Preparation of Flexible Sensors for Thoracic and Abdominal Respiration Detection Needs

Chen Yuanmin1, Zhao Mengyu1, Qiu Siyuan1, Li Yajiao1,

Wang Wenhao1, Wang Hao3, Zhu Guangying3

(1. School of Mechanical and Electrical Engineering, Beijing University of Chemical Technology, Beijing 100029;

2. State Key Laboratory of Organic-Inorganic Composite Materials, Beijing 100029;

3. Department of Radiation Oncology, China-Japan Friendship Hospital, Beijing 100029)

First Author:

Chen Yuanmin (1998-), Male, Master’s student, mainly engaged in polymer material processing and preparation, [email protected]

Corresponding Authors:

Zhu Guangying (1963-), Male, PhD, Chief Physician of the Department of Radiation Oncology, China-Japan Friendship Hospital, mainly engaged in precision radiotherapy and comprehensive treatment of lung cancer, [email protected]Sun Jingyao (1991-), Male, Assistant Professor, mainly engaged in research on advanced manufacturing of polymers, Email: [email protected]

DOI:10.19491/j.issn.1001-9278.2025.

06.008

Cite this article:

Chen Yuanmin, Zhao Mengyu, Qiu Siyuan, et al. Preparation of flexible sensors for requirement of thoracic and abdominal respiration detection[J]. China Plastics, 2025, 39(06):36-41.

CHEN Yuanmin, ZHAO Mengyu, QIU Siyuan, et al. Preparation of flexible sensors for requirement of thoracic and abdominal respiration detection[J]. CHINA PLASTICS, 2025, 39(06):36-41.

0

Introduction

With the continuous development of medical technology, respiratory-gated radiotherapy has become an important part of precision medicine. Respiratory gating technology is a technique that controls the impact of respiratory motion on the target area by monitoring the patient’s breathing. A suitable respiratory threshold is set, and when the tumor is within the threshold range, the radiotherapy machine is activated; when the tumor exceeds the threshold range, the radiotherapy machine is turned off. This ensures that radiotherapy is only performed when the tumor is in the most stable position, improving the precision and effectiveness of radiotherapy while reducing damage to normal tissues. This treatment method requires patients to undergo certain breathing training before treatment and to hold their breath during treatment, cooperating with the doctor. Therefore, a flexible, stretchable sensor with good compliance, sensitivity, wearability, and stability over a large strain range, along with its supporting sensor signal acquisition system and human-computer interaction system, is needed to achieve real-time monitoring of human respiratory signals and human-computer interaction functions. Flexible sensors have a wide range of applications in healthcare, bringing many innovations to the medical field with their unique flexibility and extensibility. For example, flexible sensors can be integrated into soft fabrics or patches to monitor patients’ physiological indicators such as heart rate, respiratory rate, skin temperature, blood pressure, and blood oxygen saturation; flexible sensors can also be embedded in rehabilitation devices to monitor patients’ muscle movements, joint angles, and body posture. By accurately obtaining this data, healthcare professionals can better understand patients’ rehabilitation progress and adjust rehabilitation plans based on real-time data; in the field of sports health, flexible sensors can be used for the smartization of sports equipment and monitoring of fitness equipment; in medical devices, flexible sensors can achieve intelligent control, such as smart infusion and smart oxygen supply, improving the efficiency and quality of medical services. Different manufacturing methods are available for flexible sensors depending on the application scenario, including deposition, composite, pressing, and spraying methods. Each processing method has its own advantages and disadvantages and applicable ranges. When selecting a processing method, comprehensive consideration should be given to specific application requirements, material characteristics, and process conditions. Meanwhile, with the continuous advancement of technology and the expansion of applications, the processing methods for flexible sensors are also continuously innovating and optimizing. Our team uses a spatial confinement forced assembly method to prepare flexible stretchable sensors. This method is a technique that forces the self-assembled network to be compacted to enhance target performance. By applying temperature and external force conditions, conductive fillers are forced to assemble with flexible substrate materials by restricting their degrees of freedom, which can greatly reduce the distance between conductive particles. By enhancing the degree of self-assembly with external force, the conductive network becomes dense and stable under the action of this external force. The flexible stretchable sensors prepared by this method exhibit good compliance, sensitivity, wearability, and stability over a large strain range.

