In Jiangning Development Zone, robots are no longer a distant imagination from science fiction movies; they are like “colleagues” of humans, busy laying tiles, painting walls, transporting, and inspecting at construction sites;

helping athletes correct their posture in sports training fields;

assisting doctors in detecting early signs of Parkinson’s disease in hospitals, and collaborating with humans in smart factories…

As the “core” of the city’s robot industry layout of “one core and multiple wings”, Jiangning Development Zone currently gathers over a hundred core artificial intelligence industry and upstream and downstream related enterprises.

01

Robots Building Houses

Construction Sites Spark an “Efficiency Revolution”

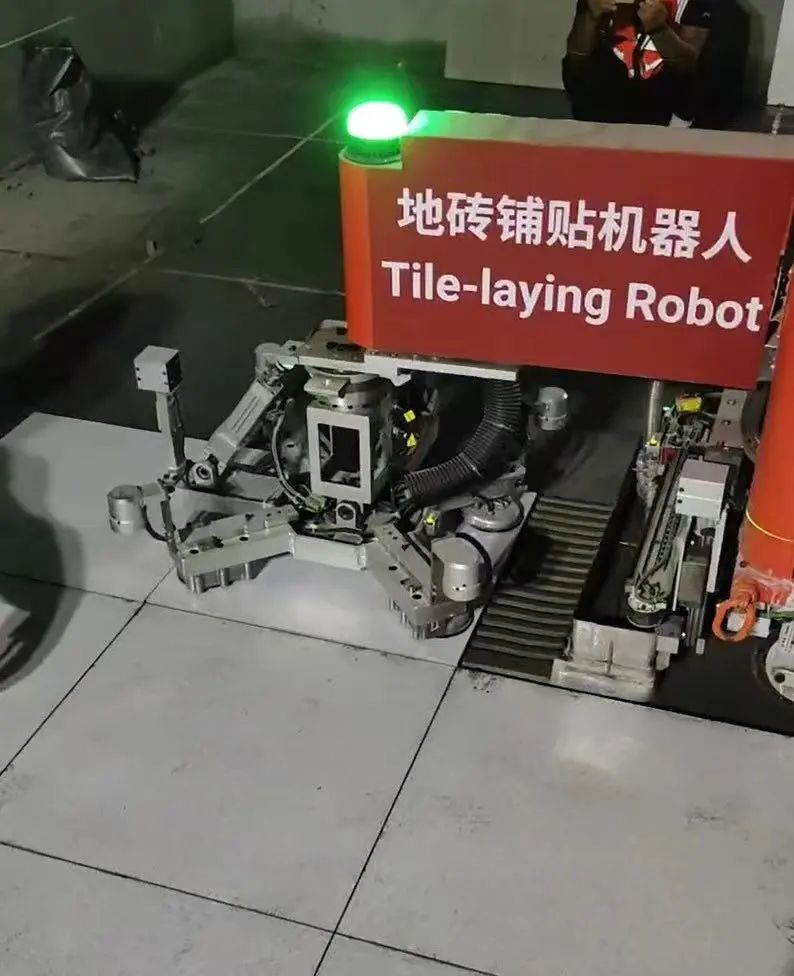

Zhuling Tile Laying Robot.

Just after the Spring Festival, Nanjing Zhuling Technology Company is busy sending tile laying robots to construction sites at home and abroad to “work”. These robots are precise in movement and fast in speed; they first scrape putty on the ground, then use mechanical arms to steadily grab a tile and lay it accurately, completing 100 square meters of laying in 8 hours, which is 4-5 times more efficient than manual labor.Last year, this robot was just promoted to the market and had a “trial run” on projects in cities like Shanghai and Nanjing.“After several years of iteration, domestic construction robot products have become stable and mature. Currently, tile laying, wall painting, spraying, drilling, measuring, and concrete mixing robots have been successively put on the market, and the industry has reached a window period,” said Dai Angang, chairman of Nanjing Zhuling Technology Company.

Meanwhile, at a residential construction site in Singapore, the putty and latex paint spraying integrated robot from Nanjing Lingque Technology Company is also in full swing. Its “arms” move flexibly up and down, while its “brain” computes rapidly, ensuring that every small corner of the wall is evenly sprayed. “This robot can complete wall painting work of 1200-1400 square meters in 8 hours, which is 1.5 times more efficient than skilled workers in China,” said Zhang Zhixiang, chairman of Lingque Technology. Last year, this robot was officially commercialized and achieved sales of tens of millions in the Singapore market that year.

Nanjing Lingque Technology Company has a “training room” for construction robots, where various robots such as floor grinding robots, latex paint spraying robots, tile laying robots, and putty latex paint spraying integrated robots gather together. Under the guidance of skilled human painters and tilers, they disassemble and imitate the fine movements of humans. The unique continuity and stability of robots allow them to quickly “graduate”, even “surpassing their masters”.

Currently, in the domestic market, the state is vigorously promoting intelligent construction, bringing a wave of policy opportunities; in the overseas market, this trend is even more urgent. For example, the Singapore Housing Development Board announced that starting from January 1, 2025, 50% of the public housing projects in Singapore will be required to use latex paint spraying robots for painting operations.

