Soy Protein Isolate (SPI) has attracted much attention due to its rich nutritional content and excellent functional properties. SPI emulsification refers to the process of disrupting the water-oil balance under the action of shear or breaking forces, uniformly dispersing oil droplets as extremely small liquid droplets in immiscible water, forming a homogeneous and stable water-oil emulsion system. Emulsifying ability is one of the important functional properties of SPI..

Ultrasonic technology can improve the functional properties of SPI emulsions, offering advantages such as small and uniform emulsion particle size, strong stability, less required surfactant, simple process, and relatively low cost. Due to the mechanical and cavitation effects of ultrasound, the cavitation bubbles in the emulsion generate extreme phenomena such as high temperature, high pressure, and localized micro-jets at the moment of collapse, exerting shear forces on the dispersed phase macromolecules, while the released energy helps to enhance the reactivity of sonochemical reactions, achieving emulsification..

Researchers Qi Dong, Wang Xiao, and Liu Bin from the School of Artificial Intelligence at Beijing Technology and Business University conducted this study by analyzing the effect of ultrasonic power on the distribution characteristics of ultrasonic cavitation, applying finite element analysis methods combined with sonoluminescence experiments to explore the distribution characteristics of cavitation fragmentation fields and acoustic flow fields in higher power sound fields. Starting from the cavitation effect of ultrasound, the enhancement of cavitation by acoustic flow, and the mixing effect of acoustic flow on the emulsion, this study discusses the mechanism of SPI ultrasonic emulsification and analyzes the emulsification effect of SPI emulsions under different ultrasonic powers.

1. Analysis of the Fragmentation Mechanism of Ultrasonic Cavitation Effects

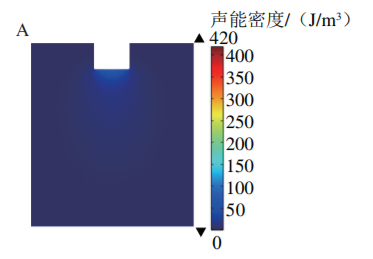

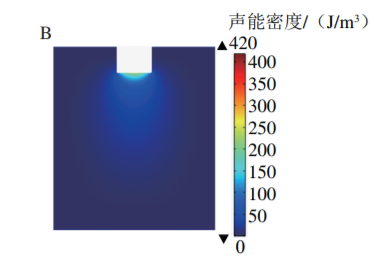

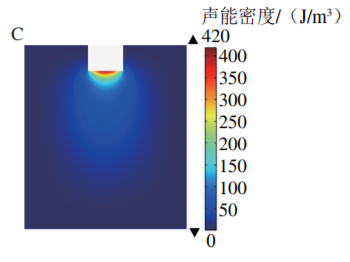

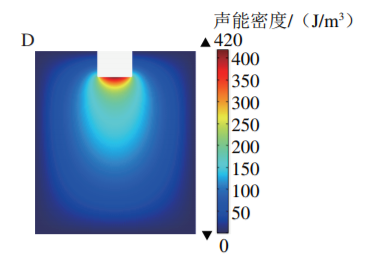

By simulating different ultrasonic input power values, the sound energy density distribution inside the chamber can be obtained. As shown in Figure 3, the area with higher sound energy density is located near the end of the amplitude rod. As one moves away from the end of the amplitude rod, the sound energy density gradually decreases and approaches zero, indicating that the area where cavitation effects occur is at the high sound energy density near the end of the amplitude rod. With the increase of ultrasonic input power, the area of high sound energy density at the end of the amplitude rod expands (i.e., the area of ultrasonic cavitation effects expands), which is beneficial for breaking the oil and water phases during emulsification, promoting interaction between water/oil droplets. It can also directly act on SPI, breaking protein molecules, destroying the rigid regional structure of proteins, exposing the hydrophobic groups inside SPI to the external environment, thus enhancing the emulsifying properties of proteins.