To address the issue of detecting small respiratory amplitudes and the complexity of commonly used detection deployments and operations, this paper will focus on improving the stretchability, sensitivity, stability, and wearability of flexible sensors, using the spatial confinement forced assembly method and screen printing method to prepare layered structure sensors, and integrating the flexible sensors into straps for measuring thoracic and abdominal respiratory amplitudes during respiratory training in respiratory-gated radiotherapy.

1

Experimental Section (Excerpt)

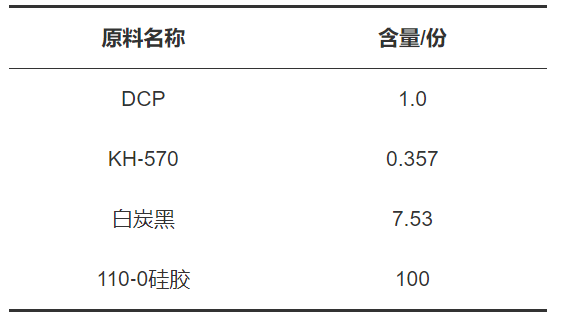

Preparation of flexible stretchable sensors: The composition of the outer insulating material is shown in Table 1. DCP, as a crosslinking agent for carbon black and methyl vinyl silicone rubber polymerization, can improve its processing performance and heat resistance. KH-570 enhances the bonding, adhesion, and compatibility between inorganic materials and organic polymers through bidirectional chemical reactions, thereby improving the mechanical properties, bonding strength, and water resistance of the composite material. White carbon black, with its porous and good insulating properties, can serve as the outer insulating material for flexible sensors. 110-0/110-2 silicone rubber is a synthetic rubber characterized by good flexibility, high heat resistance, and excellent mechanical properties.

Table 1 Composition of Outer Insulating Material

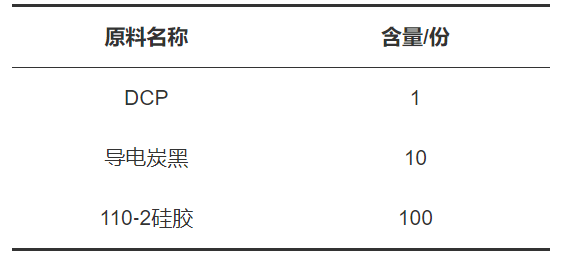

The composition of the inner conductive material is shown in Table 2. Among them, ECB has a low resistivity and good conductivity, making it suitable as the composite electrode material for the inner layer of the flexible sensor.

Table 2 Composition of Inner Conductive Material

The preparation of the flexible sensor adopts the spatial confinement forced assembly method, which is a technique that forces the self-assembled network to be compacted to enhance target performance. By applying temperature and external force conditions, conductive fillers are forced to assemble with flexible substrate materials by restricting their degrees of freedom, which can greatly reduce the distance between conductive particles. By enhancing the degree of self-assembly with external force, the conductive network becomes dense and stable under the action of this external force. The completed sensor has a “sandwich” structure, with insulating layers on the top and bottom and a conductive layer in the middle.

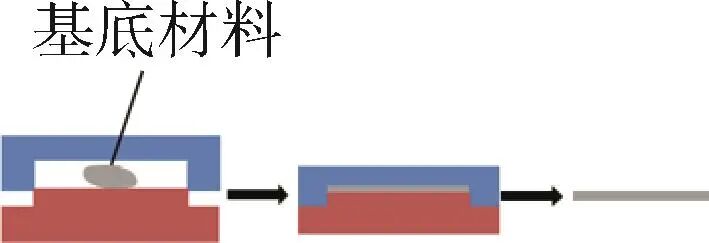

Two pieces of 304 stainless steel plates with an outer diameter of 100 mm × 240 mm and an inner diameter of 60 mm × 200 mm were taken, and the outer insulating material was placed in the hollow part between the two plates. The insulating layer material was cold-pressed using a PTFE film of 140 mm × 280 mm on both sides, as shown in Figure 1, with a pressure of 3 MPa for 3 minutes. After cold pressing, the sample was taken out, the upper PTFE film was peeled off, and the excess material was trimmed along the inner diameter of the 304 stainless steel plate.

