From LG Display official website introducing OLED

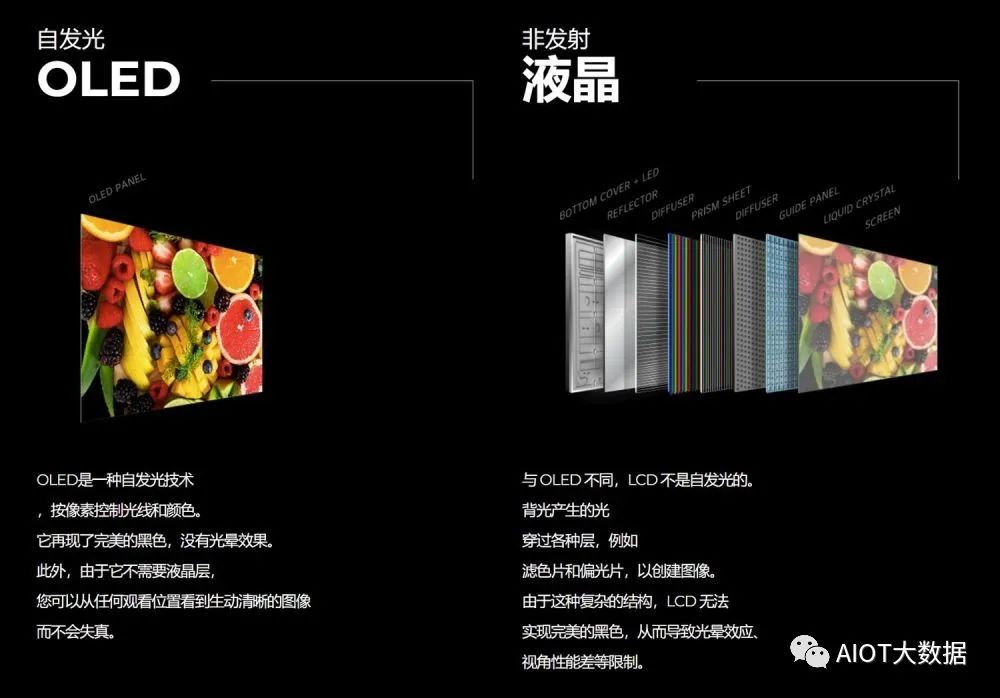

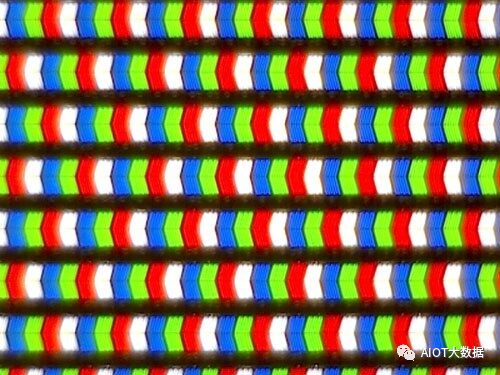

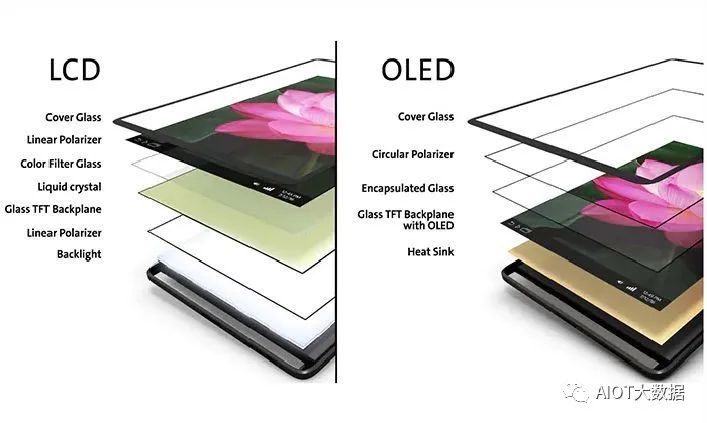

Comparison of OLED with traditional LCD screens

From LG Display official website

Being “thin” and “curved”. Since OLED does not require a large backlight layer and liquid crystal layer, it has a natural advantage in thickness over LCDs, allowing it to achieve extremely thin forms, which is in line with the current demands of smartphones, smart wearable devices, super TVs, and monitors. Additionally, since OLED does not necessarily need a “glass substrate” as the underlying and upper layer material, it can be made flexible. The foldable phones of recent years utilize this technology, using flexible PI plastic as a substrate to achieve large-angle bending.

OPPO Find N, image from Pacific Computer Network

“Pure black”. Compared to the backlight technology used in LCDs, which can only try to cover when displaying black, OLED can directly cut off the voltage transmission, stopping photon generation, resulting in a completely black display. This purity of black also creates a qualitative difference in contrast compared to LCD screens, with OLED desktop monitors often achieving a contrast ratio of 100,000:1, while LCD desktop monitors average only about 1,000:1.

From LG Display official website

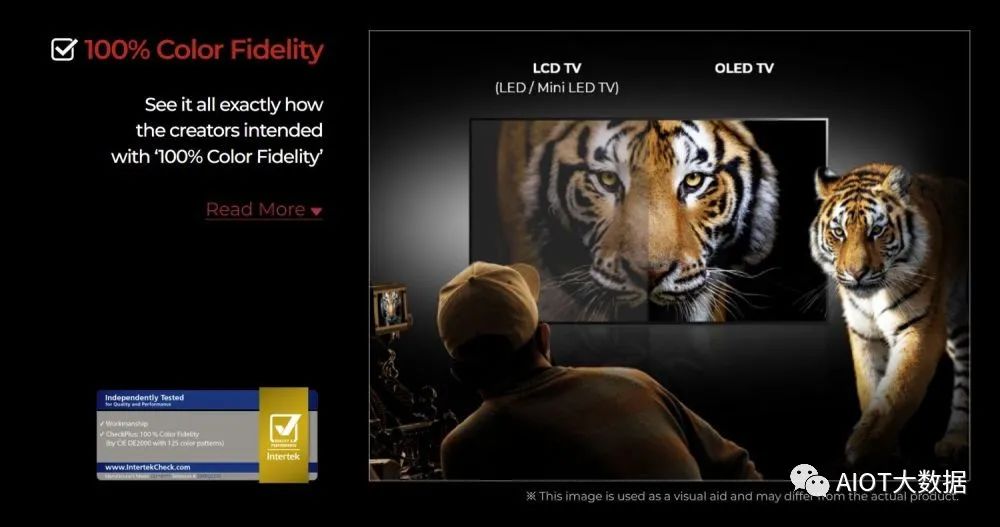

“Vivid colors”. The organic materials in OLED can emit very pure primary colors when lit, combining to create different colors. In contrast, LCD screens are limited by backlight technology and passive color display, resulting in a less rich color gamut compared to OLED.

From LG Display official website

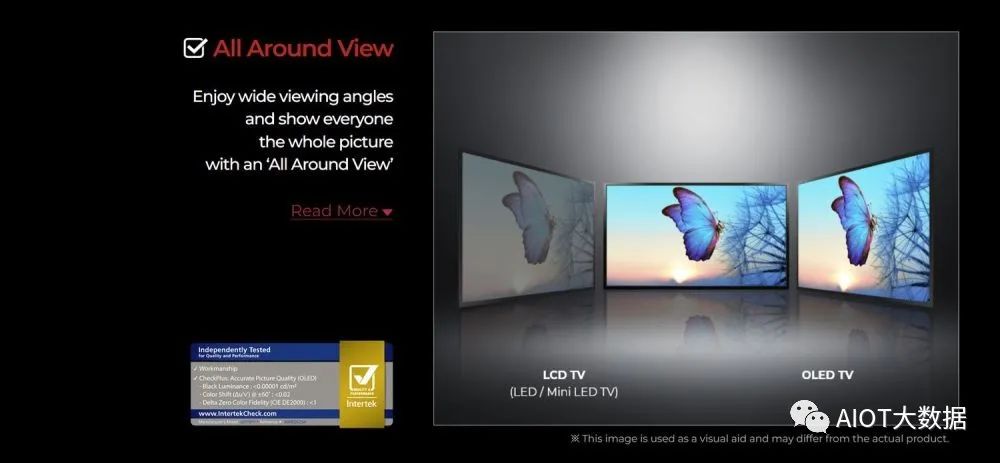

“Even brightness”. Since LCD displays require backlighting, which is mostly side-lit, they generally have average uniformity in illumination. OLED performs much better in this regard, as each pixel can emit its own light, making it easy to achieve uniform brightness and a more cohesive appearance across the screen.