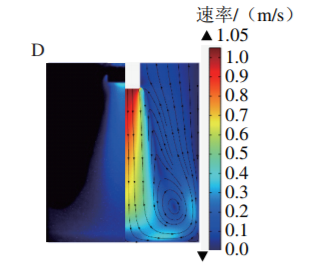

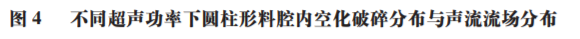

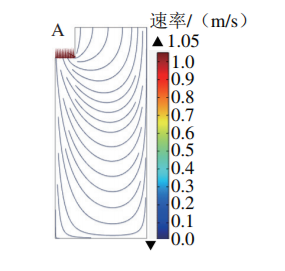

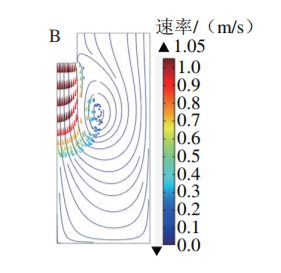

2. Analysis of the Mechanism of Cavitation Enhancement Effect Under Acoustic Flow

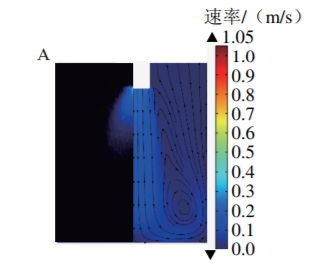

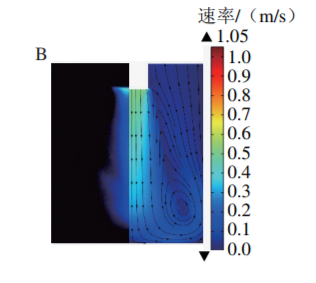

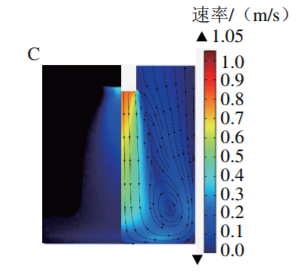

The distribution of cavitation fragmentation and acoustic flow fields under different ultrasonic input power treatments is shown in Figure 4. There are obvious differences in cavitation fragmentation distribution within the chamber. The fluid under the action of acoustic flow forms a jet starting from the end of the amplitude rod, promoting the cavitation bubbles to move axially. When the fluid contacts the bottom of the chamber, the direction of motion is deflected, moving towards the wall along the bottom of the chamber, ultimately forming stable recirculating vortices at the junction of the bottom and side walls of the chamber. Changes in ultrasonic input power can affect the distribution of acoustic flow velocity, and the dispersive effect of the acoustic flow under jet action promotes the expansion of the cavitation fragmentation distribution area, while the enhancement effect of the acoustic flow under vortex action is not significantly affected by power changes. Based on simulation results, it can be predicted that as the cavitation fragmentation distribution area of SPI in the reaction chamber expands, the fine-tuning effect enhances, and the acoustic flow effect allows the fragmented SPI to disperse more uniformly in the chamber, which is beneficial for SPI emulsification.

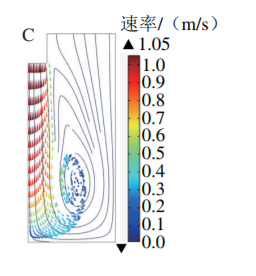

3. Analysis of the Mechanism of Acoustic Flow on Emulsion Dispersion and Mixing

Combining acoustic flow simulation and particle tracking numerical analysis, the particle motion trajectory and dispersion situation under the action of acoustic flow in a cylindrical chamber with an ultrasonic input power of 88 W can be obtained. As shown in Figure 5, the acoustic flow can effectively stir, disperse, and uniformly mix the emulsified particles in the chamber in a short time. At different moments (t), particles move from the end of the amplitude rod towards the bottom of the chamber under the action of the acoustic flow, where the acoustic radiation force generated at the end of the amplitude rod directly acts on the fluid and forms a jet, with the peak acoustic flow velocity being 1.046 m/s. Due to the influence of the solid boundary layer at the side wall of the amplitude rod, a recirculating vortex is formed at the boundary of the chamber wall, causing the particle motion trajectory to deflect and flow upwards along the wall, resulting in the particles dispersing upwards along the chamber side wall, mixing with the axially moving particles. When the input power is stable, the acoustic flow velocity stabilizes around 0.1 m/s. The motion generated by the acoustic flow will give the particles similar functional characteristics to stirring, driving the movement of particles in the chamber, thus enabling the particles in the emulsion to be stirred, dispersed, and mixed more uniformly and stably.