The “sensitivity” of capital is the most acute. Currently, Lingque Technology has completed three rounds of financing led by top dollar institutions Atypical Ventures, IDG Ventures, and XVC Ventures, with the latest round valued at nearly one billion yuan. Zhuling Technology also recently completed an important round of financing, successfully obtaining tens of millions of dollars in Pre-A round investment. This round of financing was led by Shunwei Capital, initiated by Xiaomi founder Lei Jun, marking Xiaomi’s further layout in the smart hardware field. Nanjing’s construction robot companies are working together to promote an intelligent revolution in the construction industry both domestically and internationally.

02

They Create “Tactile Nerves” and “Joints” for Humanoid Robots

Humanoid robots became a hot topic on social media during this year’s Spring Festival Gala. During the Spring Festival travel season this year, the humanoid robot Codroid 01 from Nanjing Estun Automation Co., Ltd. also became a “celebrity” in the waiting hall of Nanjing South Station. This robot “greeter” stands 1.7 meters tall, weighs 75 kilograms, and can flexibly move its shoulders, elbows, and fingers, with a silver-black color scheme that looks very high-tech, winning the favor of passengers coming and going.

Humanoid robot Codroid 01 from Nanjing Estun Automation Co., Ltd.

Estun revealed that the second-generation humanoid robot Codroid 02, which has walking capabilities, is set to be launched in the second quarter of this year, with plans to showcase it at the International Robot and Automation Technology Exhibition in Munich, Germany, in late June this year. Estun is a leader in the robotics sector, and in 2024, Estun Codroid received 100 million yuan from the National Advanced Manufacturing Fund and 30 million yuan from the provincial strategic emerging industry mother fund, becoming the first direct investment project of Jiangsu Province’s strategic emerging industry mother fund.

A relevant person in charge of the Jiangning Development Zone High-tech Park stated: “In addition to humanoid robots, the park has also nurtured a batch of key component suppliers for humanoid robots, including Nanchuan Intelligent, Kemaide Technology, Shenyuan Intelligent Technology, Inks Technology, Lingzhi Technology, and Quark Electric, with products covering reducers, controllers, sensors, etc., which are mainly used in core components of humanoid robots.”

At Nanjing Shenyuan Intelligent Technology Co., Ltd., founded by Professor Dai Zhendong, a doctoral supervisor at Nanjing University of Aeronautics and Astronautics, precision six-dimensional force sensors are being assembled. These sensors are the “tactile nerves” of robots, allowing them to sense force and adjust movements.Dai Zhendong said:“From conventional robots weighing dozens of kilograms using six-dimensional force sensors to as small as 10 grams for insect six-dimensional force testing sensors, and up to 100 tons for giant equipment testing six-dimensional force sensors, Shenyuan Technology’s products cover the needs of humanoid robots, automotive, aerospace, new energy, scientific research, and other industries.” As a leading unit of the national key R&D project “Key Technologies and Industrialization of Intelligent Six-Dimensional Force and Tactile Sensors for Robots”, Shenyuan Technology has received angel round financing from the Ministry of Science and Technology’s China Science and Technology Innovation Fund. Currently, products have been sold to the United States and EU countries such as Germany, Denmark, and Sweden.

Multi-dimensional force sensors.

Expanding ideas, Shenyuan Technology combines research on animal behavior and biomechanics to provide data for robot training, opening up new avenues in competitive sports, robot training, and medical fields. In training fields, the motion reaction testing system developed by the company is helping athletes correct their posture; in collaboration with well-known domestic hospitals, the medical robot training system observes the gait behavior and mechanical changes of middle-aged and elderly people to detect early signs of Parkinson’s disease. Dai Zhendong said: “This is a newly emerging ‘blue ocean’ with huge market potential. Our product technology is strong, cost-effective, and we are confident in competing globally!”

Inks Technology’s main mass-produced products.

The cost of robot joint modules accounts for about 40% of the total cost of robots, and its technical level determines the precision and flexibility of robot movements. Nanjing Inks Intelligent Technology Co., Ltd. was established in 2022, with a core team composed of master’s graduates from Nanjing University of Aeronautics and Astronautics and Huazhong University of Science and Technology. “The joint modules we developed are highly integrated with reducers, motors, drivers, encoders, and other components, suitable for complex motion control systems such as biped robots, quadruped robots, and robotic arms. In 2024, the company received tens of millions in financing from leading institutions like Oasis Capital, and its products have achieved mass production. This year, an additional 2000 square meters of factory space will be added to expand production capacity,” said the person in charge of the company.

Production workshop of Estun Automation Co., Ltd. Correspondent Wang Qiang Nanjing Daily/Zijinshan News reporter Feng Peng photo

A relevant person in charge of the Jiangning Development Zone High-tech Park stated that the park is currently promoting the establishment of innovative platforms such as the Future Robot and Artificial Intelligence Joint R&D Experimental Center led by Estun, the humanoid robot and core component pilot platform, and the provincial robot industry benchmark incubator, while actively planning the construction of the “Jiangsu Province Embodied Intelligence Industry Innovation Center”. Among them, the Future Robot and Artificial Intelligence Joint R&D Experimental Center is jointly built by Estun (Future Technology Research Institute) and Southeast University, with plans to be operational by June 2025, establishing three major technology platforms: embodied intelligence (AI robots), intelligent perception (spatial vision technology), and AI platform (data center and model service platform).