From LG Display official website

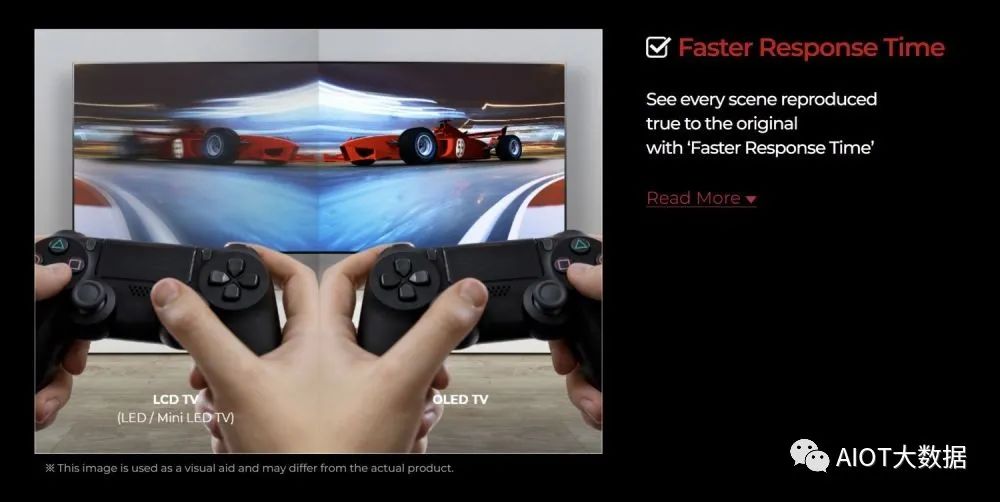

“Fast response”. Unlike LCD screens, which require time for liquid crystal molecules to realign, OLED’s method of controlling pixels with voltage allows for significantly faster response times. Theoretically, OLED screens can achieve response delays as low as 0.1ms, while even the fastest gaming IPS LCD screens have response times around 5ms.

From LG Display official website

But does this mean OLED is invincible? Does OLED have no drawbacks? Certainly not.

“Burn-in”. Since the color emission principle of OLED comes from organic materials, one must consider the degradation and shorter lifespan of these materials. Additionally, the lifespan of the red, green, and blue subpixels of the same area is not the same, leading to accelerated degradation of one color (blue has the shortest lifespan), which can cause serious color shifts in the displayed content, sometimes forming patterns from the degraded areas. This is why some OLED phones and TVs show yellowing after prolonged use.

Image from the internet, the status bar at the bottom remains visible against a pure white background, indicating OLED burn-in phenomenon.

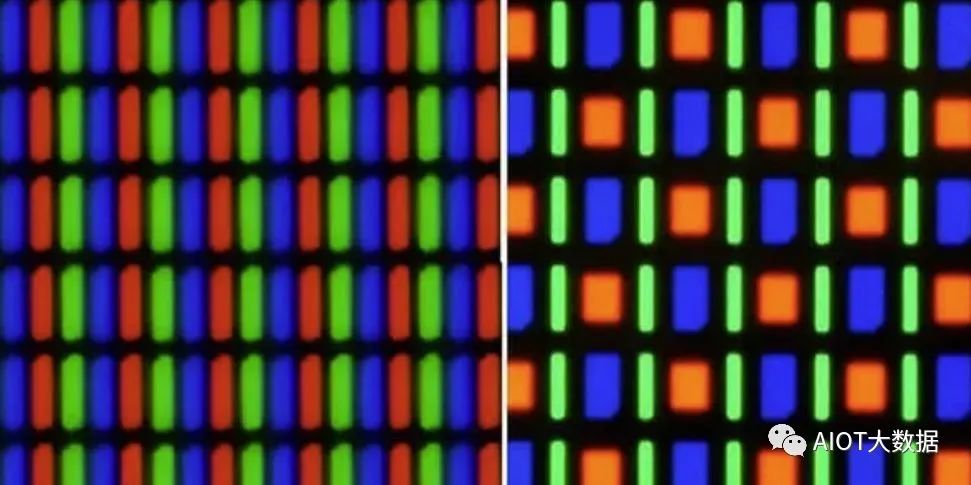

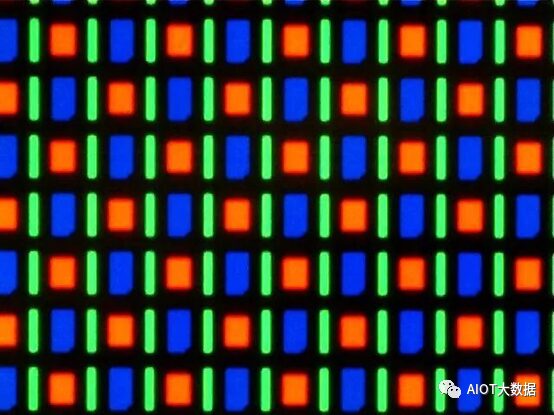

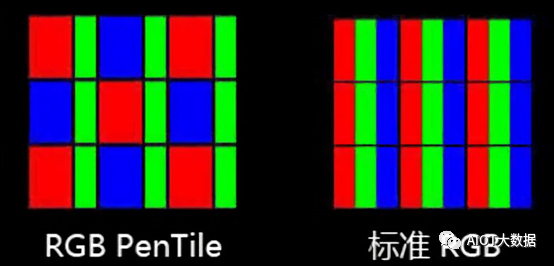

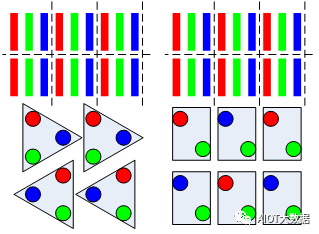

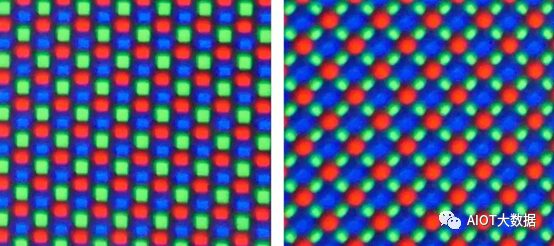

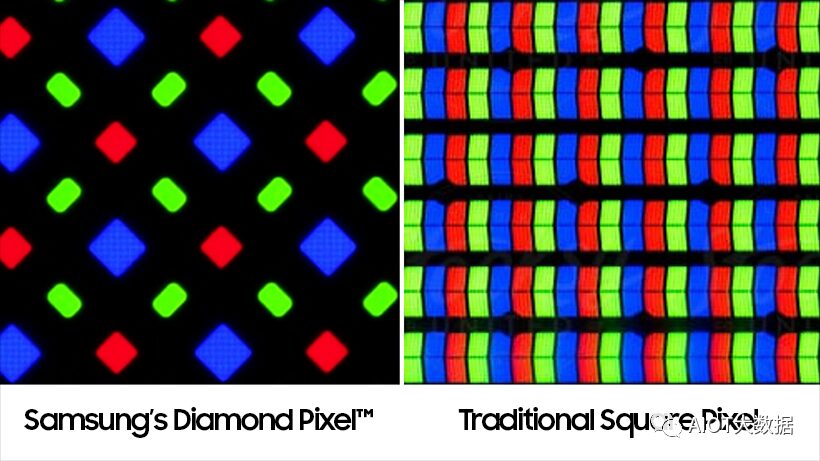

“Lower detail at the same resolution”. To address the aforementioned burn-in issue, OLED manufacturers generally adjust the size, position, and quantity of the red, green, and blue subpixels to ensure their lifespans are roughly equal. In the early stages of the OLED market, Pentile arrangements were used, which reduced the number of pixel points by one-third compared to standard RGB arrangements, resulting in a detail level of only 2/3 that of the same-resolution LCD screens. Although advancements have led to new subpixel arrangements, such as Samsung’s diamond arrangement and Huaxing Optoelectronics’ pearl arrangement, these still only achieve a maximum of around 83% density compared to standard RGB vertical arrangements.

Image from the internet, left is standard RGB arrangement, right is Pentile arrangement

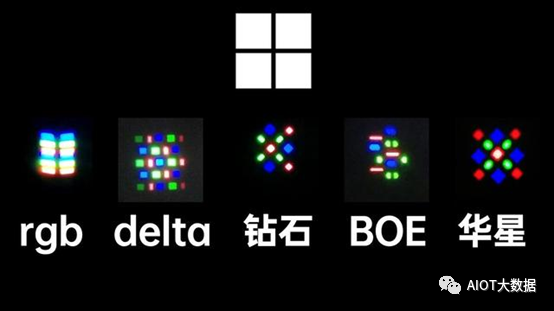

Latest OLED pixel arrangements developed by various panel manufacturers

Many smartphone consumers do not understand the importance of OLED subpixel arrangements. Ultimately, the colors on the screen are produced by the combination of red, green, and blue subpixels. However, the blue subpixel has a particularly short lifespan and ages very quickly. Over time, the luminous efficiency of the blue pixel drops sharply, leading consumers to see yellowish and color-shifted screens, severely affecting the user experience.

