In April 2025, Nanjixiong is significantly compiling a list of Chinese 3D printing service providers, discovering a number of powerful enterprises. For details, see “List of Hundreds of 3D Printing Service Providers Exposed, Resin Parts Priced as Low as 0.4 Yuan per Gram, Annual Revenue Up to 600 Million Yuan“. Various service providers have sent introductions of their production facilities to Nanjixiong, which have been compiled into the 3D printing manufacturers directoryhttps://www.nanjixiong.com/forum-244-1.html column.

Xian Aerospace Electromechanical Intelligent Manufacturing Co., Ltd. (referred to as Xikong Intelligent Manufacturing), established in April 2020, is a technology-driven enterprise engaged in metal and multi-material intelligent additive manufacturing for aerospace power, new energy vehicles/machines, and other fields, originating from the transformation of achievements from Xi’an Jiaotong University. It is positioned as a provider of metal and multi-material intelligent additive manufacturing equipment and a manufacturer of components for (aerospace) energy power.

The company currently has two main business areas.

Main Business One: Development and production of “Intelligent Three Printing” equipment, including intelligent laser forging printing equipment, intelligent electron beam point printing equipment, intelligent laser surface printing equipment, and 3D printing intelligent monitoring systems. The laser forging printing equipment is a company innovation, divided into powder bed forging printing and powder feeding forging printing equipment. By using ultra-fast laser reinforcement composites, it addresses issues such as cracking, deformation, and insufficient fatigue performance in traditional laser 3D printed parts, improving the mechanical properties of metal and multi-material printing to the level of forgings. Currently, 150mm, 300mm, and 650mm powder bed forging printing equipment have been developed, as well as two types of powder feeding forging printing equipment. The electron beam point printing equipment improves the precision and surface finish of electron beam powder bed printing (comparable to SLM) through “point melting” and, combined with powder support and substrate-free printing, reduces manufacturing costs. By using multiple guns for printing, the printing speed and dimensions are further increased, with 100mm, 200mm, 420mm, and 550mm electron beam equipment already developed. The laser surface printing equipment increases the printing rate by controlling the laser projection from point to line to surface area, thereby reducing manufacturing costs, with prototype testing completed. The SLM intelligent monitoring system series products have already supplied hundreds of sets to customers. Main Business Two: Manufacturing of (aerospace) energy power components based on “Intelligent Three Printing”, primarily serving the development of new productive forces in low-altitude economy, commercial aerospace, biomanufacturing, and robotics, as well as traditional aerospace and consumer electronics manufacturing. Intelligent forging printing is used for the manufacturing/remanufacturing of high-performance metal and non-metal components in aircraft engines and medical applications; intelligent point printing is used for manufacturing difficult-to-process metal components such as copper, titanium-aluminum alloys, titanium alloys, and high-temperature alloys for aerospace power, consumer electronics, and thermal equipment; intelligent surface printing is used for mass manufacturing of metal/non-metal components in new energy vehicles/machines and robotics. The company has established production lines for the manufacturing and remanufacturing of turbine blades, casings, and copper components for aviation power, with multiple components for enterprises under AVIC and CASC already in mass production.

The company has a research and management team composed of PhDs, Masters, and MBAs from renowned universities such as Xi’an Jiaotong University and Xi’an University of Technology, undertaking or participating in multiple national and provincial key research and development projects, applying for over 100 patents, and obtaining more than 50 approved invention patents. It has been recognized as a high-tech enterprise and a national “specialized, refined, and innovative” small giant enterprise, selected as a council member of the Ministry of Industry and Information Technology’s Additive Manufacturing Industry Alliance and as a typical application scenario case. The company has received national military standards and national quality management system certifications, as well as CNAS laboratory accreditation, and has won awards in national aviation innovation and entrepreneurship competitions, including a first prize in provincial and ministerial technical invention. The company has established an intelligent additive manufacturing technology center for energy power equipment and a joint R&D center “i-3D” with Xi’an Jiaotong University, inviting several academicians and national-level experts as members of the technical committee. The company has established strategic partnerships with Xi’an Jiaotong University Aviation Engine Research Institute, National Local Joint Engineering Research Center for Equipment Operation Safety Assurance and Intelligent Monitoring, National Key Laboratory for Metal Material Strength, Qingdao Aerospace Power Structural Safety Research Institute, National Key Laboratory for Lightweight Turbine Power at the Institute of Engineering Thermophysics, Chinese Academy of Sciences, and the National Local Joint Engineering Center for Intelligent Transmission and Control at Southwest University, among others, and is a major member unit of the Shaanxi Province aviation industry chain and hydrogen energy innovation center. In 2023, the company established a wholly-owned subsidiary in Qingdao and plans to establish a subsidiary in Chongqing in 2025. The Qingdao subsidiary is mainly responsible for laser powder feeding forging printing business, while also handling material preparation and civil printing services in the northern region; the Chongqing subsidiary will focus on cold metal fusion/non-metal surface printing processes, material research and development, and manufacturing services, while also managing civil printing services in the southwestern region.

