Follow Us – Everyday Progress 【AxX Dental Lab

3D printing technology usage may signify a revolution, bringing profound impacts and changes to future manufacturing, social production models, and human lifestyles. 3D printing will disrupt traditional manufacturing; however, there are many issues with 3D printing that may hinder its future and its potential impact on traditional industries.

When mentioning 3D printing, many people may think it is a very new technology, but in fact, it is not. The history of 3D printing technology is not much shorter than that of inkjet printing; it was born in 1986. The idea of converting digital 3D graphics into physical objects was first patented by Charles W. Hull (US Patent 4573330), whose principle is stereolithography. This technology will be elaborated on later. It is worth noting that Mr. Hull is also the founder of 3D Systems and launched the first industrial 3D printing device.

In the late 1980s, 3D Systems’ equipment became popular. At the same time, two other 3D forming technologies emerged: Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS). The FDM technology was invented by Scott Crump in 1988, and Stratasys commercialized this technology the following year, selling the first 3D printing product based on FDM technology in 1992. In the same year, DTM also launched a product based on Selective Laser Sintering technology. In 1993, the Massachusetts Institute of Technology applied for a new 3D printing technology called “3 Dimensional Printing techniques,” which relies on existing inkjet technology, and Z Corporation obtained the patent license from MIT, launching the first product in 1995.

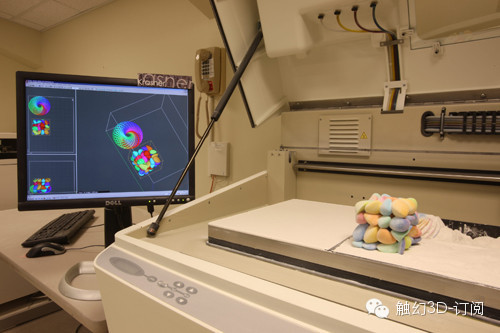

The following decade was a period of development for 3D printing, with various companies striving to reduce the cost of 3D printing. In 2005, ZCorp launched a milestone 3D printer product, the “Spectrum Z510,” which was the first product capable of high-resolution color 3D printing.

ZCorp SpectrumZ510 3D printer color 3D printing demonstration.

In 2006, another landmark event occurred in the 3D printing world. An open-source 3D printing project called Reprap was announced, allowing interested readers to visit their official website. This initiative freed 3D printing from patent constraints in many fields, enabling ordinary people to engage in 3D printing. However, the 3D printing devices based on this open-source project can only print relatively small objects. Nevertheless, this technology has become very popular; within just four years, a complex product family has developed. On Taobao, a 3D printer capable of printing 12 cm cubes costs only about 4000 yuan, making it quite affordable. Users interested in this technology can purchase one for home 3D forming work, but it should be noted that 3D printers are relatively large, occupying space similar to that of a 29-inch color television or even larger.

Mainstream Technologies: SLA and FDM

Stereolithography

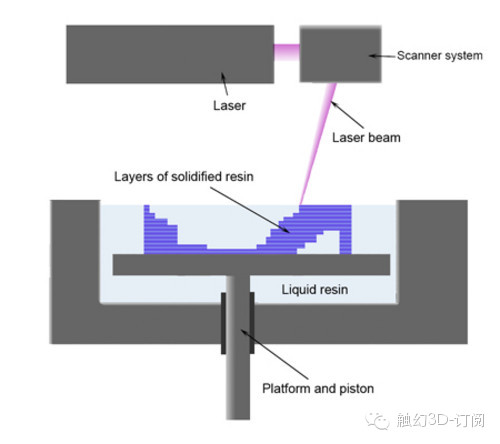

Illustration of stereolithography technology

Stereolithography technology can be imagined as slicing a cucumber into very thin slices and then reassembling it into a whole. First, the software “slices” the 3D digital model into several planes, creating many cross-sections. During operation, there is a liftable platform surrounded by a liquid tank filled with a liquid that can be cured by ultraviolet light. The ultraviolet laser starts from the bottom layer, curing the bottom layer, then the platform descends, curing the next layer, and so on until the final shape is formed.

