necessary. An IEEE paper titled “Voltage Control for Enhanced Power Electronic Efficiency in Series Hybrid Electric Vehicles” describes many methods for studying different architectures and schemes for various DC-link voltages and DC/DC converter controls.

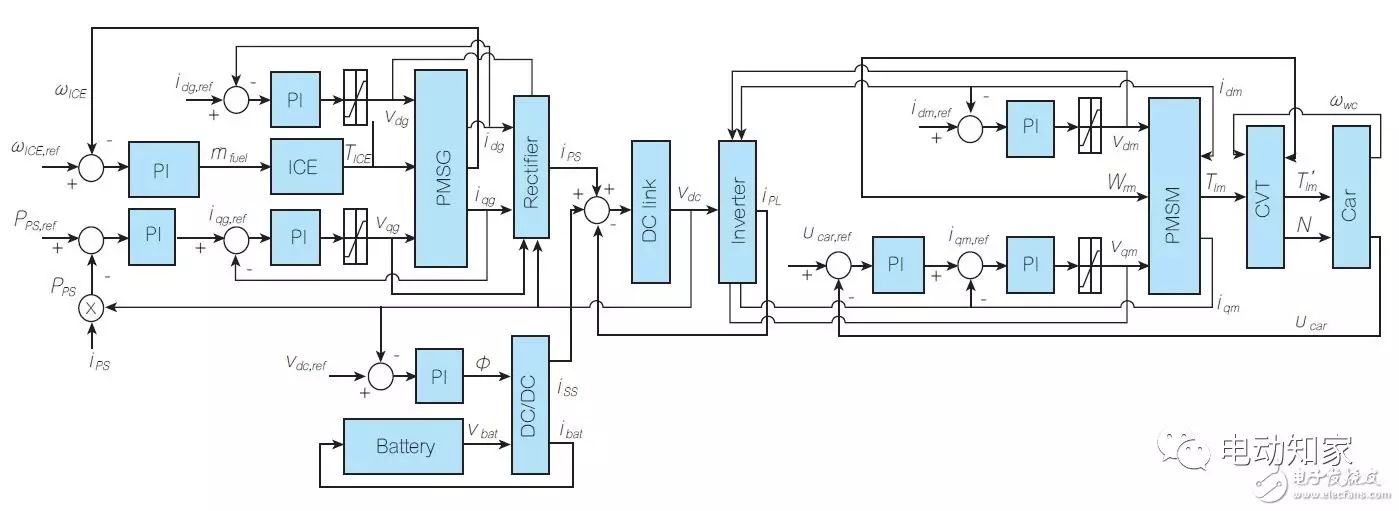

The following will discuss the proportional control law, which is used to control the dynamic DC-link voltage to achieve phase shifts between the gate switching waveforms of the DAB DC/DC converter. This converter is located between the DC-link and the battery in a series hybrid vehicle powertrain, as shown in Figure 4. In this case, the controller reduces power losses in both the DC/DC converter and the entire powertrain.

Figure 4 Interconnection diagram of the hybrid vehicle powertrain in the control schematic. The engine (ICE), continuously variable transmission (CVT), permanent magnet synchronous motor (PMSG), or the primary power source of the hybrid vehicle, and the permanent magnet synchronous motor (PMSM) or propulsion load of the hybrid vehicle are key components of the system shown in the figure.

In this model, the diesel engine is the primary power source for the hybrid vehicle, while the DC battery serves as the secondary power source. The management control system (SCS) controls the power ratio provided by these two power sources based on the battery state of charge (SOC) and motor load.

In fact, in this series hybrid vehicle, the DC-link voltage will constrain the conditions imposed on the ideal operating region of the PMSM and PMSG corresponding to the modulation index, thus avoiding situations that lead to signal distortion and reduced system efficiency due to over-modulation. Keeping the modulation index close to 1 can improve the overall efficiency of the power circuits in the powertrain, maximizing the efficiency of inverters and rectifiers, where the switching process is the main factor of efficiency loss, so reducing the switching voltage can improve efficiency.

