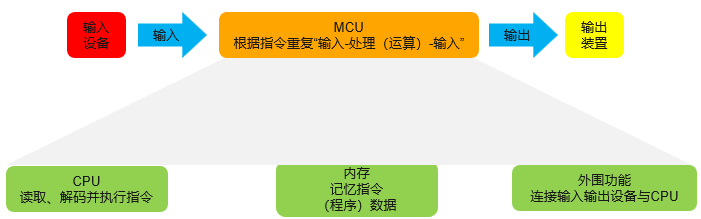

With the rapid development of technology, the automotive industry is experiencing unprecedented changes. From traditional internal combustion engine vehicles to new energy vehicles, and now to smart cars, automobiles have become not just a means of transportation but a smart partner in people’s lives. In this process, automotive electronic systems play an increasingly important role. The automotive MCU chip, or Microcontroller Unit chip, is a highly integrated semiconductor chip widely used in modern vehicles. It is a small chip that integrates the core functions of a processor, memory, and input/output (I/O) peripherals, capable of executing program code, controlling external devices, and managing various functions of the vehicle.

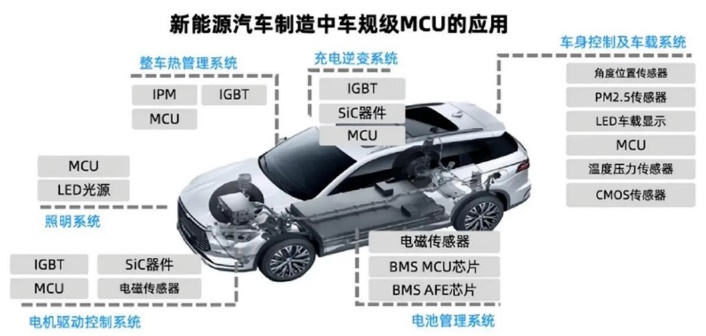

MCU (Micro Controller Unit) is an integrated circuit that integrates CPU, memory, input/output interfaces, and various peripherals. In vehicles, MCUs are responsible for controlling and monitoring various electronic systems to ensure reliability and safety. The main application areas of MCUs include engine control, transmission control, braking systems, body electronics, chassis control, and in-vehicle entertainment information systems.

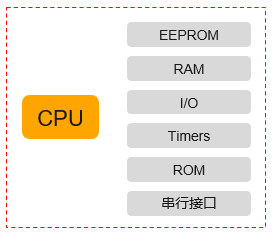

MCU Chip Schematic Diagram

|

Module |

Function |

|

CPU

|

CPU (Central Processing Unit) is the core processing unit that runs system software/application software, working with other hardware modules within the chip to achieve various functions of the product. |

|

EEPROM |

EEPROM (Electrically Erasable Programmable Read-Only Memory) is mainly used for storing and preserving data, which can remain intact even when the power is off. |

|

RAM |

RAM (Random Access Memory) is a major type of memory in computers and other electronic devices, playing a crucial role in data processing and storage. |

|

ROM |

ROM (Read-Only Memory) is a type of memory used for storing fixed data, playing an important role in computers and electronic devices. |

|

Timers |

Timers play an important role in computer science and electronic engineering, used for measuring time intervals, executing periodic tasks, and controlling the sequence of events. |

1. Classification by Data Bits

According to data bits, MCUs can be classified into different types such as 4-bit, 8-bit, 16-bit, 32-bit, and 64-bit. The more data bits, the greater the amount of data the MCU can process, and the stronger its performance.

|

Type |

Characteristics |

Applications |

|

4 Bit |

Low operating voltage, low power consumption |

4-bit MCUs are the most basic type, with a core that processes only 4 bits of data at a time. They are typically used for very simple control tasks, such as in some household appliances, small robots, and sensor interfaces. They are characterized by low cost and low power consumption but have limited processing capability and speed. |

|

8 Bit |

Low cost, technology specialization, and application specialization 8-bit MCUs operate at frequencies between 16-50MHz, are simple, energy-efficient, and low-cost. |

8-bit MCUs have a processor core with an 8-bit data width, meaning they can process 8 bits of data at a time. They have higher processing capabilities and richer peripheral interfaces than 4-bit MCUs, suitable for more complex control tasks, such as industrial automation and consumer electronics. Their performance and functionality are typically stronger than 4-bit MCUs but slightly lower than 16-bit and 32-bit MCUs. |

|

16 Bit |

16-bit MCUs have higher performance than 8-bit ones, with faster response times and lower costs.16-bit MCUs operate at frequencies between 24-100MHz. |

16-bit MCUs have a processor core with a 16-bit data width, allowing them to process 16 bits of data at a time. They are typically used for more complex applications, such as industrial control systems, automotive electronic systems, and medical devices. They provide higher data processing speeds and more peripheral interfaces, but their cost is generally higher than that of 8-bit MCUs. |

|

32 Bit |

Powerful processing capabilities; currently, mainstream market is still dominated by 32-bit MCUs, which typically operate at frequencies between 100-350MHz, providing excellent performance, diverse applications, but with increased program code length compared to 8/16-bit MCUs by 30%-40%, higher memory capacity requirements, and reduced cost control space. |

32-bit MCUs are the highest-end type, with a processor core that has a 32-bit data width, allowing them to process 32 bits of data at a time. They offer immense processing power and memory capacity, suitable for high-performance applications such as computer peripherals, network devices, smartphones, and autonomous vehicles. 32-bit MCUs typically have more peripheral interfaces and higher performance, but their costs are also relatively high. |

In summary, the higher the bit width of an MCU, the more powerful its processing capability, memory capacity, and performance. However, higher bit widths also mean higher costs and power consumption. When selecting an MCU suitable for a specific application, design engineers need to determine which type to use based on the specific requirements of the application.