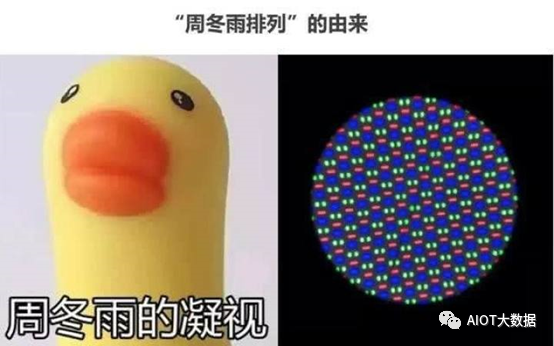

To resolve the color shift issue caused by differing lifespans of the three subpixels, major screen manufacturers have had to focus on pixel arrangements. Originally, red, green, and blue subpixels of equal size were made into various sizes, including the well-known Zhou Dongyu arrangement and Samsung’s diamond arrangement.

Today, we will comprehensively discuss the pixel arrangement methods of smartphone screens.

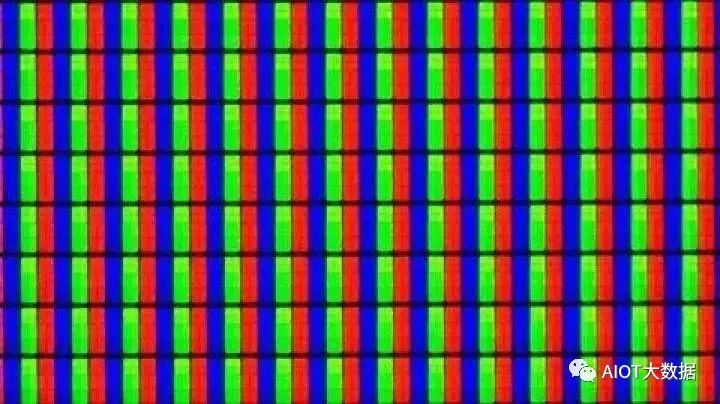

Standard RGB

As one of the most important indicators for measuring smartphone screen parameters, the fineness of the screen, or resolution, is the main criterion. In the early days of smartphones, IPS screens were still mainstream, and they primarily used standard RGB arrangements.

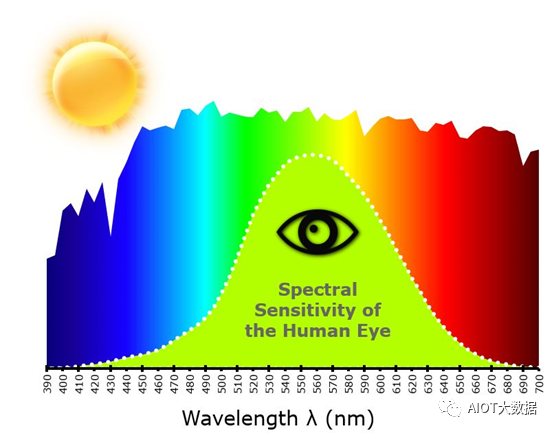

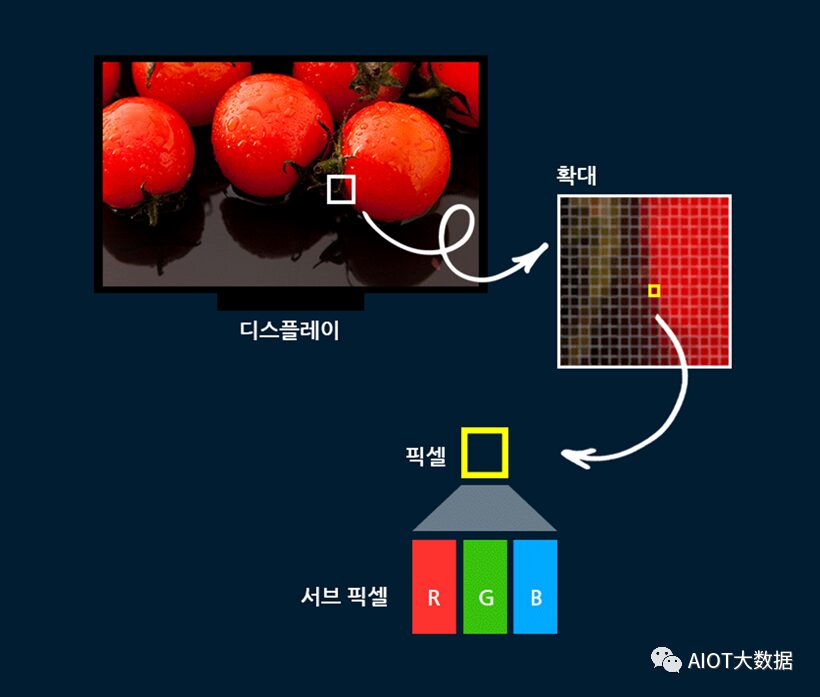

We all know that all colors on smartphone screens are composed of the three primary colors of red, green, and blue. The reason for these three colors is that the cone cells in the human eye are most sensitive to them, which is the universal “RGB color model” in the display industry.

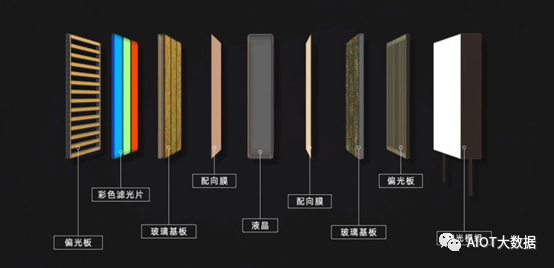

Each pixel is composed of three color subpixels, and light is emitted through the liquid crystal layer to adjust the proportion of the three colors, while the brightness of each pixel is adjusted by voltage.

Image source: Paper Crane

In the LCD era, the vast majority of smartphones used this standard RGB pixel arrangement, where each pixel consists of three complete subpixels, and the entire screen also has a complete pixel layout.

RGBW

In addition to this common arrangement, there are also various variant styles:

RGBW is based on RGBG (adding a green pixel to the standard arrangement) and replaces the green pixel with a white pixel to increase brightness, but this comes at the cost of color performance.

PenTile

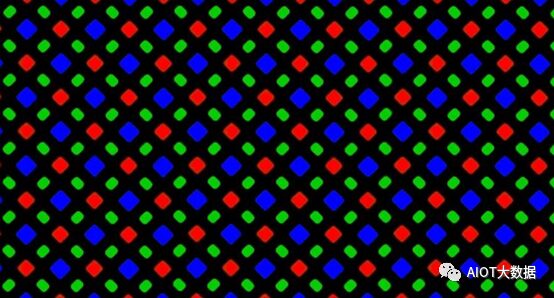

With the development of OLED screens, they have gradually become the mainstream in the smartphone industry. Because OLED does not require a backlight layer and liquid crystal layer, the screen is thinner and lighter compared to LCDs. However, due to the self-emitting nature of OLED’s single subpixel and its relatively short lifespan, OLED manufacturers have changed pixel arrangements to extend screen lifespan and reduce costs.

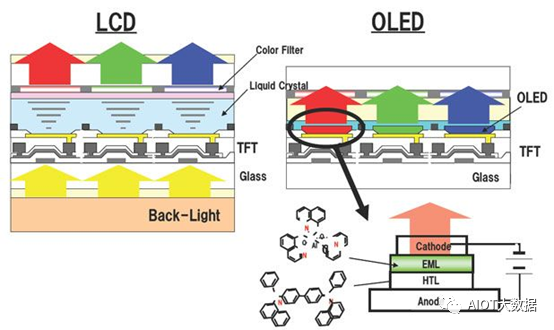

Samsung developed the “PenTile” screen arrangement, which focuses on reducing pixel count.

As seen, compared to standard RGB, PenTile arrangement reduces the number of blue and red pixels while retaining the green pixel intact. Two adjacent pixels share one green pixel, thus reducing the total number of subpixels by about one-third at the same resolution.

The main goal is to maximize the display area of blue while ensuring green displays normally. Green is located in the middle of the visible light spectrum, making it the color that the human eye is most sensitive to; when green has issues, it is easily noticeable. Conversely, the human eye’s response to red and purple at the edges of the spectrum is weaker, thus they are not the focus of consideration.