Figure 1 Schematic Diagram of Insulating Layer Preparation

One piece of 304 stainless steel plate with an outer diameter of 100 mm × 240 mm and an inner diameter of 60 mm × 200 mm was taken, and the inner conductive material was placed in the hollow part of the 304 stainless steel plate. The sample was covered with PTFE films of 140 mm × 280 mm on both sides and placed in a hot press for imprinting treatment at a temperature of 210 °C, with a pressure of 3 MPa for 10 minutes. After hot pressing, the sample was cooled in an environment of 20 °C for 5 minutes. The cooled sample was then trimmed to obtain the middle conductive layer, as shown in Figure 2.

Figure 2 Pattern of the Middle Conductive Layer

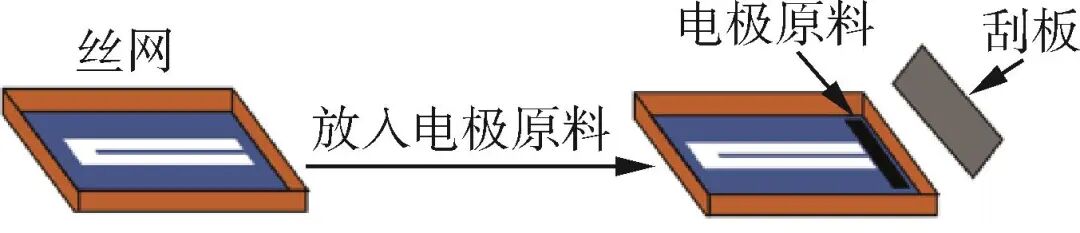

5 g of carbon ink (mainly composed of graphite, carbon powder, resin, hardener, etc., a single-component thermosetting conductive ink that can form a resistive conductor after curing) was taken, and 0.5 g of oil (used to adjust the ink viscosity, enhance printability, dilute coloring power, and increase print area) was added. The two were mixed in a vacuum mixer for 3 minutes at a speed of 2000 r/min to obtain the conductive material. The material was placed on a 200 mesh screen and scraped repeatedly 5 times with a scraper to complete the printing of the sensing unit with a thickness of 13 μm, as shown in Figure 3.

Figure 3 Schematic Diagram of Conductive Layer Preparation by Screen Printing Method

Two pieces of outer insulating material and one piece of inner conductive material were arranged in a sandwich structure in a mold made of 304 stainless steel with an outer diameter of 100 mm × 240 mm and an inner diameter of 60 mm × 200 mm. The sample was covered with PTFE films of 140 mm × 280 mm on both sides. The sample was placed in a hot press for imprinting treatment at a temperature of 210 °C, with a pressure of 1 MPa for 20 minutes. After hot pressing, the sample was cooled in an environment of 20 °C for 3 minutes. The upper PTFE film was peeled off, and the sample was trimmed along the inner diameter of the stainless steel plate to obtain the flexible sensor. When monitoring human chest respiration, different individuals have different chest circumferences, and the sensor needs to be pre-stretched before the start of respiratory training. The prepared sensor is packaged in a graduated strap and connected to the corresponding signal acquisition system. A polyamide strap is used instead of an elastic band to prevent deformation of the strap from interfering with the measurement results. The final respiratory monitoring sensor strap is shown in Figure 4.

Figure 4 Actual Wearing Effect of Thoracic and Abdominal Respiration Flexible Sensor

Through preliminary testing of the flexible stretchable sensors prepared by the spatial confinement forced assembly method and the screen printing method, it was found that the flexible stretchable sensors prepared by the spatial confinement forced assembly method have the characteristic of large deformation, while the flexible stretchable sensors prepared by the screen printing method have high sensitivity. However, the sensors prepared by the screen printing method can only be used in environments with small strains. After respiratory testing, the change in chest and abdominal circumference during human respiration is 2% to 10%, and this range of change requires the sensor to adapt to a working environment with a large deformation measurement range, thus the flexible stretchable sensor prepared by the spatial confinement forced assembly method was selected.

The signal acquisition of the flexible sensor is composed of a bridge voltage divider circuit and an Arduino Uno development board data acquisition system; a signal generator (AFG2000), oscilloscope (TBS1000S), filter (LTC1564), and frequency response analyzer (Venable 5140) are used to process the signals, and the sensitivity, linearity, response time, hysteresis, and repeatability of the flexible sensor were tested to analyze the impact of these performances on the sensor’s measurement of human thoracic and abdominal respiration.