This mechanism, which can minimize power losses, is the continuous zero-voltage switching (ZVS) mechanism, which is most suitable for vehicles with high hybrid factors (HF), especially in urban environments. The hybrid factor refers to the ratio of installed power from the power source to the total installed power. This hybrid factor affects fuel consumption in hybrid vehicles.

Automotive Inverters

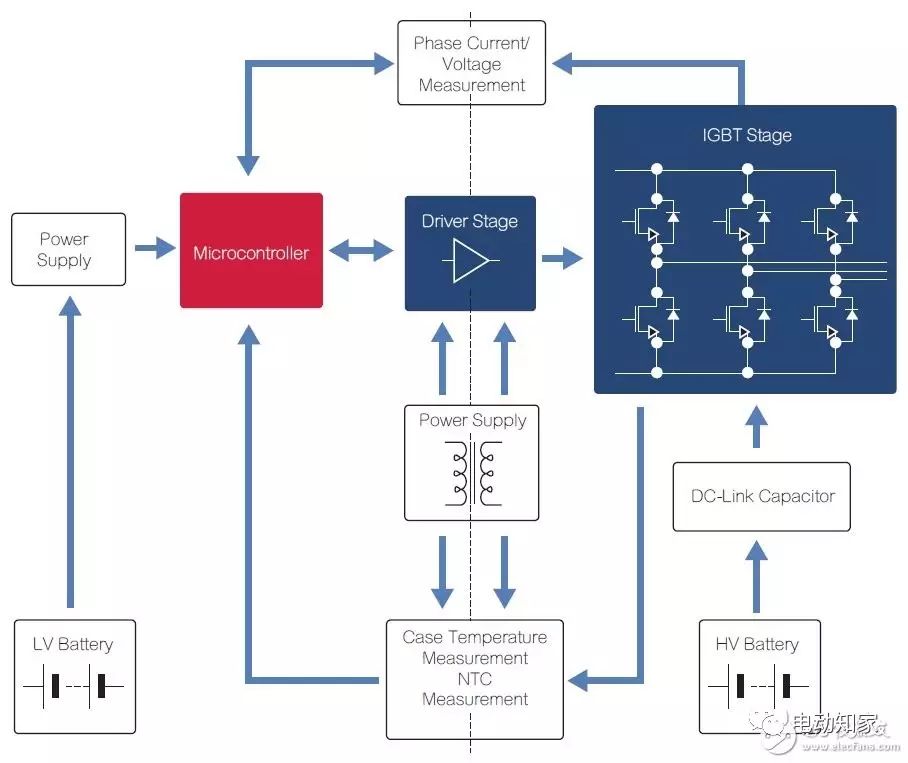

The main power inverter controls the motors in the power transmission system and is an important device in hybrid/electric vehicles. The power inverter functions similarly to the engine management system (EMS) in combustion engine vehicles, determining driving behavior. This inverter is applicable to any motor, such as synchronous, asynchronous, or brushless motors, controlled by an integrated electronic PCB. This PCB is specially designed by automotive manufacturers to minimize switching losses and maximize thermal efficiency. Another function of the inverter is to capture energy released during regenerative braking and feed it back to charge the battery. The driving distance of hybrid/electric vehicles is directly related to the efficiency of the main inverter (Figure 5).

Figure 5 Infineon’s main inverter framework in hybrid/electric vehicles. (Image source: Infineon)