The critical issue is blue. In OLED screens, the luminous efficiency of blue is lower than that of red and green. Thus, to achieve the same brightness as the other two colors, a higher current is required, which accelerates the degradation of blue, affecting the lifespan and color accuracy of the entire screen. To solve this problem, blue’s luminous area needs to be increased, allowing for brightness while reducing the current through blue, thereby extending the screen’s lifespan.

Due to factors like process and cost, the current PenTile arrangement is the most common arrangement for Samsung OLED screens. With four subpixels arranged in a diamond shape, it is also known as the diamond arrangement, for which Samsung has applied for a patent.

However, this leads to two issues:

The first is reduced resolution. Although the pixel count is the same as standard RGB, the reduced number of subpixels inevitably lowers the resolution. Generally, the “equivalent RGB PPI” of PenTile arrangement screens is about two-thirds that of standard RGB, meaning a 1080P resolution PenTile screen has an equivalent RGB PPI of approximately 720P. This is one reason why Samsung opts for high-resolution screens in flagship models.

Furthermore, PenTile arrangements face various peculiar issues: displaying pure yellow requires turning off all blue subpixels, resulting in black dots in yellow due to the self-emitting nature of OLED; displaying orange requires lowering blue brightness, leading to a “graininess” effect at twice the pixel distance due to the arrangement.

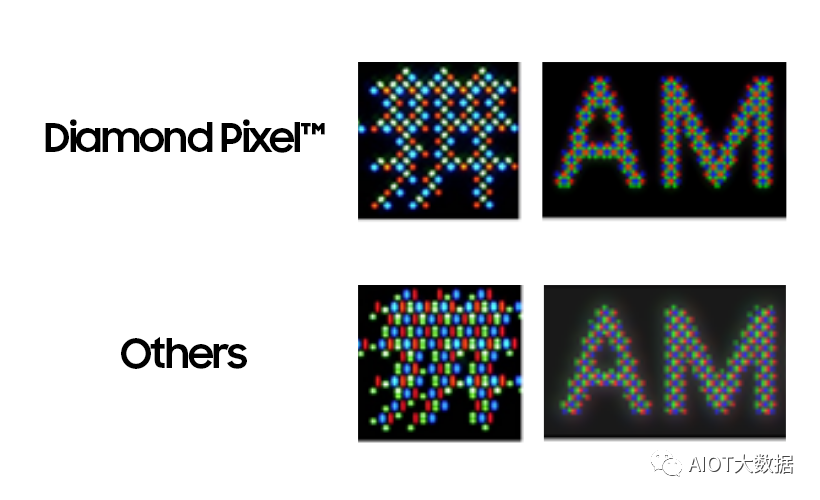

More importantly, there is the color fringe issue, which involves subpixel rendering technology.

Subpixel rendering leverages the characteristic of display panels containing monochrome subpixels to enhance the readability of fonts on the screen. This technology allows for the breaking of the “group” limitation when rendering such fonts, borrowing subpixels from adjacent pixels at the jagged edges of strokes, enabling smooth transitions of curved strokes.

Theoretically, the higher the pixel density of a display panel, the smaller the jagged edges of font edges, and the range of readability improvement brought by subpixel rendering decreases. Most popular smartphones in the market currently use Samsung AMOLED panels, which can only achieve one-way subpixel rendering, optimizing vertical strokes during normal use and only optimizing horizontal strokes when rotated to landscape mode.

The iPhone X supports comprehensive subpixel rendering, thus the color fringe issue in the OLED screens of recent iPhone generations is significantly better than that of Samsung.

Delta

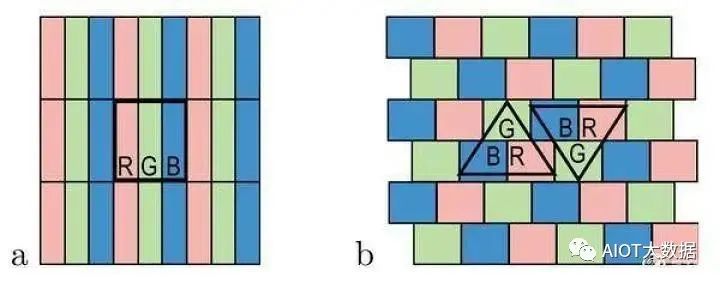

Having clarified PenTile, the commonly used Delta is easy to explain.

Similar to PenTile, Delta is also aimed at addressing the lifespan issue of OLED screens. However, since PenTile’s arrangement is trademarked and patented by Samsung, other screen manufacturers had to find alternative solutions, leading to the birth of the Delta arrangement.

This pixel arrangement has the same number of RGB subpixels, but each color’s pixel count is reduced by one-third, with six subpixels sharing one surrounding pixel, resulting in a lower effective resolution. Additionally, displaying vertical lines may exhibit odd jaggedness.

BOE’s “2 in 1” arrangement (Zhou Dongyu arrangement)

Domestic manufacturers like BOE use the “Zhou Dongyu arrangement” for OLED screens, which is characterized by the green subpixels being split into two smaller parts. This arrangement has the same number of RGB subpixels, but each color’s pixel count is reduced by one-third, with six subpixels sharing one surrounding pixel.

The reason for this arrangement is that the PenTile arrangement has already been patented by Samsung. Therefore, domestic manufacturers seeking to solve the lifespan issue of subpixels had to seek alternative paths, resulting in BOE’s “Zhou Dongyu arrangement”. This arrangement expands the area of blue and red subpixels to extend the screen’s lifespan while avoiding Samsung’s patent.

TCL Huaxing Pearl arrangement

The Pearl arrangement is Huaxing Optoelectronics’ OLED pixel arrangement. Similar to the diamond arrangement, each pixel is composed of R-G and B-G combinations, with the G subpixel being the real pixel, while R and B subpixels are reduced by half compared to Real RGB. To further enhance the lifespan of OLED panels, the Pearl arrangement modifies the subpixel shape to be arc-shaped, breaking the polygonal limitations of the Diamond arrangement. Under the same design conditions, the opening ratio of Diamond pixel arrangements is 17%, while TCL Huaxing Pearl’s can reach 20%, offering a larger opening ratio and longer luminous lifespan. The Pearl arrangement is one of the higher-quality screens among domestic screens, used in some models of Xiaomi 10 and Xiaomi 10 Ultimate Edition.

Of course, the arrangement of smartphone screens is only one indicator determining screen quality; more crucial is the ability to control the screen. For instance, the same panel from Sony’s television performs much better than domestic TVs. I have both Xiaomi 10 and Xperia 1 smartphones, and in terms of screen viewing experience and detail, Sony’s is significantly superior. It is currently the only 4K OLED HDR screen, indicating that in the context of OLED resolution reduction, 4K is still very necessary for audiovisual experiences.

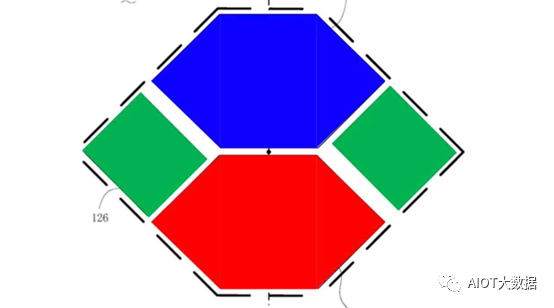

BOE hexagonal crystal pixel arrangement

BOE’s new patent application from August 31, 2020, features a hexagonal subpixel arrangement, also referred to as a honeycomb arrangement, similar to the well-known diamond arrangement. This represents the latest patent of BOE in screen subpixel arrangements.

According to the patent document, this new OLED subpixel arrangement maintains OLED’s advantages of being lighter, thinner, brighter, and more energy-efficient while achieving high-resolution displays through a new RGB pixel arrangement structure.

It is reported that the display panel using this pixel arrangement includes multiple pixel units arranged in an array, each pixel unit contains a first subpixel, a second subpixel, and two third subpixels located within a virtual hexagon: the first and second subpixels are adjacent, and both third subpixels are adjacent to the first and second subpixels; adjacent pixel units in the column extension direction share the first and second subpixels, while adjacent pixel units in the row extension direction share one third subpixel. Any first subpixel in the display panel can form an independent pixel unit with an adjacent second subpixel and two adjacent third subpixels, thus allowing subpixels to achieve high-resolution display effects through color borrowing from low-resolution physical arrangements.

As a basic foundation for screen display effects, the arrangement of screen pixels can somewhat determine the final display quality of a screen. However, a screen’s quality is not solely based on its foundation, but also includes color gamut, color accuracy, and other specific calibrations.