2

Results and Discussion

In 1856, British physicist Lord Kelvin discovered the electrical resistance strain effect of metallic materials—when metallic materials are stretched or compressed under external forces, their resistance values change accordingly. The calculation of the resistance of metallic materials is shown in Equation (1). Where R is the resistance value (Ω), ρ is the resistivity (Ω/m), L is the length of the metallic material (m), and S is the cross-sectional area of the metallic material (m2).

The flexible stretchable sensor prepared in this paper is a resistance (strain) sensor based on the semiconductor strain effect, which is similar to the metallic strain effect, using the resistance changes caused by the changes in chest and abdominal circumference during breathing to monitor respiratory signals. The use of semiconductor strain gauges has the advantage of being small in size, highly sensitive, and having low mechanical hysteresis, making them more suitable for reading human-related vital sign signals than metallic strain gauges. After respiratory testing, the change in chest and abdominal circumference during human respiration is 2% to 10%. After binding the flexible sensor to the human body, under the influence of respiratory stretching stress, the changes in the conductive fillers inside the flexible stretchable sensor during stretching lead to changes in resistance, which can be measured by the bridge voltage divider circuit due to the voltage changes caused by the changes in sensor resistance.

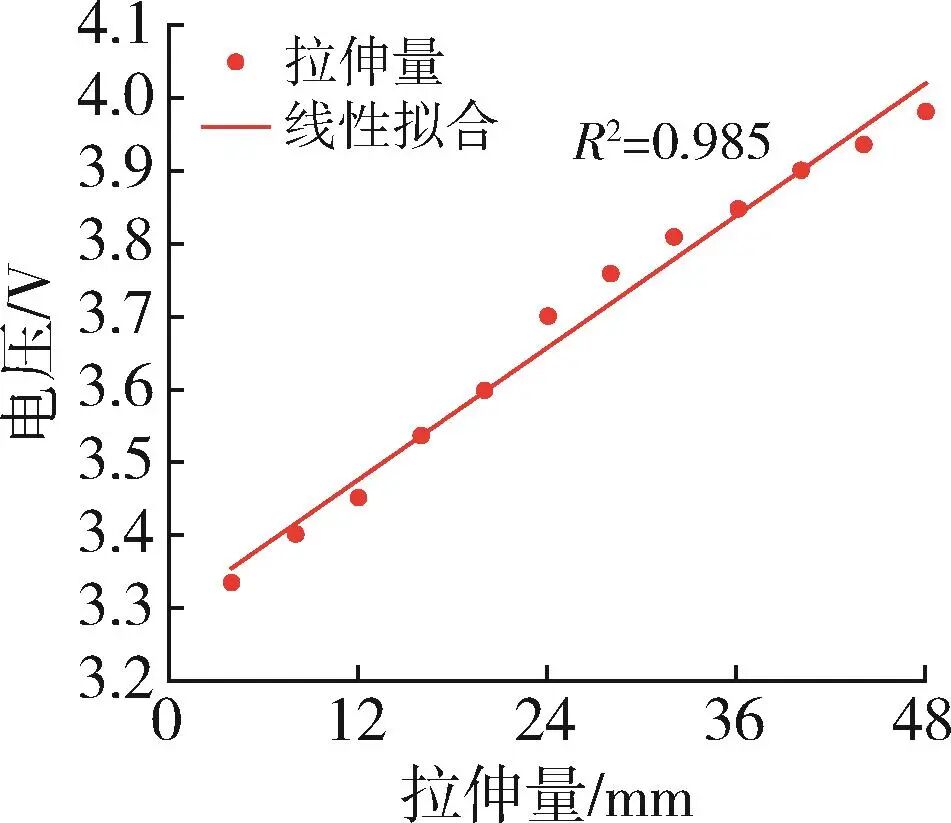

Through stretching, the limit stretch of the sensor is approximately 26% of its original length, thus using a 2% strain as the unit for measurement, the output voltage of the flexible sensor was measured in the range of 0% to 24% strain, resulting in the output voltage curve of the flexible stretchable sensor as shown in Figure 5. By performing linear fitting on the scatter plot, the sensitivity of the flexible sensor in the range of 0% to 24% strain was obtained as K=0.015 V/mm, with a linearity of 0.985, indicating that the sensor’s performance is stable within the 0% to 24% strain range. In respiratory detection, the sensitivity and linearity of the sensor significantly impact the accuracy and reliability of the detection. The middle layer of this sensor uses carbon black as a semiconductor material, and conductive carbon black has a low resistivity, which can enhance the sensor’s sensitivity. Additionally, the insulating layer material, white carbon black, is a porous silica with a high specific surface area and porous structure, which also helps improve the sensor’s sensitivity, allowing it to respond quickly and accurately to small deformations, ensuring the reliability of signal acquisition during respiratory monitoring training.