Nanjing University of Aeronautics and Astronautics. Photo provided by the university

In the “legion” of robots in Jiangning Development Zone, the “Nanjing University of Aeronautics and Astronautics” is a backbone force. Looking back at history, Nanjing University of Aeronautics and Astronautics has had an inseparable bond with Jiangning since the planning period of the Jiangjun Road campus. In the past three years, the two sides have carried out over 300 cooperative projects. Last year, Jiangning Development Zone and Nanjing University of Aeronautics and Astronautics jointly launched the creation of the “Huan Nanhang Technology Innovation Belt”, with a total planned area of about 10 square kilometers, aiming to drive the addition of 20 billion yuan in new industrial scale within five years, with the robot industry being one of the important cooperation directions.

03

“Industrial Eye” Enhances “Made in China”

In the field of intelligent manufacturing, robots are making a significant impact, stirring up industrial transformation.

In the laboratory of Nanjing Yuntong Technology Co., Ltd., a vision robot is scanning a car, continuously transmitting big data to the workstation system. In no time, a “clone” version of the virtual car appears on the screen, and any detail dimensions, geometric features, and deviation analysis can be quickly reported by the computer.

Company chairman Li Guidong, a PhD graduate from Nanjing University of Aeronautics and Astronautics, said: “Detection and measurement are key links in intelligent manufacturing. What outsiders don’t know is that in the past, measuring the seams of super-large products like airplanes relied on manual labor. Workers used testing plates of varying thicknesses to insert into the gaps of the aluminum alloy shell of the airplane to check for compliance. However, vision robots excel at non-contact measurement, and can measure various dimensions of large equipment with a simple ‘scan’, making them particularly suitable for measuring large equipment like airplanes and rockets. Our developed vision robots have broken the foreign monopoly and are now supplying to COMAC for models like C919.”

A new generation of integrated measurement and processing equipment has also emerged at Yuntong Technology, which has revolutionized the traditional processing flow of components. “Traditional CNC machine tools are like a ‘blind box’; no one knows in advance whether the produced product is qualified, requiring production first and then testing. In contrast, integrated measurement and processing equipment acts like an ‘industrial eye’ installed in the machine tool, measuring online and adjusting in real-time, greatly improving the yield rate,” Li Guidong said. As a specialized and innovative small and medium-sized enterprise in Jiangsu Province, Yuntong Technology has seen its output value grow at an average rate of 30% in recent years, with a target output value of 80 million yuan this year.

Walking into the factory of Jiangsu Daoda Intelligent Technology Co., Ltd., OHT intelligent overhead cranes are operating in an orderly manner. In a 12-inch semiconductor factory, OHT cranes are essential key equipment due to their high complexity, technical challenges, and high market entry barriers, which have long been dominated by foreign manufacturers. However, Daoda Technology has broken this situation through independent research and development, successfully accelerating the semiconductor industry. A relevant person in charge of Daoda Technology stated that the company provides not only this product but also a complete set of solutions for semiconductor manufacturers. In the field of smart factories, semiconductor factories have the highest technical requirements and the greatest difficulty. Daoda Company currently possesses complete control and scheduling capabilities for smart factory processes, able to intelligently solve issues such as yield management and real-time control of materials during the entire transportation process.

Reflecting on the journey so far, Daoda Technology has steadily advanced: in 2022, it received Pre-A round investment from Yida Capital, with a valuation of nearly one billion yuan; in 2023, it was approved as a specialized and innovative small and medium-sized enterprise in Jiangsu Province; and in December 2024, it completed several hundred million yuan in A round financing, achieving a new high valuation, becoming a leading enterprise in the semiconductor handling robot sector.

With the rapid development of industries such as gluing and welding, the complexity of processes, production quality, and production rhythm requirements are increasing, making automatic trajectory planning an inevitable trend in industrial development.

Nanjing Pengli Technology Industrial Group combines its self-developed 3D industrial camera with six-axis industrial robots to innovatively develop a 3D vision robot trajectory guidance system. This system has high precision and strong stability, significantly reducing labor costs and safety hazards in production scenarios in industries such as gluing and welding. In 2024, this system was rated among the TOP 30 in the machine vision industry chain.

It is reported that to promote the development of the robot industry, Jiangning Development Zone has currently laid out upstream core components, midstream body manufacturing, and downstream system integration and application, covering various directions such as industrial robots, service robots, and special robots. Here, a “dance” between humans and robots has just begun.

Source: Zijinshan Observation

Editor: Mao Xinyue, Qi Zhonggan

Chief Editor: Wang Qiang

Reviewed by: He Zhenning

Published by: Chen Ximu

Nanjing Jiangning Economic and Technological Development Zone ReleasePublished

More

Wonderful

Content

Please scan the QR code on the right

WeChat ID

jnkfq1992