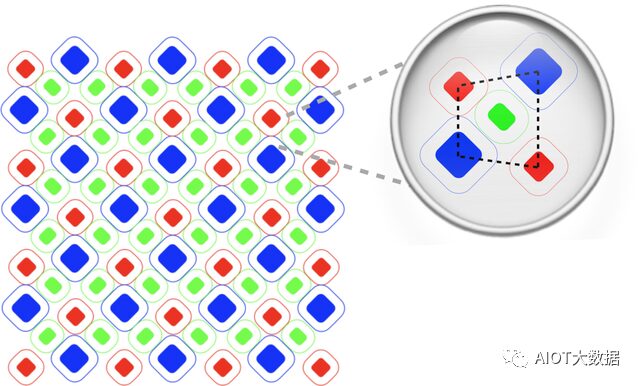

Diamond Pixel

Diamond Pixel is an effective image quality improvement technique where pixels, the basic units that make up the display screen, are arranged in a diamond shape.

In displays, pixels refer to the basic units that form the screen image. The images appearing on smartphone, monitor, or television screens are achieved by clustering several of these pixels together to form a larger image.

Additionally, the so-called basic units, pixels, can be further subdivided into smaller units. This is akin to breaking a single molecule down into multiple atoms. A pixel is typically composed of three primary color lights: red (R), green (G), and blue (B). These smaller pixels, each representing a single color, are called subpixels, and they can be categorized into several types based on their construction methods.

The traditional subpixel arrangement is in a row of R, G, and B, as shown on the right. In contrast, the Diamond Pixel arrangement groups them into a diamond shape, as shown on the left. The human eye perceives green the best, and the Diamond Pixel arrangement minimizes the size of green elements while distributing them closely, effectively highlighting the characteristics of RGB colors.

In simple terms, users want high resolution, which means displays with high pixel density (number of pixels per inch). The more tightly packed pixels we can have, the better. To achieve the highest resolution or pixels per inch (PPI), Samsung displays have successfully designed optimal spatial frequency layouts, with the entire display layout being symmetrically arranged at a 45-degree diagonal. This strategic placement results in green pixels being twice the number of blue and red pixels, and as mentioned earlier, green is the most noticeable color.

Notably, Diamond Pixel is an advanced technology that can clearly and accurately express vertical and horizontal lines as well as diagonals, even in text where readability is crucial.

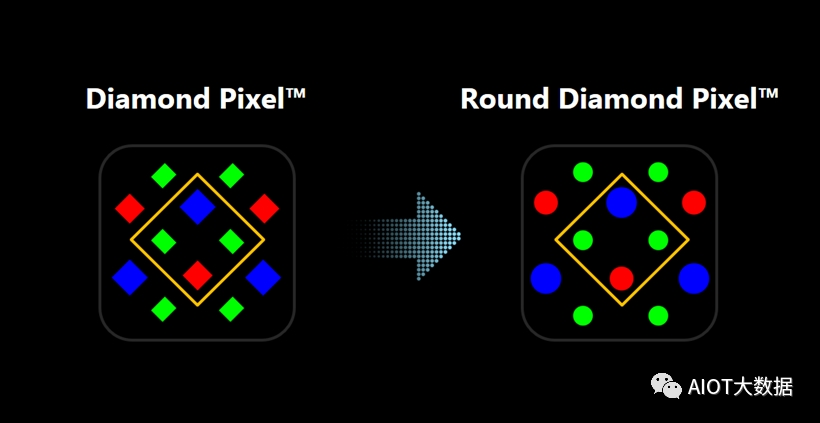

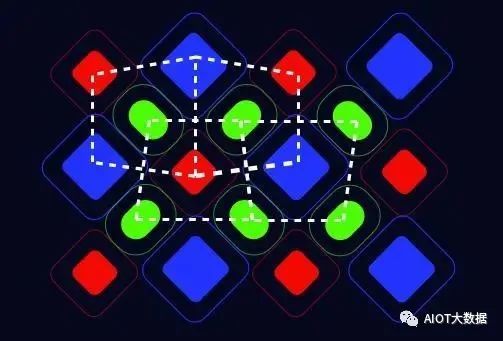

Round Diamond Pixel

Round Diamond Pixel is an image quality optimization technique that makes the basic unit pixels of the display screen into round subpixels, then arranges them in a diamond structure.

In displays, “pixels” refer to the basic units that make up the screen image. The images appearing on smartphone, monitor, or television screens are achieved by clustering several of these pixels together to form a larger image.

Furthermore, the basic unit pixels can be further subdivided into smaller units. This is similar to considering breaking a single molecule down into multiple atoms. A pixel typically consists of three primary color lights: red (R), green (G), and blue (B). These smaller pixels, each representing a single color, are called “subpixels”, which can be categorized into stripes, diamonds, etc. based on their construction methods.

The human eye perceives green the best, and the Diamond Pixel arrangement minimizes the size of green elements while distributing them closely, effectively highlighting the characteristics of RGB colors.

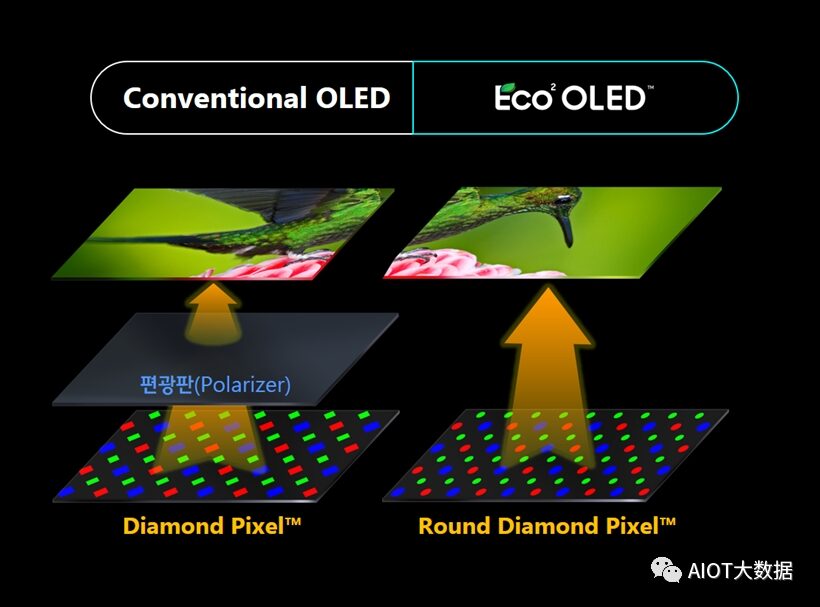

In 2021, Samsung Display will launch Eco OLED technology, which improves light transmittance by 33% by eliminating the opaque plastic components typically attached to displays, and is released together with optimized image quality.

This removal of the polarizing layer technology is a rather revolutionary change, requiring optimization of pixel structures to ensure better light transmittance. This is why Samsung Display introduced Round Diamond Pixel, which can perfectly illuminate light with round red, blue, and green pixel points. Although the pixel arrangement and resolution are the same as the iconic Diamond Pixel arrangement, the Round Diamond Pixel for Eco OLED displays allows smartphone users to enjoy brighter screens with lower power consumption.

Developed by Samsung Display, Round Diamond Pixel is a technology that improves subpixel diffraction control compared to existing Diamond Pixel arrangements.

鼎型像素排列

鼎型像素排列 is a combination of subpixels composed of isosceles trapezoids, resembling the side view of a bronze vessel from China’s bronze age, known as 鼎.

Therefore, whether it is the sub-screen area for under-screen cameras, the main screen area, or full-screen and foldable screens, as long as the pixel arrangement meets the isosceles trapezoid characteristic, regardless of the size and shape of the subpixel area, it belongs to 鼎型像素排列.

It is worth mentioning that this pixel arrangement also helps improve the transmittance of the sub-screen camera area, thereby enhancing the photo quality of the front camera.

But why make a group of subpixels form an isosceles trapezoid? According to Visionox, the answer lies in the patent of this pixel arrangement design.

In 2016, Kunshan Guoxian Optoelectronics Co., Ltd. submitted a patent application for “AMOLED pixel structure and display device”.

The patent application abstract proposed the design concept of this pixel structure: the AMOLED pixel structure includes several first subpixels, second subpixels, and third subpixels, with the third subpixel being the B subpixel. The centers of the two first subpixel light-emitting regions and two third subpixel light-emitting regions surrounding the second subpixel light-emitting region form a virtual isosceles trapezoid… increasing process margin.

Increasing process margin means that from the very beginning of the pixel arrangement design, the goal is mass production. After obtaining the patent, Visionox began the process of introducing it into mass production. In addition to designing the structure between pixels, Visionox can also design overall solutions that include TFT and SPR algorithms based on customer needs, and quickly introduce them into mass production.