Figure 5 Voltage Curve at Different Stretching Amounts

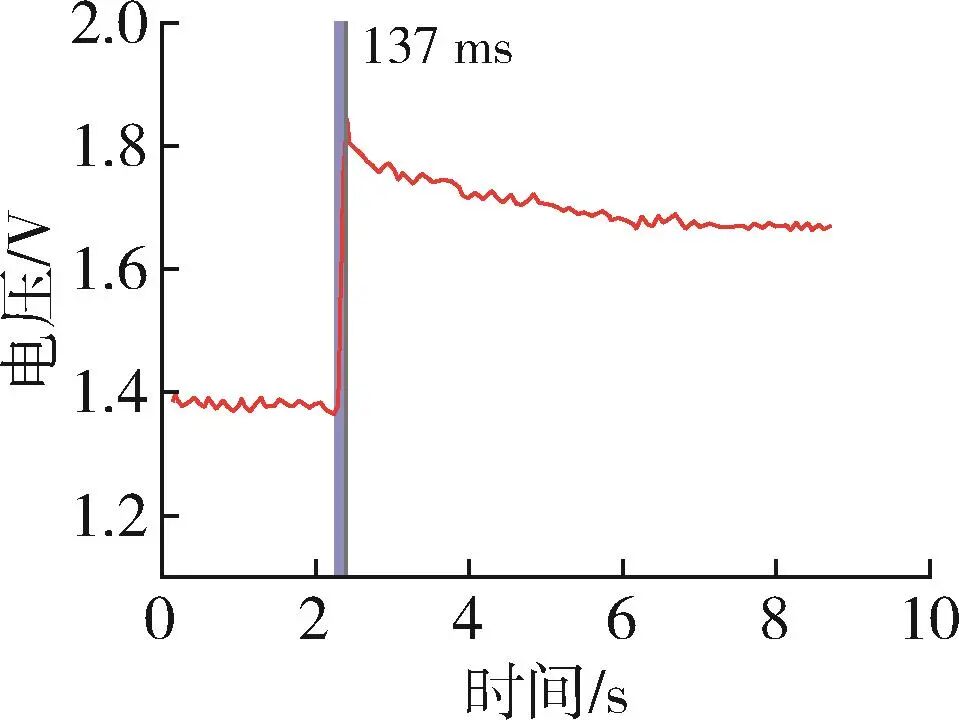

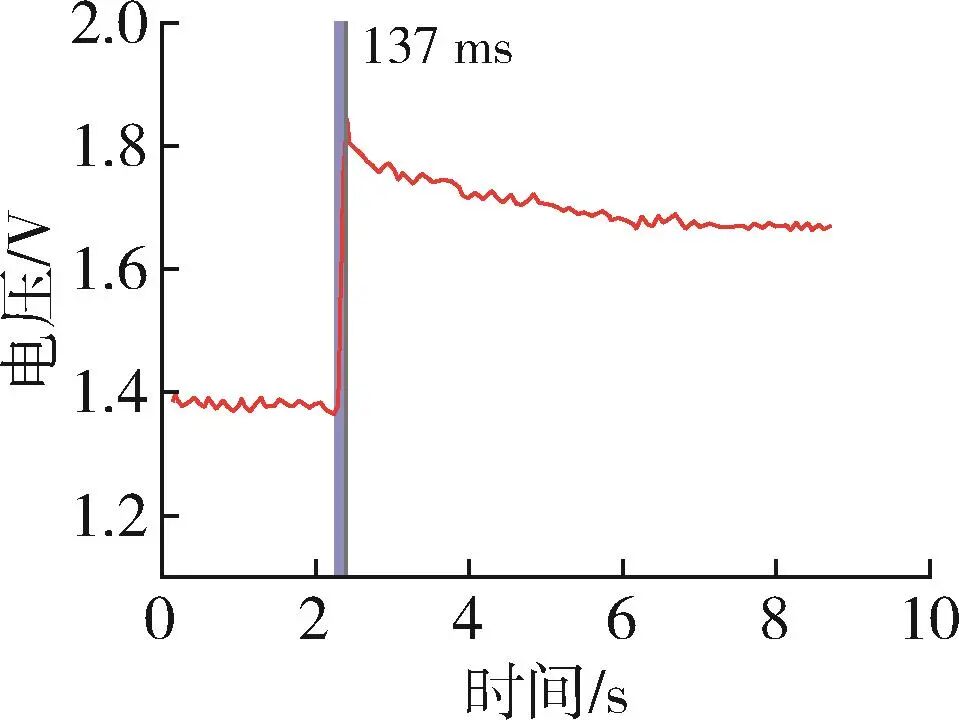

The response time of the sensor refers to the time it takes for the sensor to output a response after being stimulated by external forces. For applications that require real-time monitoring of patient respiration, the response time of the sensor is particularly important; a shorter response time means that the sensor can respond more quickly to changes in input signals, thus providing more timely and accurate data. During human respiration, when the thoracic cavity expands, the sensor is in a stretched state, at which point the distance between the conductive fillers inside the sensor rapidly increases, reducing the connectivity of the conductive filler network, lengthening the current path, and thus increasing resistance. A 10% strain test was conducted on this flexible stretchable sensor, and the response time Tr was relatively short, approximately 137 ms, as shown in Figure 6. After respiratory testing, the response time of this sensor meets the requirements for collecting respiratory signals during respiratory training.

Figure 6 Response Time of the Sensor

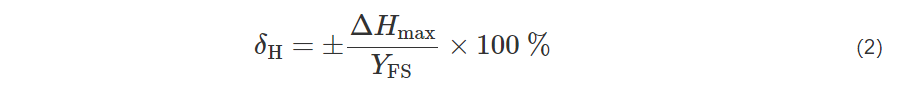

A 10% strain test was conducted on this sensor, and the results are shown in Figure 7, where ∆Hmax=0.051 V, YFS=48 mm, with the calculation formula shown in Equation (2), where δH is the return error, ∆Hmax is the maximum difference in output values between the forward and reverse strokes, and YFS is the full-scale input. The return error δH=1.06%, indicating that the sensor has a low hysteresis, which helps improve the real-time measurement. Good hysteresis also reduces errors caused by time delays, mainly because the spatial confinement forced assembly method used to prepare the sensor can greatly enhance the density of the conductive fillers, helping to form a continuous and stable conductive network, thus reducing the jumping resistance and hysteresis of the current between fillers. This density can also more evenly distribute mechanical stress, improving the consistency of the composite material and reducing local stress concentration.