For example, if an application only requires basic control functions, a 4-bit or 8-bit MCU may be sufficient. If the application needs to process large amounts of data or execute complex algorithms, a 32-bit MCU may be more appropriate.

2. Classification by Core Architecture

According to core architecture, MCUs can be classified into those based on 8051 architecture, ARM architecture, and RISC-V architecture, among others. Different architectures have different performance and power consumption characteristics.

|

8051 Architecture Chip |

The 8051 architecture is an early microcontroller architecture introduced by Intel in the early 1980s. It is a Complex Instruction Set Computer (CISC) architecture with the following characteristics: Ø Simple instruction set, easy to learn and use. Ø Smaller data and program storage space. Ø Slower processing speed and lower performance. Ø Suitable for simple control tasks and embedded systems. Due to its performance limitations, 8051 architecture chips are gradually being replaced by more efficient architectures in modern applications. |

|

ARM Architecture-based Chips |

ARM architecture is a Reduced Instruction Set Computer (RISC) architecture designed by ARM Holdings. It has the following characteristics: Ø Efficient instruction set, reducing the number of cycles required for instruction execution. Ø Highly customizable, allowing manufacturers to adjust chip designs based on needs. Ø Low power consumption and high performance, suitable for various applications including mobile devices, embedded systems, and automotive electronics. Ø Broad application support and ecosystem, including development tools and software libraries. ARM architecture-based chips are very popular in modern electronic devices, especially in smartphones and tablets. |

|

RISC-V Architecture-based Chips |

RISC-V is an emerging open-source instruction set architecture initiated by the University of California, Berkeley. It has the following characteristics: Ø Simple, extensible instruction set, allowing for everything from simple single-core processors to complex multi-core processors. Ø Highly modular, supporting customization and expansion. Ø Open source and free to use, attracting a lot of researchers and companies to participate in development. Ø Suitable for a wide range of applications from embedded systems to high-performance computing. RISC-V architecture-based chips are gaining attention for their flexibility and customizability, especially in applications that require high performance and low power consumption. |

Chips based on 8051 architecture, ARM architecture, and RISC-V architecture each have their unique characteristics, with differences in performance, power consumption, application fields, and ecosystems. 8051 architecture chips are suitable for simple control tasks, while ARM architecture chips are very popular in modern electronic devices. RISC-V architecture chips are notable for their flexibility and customizability. When selecting a chip suitable for a specific application, the specific needs of the application should guide the choice of architecture.

3. Classification by Application Field

MCUs can be classified into general-purpose and dedicated types based on application fields. General-purpose MCUs are suitable for a wide range of industrial and consumer applications, while dedicated MCUs target specific applications, such as automotive, medical, and IoT.

4. Classification by Performance

MCUs can be classified into low-end, mid-range, and high-end based on performance. Low-end MCUs are suitable for simple control tasks, mid-range MCUs are suitable for moderately complex applications, and high-end MCUs are suitable for high-performance computing tasks.

5. Classification by Integration Level

MCUs can be classified into microcontroller units and system-on-chip (SoC) based on integration level. Microcontroller units contain only the CPU and basic peripherals, while system-on-chip devices are highly integrated, including processor cores, memory, graphics processing units, etc.

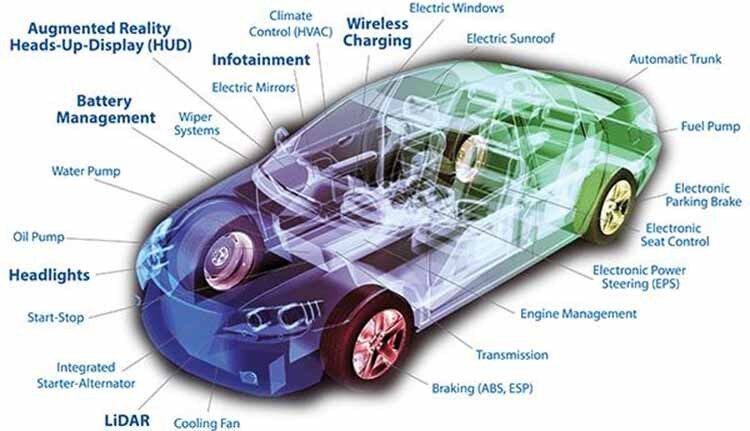

In vehicles, MCUs are responsible for controlling and monitoring various electronic systems to ensure vehicle reliability and safety. MCUs (Microcontroller Units) are widely used in automotive applications and are core components of modern automotive electronic systems. Here are some major application areas and their functions:

1. Engine Control:

-

Function:MCU chips play a core role in the Engine Control Unit (ECU), responsible for monitoring and managing engine performance, including fuel injection, ignition timing, emissions control, etc.

-

Application:Ensures stable engine operation under various conditions, improving fuel efficiency and reducing emissions.