For example, Visionox’s recently released 1Hz low-power Hybrid-TFT also adopts the 鼎型像素排列.

Currently, the patents related to 鼎型像素排列 have not only been authorized in mainland China but also in Taiwan and the United States. Additionally, Visionox has laid out a family of patents related to 鼎型像素排列.

PMW dimming of OLED

“High-frequency flicker” has become well-known in recent years due to some news in the mobile phone industry, especially the new iPhone released last year, which was criticized by many users for its high-frequency PMW dimming technology, causing eye strain. So what is PMW dimming? PMW dimming is a pulse-width modulation technology with a relatively complex principle. Simply put, adjusting the brightness of a lamp normally involves turning a knob to adjust the voltage and resistance (DC dimming); whereas PMW dimming involves rapidly turning the light on and off in a very short time, utilizing the eye’s persistence of vision to control brightness. This is necessitated by the uneven display of OLED screens at low brightness.

Principle of OLED light emission

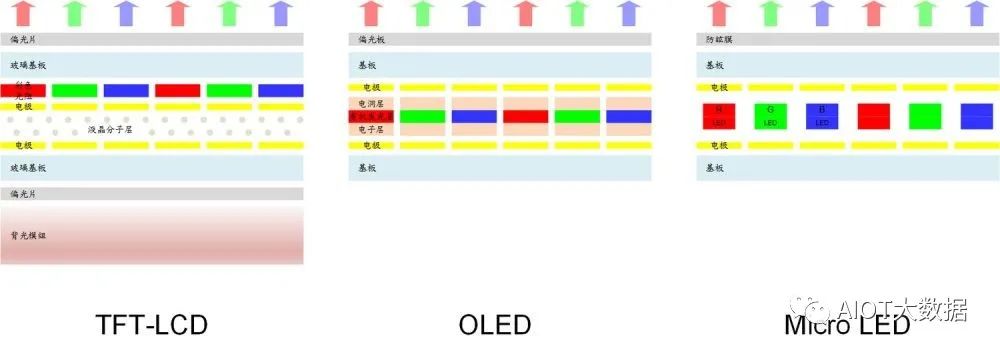

OLED (Organic Light-Emitting Diode) is an organic material light-emitting technology first developed in the 1950s by the French, later evolved by Kodak and the University of Cambridge in the UK, and mass-produced by companies like SONY, Samsung, and LG in the 21st century.

Basic structure of OLED: 1. Cathode ( ) ; 2. Emissive Layer (EL); 3. Anode holes and cathode electrons combine in the emissive layer to produce photons; 4. Conductive Layer; 5. Anode (+), from Wikipedia.

In simple terms, the principle of OLED can be likened to giving organic materials an “electric shock”; when the anode and cathode are energized, the organic materials “light up”. Since the red, green, and blue points in each pixel can be controlled to emit light by individual voltages, there is no need for a large backlight to serve as the “light source” for the screen, thus this technology is also known as self-emitting technology.

From the principle of OLED light emission, we can see that compared to LCD technology, it is much simpler at the principle level. At the same time, OLED has many advantages over traditional LCD screens. Although there are some drawbacks, they do not overshadow its merits. The most important definition of a good screen should be its ability to reproduce the world’s true colors as accurately as possible, and in this regard, OLED certainly excels. But is OLED the ultimate answer? You can look at the following two technologies.

From LG Display official website

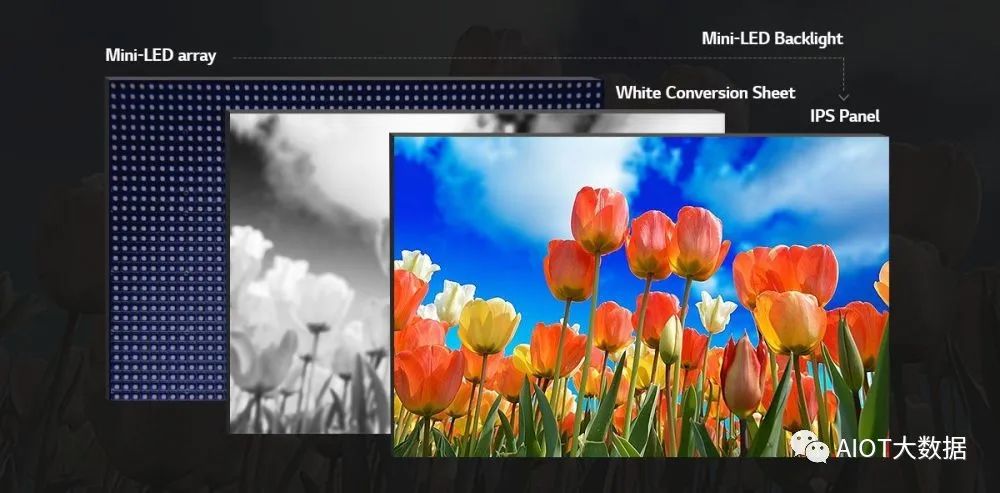

Mini LED and Micro LED

Among them, Mini LED technology was discussed in our previous issue. The principle is to replace the original LED backlight panel with thousands of individual LED beads, where multiple LED beads form a backlight matrix, with each backlight matrix capable of becoming an independent light control zone. For example, a top Mini LED gaming screen on the market has 4096 LED beads, with every two forming a control area, resulting in 2048 independent control areas.