Figure 7 Difference Between Forward and Reverse Strokes

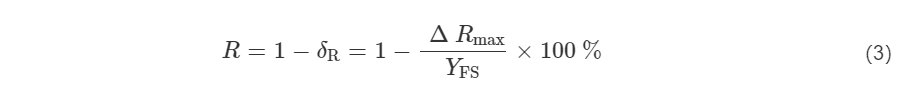

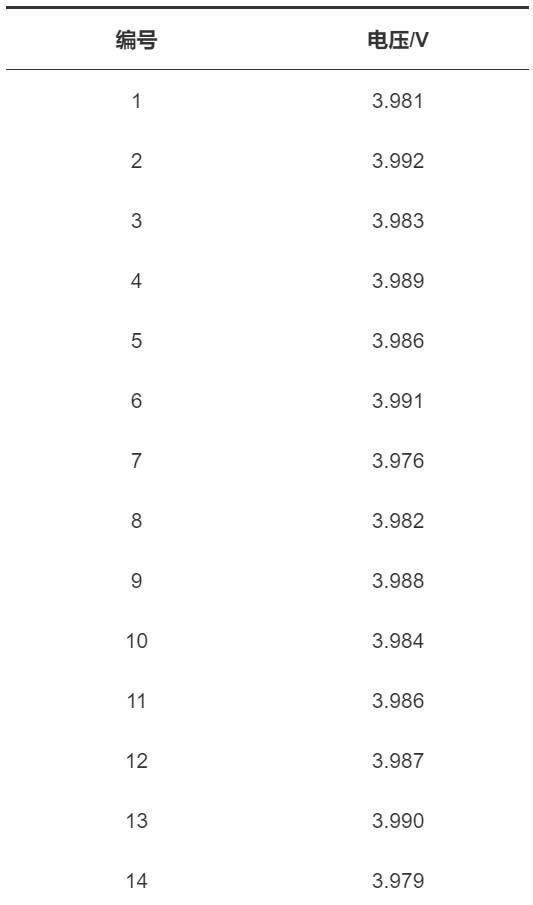

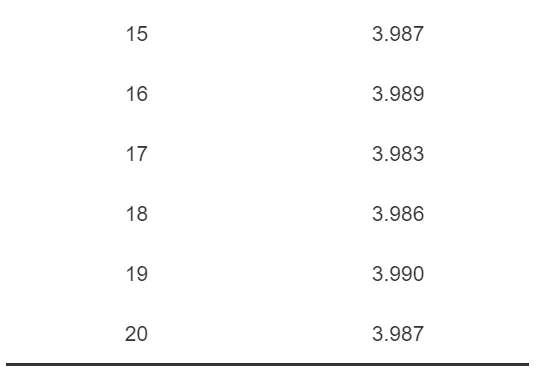

The repeatability of the sensor refers to its ability to continuously output the same response under the same operating conditions when the input varies continuously across the entire measurement range. Repeatability can be calculated using the standard deviation formula [Equation (3)], where δR is the non-repeatability index, and the repeatability R is 1-δR, with ∆Rmax being the maximum error between the output values corresponding to the same input point in the same direction, and YFS being the full-scale input. From Table 3, ∆Rmax= (3.992-3.976) V = 0.016 V, with full-scale input YFS= 48 mm, thus the non-repeatability index δR is calculated to be 3.33%, resulting in a repeatability of 96.67% for the sensor.

The repeatability of the sensor refers to its ability to continuously output the same response under the same operating conditions when the input varies continuously across the entire measurement range. Repeatability can be calculated using the standard deviation formula [Equation (3)], where δR is the non-repeatability index, and the repeatability R is 1-δR, with ∆Rmax being the maximum error between the output values corresponding to the same input point in the same direction, and YFS being the full-scale input. From Table 3, ∆Rmax= (3.992-3.976) V = 0.016 V, with full-scale input YFS= 48 mm, thus the non-repeatability index δR is calculated to be 3.33%, resulting in a repeatability of 96.67% for the sensor.

Table 3 Voltage Values Corresponding to Full-Scale Input

A 1-minute breathing test was conducted on a normal male, with each inhalation and exhalation amplitude and time kept as consistent as possible, resulting in the sensor capturing the test results of four consecutive cycles, as shown in Figure 8. Through the repeatability index and the test results of four consecutive cycles, it can be seen that the amplitude and frequency of changes are almost consistent, indicating that the sensor has good repeatability.

A 1-minute breathing test was conducted on a normal male, with each inhalation and exhalation amplitude and time kept as consistent as possible, resulting in the sensor capturing the test results of four consecutive cycles, as shown in Figure 8. Through the repeatability index and the test results of four consecutive cycles, it can be seen that the amplitude and frequency of changes are almost consistent, indicating that the sensor has good repeatability.