Advantages and Disadvantages of Stereolithography Technology

Advantages: High precision, can achieve accurate surfaces and smooth effects, with a precision of 0.05 mm to 0.15 mm per layer.

Disadvantages: Limited materials can be used, and it cannot form in multiple colors.

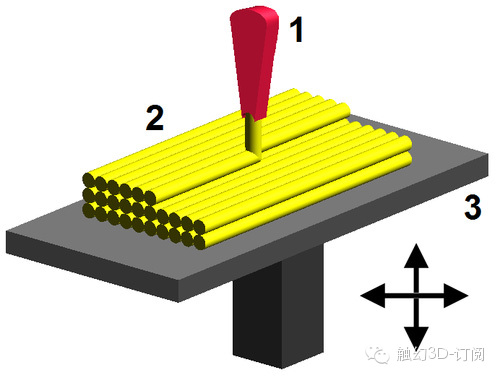

Fused Deposition Modeling

(FDM)

Fused Deposition Modeling technology also requires slicing the 3D model, but the forming principle differs. Those familiar with advanced mathematics know about integration; FDM technology melts materials into liquid using high temperatures, then extrudes tiny spherical particles through a nozzle. These particles solidify immediately after being extruded, forming physical objects through their arrangement in three-dimensional space.

1. Nozzle; 2. Deposition material; 3. Platform that can move in multiple directions;

Advantages: Higher forming precision, stronger physical strength, and can form in color.

Disadvantages: Rough surface after forming.

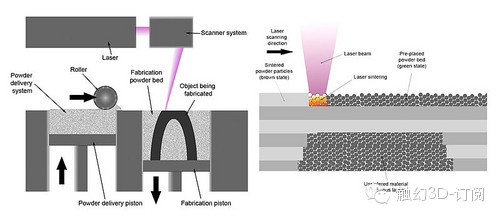

Selective Laser Sintering

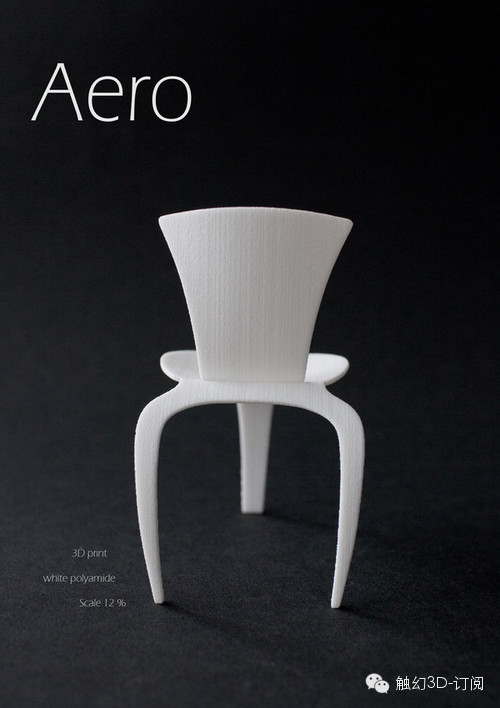

(SLS)

Selective Laser Sintering technology slices the 3D model and fills a container with the material powder to be sintered. These powders can be very fine, and then a high-power carbon dioxide laser starts sintering the 3D cross-section shape from the bottom layer. The platform descends, and a material roller spreads a thin layer of powder on top of the already sintered part, repeating the process until the entire shape is formed.

Advantages: Very high material strength, with a wide range of selectable materials from metals to polystyrene.

Disadvantages: Low forming precision, rough surface after forming, cannot form in color.

3 Dimensional Printing Techniques

This technology is similar to the 2D inkjet printers we use today, using multiple nozzles to spray forming materials layer by layer to print 3D objects. The forming materials are divided into two types: one is the powder used for forming, and the other is the adhesive, which can cure quickly.

Advantages and Disadvantages of 3D Printing Techniques:

Advantages: High forming precision, can form in color.