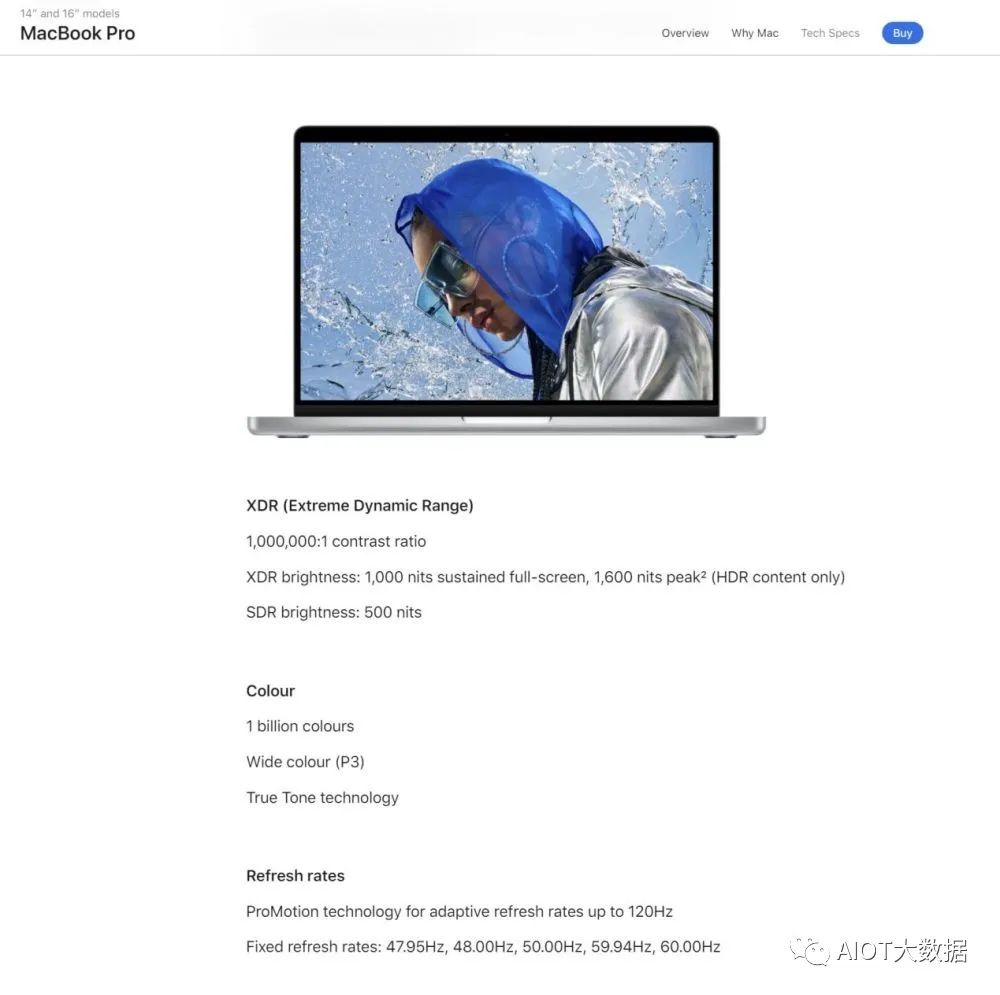

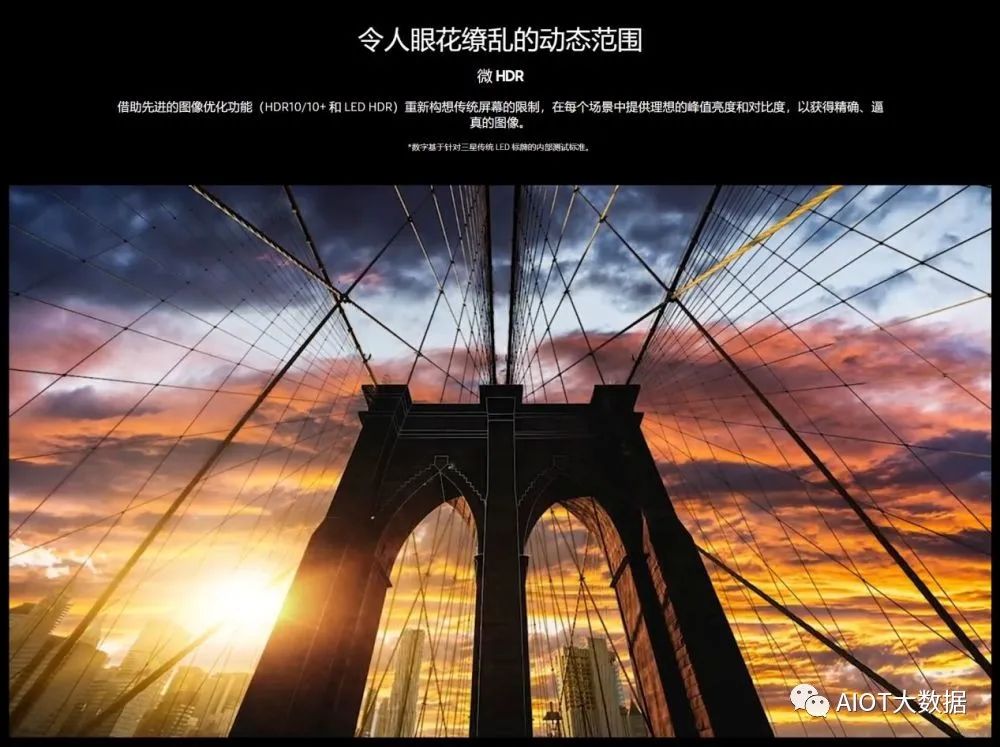

The advantage of this approach is that Mini LED can achieve ultra-high contrast and more refined, adjustable local brightness similar to OLED. When displaying black areas, the LEDs in that area are turned off, theoretically achieving contrast ratios equal to OLED displays, while avoiding the risk of burn-in associated with long-term use of OLED displays. Mini LED also has a significant advantage in that its independent area LEDs can quickly generate high brightness in a short time. Some excellent Mini LEDs can achieve a peak brightness of 2000 nits, and common Mini LEDs generally pass HDR1000 certification, making them very friendly for HDR content, allowing high-quality Mini LEDs to rival OLED.

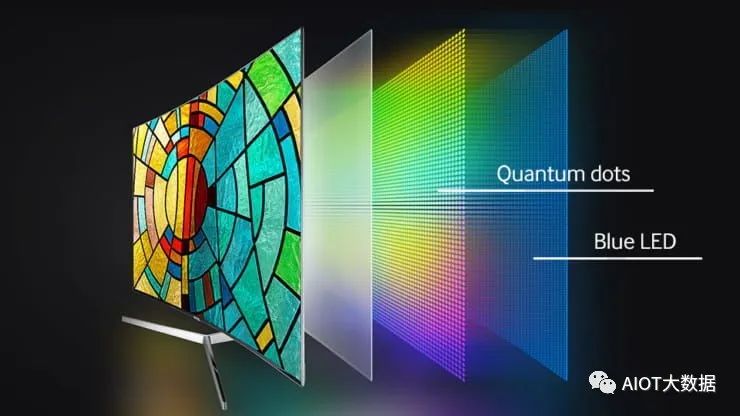

However, Mini LED is still a newly perfected screen type, and it cannot escape the inherent viewing angle and narrow color gamut issues of LCD screens. To address the narrow color gamut issue, a quantum dot film (QLED technology) must be added to Mini LED displays to enhance the color gamut, but this significantly increases the cost of the display, making it not worth the investment. Currently, advanced Mini LED displays have reached the level of high-end OLEDs, while still maintaining about a 15% cost advantage.

Thanks to the aggressive attitude of domestic screen manufacturers towards the Mini LED market, it is expected that within the next five years, Mini LED backlight technology will gradually become the mainstream backlight technology for mid-to-high-end displays, with continuous improvements in technology, increasing the number of LED beads, and refining control technology.

The new Macbook Pro series released by Apple last year features a Mini LED screen

Currently, while OLED has occupied the vast majority of the self-emitting screen market, Mini LED is on the rise, but there is a “new emperor” that has already been nurtured, and its “imperial aura” has already threatened the former two. This is Micro LED.

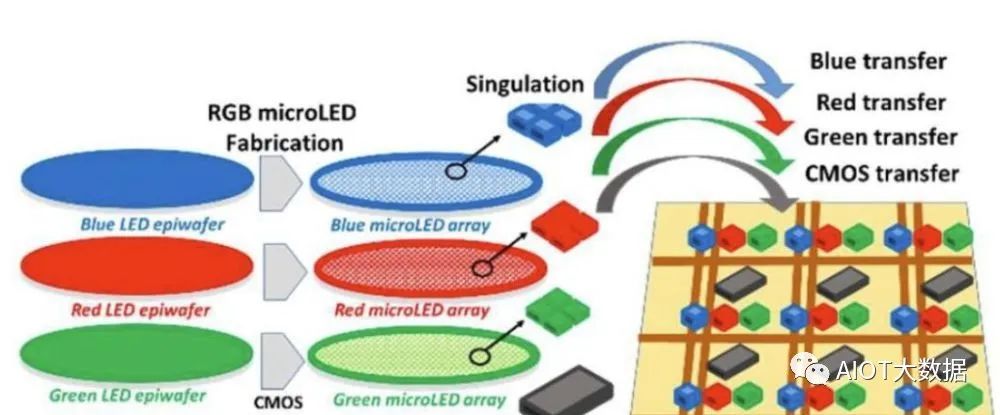

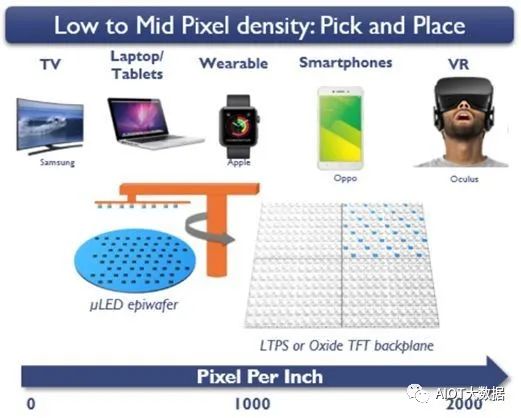

Micro LED (Micro Light Emitting Diode Display) operates on the principle of miniaturizing the red, green, and blue LED structures into thin films, with sizes ranging from 1 to 10 microns; these micron-level LEDs are then transferred in bulk to a circuit substrate, with circuitry and transistors installed under each micro LED, completing a simple Micro LED display.

From Samsung Display’s official website introducing Micro LED

Each pixel of Micro LED contains RGB subpixels that can self-emit and be independently controlled. For instance, Sony’s first Micro LED product, the Crystal LED, launched in 2012, has an area of 55 inches and a resolution of 1920×1080, with the number of micro LEDs being 6,220,800. Compared to high-end Mini LED displays with around 20,000 beads, the technical difficulty of Micro LED is significantly higher.