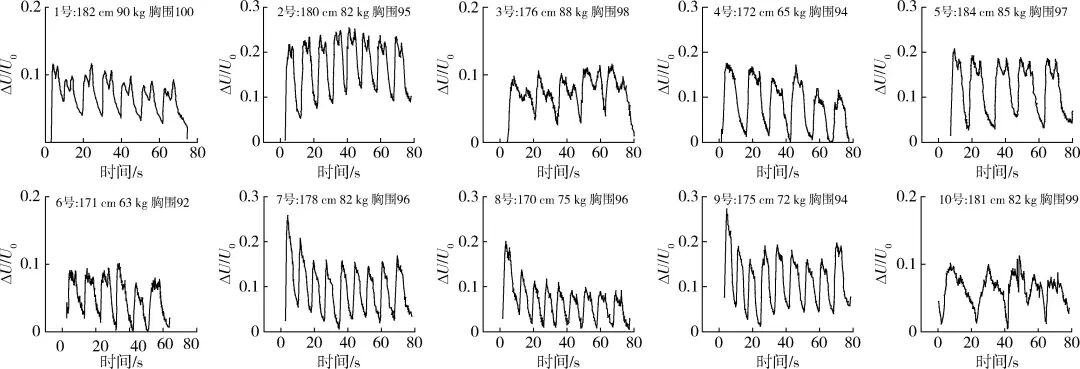

Figure 8 Amplitude Chart of Chest Inhalation and Exhalation

After testing the performance of the strap-type respiratory sensor, it was found that it meets the requirements for thoracic and abdominal respiration detection in terms of working range, sensitivity, response time, hysteresis, and repeatability. Therefore, we selected 10 individuals with different heights, weights, and chest circumferences, and the sensor strap was tied slightly above the nipple position. Based on the different chest circumferences of the participants, the sensor was pre-stretched accordingly and marked. Multiple groups of respiratory training were conducted, and the respiratory monitoring data obtained is shown in Figure 9. The chart data from the chest breathing test reflects that the shape of the test curve is significantly influenced by the participants’ body types, lung capacity, and respiratory conditions. Individuals with better cardiopulmonary function show smoother transitions in their test curves; while individuals with better lung capacity exhibit relatively larger changes in the respiratory detection curves. However, when there is coughing during deep breathing, the test results can become irregular, as shown by subject 10. The heart is a vital organ in the human body, and radiation exposure to the heart during radiotherapy may increase the incidence of cardiovascular diseases. However, respiratory training techniques can effectively reduce radiation exposure to the heart and other critical organs. During radiotherapy, patients can effectively reduce the radiation dose to the heart by taking deep breaths and holding their breath, allowing the lung tissue to fill with air and expand, thus creating an effective barrier between the chest wall and the heart. Using this sensor for respiratory training before radiotherapy for breast cancer patients can effectively reduce the radiation dose to the heart, thereby lowering the risk of coronary heart disease caused by radiotherapy.

Figure 9 Sample Data from 10 Chest Breathing Training Tests

3

Conclusion

(1) A flexible stretchable sensor was prepared using the spatial confinement forced assembly method, which features simple operation, low cost, and stable performance.

(2) Within the strain range of 0% to 24%, this flexible stretchable sensor exhibited good sensitivity (K=0.0015 V/mm) and high linearity (R²=0.985), with the resistance changes of the conductive material being proportional to the degree of stretching.

(3) During the 10% strain test, the response time (Tr) of the sensor was 137 ms, and this rapid response speed is suitable for real-time monitoring of respiratory dynamics.

(4) The input-output curve of the sensor is nearly consistent, with a return error (δH) of only 1.06%, reducing the potential for error accumulation in long-term monitoring.

(5) Under 24% stretching conditions, the voltage output of the sensor fluctuates very little, with a repeatability of up to 96.67%, demonstrating its stability and reliability in continuous monitoring.

(6) Data collected from 10 individuals with varying chest circumferences during respiratory training indicate that this sensor has significant clinical research value in mitigating the potential harmful effects of radiation therapy on the heart and other vital organs of tumor patients.

Scan the QR code to read the full text

“China Plastics” is a national (central-level) scientific and technological journal approved by the National Science and Technology Commission and the National Press and Publication Administration, published monthly, sponsored by the China Plastics Processing Industry Association, Beijing University of Chemical Technology, and the Light Industry Plastics Processing Application Research Institute.“China Plastics” is a core journal in the national Chinese core journal list, a dual-effect journal of the Chinese Academy of Sciences, a core journal indexed by the American Chemical Abstracts (CA), a source journal for statistical analysis of Chinese scientific papers, and a core journal of the Chinese Science Citation Database (CSCD), and has won the third National Journal Award.“China Plastics” is published on the 26th of each month, distributed publicly at home and abroad, CN11-1846/TQ, ISSN1001-9278.

For submissions, please log in to the official website:

www.plaschina.com.cn

www.chinaplasticjournal.com

For subscriptions, please contact the editorial office:

010-68985541

Scan to follow us

Editorial Office of China Plastics