Disadvantages: Rough surface after forming, poor material strength, and poor surface details after forming.

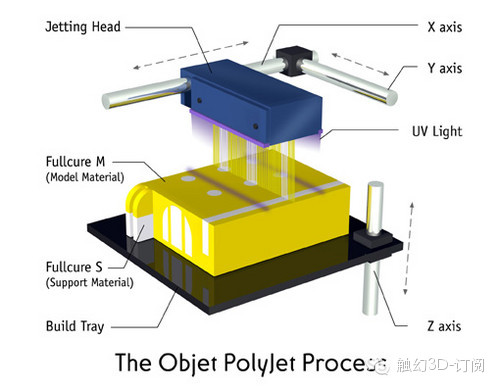

Polyjet and Polyjet Matrix

Polyjet technology has many advantages in 3D printing

This is a recently invented technology, with the Polyjet matrix released by Object Geometries in 2007. Its principle is to spray ultra-thin layers of photopolymer, and it can spray various materials, with the thinnest layer being only 16 microns.

Advantages and Disadvantages of Polyjet Technology:

Advantages: Precise forming, smooth surface, rich details, and can form in color.

Disadvantages: Low strength of forming materials.

Essential 3D Scanning

To perform 3D printing, a digital 3D model is necessary. Besides using CAD and other 3D design software for 3D modeling, a way to create a digital 3D model from physical objects through scanning is needed, which is done using a 3D scanner.

Handheld 3D Scanner

Common types of 3D scanners include contact and non-contact types. Currently, the non-contact surface light grid 3D scanners are key products in the market, combining structured light technology, phase measurement technology, and computer vision technology. They are characterized by fast speed and high precision (0.03 mm) and can scan large volumes of objects.

Archaeology and Paleontology

As we know, many cultural relics are very precious and cannot be moved frequently. 3D printing technology can replicate these relics, such as ceramics and bronzes, allowing users to know their accurate 3D shapes, which helps enhance the appreciation of cultural relics, as certain specific shapes were only produced during specific historical periods. In paleontology, 3D printing can replicate entire ancient animal skeletons and shapes, providing researchers with a more three-dimensional understanding.

3D printed cultural relics

China is a major cultural relic country, but many Chinese relics have gone abroad during various wars, especially Buddhist sculptures, many of which have been separated from their bodies; the bodies remain in China while the heads have either been robbed or smuggled abroad. Through 3D printing technology, both parts can be scanned separately, and using computer technology, they can be stitched together to form a complete Buddhist sculpture, restoring its historical appearance.

Medicine

3D printing has many applications in medicine, primarily in complex surgeries and dentistry.

The complexity of human body structures often exceeds our imagination. Sometimes, surgeons can only make possible judgments for complex surgeries based on medical imaging data such as CT or MRI scans. However, when the complexity exceeds expectations, the success rate of the surgery can be low. 3D printing technology can utilize existing medical imaging data to first print a 3D model of the patient, allowing simulations on the model to determine feasible surgical plans.

3D printing helps dentists provide perfect oral care for patients

Dentistry is another hot area for 3D applications. In Europe and America, dentists earn high incomes because this job relies heavily on experience. Many patients have had impressions taken during dental fittings, which dentists then adjust based on their experience. However, if the patient’s oral cavity is scanned and modeled in 3D, they can accurately print the patient’s oral structure, helping dentists create precise dentures.

Architecture

For those not in the architecture profession, few can visualize the 3D shape of a building just by looking at architectural drawings. Manually creating architectural models can be very costly, especially in Western countries where labor is expensive. However, with 3D printing technology, it is now easy and fast to print an architectural model in a short time, and even if clients have modification suggestions, a new model can be completed quickly, improving efficiency in the design phase.