2. Transmission System:

-

Function:In automatic transmissions, MCU chips control the shifting logic to ensure optimal power transmission and fuel efficiency under different driving conditions.

-

Application:Optimizes driving experience and improves fuel economy.

3. Body Electronics:

-

Function:MCU chips control body electronic systems such as windows, door locks, seat adjustments, and lighting.

-

Application:Provides a comfortable and convenient driving experience.

4. Safety Systems:

-

Function:MCU chips are responsible for monitoring vehicle motion and collision situations in systems like Anti-lock Braking System (ABS), Electronic Stability Control (ESC), and airbags, controlling the deployment of airbags.

-

Application:Ensures passenger safety in emergencies.

5. In-Vehicle Entertainment and Information Systems:

-

Function:MCU chips are responsible for processing and displaying information in in-vehicle entertainment systems, such as navigation, audio, and video playback.

-

Application:Provides rich in-vehicle entertainment and information functions, enhancing the driving experience.

6. Advanced Driver Assistance Systems (ADAS):

-

Function:MCU chips monitor vehicle dynamics such as steering angle, speed, and yaw rate to maintain vehicle stability.

-

Application:Helps drivers control the vehicle and prevent loss of control in emergency obstacle avoidance or slippery road conditions.

Overall, automotive MCU chips play a crucial role in ensuring vehicle performance, enhancing driving safety, and comfort. With ongoing technological advancements, they not only improve vehicle performance and safety but also provide automotive manufacturers with more room for innovation. As technology progresses, we can expect the applications of MCUs in vehicles to become more widespread and profound. In the future, the application of MCU chips will be broader, bringing more innovations and improvements to the automotive industry.

In the automotive industry, the evaluation indicators of MCUs (Microcontroller Units) are crucial as they directly affect vehicle safety, performance, and reliability. Here are some key MCU evaluation indicators:

1. Operating Temperature Range:

MCUs need to operate stably under extreme temperatures, typically covering a wide industrial temperature range. Automotive-grade MCU chips generally require an operating temperature range of -40°C to +125°C. This temperature range covers various climate conditions in which vehicles operate, including extreme low and high temperatures. This strict temperature range requirement ensures that automotive-grade MCU chips can be widely used in the automotive industry, especially in automotive electronic systems that need to withstand extreme temperature changes.

2. Power Supply Voltage Range:

MCUs should be able to operate stably under different power supply voltages to adapt to various vehicle power conditions. The operating voltage range of automotive-grade MCU chips is generally broad to meet the needs of different automotive electronic applications. For example, the GD32A503 series automotive-grade MCU released by GigaDevice operates on a wide voltage supply of 2.7-5.5V. This wide voltage range design allows automotive-grade MCUs to adapt to various voltage conditions that may be encountered in automotive electronic systems, thereby improving their flexibility and reliability in practical applications.

3. Clock Frequency:

A higher clock frequency typically means faster processing speed but also increases power consumption. The clock frequency of automotive-grade MCU chips, which indicates the speed at which the core operates, is one of its important performance indicators, directly affecting its computation speed and processing capability. For example, a chassis domain MCU may require a main frequency of no less than 200MHz to meet high performance and high computing power needs. Low frequencies such as 8MHz are suitable for simple control tasks with low performance requirements, while high frequencies such as 1.2GHz are suitable for high-performance computing and complex real-time control tasks.

The clock frequency of automotive-grade MCU chips is crucial for their operational correctness and performance. If the clock frequency exceeds specified limits, it may lead to performance, protocol, and timing failures. Therefore, during the design process of automotive-grade MCUs, various effective safety mechanisms need to be considered to ensure the stability of the clock signal frequency. For example, some MCUs may use a Clock Management Unit (CMU) module to detect and monitor the frequency of the clock signal and generate events as necessary to ensure the safe operation of the system.

In summary, the clock frequency of automotive-grade MCU chips is one of the important parameters for measuring their performance and applicability, directly affecting their application and performance in automotive electronic systems. When selecting and using automotive-grade MCUs, their clock frequency should be considered based on the specific application scenario requirements.

4. Memory Capacity and Type:

MCUs need sufficient memory to store control algorithms and data, as well as enough RAM to process real-time data. Automotive-grade MCU chips typically include different types of memory, such as RAM, ROM, FLASH, etc., for storing program code, data, and parameters.

Among them, ROM is a read-only program memory built into the chip, mainly used to store the chip’s built-in bootstrap code, chip ID, vendor information, etc. RAM is a volatile memory used for temporarily storing data and running programs. FLASH is a non-volatile memory used for storing program code and system parameters.