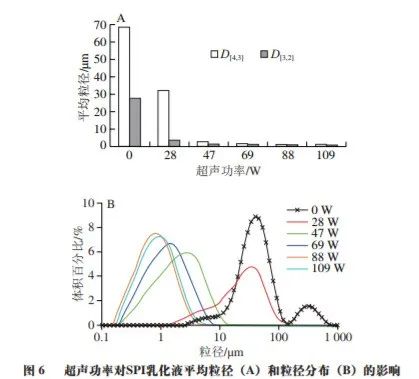

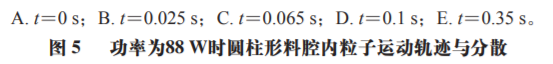

4. Analysis of Emulsion Particle Size Treatment Effects

The impact of ultrasonic treatment on the particle size of SPI emulsions is shown in Figure 6. The particle sizes D[3,2] and D[4,3] of SPI emulsions decrease with the increase of ultrasonic input power. Compared to untreated SPI emulsions, those treated with an ultrasonic power of 28 W show a reduction in D[3,2] and D[4,3] of 87.5% and 53.0%, respectively; increasing input power further reduces the average particle size of the emulsions; at 88 W input power, D[3,2] and D[4,3] reach their minimum values; when the input power increases to 109 W, D[3,2] and D[4,3] slightly increase (Figure 6A). Increasing ultrasonic power causes the particle size distribution curve of SPI emulsions to shift towards smaller particle sizes, with a decrease in the lateral span; the particle size distribution curve of the 28 W ultrasonic treatment group shifts slightly to the left compared to the original curve, reducing from two peaks to one peak; as ultrasonic power continues to increase, the particle size distribution curve continues to shift leftward, and the lateral span continues to decrease; at 88 W input power, the particle size distribution range approaches the limit, with most particle sizes between 0.5 and 1.3 μm; at 109 W ultrasonic power, the particle size distribution curve begins to shift rightward, indicating an increasing trend in particle size (Figure 6B).

The cavitation enhancement effect caused by changes in ultrasonic power can influence the particle size changes of SPI emulsions. At lower ultrasonic power, the acoustic flow velocity is low, and no acoustic flow phenomenon occurs, resulting in a small and weak cavitation distribution range concentrated at the end of the amplitude rod; the energy generated by the cavitation bubbles has limited effects on SPI molecules and oil droplets in the emulsions, leading to negligible fragmentation effects. As ultrasonic input power increases, the number of cavitation bubbles increases, and bubble aggregation can cause cavitation shielding phenomena. Even though the cavitation enhancement effect generated by acoustic flow at high input power can expand the ultrasonic cavitation distribution range, its effect on SPI emulsions is limited. Therefore, at an ultrasonic input power of 109 W, the average particle size and particle size distribution of SPI emulsions show the opposite effect, with particle sizes increasing instead of decreasing.

The cavitation enhancement effect caused by changes in ultrasonic power can influence the particle size changes of SPI emulsions. At lower ultrasonic power, the acoustic flow velocity is low, and no acoustic flow phenomenon occurs, resulting in a small and weak cavitation distribution range concentrated at the end of the amplitude rod; the energy generated by the cavitation bubbles has limited effects on SPI molecules and oil droplets in the emulsions, leading to negligible fragmentation effects. As ultrasonic input power increases, the number of cavitation bubbles increases, and bubble aggregation can cause cavitation shielding phenomena. Even though the cavitation enhancement effect generated by acoustic flow at high input power can expand the ultrasonic cavitation distribution range, its effect on SPI emulsions is limited. Therefore, at an ultrasonic input power of 109 W, the average particle size and particle size distribution of SPI emulsions show the opposite effect, with particle sizes increasing instead of decreasing.

