Technological development is advancing rapidly.

New products, new materials, and new processes are emerging endlessly,

injecting continuous new momentum into the construction industry.

What do 3D printed construction molds and components look like?

How do construction robots replace manual labor?

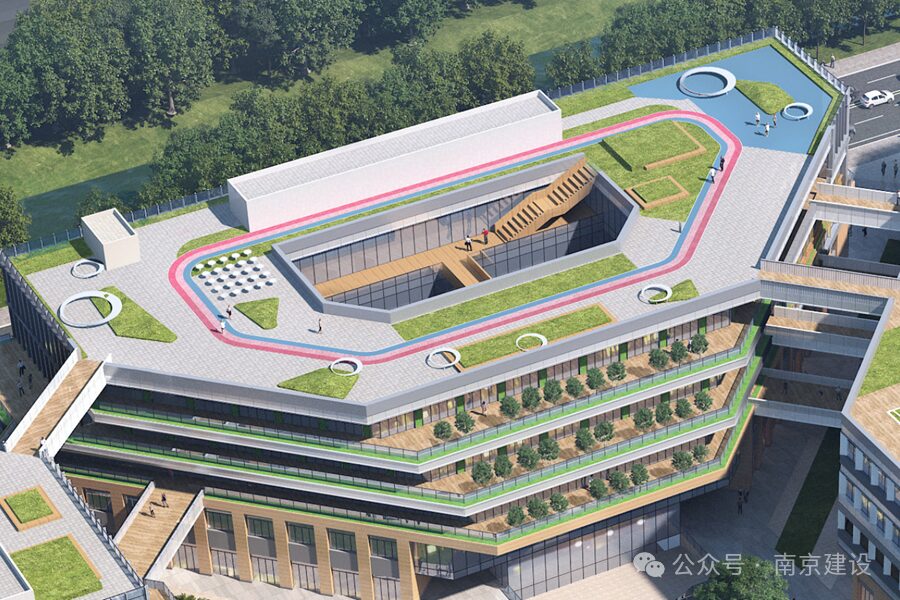

Let’s explore the municipal smart construction pilot project

Southern New City International Road Community Center

to find out.

3D Printed Construction Molds: Turning Blueprints into Physical Models

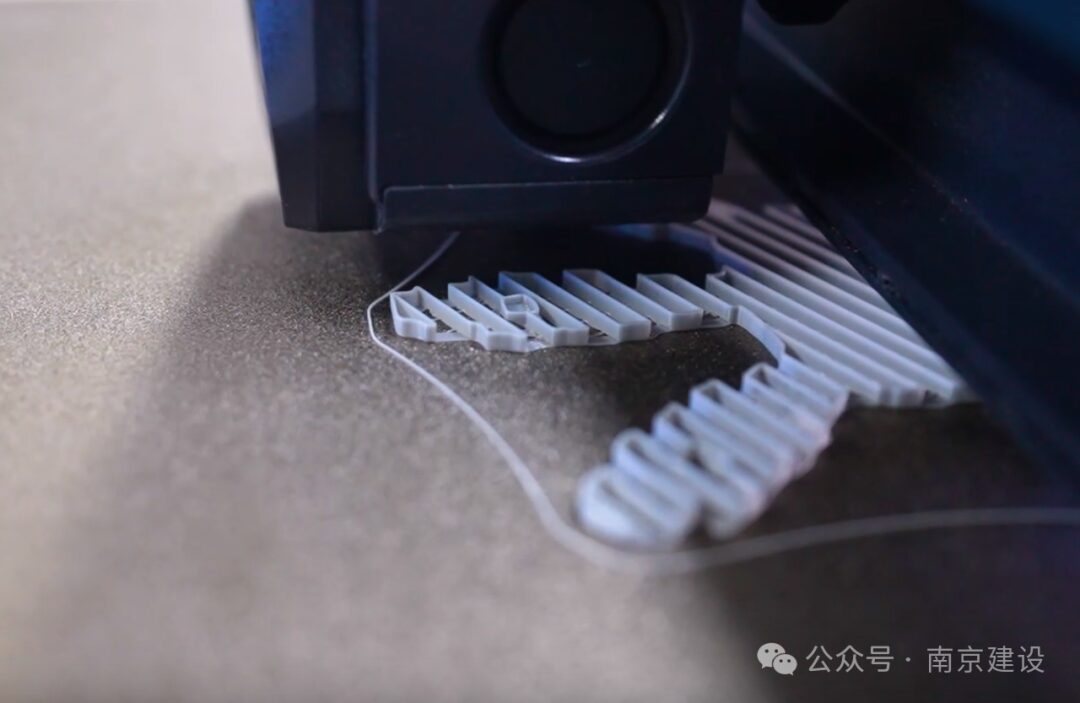

Accompanied by the sound of the 3D printer “clattering,” wooden materials are fed into the nozzle, melted by heat, forming a printing line with a diameter of 0.2 millimeters. Layer by layer, the “two-dimensional plane” gradually grows into a “three-dimensional structure,” resulting in a printed construction mold.