In automotive electronic systems, automotive-grade MCU chips usually have various types of memory, including SRAM (Static Random Access Memory), DRAM (Dynamic Random Access Memory), NOR Flash (non-volatile memory), and NAND Flash (non-volatile memory). These different types of memory can meet various application needs, such as real-time data processing, storing program code, and configuration data. The application of these memories in automotive electronic systems reflects their respective advantages, such as the high-speed performance of SRAM, the fast startup and reliability of NOR Flash, and the large-capacity data storage capability of NAND Flash. With the continuous advancement of automotive technology, the demand for memory is also increasing, and the development and application of these memory technologies are crucial for the advancement of automotive electronic systems.

|

Category |

Full Name |

Function |

|

1. RAM |

Random Access Memory |

RAM is an internal memory that exchanges data directly with the CPU and can be read and written at any time (except during refresh), typically serving as temporary data storage for the operating system or other running programs. RAM can read or write information from any specified address at any time. The main difference between RAM and ROM (Read-Only Memory) is the volatility of the data, meaning that once the power is cut off, the stored data will be lost. |

|

1.1 SRAM |

Static Random Access Memory |

SRAM is a type of random access memory whose “static” characteristic means that as long as power is maintained, the data stored internally can remain unchanged. SRAM can retain data without needing refresh circuits, thus offering higher performance. It is mainly used as a cache between the CPU and main memory. |

|

1.2 DRAM |

Dynamic Random Access Memory |

DRAM is a type of semiconductor memory. The working principle of DRAM is to use the amount of charge stored in capacitors to represent whether a binary bit (bit) is 1 or 0. Due to the leakage current phenomenon of transistors, DRAM needs to be periodically charged to maintain data. |

|

2. ROM |

Read-Only Memory |

The main characteristic of ROM is that it can only read previously stored data and cannot write new information. Once data is written to ROM, it becomes fixed, and even when power is cut off, the information will not be lost. Therefore, ROM is also referred to as fixed memory. The data stored in ROM is usually written before the system is powered on, and during operation, it can only be read, unlike random storage (RAM) which can be quickly and conveniently rewritten. |

|

2.1 Mask ROM |

Mask Read-Only Memory |

Mask ROM is a special type of read-only memory whose content is pre-written or programmed by the manufacturer during the integrated circuit manufacturing process. The data in this memory is permanent because it is one of the main types of non-volatile memory. The main advantage of mask ROM is that its stored content is fixed, and the information remains even after power is cut off, making it highly reliable. However, its drawback is that once the information is written (manufactured), it cannot be modified, making it inflexible, and the production cycle is relatively long, leading to a high dependency between users and manufacturers. |

|

2.2 PROM/OTP |

Programmable Read-Only Memory/One Time Programmable Read-Only Memory (OTP-ROM) |

PROM is a type of computer memory chip that allows users to write data into the device using specialized hardware (PROM programmer). Once programmed, it can only be used for that specific data and cannot be reprogrammed. This type of memory is usually used in products such as video game consoles and electronic dictionaries. |

|

2.2.1 EPROM |

Erasable Programmable Read-Only Memory |

EPROM is a non-volatile computer memory chip that retains data even when power is cut off. EPROM can be erased by exposure to strong ultraviolet light, and these chips have a transparent quartz window for UV erasure. Once programming is complete, EPROM can only be erased using ultraviolet light. EPROM chips can be repeatedly erased and written, solving the issue of PROM chips being write-once. |

|

2.2.2 EEPROM |

Electrically Erasable Programmable Read-Only Memory |

EEPROM is a type of non-volatile memory chip that retains data even when power is cut off. EEPROM can be erased and reprogrammed on a computer or specialized device. Its characteristic is that it can randomly access and modify any byte, allowing for writing either 0 or 1 into each bit. This type of memory is generally used in plug-and-play scenarios, such as BIOS storage in personal computers or to store hardware setting data. Additionally, EEPROM is often used in “hardware locks” to prevent illegal software copying. Unlike EPROM, EEPROM does not require ultraviolet light for erasure but can erase information on the chip using specific voltages to write new data. EEPROM has various operational modes, including read mode, write mode, erase mode, and verification mode. When writing data to EEPROM, a certain programming voltage is still required, and the minimum modification unit is a byte, meaning it does not need to erase everything to write new data. |

|

2.2.3 NOR Flash |

NOT-OR Logic Memory |

NOR Flash (non-volatile memory): Due to its programmable capability, NOR Flash is used in many applications as a replacement technology for EEPROM. It is particularly suitable for storing important information such as program and operating system data and has gained attention in the rapid development of autonomous driving vehicles. NOR Flash is mainly used for storing program code, also known as Code Flash. It has high read speeds and reliability but relatively high density and cost. NOR Flash can support in-chip execution, meaning applications can run directly in flash memory without needing to read the code into system RAM. The mainstream capacity of NOR Flash is 512Mb, suitable for storing small amounts of code. Its application in vehicles mainly focuses on scenarios that require fast startup and high reliability. NOR Flash has advantages such as fast read speeds, high stability, and data retention even after power loss, making it suitable for automotive dashboards, central multimedia screens, ADAS (Advanced Driver Assistance Systems), and peripheral cameras. Due to its instant-on capability, NOR Flash is particularly important in automotive dashboards as it can immediately start basic functions. The demand for NOR Flash in ADAS systems is also increasing, especially with the development of autonomous driving technology. Additionally, NOR Flash’s high heat resistance and data retention time of up to 20 years make it highly valuable in automotive applications. |

|

2.2.4 NAND Flash |

NOT-AND Logic Memory |

NAND Flash is suitable for large-capacity data storage, such as in smartphones, PCs, tablets, USB drives, solid-state drives, and servers. NAND Flash is typically used for large-capacity data storage due to its high density and low unit cost. Its read and write speeds are relatively slow, but it can perform erasure and programming operations quickly. NAND Flash is widely used for storing files, music, videos, and other large data. Its capacity can reach 2Gb or even larger. |

The memory capacity and type of automotive-grade MCU chips are crucial performance indicators that directly affect their application and performance in automotive electronic systems. Since different manufacturers and models of automotive-grade MCUs may have different memory capacities and types, specific values may vary.