Dual Voltage Battery System

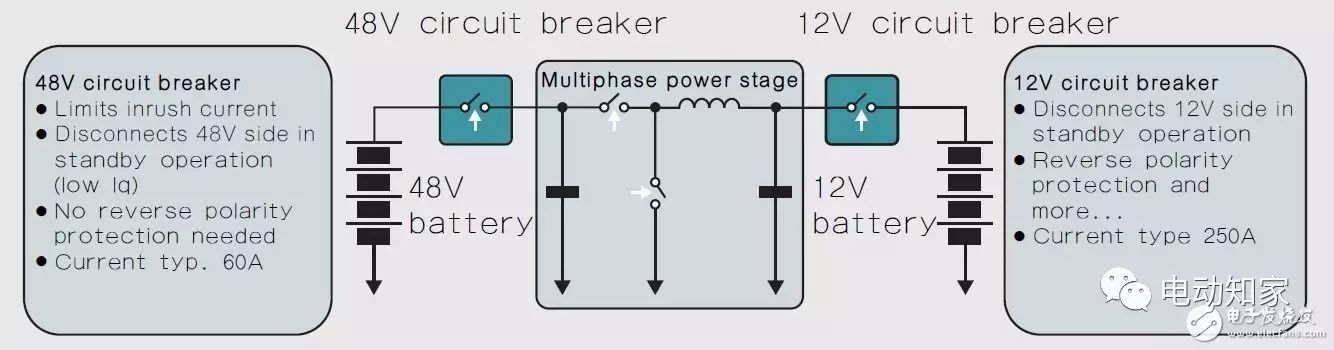

Managing batteries in hybrid and electric vehicles requires high-voltage technology. The dual voltage system that combines 12V and 48V batteries requires bidirectional DC/DC conversion, as shown in Figure 6, aimed at circuit protection and supporting structured functions.

Figure 6 Bidirectional DC/DC converter from 48V to 12V.

Additionally, there is usually a single-phase 3.5kW or 7kW on-board charger module (OBCM) in automotive architecture design, used to charge electric vehicles or plug-in hybrid electric vehicles (PHEVs) from the grid. Conversely, electric vehicles and plug-in hybrid electric vehicles can serve as energy sources and can be integrated into smart grids with renewable energy as storage devices. Smart grid operations consider smart charging and discharging for electric vehicles and plug-in hybrid electric vehicles, which is why the OBCM must be a bidirectional DC/DC charger.

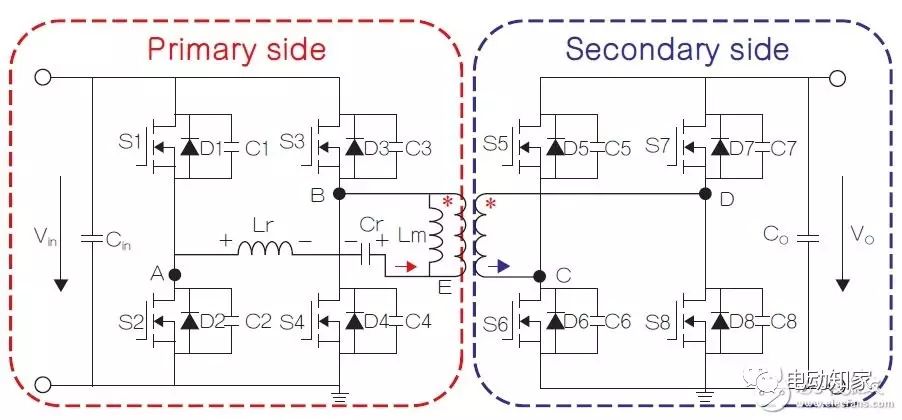

The optimal architecture for this design is a boost series resonant bidirectional topology, as shown in Figure 7. It operates above the resonant frequency and has zero-voltage switching capability, achieving maximum power transfer performance at minimal switching frequency points. Compared to unidirectional power flow converters, this technology replaces diode rectifiers with MOSFET rectifiers. This solution also has higher efficiency and wider battery capacity. A major drawback of this architecture shown in Figure 7 is that the rectifier bridge has significant losses when turned off, which must be addressed in future designs.

Figure 7 Designers sometimes use modulated DAB converters to control simple high-frequency isolation; the advantage of this architecture is lower component stress; its main drawback is that ZVS cannot be extended across the entire output range, especially under light load conditions. This diagram shows that the boost series resonant bidirectional converter is a better architecture.