From Samsung Display’s official website introducing Micro LED

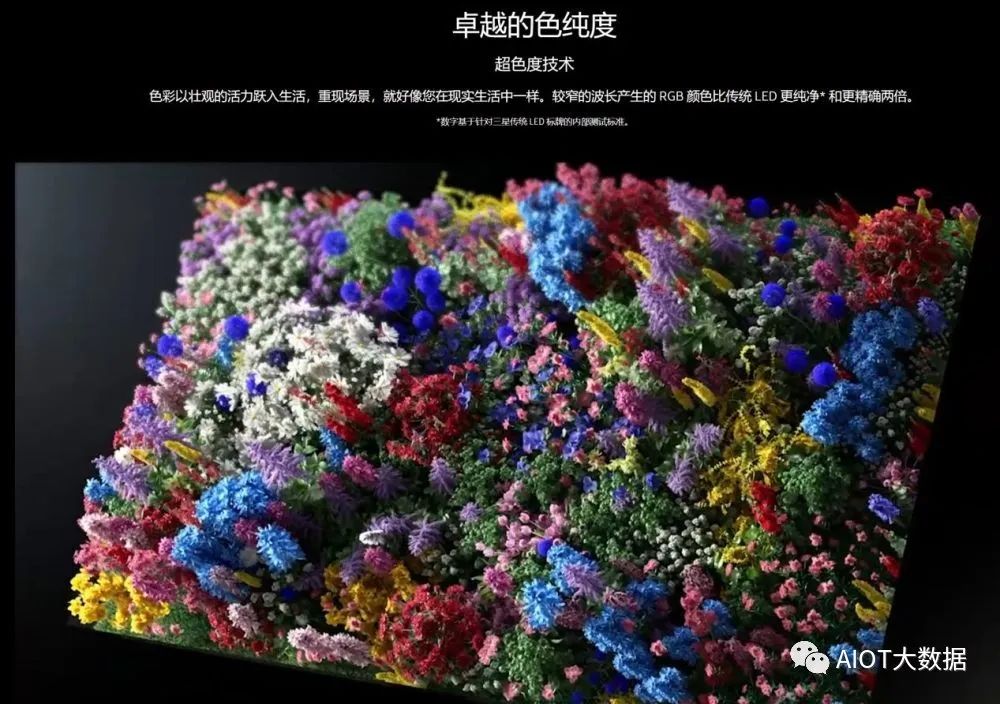

Due to the self-emitting nature of Micro LED’s individual micron LEDs, it excels in color performance, with the peak wavelength of the micro LED’s emission spectrum being approximately 20nm, providing extremely high color saturation, often exceeding 120% NTSC. This is almost identical to the color gamut offered by top OLED displays. Additionally, due to the stability of inorganic materials, colors can remain consistent and stable regardless of how long they are used, a characteristic that OLED cannot match. Micro LED also maintains the ability to display pure black at the pixel level, which is more direct and pure than the backlight control of Mini LED.

From Samsung Display’s official website introducing Micro LED

Another advantage of Micro LED is its energy efficiency and ultra-brightness. In traditional LCD TVs, the display efficiency is about 3%. The loss in LCD comes from color filters, polarizers, and energy loss in LC materials, resulting in low efficiency. In contrast, Micro LED’s simple structure and low energy consumption allow for higher photoelectric conversion efficiency, with power consumption as low as 10% of LCD and 50% of OLED, significantly reducing electricity usage while allowing for higher energy to be directly emitted, achieving peak brightness close to 2000 nits.

From Samsung Display’s official website introducing Micro LED

Micro LED almost combines all the advantages of OLED and LCD, offering high brightness, wide color gamut, high contrast, and long lifespan, low power consumption, and fast response. It can be said to be the culmination of future screen technology. But why hasn’t Micro LED become widespread despite its many advantages?

It can be said that its success also brings challenges. The advantage of Micro LED comes from its millions of micron LEDs, and the difficulty also lies here. Currently, Micro LED faces three main technical challenges: quantum efficiency droop (limited effective luminous area, low efficiency of red LEDs), drive capability matching issues (requiring high current and low power drive materials), and mass transfer problems (high process and precision requirements, high costs). The most critical issue lies in the mass transfer problem.

Illustration of mass transfer

Mass transfer technology is the mainstream and ideal manufacturing technology for Micro LED. Since Micro LED is a unit of micrometers, it needs to be manufactured on silicon wafers rather than directly on the display substrate. This requires transferring the micro LEDs produced on silicon wafers to the display substrate. This transfer technology is called mass transfer. As the micro LED chips to be transferred are about 1/10 the thickness of a hair, it requires extremely precise operations; transferring tens of thousands or even hundreds of thousands of LEDs at once presents a significant challenge.

Illustration of mass transfer, from eeNews

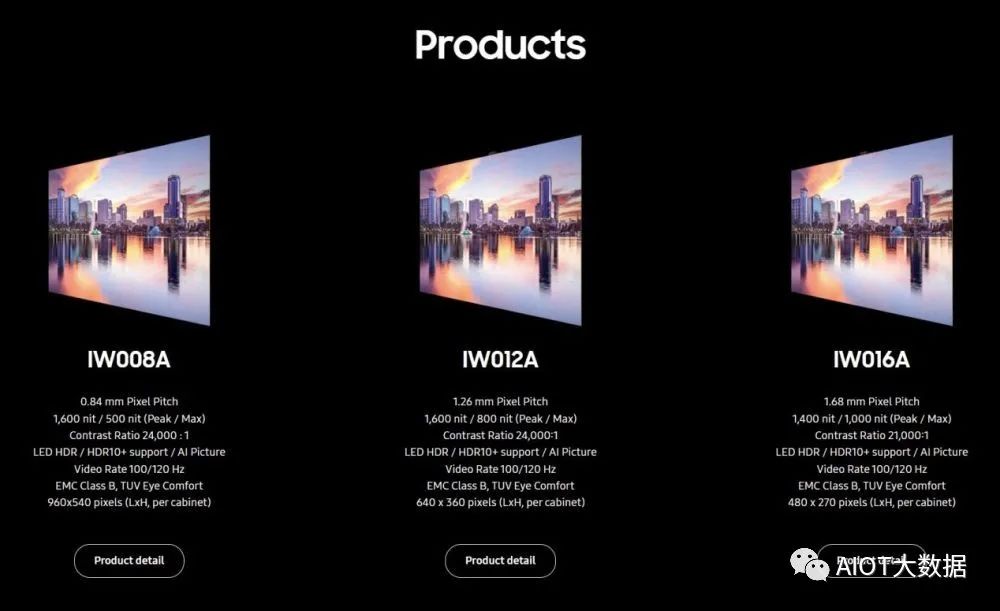

At the same time, the cost of manufacturing massive numbers of micro LEDs is quite high. For example, a 2K resolution Micro LED screen requires about 11.05 million micro LEDs to achieve. Given the current manufacturing difficulties, this dictates that the cost and price of Micro LED will be quite high. Currently, there are no officially mass-produced Micro LED products in the consumer sector. The closest product to us is Samsung’s The Wall commercial screen, which uses a Micro LED panel module of 806.4×453.6mm, with each module having a resolution of 960×540, borderless design, and perfect splicing. Each module can achieve brightness between 250 and 2000 nits, with a contrast ratio of about 10,000:1, 16bit color depth, and refresh rates of up to 100/120 Hz. The price can exceed an astonishing 100,000 US dollars.

Although Micro LED still faces significant challenges in technology, cost, and manufacturing, this does not deter major screen manufacturers and brands from pursuing it. One of the most successful tech brands in the world, Apple, began laying out Micro LED in 2020, collaborating with Taiwanese LED manufacturer Epistar and LCD panel manufacturer AUO to build a new factory in the Hsinchu Science Park Longtan branch, with an estimated total investment of NT$10 billion (US$334 million). In a public report, Apple stated, “Like OLED, Micro-LED is also self-emitting. However, compared to OLED, Micro-LED can support higher brightness, higher dynamic range, and wider color gamut while achieving faster refresh rates, wider viewing angles, and lower power consumption, all of which are qualities that Apple favors.”

Once Micro LED becomes mainstream, it is believed to become the primary choice for future screen materials, and its modular assembly method will allow screens to be customized according to user preferences, ushering in the “DIY era” for displays.

From Samsung Display’s official website introducing Micro LED

Currently, the self-emitting screens that are well-developed and widely accepted in the market are OLEDs, but OLED will not dominate the self-emitting screen camp for long, as Mini LED is set to make a leap in the coming years. Once the zoning backlight technology and control chips mature, its long lifespan, no degradation, and no burn-in advantages will become apparent. Micro-LED is poised to be the major trend in screen development for the next 20 years, with its modular, miniaturized product form factor, high brightness, wide color gamut, high contrast, low power consumption, and fast response characteristics ensuring its ultimate success.

The production method determines the respective costs and commercialization prospects

The production method of OLED displays still follows the most optimal automated production method developed over the past fifty years, which is large-area one-time replication process technology, allowing multiple products to be produced simultaneously on a single substrate, resulting in low production costs, high efficiency, and stable product quality.

In contrast, even if Mini LED and Micro-LED achieve mass transfer technology, the need for single-point packaging, testing, and calibration of each LED chip means that the production costs in certain processes increase exponentially. This is why a flat panel display can cost a few thousand dollars, while LED displays can cost tens of thousands.

Thus, OLED displays can meet the consumer-level TO C market demand with super high cost-performance ratio, while Mini LED and Micro-LED can only exist in some “engineering-level” projects, becoming part of the basic infrastructure budget.