For example, the GD32A503 series automotive-grade MCU from GigaDevice has a Flash capacity of up to 8MB and an SRAM capacity of up to 640KB. This high-capacity design allows automotive-grade MCUs to handle more complex data and algorithms to meet the increasing data processing demands in automotive electronic systems.

5. Peripheral Interfaces:

MCUs need to support various communication interfaces, such as CAN, LIN, Ethernet, etc., to connect different systems within the vehicle.

6. Security and Encryption:

MCUs need to have certain security features, such as secure boot, encryption, and authentication, to protect vehicles from hacking.

7. Fault Diagnosis and Self-Recovery:

MCUs need to have fault diagnosis and self-recovery capabilities to ensure stable system operation.

8. Power Consumption:

Low power consumption design is particularly important for battery-powered electric vehicles to extend battery life.

Automotive MCU chips achieve low power consumption through several methods:

8.1 Advanced Manufacturing Processes:

For example, the GD32L233 series MCU from GigaDevice uses 40nm ultra-low power (ULP) manufacturing technology, which can reduce power consumption at the hardware level.

8.2 Specialized Optimized Low-Power Analog IP:

For example, the GD32L233 series MCU integrates specially optimized low-power analog IP to reduce energy loss.

8.3 Low-Power Digital Design Methodologies:

For example, the GD32L233 series MCU adopts various low-power digital design concepts, such as multi-voltage domain designs, to control the power on and off of idle modules, avoiding unnecessary energy loss.

8.4 Rich Peripheral Interfaces and Flexible Power Supply Modes:

For example, the GD32L233 series MCU provides various operating modes and sleep modes, as well as rich peripheral interfaces, including up to 4 general-purpose 16-bit timers, 2 basic timers, and 1 32-bit low-power timer, along with standard and advanced communication interfaces.

8.5 Highly Integrated Functions and Efficient Processing Capabilities:

For example, TI’s MSPM0 series MCU integrates high-performance analog signal chain control, ADC, DAC, and other functions, while also having excellent operating power consumption and sleep power consumption parameters.

Through these methods, automotive MCU chips can achieve low power operation while ensuring performance, which is crucial for improving vehicle efficiency and extending battery life.

9. Packaging Types and Pin Count:

The packaging type and pin count of MCUs directly affect their layout and application on the circuit board.

Common packaging methods include: QFN, LQFP, and LFBGA:

QFN, LQFP, and LFBGA are different types of integrated circuit packaging technologies widely used in electronic design, including automotive electronics. These packaging technologies not only affect the size and shape of chips but also impact their electrical performance, thermal performance, and assembly methods. Here is a brief overview of these packaging technologies:

9.1 QFN (Quad Flat No-lead):

QFN packaging is a type of leadless packaging with a flat square or rectangular shape. It connects to the circuit board through solder balls located at the bottom of the package. The main advantages of QFN packaging include smaller package size, excellent thermal performance, and good electrical performance. Due to the absence of leads, QFN packaging occupies less space on the circuit board, which is advantageous for space-constrained applications (such as portable devices or automotive electronics).

9.2 LQFP (Low Profile Quad Flat Package):

LQFP packaging is a flat package with a low profile, featuring short pins that extend from all four sides of the package, usually arranged in a matrix. LQFP packaging is favored for its good thermal performance and high pin density. This packaging is suitable for complex integrated circuits that require many pins, such as microcontrollers and certain types of ASICs.

9.3 LFBGA (Low Profile Fine Pitch Ball Grid Array):

LFBGA packaging is a ball grid array packaging technology where solder balls are arranged in a fine pitch at the bottom of the package. Similar to QFN packaging, LFBGA packaging also offers smaller package size and good thermal performance. The fine pitch of the solder balls allows for higher pin density, which is useful for integrated circuits with a high number of pins.

|

QFN32 |

QFN32 packaging is a type of integrated circuit (IC) packaging that belongs to the leadless (Quad Flat No-Lead) packaging series. In this packaging, “32” refers to the number of pins, indicating that there are 32 solder points at the bottom of the package for connecting the chip to the circuit board. The main features of QFN32 packaging include: Leadless Design:QFN packaging has a flat bottom without traditional leads, connecting to the circuit board through solder balls. Compact Size:Due to the absence of leads, QFN packaging occupies less space on the circuit board, suitable for space-constrained applications. Thermal and Electrical Performance:QFN packaging has good thermal and electrical performance, suitable for use in high-temperature or high-voltage environments. Pin Pitch:The pin pitch of QFN32 packaging is 32mil (0.032 inches), which is the center-to-center distance between pins. Application Fields:QFN32 packaging is widely used in automotive electronics, industrial control, communication devices, consumer electronics, etc. QFN packaging technology is widely used in electronic design due to its excellent thermal performance, compact size, and good electrical performance. |