Delphi Integration and Wiring

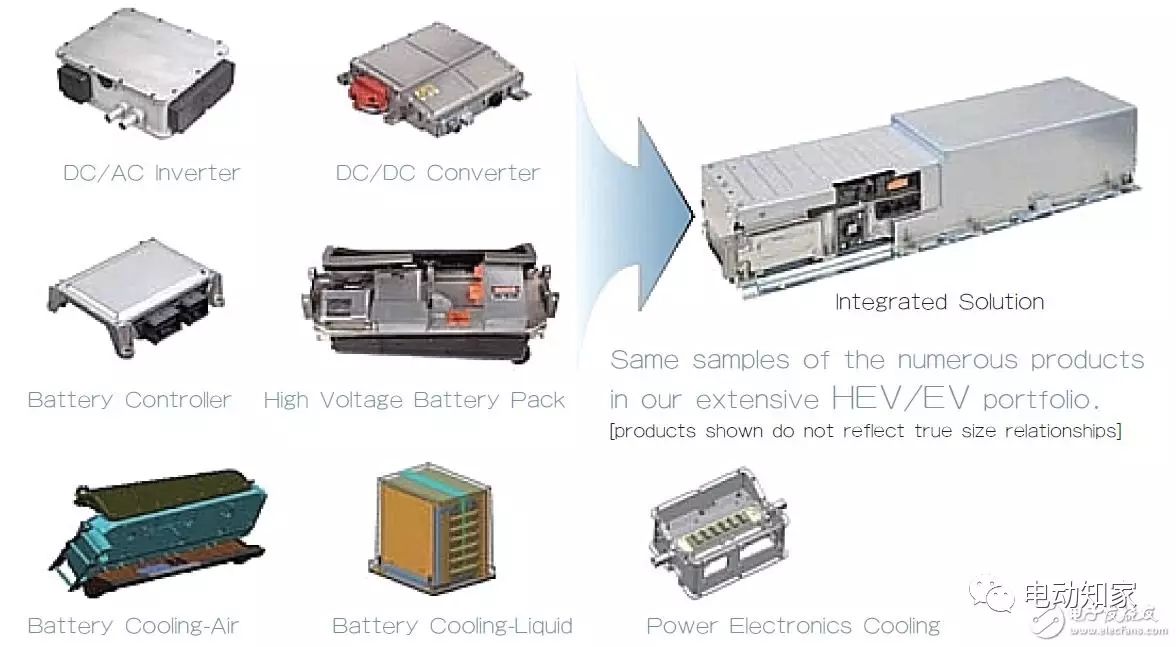

Delphi has integrated all the components discussed in this article along with several other power electronic components for hybrid electric vehicles (Figure 8), which is impressive.

Figure 8 Delphi achieves high integration in hybrid/electric vehicles.

Using appropriate internal connectors in hybrid/electric vehicles is also very important (Figure 9).

Figure 9 A key element in hybrid/electric vehicles is minimizing mass. Delphi has made significant innovations in small gauge cable technology, insulation materials, and lighter copper substitutes (such as aluminum or some special proprietary alloys). (Image source: Delphi)