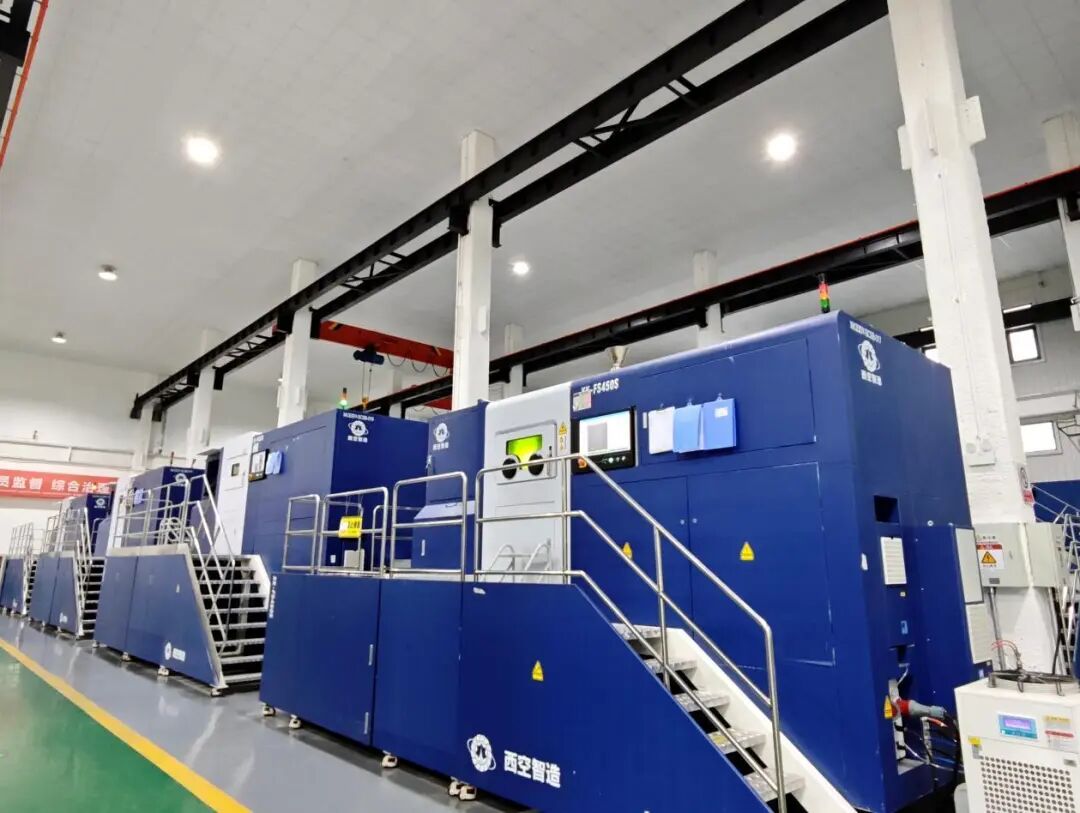

The company currently has 34 printing devices (including those at the Qingdao subsidiary), with 27 laser powder bed devices covering sizes from 260mm to 1250mm, 5 electron beam devices, and 2 laser energy deposition devices, capable of meeting the printing needs of different sized parts. There are also post-processing equipment such as sandblasting machines, powder cleaning machines, and heat treatment furnaces.

The company has mastered laser additive manufacturing process technologies for materials such as TiAI alloys, high-temperature alloys, pure copper/copper alloys, aluminum alloys, and difficult-to-weld materials, forming a comprehensive set of performance data covering deposition states and various heat treatment conditions.

At the same time, the company possesses additive manufacturing technologies for thin-walled complex channel parts, complex channel parts, laser coaxial powder feeding forming/repair technology, arc additive repair technology, and electron beam melting forming (EBM) technology. Multiple additive manufacturing products have passed thermal testing, and some products have been applied in aviation and aerospace high-temperature components, titanium-aluminum lightweight components, and complex structural parts, gaining rich processing experience. Xikong Intelligent Manufacturing is a leading provider of online intelligent monitoring technology solutions for the laser selective melting process in China. Its developed online intelligent monitoring system is mainly used for real-time monitoring, analysis, evaluation, and control of the powder quality in laser selective melting equipment, automatically capturing images at the end of laser scanning and powder laying, intelligently identifying various powder laying defects, diagnosing powder laying anomalies, transforming “blind fixed printing” into “observed variable printing”, enhancing manufacturing quality and unmanned operation capabilities. The technology is internationally advanced, with several monitoring products including the laser powder bed monitoring system V5.0.0, large-format laser powder bed intelligent grafting system, and laser melt pool morphology monitoring system V2.0.0, comprehensively breaking through industry limitations and leading a new revolution in 3D printing intelligent online monitoring systems.

Recent Hot Articles from Nanjixiong:

“Breaking: Police Arrived at 3D Printing Company to Arrest for Internal Embezzlement”

“I Dreamed of Raising 20 Billion Yuan to Acquire All Foreign Listed 3D Printing Companies and Achieve 290 Billion Yuan in A-Share Market”

“China’s 100-Meter-Level Metal 3D Printer to be Completed in Tianjin, Developed by Beijing Institute of Technology, with Ultra-Large Specification Metal Lattice Structure Multi-Arc Parallel 3D Printing Technology and Equipment”

“CCTV Report: Under Tariff Bullying, Delayed US 3D Printing Toy Orders are Gradually Returning”

Notice to 3D Printing Professionals:

△Scan to open the Nanjixiong website, set WeChat to Star Mark☆, or open it with a mobile browser and set it to the mobile desktop