|

LQFP48 64 80 100 144 176 |

LQFP (Low Profile Quad Flat Package) is a four-sided flat leadless integrated circuit packaging technology, with pins extending from all four sides of the package in a rectangular arrangement. The number of pins in LQFP packaging can be customized according to needs, with common pin counts including 48, 64, 80, 100, 144, and 176. These packaging technologies are widely used in various electronic devices due to their high pin density and good assembly compatibility. Application cases of LQFP packaging include: Microcontrollers (MCUs):Many microcontrollers adopt LQFP packaging, especially in applications requiring many I/O pins, such as industrial control, control boards for household appliances, etc. Communication Devices:In routers, switches, and other network devices, LQFP packaging is used for various processing and interface ICs. Automotive Electronics:In vehicles, LQFP packaging is used for various ECUs (Electronic Control Units), such as engine control units, safety systems (such as ABS), and in-vehicle entertainment systems. Consumer Electronics:In smartwatches, wearable devices, and home electronics, LQFP packaging is used for various sensors and processing ICs. Industrial Automation:In industrial automation systems, LQFP packaging is used for various control and processing ICs. LQFP packaging is particularly suitable for space-constrained applications due to its compact size and high pin density. Its thermal and electrical performance also makes it an ideal choice for various electronic devices. As electronic devices continue to evolve towards smaller and more efficient designs, the importance of LQFP packaging is also increasing. |

|

LFBGA516 |

LFBGA516 is a fine-pitch ball grid array (Low Profile Fine-pitch Ball Grid Array) packaging technology used for integrated circuit chips. This packaging technology features a fine-pitch solder ball array, a low-profile design, and surface mount technology. LFBGA516 packaging has 516 solder balls, with a package size of 14 x 14 x 1.2 millimeters. This packaging style is suitable for surface mount technology, with solder balls located at the bottom of the package, making it suitable for various types of electronic devices, especially in space-limited applications. Fine Pitch Solder Ball Array:The solder balls in LFBGA packaging are closely spaced, which helps improve the electrical performance and signal integrity of the package. Low Profile Design:The thickness of LFBGA packaging is low, which minimizes its impact on circuit board layout, particularly in space-constrained applications. Surface Mount Technology (SMT) Compatible:LFBGA packaging uses surface mount technology, making it suitable for automated production lines. High Pin Density:LFBGA516 has 516 solder balls, providing high pin density, facilitating complex circuit designs. Good Thermal Performance:LFBGA packaging has good thermal performance, facilitating heat dissipation, making it particularly suitable for high-performance electronic devices. Electrical Performance:LFBGA packaging has good electrical performance, providing stable signal transmission. Suitable for Various Applications:LFBGA516 packaging is widely used in automotive electronics, industrial control, communication devices, etc. Suitable for Automated Production Lines:The fine pitch and surface mount characteristics of LFBGA packaging make it suitable for automated production lines, improving production efficiency. Flexible Size:The size of LFBGA packaging can be customized according to requirements to meet different application needs. Reliability:LFBGA packaging has high reliability, capable of stable operation in harsh environments. In summary, LFBGA516 packaging technology has been widely used in electronic design due to its high pin density, good thermal performance, and electrical performance. |

When selecting MCUs or other integrated circuits’ packaging types, various factors need to be considered, including circuit board space, thermal management needs, electrical characteristics, assembly processes, and costs. For example, in automotive electronics, due to space constraints and high reliability requirements, QFN and LFBGA packaging are favored for their excellent thermal performance and compact size. Meanwhile, LQFP packaging is widely used in various electronic devices due to its high pin density and good assembly compatibility.

10. Environmental Adaptability:

MCUs need to adapt to vibrations, shocks, and electromagnetic interference that may be encountered in automotive environments. To meet these needs, automotive MCU chips typically employ the following methods and techniques:

10.1 Advanced Packaging Technologies:

Using high-standard packaging technologies to protect chips from external environmental impacts, such as waterproof, dustproof, and shock-resistant packaging materials and structures.

10.2 Enhanced Circuit Design:

By optimizing circuit design to enhance the chip’s anti-interference and shock resistance capabilities, such as using electromagnetic shielding and anti-interference circuit designs.

10.3 Temperature Adaptability Design:

Considering temperature variations in automotive environments, MCU chips need to have good temperature adaptability to operate normally under extreme temperature conditions.

10.4 Compliance with Automotive Standards:

Automotive chips need to pass strict certification standards, such as AEC-Q100 certification, which includes a series of tests such as accelerated environmental stress tests, accelerated lifecycle simulation tests, and package assembly integrity tests, to ensure that the chips can operate stably in harsh automotive environments.

In conclusion, automotive MCU chips adapt to vibrations, shocks, and electromagnetic interference in automotive environments through advanced packaging technologies, enhanced circuit designs, temperature adaptability designs, and compliance with automotive standards. These measures ensure the stability and reliability of MCU chips in automotive electronic systems.

11. Reliability and Lifespan:

MCUs need to operate stably over long periods and have a long lifespan.