Electric Wheel Drive Systems

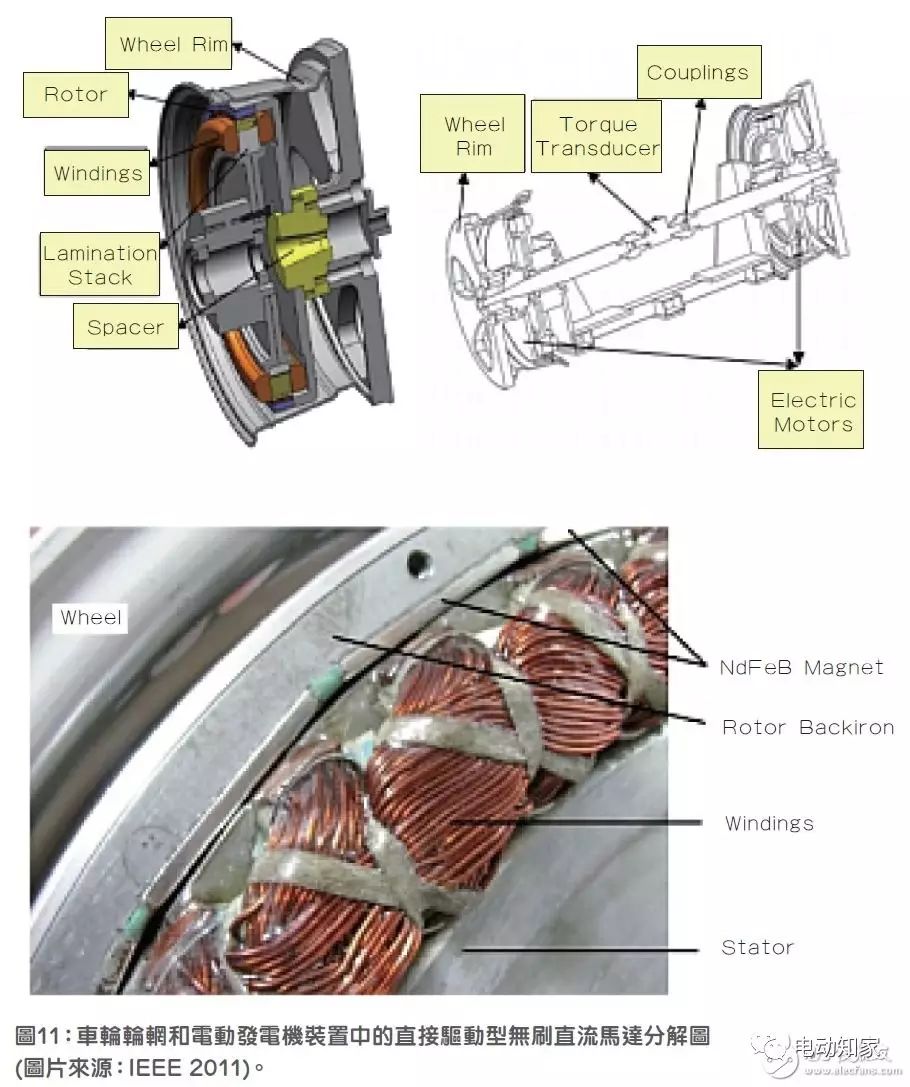

The article “Design and Implementation of an Electric Drive System for In-Wheel Motor Electric Vehicle Applications” recommends a motor drive system suitable for hybrid and electric vehicles. A Matlab SIMULINK model has been successfully developed for a motor drive hybrid vehicle that provides computational performance. Two 14kW DC brushless motors have been designed and manufactured based on literature, installed in the wheel rims of the hybrid vehicle.

Figure 10 A brushless DC motor in a rear wheel.

Additionally, two independently driven rear wheels have also been installed on a Fiat Linea vehicle. By detecting the angle of the steering wheel, electronic control technology replaces the mechanical differential. The power control system of the vehicle and the electronic control unit (ECU) communicate via the CAN bus, successfully cascading the power-driven rear wheels and the ICE-driven front axle.

This design opts for brushless DC motors with centralized coils due to their low power-to-weight ratio and high efficiency, making them easy to control.

Figure 11 Breakdown of direct drive brushless DC motors in wheel rims and electric generator devices.

Drivers

The power driver for brushless DC motors consists of an integrated power module (IPM), an 8-bit microcontroller, and an electronic control system. Driver software is developed for IGBT commutation control and pulse width modulation (PWM) voltage control. The system features optical isolation, current and temperature protection, and also embeds speed, current, and voltage sensors.

In conclusion, this article has introduced some recent developments in power management for electric and hybrid vehicles. More developments are sure to emerge in the future, further improving these systems for the benefit of the planet. (Source: EDN Taiwan)