At the International Road Community Center project site, the chief engineer demonstrated a small 3D printer and a freshly printed square mold. The 3D printer can produce molds of different sizes and curves as needed, which can then be assembled like “building blocks” to create construction models for technical disclosure or as construction templates.

“Traditionally, it might take workers two days to process a beam and column template. However, 3D printing can produce a finished template in just one morning, significantly improving efficiency. The printed template is formed in one go, eliminating the need for sanding and secondary processing,” the chief engineer explained.

3D Printed Landscape Features: Easy and Quick Installation On-Site

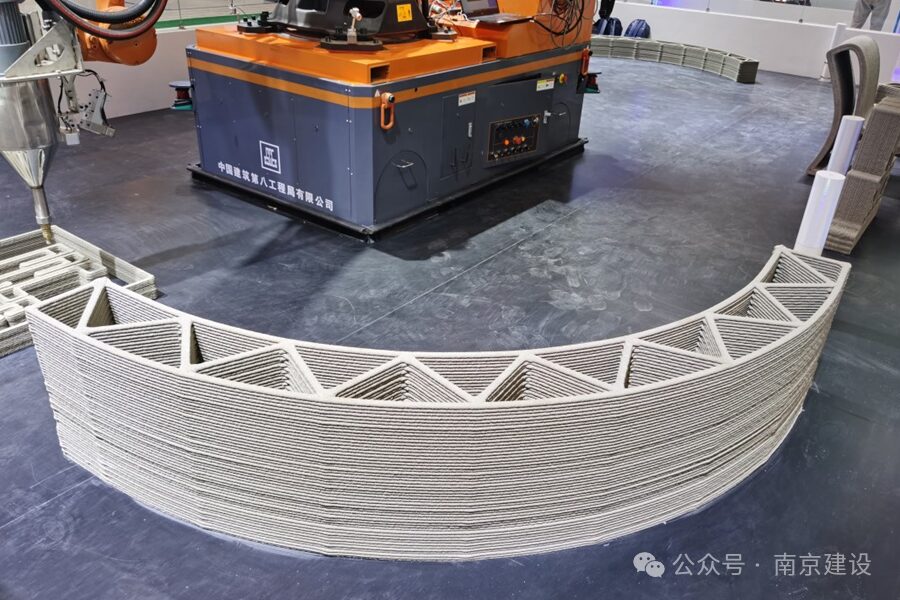

3D printing technology is also applied to landscape features and building metal components. Using construction waste, finished components are custom printed in factories and then transported to the site for installation. Digital modeling in factories allows for custom shapes, patterns, and sizes to be quickly formed, effectively saving construction time.

The project plans to install landscape features such as artistic flower beds, benches, and fences in the sunken plaza, citizen lecture hall, and rooftop of the community center, printing them according to the needs of the scene. A carbon-negative pavilion will be constructed at the northeast corner of the rooftop, using glued wood for the posts and metal 3D printing for the connections, with photovoltaic panels installed on top.

Once the components arrive on-site, only a few workers are needed for assembly, making the process not only simple and quick compared to traditional construction methods but also eliminating the need for formwork, casting, and dismantling processes, thus improving construction efficiency.

Robots on the Job: More Efficient and Intelligent Construction

The International Road Community Center has completed the main structure of the basement level two and is currently working on basement level one. On-site, I saw a newly deployed chipping robot. In poured concrete structures, after the slab is poured, it needs to be chipped before the next layer can be poured to ensure thatthe concrete bonds firmly.

“In this process, the chipping robot can replace manual labor, freeing up hands and improving construction efficiency and precision,” the chief engineer explained. In the later stages of the project, robots will also be used for concrete leveling, smoothing, and polishing, as well as putty spraying and plastering, making construction smarter and more efficient.

Another robot currently on duty is an inspection robot. “This little vehicle can perform unmanned inspections and internal repairs of air ducts and large pipes. Manual inspections require crawling inside, but the inspection robot can replace manual labor, increasing safety and saving costs and time on inspections,” the chief engineer said.

As a municipal smart construction pilot project, the International Road Community Center will also apply new materials and technologies such as prefabricated light steel frame composite exterior wall panels to enhance the level of new industrialized construction. Our city will continue to cultivate municipal smart construction pilot projects and pilot enterprises with smart construction system solution capabilities to promote the transformation and upgrading of the construction industry, achieving high-quality development.

Source: Market Department, Southern New City Management Committee

Photo Source: Municipal Construction Committee News Center, etc.

Image Copyright: Nanjing Urban and Rural Construction Committee, please indicate the source when forwarding

Editor: Li Jie Review: Cheng Cheng Published: Ning Jianxuan

“

Recommended Reading——