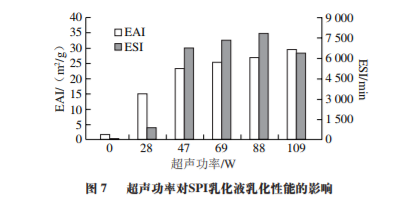

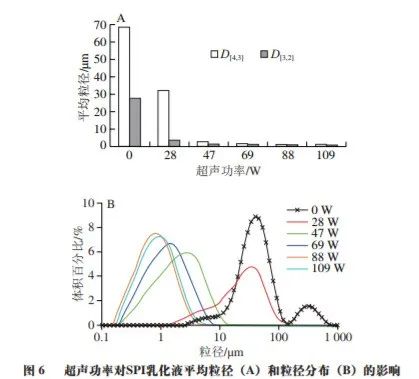

5. Analysis of Emulsifying Activity, Emulsifying Stability, and Apparent Stability of Emulsions

The effect of ultrasonic treatment on the emulsifying activity and stability of emulsions is shown in Figure 7. The emulsifying activity increases with the increase of ultrasonic power, reaching a maximum at 109 W, while the emulsifying stability shows a trend of first increasing and then decreasing with the increase of ultrasonic power, peaking at 88 W. At 28 W ultrasonic power, the cavitation bubbles aggregate at the end of the amplitude rod, and no acoustic flow phenomenon occurs, resulting in low ultrasonic cavitation intensity and distribution range, leading to weak effects of cavitation on SPI emulsions and a small increase in emulsifying stability. At 47 W, the acoustic flow phenomenon appears. Meanwhile, the impact, rotation, and vortex motion under the action of acoustic flow can disperse and quickly move the hydrophobic groups of proteins along the streamlines of the acoustic flow, thereby expanding the reaction area of the emulsions and interfering with the aggregation of droplets and SPI molecules, making the emulsion system more homogeneous and stable, thus improving the emulsifying activity and stability of the emulsions. As ultrasonic power continues to increase, the dispersive effect of the acoustic flow is further enhanced, resulting in a continuous increase in emulsifying activity and stability; after the ultrasonic power exceeds 88 W, the emulsifying stability of the emulsions decreases, possibly due to the aggregation of protein molecules in the emulsions under the influence of electrostatic and hydrophobic forces, making it harder for the protein molecules to adsorb at the oil-water interface, leading to reduced emulsion stability..

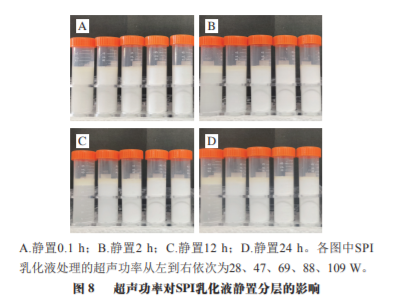

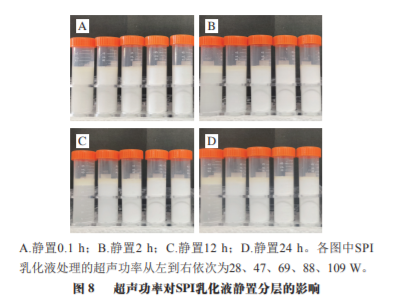

The apparent stability effects of emulsions after different ultrasonic power treatments are shown in Figure 8. With the increase of ultrasonic treatment power, the stratification phenomenon of SPI emulsions significantly weakens; when the ultrasonic power reaches 88 W, the apparent stability of the emulsions reaches an optimal state, with no significant stratification after standing for 24 hours; when the ultrasonic power continues to increase, there is no significant change in the apparent stability of the emulsions. In summary, with the increase of ultrasonic power, the effects of ultrasonic cavitation and acoustic flow dispersion mixing have a significant role in maintaining the uniform stability of SPI emulsions.

The apparent stability effects of emulsions after different ultrasonic power treatments are shown in Figure 8. With the increase of ultrasonic treatment power, the stratification phenomenon of SPI emulsions significantly weakens; when the ultrasonic power reaches 88 W, the apparent stability of the emulsions reaches an optimal state, with no significant stratification after standing for 24 hours; when the ultrasonic power continues to increase, there is no significant change in the apparent stability of the emulsions. In summary, with the increase of ultrasonic power, the effects of ultrasonic cavitation and acoustic flow dispersion mixing have a significant role in maintaining the uniform stability of SPI emulsions.

This experiment applied finite element simulation of the sound field to analyze the results of ultrasonic cavitation distribution characteristics, predicting the motion of cavitation bubbles under acoustic flow effects. Combined with particle tracking simulation under acoustic flow conditions, the dispersion and mixing of particles in the emulsions were analyzed, exploring the mechanisms of cavitation effects, acoustic flow enhancement, and the role of acoustic flow in the dispersion and mixing of emulsions in SPI ultrasonic emulsification, and studying the emulsification effects of SPI under different ultrasonic input powers. The results indicate that increasing ultrasonic power can expand the high sound energy density area in the reaction chamber, significantly enhancing the cavitation effect in areas far from the sound source, improving the fine-tuning effect and emulsifying performance of SPI molecules. At high ultrasonic power, acoustic flow generated by jet and vortex actions promotes the axial movement of cavitation bubbles, which after reaching the bottom of the chamber, recirculate and disperse upwards, expanding the cavitation fragmentation area, achieving the effect of cavitation enhancement. Furthermore, changes in ultrasonic power can affect the distribution of acoustic flow velocity fields, having a significant impact on the acoustic flow under jet action, while having a smaller effect on the acoustic flow under vortex action; the dispersive effect generated by acoustic flow allows the hydrophobic groups of SPI to disperse and move rapidly along the streamlines of the acoustic flow, expanding the reaction area of the emulsions, interfering with the aggregation of droplets and SPI molecules, allowing the particles in the emulsion to disperse more uniformly and stably, and enabling thorough stirring, dispersion, and mixing of materials in the chamber in a short time. The effects of different ultrasonic powers on the emulsification characteristics of SPI emulsions are as follows: as the ultrasonic power increases, the particle size of SPI emulsions decreases, and the emulsifying activity, emulsion stability, and apparent stability of the emulsions are effectively improved, with the best results at a power of 88 W. This study combines simulation analysis and experimental measurements to analyze and study the mechanism and effects of SPI ultrasonic emulsification, providing new ideas for solving the issues of poor traditional ultrasonic emulsification effects, achieving efficient energy conversion in ultrasonic emulsification applications, saving costs, and improving reliability.