3D printing planning for a London neighborhood

Industry

Industry is the core field for 3D printing applications. Nowadays, industrial design is extremely important, often the key to a product’s success or failure. Throughout the process from design to productization, the involvement of 3D printing technology accelerates the pace of industrial design, as it can quickly realize the physical manifestation of industrial designs, especially in the automotive sector, where large physical objects can now be printed. Physical manifestation is an essential step in design, allowing both designers and decision-makers to visually see the product’s shape and make decisions on whether to mass-produce it. Of course, due to technologies like selective laser sintering, small batch production is also possible, as this technology can form metals. Sometimes, small batch 3D printing is more cost-effective than digital machining, casting, or stamping.

Entertainment Industry

The image shows a hand prop from “Iron Man 2,” a product of 3D printing

In movies, we see many humanoid monsters portrayed by actors. Traditionally, film production bases like Hollywood use manual techniques for these special effects, but now, 3D printed models dominate the scene, allowing for easy printing of personalized monster masks and full-body gear with realistic effects.

Personal Object Creation

123DCatch was originally a plugin for Autodesk’s AutoCAD, and it can now also be used on iPhones. By taking multiple angles of the same object, 3D data can be generated. Similar applications include Trimensiona, and interested users can search for them on the app store.

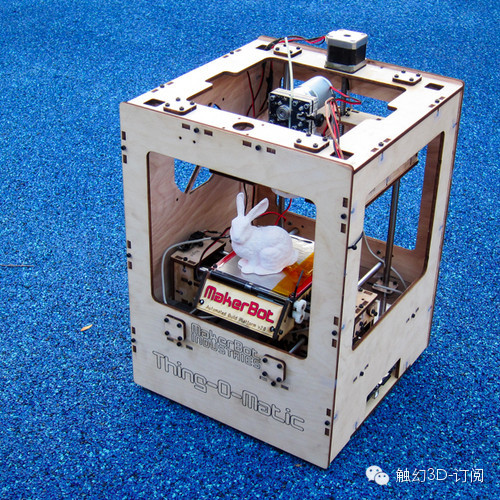

MakerBot’s home 3D printer

With these digital files, individual users have two options: either buy a 3D printer, which costs around 4000 yuan and can print 3D objects about ten centimeters on each side, or send the digital files to specialized forming companies that will print them and ship them to users, though this service comes at a cost. Currently, some websites offer this service, but their primary clientele is in Europe and America, making shipping to China quite expensive.

3D Printing: The Future of Printing?

The term 3D printing is becoming increasingly popular and is quickly being applied worldwide. A friend of mine who runs a factory in Guangdong mentioned that the cost of printing a model in Guangdong is about 500 yuan, which is not expensive considering product development costs. Nowadays, a 3D printer costing around 4000 yuan can produce small products or parts.

Compared to the 2D printing market, which is worth hundreds of billions to over a trillion dollars annually, the annual market space for 3D printing is only a few hundred million to a few billion dollars, still a developing market. However, in February 2011, The Economist stated, “3D printing technology can cheaply produce everything from single items to thousands of products, thus disrupting economies of scale, just as those 3D printing companies have done… Just as the printing press of 1450, the steam engine of 1750, and the transistor of 1950, no one could accurately predict their broad applications in the future. No one can predict the long-term impact of 3D printing technology. 3D printing technology has arrived, and it may disrupt every field it touches in the future.”

3D printing giant Stratasys went public on NASDAQ in 2008.

However, we see that traditional printing industry giants have adopted a wait-and-see approach to the development of companies like Stratasys and 3D Systems. For these giants, the traditional 2D printing business is still substantial, and these 3D printing companies are still small enough for the Fortune 500 companies. Once these traditional printing giants become interested, acquisitions in the capital market are not out of the question.

3D printing indeed has many issues that need improvement, but innovation in aspects such as printing materials, the operation of print heads, and printing control technology is the best way forward. 3D printing is a new digital manufacturing technology that will change our lifestyles and work methods, but it will inherit existing technologies for a certain period; it is a beneficial supplement to traditional industry. With technological advancements, especially in the application of interdisciplinary sciences, significant breakthroughs in 3D printing technology will occur, potentially making it a leading player in manufacturing. In the future, if 3D printing achieves easy operation, high efficiency, high precision, and low cost, it will bring about an “industrial revolution!”