The reliability and lifespan requirements of MCU (Microcontroller Unit) chips are particularly important in automotive environments. To meet these requirements, MCU chips must undergo a series of rigorous tests and certifications. These tests include:

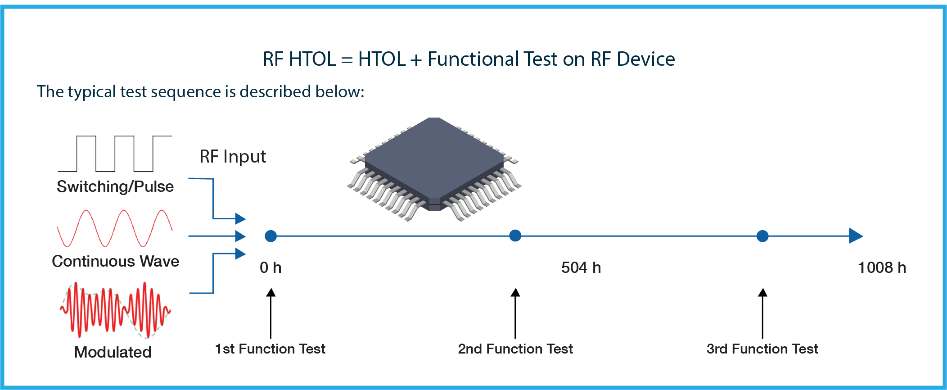

11.1 Lifespan Testing Projects:

Such as Early Failure Rate Testing (EFR), High/Low-Temperature Operating Lifetime Tests (HTOL/LTOL), etc., used to assess process stability, accelerated defect failure rate, and device durability under extreme heat and voltage conditions.

11.2 Environmental Testing Projects:

Such as Preconditioning Tests (PRE-CON), Thermal Shock Tests (THB), High-Accelerated Lifespan Tests (HAST), Pressure Cycling Tests (PCT), etc., used to simulate the durability of ICs under certain humidity and temperature conditions before use and evaluate their performance and reliability under different environmental conditions.

These testing projects help ensure that MCU chips can operate stably and reliably in automotive environments, meeting the automotive industry’s demands for high performance, high reliability, and long lifespan.

12. Software and Ecosystem Support:

Good software support and development tools are crucial for rapid development and system integration.

The software and ecosystem support for MCU chips is vital for developers as it directly impacts development efficiency and application reliability. For example, Infineon’s AURIX™ TC4x series MCUs provide rich software and ecosystem support. This ecosystem includes the Synopsys Virtualizer™ Development Kit (VDK) and DesignWare® ARC® MetaWare toolchain for software development and PPU software development. Additionally, there are partner products supporting MATLAB automatic code generation, as well as software development kits (SDKs).

In the automotive field, the software ecosystem for automotive-grade MCUs includes various aspects such as AUTOSAR architecture, non-AUTOSAR software, operating systems, boot and information security software, functional safety software, and software development toolchains. The AUTOSAR architecture is an open automotive electronic system architecture designed to provide a standardized approach to developing and managing software for automotive electronic systems. It includes application layer, runtime environment layer, and infrastructure layer for modularity, reusability, and scalability of automotive electronic systems.

These ecosystem support measures not only improve development efficiency but also simplify the learning and application processes, providing comprehensive support and resources for MCU chip users. For example, GigaDevice’s GD32 MCU ecosystem includes official tools, partner tools, embedded software, cloud connectivity, and training, aimed at supporting MCU development and applications.

13. Certification and Standards Compliance:

MCUs need to comply with relevant automotive industry standards and certifications, such as ISO 26262 (functional safety). The design and manufacturing of automotive-grade MCUs follow strict standards and certification processes, including ISO/TS16949, AEC-Q100, ISO 26262, etc., to ensure their reliability and safety in automotive electronic systems. Automotive-grade MCUs must meet a series of strict standards, including internationally recognized safety and reliability standards for electronic and electrical products during the design phase, such as ISO 26262, during wafer fabrication and packaging stages such as AEC-Q001-004, and during certification testing stages such as AEC-Q100 and AEC-Q104 standards. These standards cover various tests including High-Temperature Operating Lifetime Tests (HTOL), Early Failure Rate Tests (ELFR), Electrostatic Discharge Human Body Model (HBM), Electrostatic Discharge Charged Device Model (CDM), High-Temperature Gate Leakage Tests (LU-HT), Electromagnetic Compatibility Tests (EMC), and 19 other tests.

Domestic authorities are also accelerating the formulation and implementation of reliability-based standards, ensuring a consistent understanding of automotive chip requirements among all parties to avoid confusion. In the AEC-Q100 standard, temperature grades determine the temperature conditions for all AEC-Q100 tests; for example, the new version of the AEC-Q100 has a maximum operating temperature range (Level 0) of -40℃ to 150℃, and the minimum range (Level 3) is -40℃ to 85℃, with two intermediate levels: Level 1: operating temperature range -40℃ to 125℃ (general level), Level 2: operating temperature range -40℃ to 105℃.

|

International Certification Standards |

|||

|

Quality Management System |

Functional Safety Assurance |

AEC-Q Reliability Standards |

|

|

IATF16949 |

ISO 26262 |

AEC-Q-100: for automotive ICs |

AEC-Q-101: for discrete devices |

|

AEC-Q-102: for LEDs |

AEC-Q-103: for MEMS, etc. |

||

|

AEC-Q-104: for multi-chip modules |

AEC-Q-200: for passive components |

These evaluation indicators are crucial for automotive manufacturers as they directly impact the performance, safety, and reliability of vehicles. When selecting suitable MCUs, automotive manufacturers need to weigh these indicators based on specific application needs and environmental conditions to ensure that the selected MCU can meet the long-term requirements and expected goals of the project.