This article “Mechanism of Ultrasonic Emulsification of Soy Protein Isolate” is sourced from “Food Science” 2023, Volume 44, Issue 9, Pages 32-38, authored by Qi Dong, Wang Xiao, Liu Bin, et al. DOI:10.7506/spkx1002-6630-20220412-139. Click below to read the original article for more information.

This experiment applied finite element simulation of the sound field to analyze the results of ultrasonic cavitation distribution characteristics, predicting the motion of cavitation bubbles under acoustic flow effects. Combined with particle tracking simulation under acoustic flow conditions, the dispersion and mixing of particles in the emulsions were analyzed, exploring the mechanisms of cavitation effects, acoustic flow enhancement, and the role of acoustic flow in the dispersion and mixing of emulsions in SPI ultrasonic emulsification, and studying the emulsification effects of SPI under different ultrasonic input powers. The results indicate that increasing ultrasonic power can expand the high sound energy density area in the reaction chamber, significantly enhancing the cavitation effect in areas far from the sound source, improving the fine-tuning effect and emulsifying performance of SPI molecules. At high ultrasonic power, acoustic flow generated by jet and vortex actions promotes the axial movement of cavitation bubbles, which after reaching the bottom of the chamber, recirculate and disperse upwards, expanding the cavitation fragmentation area, achieving the effect of cavitation enhancement. Furthermore, changes in ultrasonic power can affect the distribution of acoustic flow velocity fields, having a significant impact on the acoustic flow under jet action, while having a smaller effect on the acoustic flow under vortex action; the dispersive effect generated by acoustic flow allows the hydrophobic groups of SPI to disperse and move rapidly along the streamlines of the acoustic flow, expanding the reaction area of the emulsions, interfering with the aggregation of droplets and SPI molecules, allowing the particles in the emulsion to disperse more uniformly and stably, and enabling thorough stirring, dispersion, and mixing of materials in the chamber in a short time. The effects of different ultrasonic powers on the emulsification characteristics of SPI emulsions are as follows: as the ultrasonic power increases, the particle size of SPI emulsions decreases, and the emulsifying activity, emulsion stability, and apparent stability of the emulsions are effectively improved, with the best results at a power of 88 W. This study combines simulation analysis and experimental measurements to analyze and study the mechanism and effects of SPI ultrasonic emulsification, providing new ideas for solving the issues of poor traditional ultrasonic emulsification effects, achieving efficient energy conversion in ultrasonic emulsification applications, saving costs, and improving reliability.

This article “Mechanism of Ultrasonic Emulsification of Soy Protein Isolate” is sourced from “Food Science” 2023, Volume 44, Issue 9, Pages 32-38, authored by Qi Dong, Wang Xiao, Liu Bin, et al. DOI:10.7506/spkx1002-6630-20220412-139. Click below to read the original article for more information.

Intern Editor: Liang Wenjing, School of Public Health, Mudanjiang Medical University. Editor: Zhang Ruimei. Click below to read the original article for the full text. Images are sourced from the original article and stock images.

Professor Sun Dongmei from Heilongjiang Bayi Agricultural University, et al.: Research progress in rapid detection of foodborne pathogenic bacteria using recombinant enzyme polymerase amplification, recombinant enzyme-mediated isothermal amplification, and enzyme-catalyzed recombinant isothermal amplification techniques.

“Food Science”: Dr. Zhou Hui from Dalian Ocean University, et al.: Research progress on the separation of bioactive peptides based on mixed-mode chromatography.

“Food Science”: Professor Liu Zhenquan from Beijing University of Chinese Medicine, et al.: The effect and mechanism of Lactobacillus plantarum P9 on functional constipation in mice.

“Food Science”: Associate Professor Deng Lili from Southwest University, et al.: The regulatory effect of blue light from light-emitting diodes on chlorophyll metabolism in early-ripening citrus fruits.

“Food Science”: Professor Liu Shutao from Fuzhou University, et al.: The impact of coarse grain fast-cooking rice replacing high-fat diets on glucose and lipid metabolism in type 2 diabetic mice.

“Food Science”: Associate Professor Wang Faxiang from Changsha University of Science and Technology, et al.: The effect of chitosan composite preservation on the muscle protein of refrigerated grass carp.