In 2023, China’s automotive MCU (Microcontroller Unit) industry is experiencing significant development. With the rapid growth of the Chinese automotive market, especially in the fields of new energy vehicles and smart cars, the demand for MCUs continues to rise. Here are some key developments in the Chinese automotive MCU industry:

1. Market Size and Growth:

According to statistics, the market size of MCUs in China was approximately $5.4 billion in 2021, and it is expected to reach $5.7 billion in 2022. By 2026, the market size is expected to exceed 50 billion RMB. This indicates that the Chinese MCU market is growing rapidly.

2. Application Fields:

MCUs are widely used in the automotive industry, including engine control, transmission control, braking systems, body electronics, safety systems, chassis control, and in-vehicle entertainment and information systems. With the development of automotive electrification and intelligence, the application of MCUs in vehicles will become more widespread and profound.

3. Technological Development:

MCU technology in China is continuously evolving, particularly in applications within new energy vehicles and smart cars. Domestic semiconductor companies are increasing their R&D efforts to meet the growing market demand.

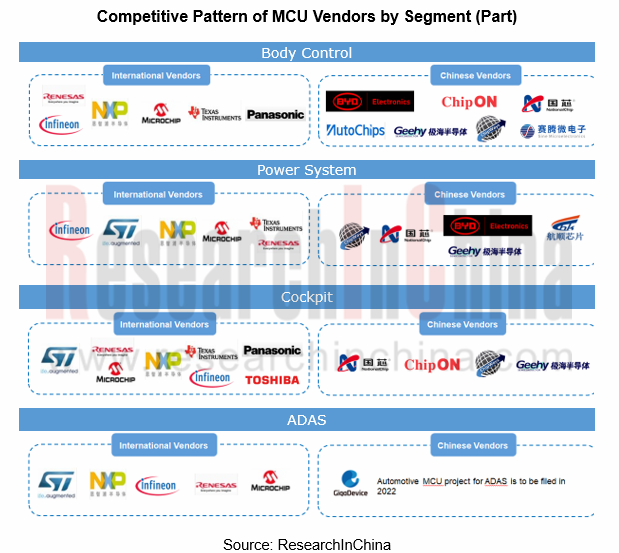

4. Market Competition:

Despite the rapid growth of the Chinese MCU market, global competition remains fierce. Currently, the global MCU market is mainly dominated by chip giants from Europe, America, and Japan, while the domestic MCU market has a relatively low localization rate, primarily focused on consumer-grade products. While the domestic MCU market is growing rapidly, global competition remains intense. International manufacturers such as NXP, Renesas, and Infineon dominate the global market. Domestic manufacturers face challenges in entering the high-end market, especially in the automotive-grade MCU field with high safety and reliability requirements.

5. Development Challenges:

The performance requirements for automotive-grade MCUs are high, the certification cycle is long, and the global vehicle supply chain is essentially solidified, posing a challenge for domestic MCU manufacturers. However, some domestic manufacturers are starting with mid-to-low-end automotive-grade MCUs that are less related to safety performance. Some major domestic MCU manufacturers include GigaDevice, Guoxin Technology, BYD Semiconductor, Jiefa Technology, Xinhai Technology, Zhongying Electronics, Unisoc, and Fudan Microelectronics. These companies have made progress in body control, dashboards, touch control, and are gradually beginning to develop high-end MCUs, such as those for smart cockpits and ADAS.

In summary, China’s automotive MCU industry is in a rapidly developing stage. With technological advancements and growing market demand, there is immense potential for future development. At the same time, facing international competition and market challenges, domestic companies need to continuously strengthen R&D and technological innovation.

The technological development trends of automotive MCU (Microcontroller Unit) chips are moving towards stronger processing capabilities, lower energy consumption, and higher integration levels. These advancements not only enhance the intelligence level of vehicles but also drive the automotive industry towards greater efficiency and environmental friendliness.

1. Stronger Processing Capabilities:

As automotive electronic systems become increasingly complex, MCU chips need to process more data and more complex algorithms. Therefore, the next generation of MCU chips adopts more advanced processor architectures, providing higher computing capabilities and data processing speeds. For example, MCU chips that use multi-core processor architectures can process multiple tasks in parallel, improving system efficiency and response speed.

2. Lower Energy Consumption:

Energy conservation and environmental protection are important trends in modern automotive development. MCU chips achieve lower energy consumption through advanced manufacturing processes and power management technologies. For example, MCU chips designed with low power consumption and high energy efficiency can reduce energy consumption without sacrificing performance.

3. Higher Integration Levels:

With the development of semiconductor technology, MCU chips integrate more and more functions, such as analog signal processing, safety functions, and wireless communication.

Highly integrated MCU chips can reduce the number of electronic components in vehicles, lowering system costs while improving reliability and stability.

In terms of future trends, as autonomous driving technology develops, MCU chips will play an increasingly important role. Autonomous driving systems need to process large amounts of sensor data and make real-time decisions. Therefore, future MCU chips will need to have higher computing power, lower latency, and higher reliability.

At the same time, with the development of vehicle networking and Internet of Vehicles technology, MCU chips will also need to support more advanced communication protocols and security features to ensure data security and privacy.

In summary, the technological development trends of automotive MCU chips will continue to drive the development of the automotive industry, providing strong technical support for future smart vehicles. With ongoing technological advancements, we can expect future vehicles to be smarter, more efficient, and more environmentally friendly.

END