Click to Follow Mushroom Cloud

About Shanghai Yangshan Deepwater Port

Innovative Research on Intelligent Service System

Source: Excellent Works of the 5th National Youth Artificial Intelligence Challenge – Open Source Hardware Creative Manufacturing Special Competition

Participating Students: Chang Muchan from Shanghai Baoshan District Gucun Experimental School and Wu Si’an from Shanghai Peijia Bilingual School

Guiding Teachers: Shi Yuepeng, Kong Cheng

Main Purpose of the Work

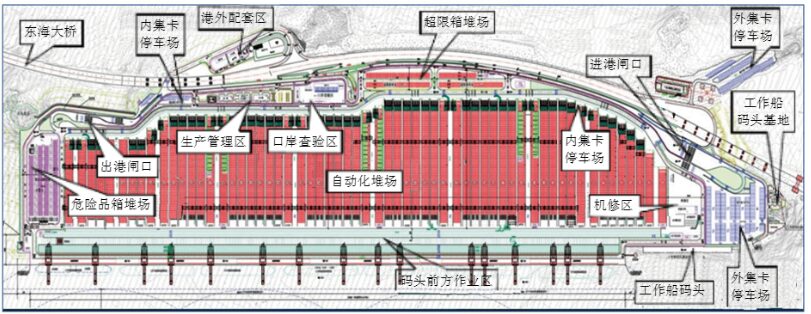

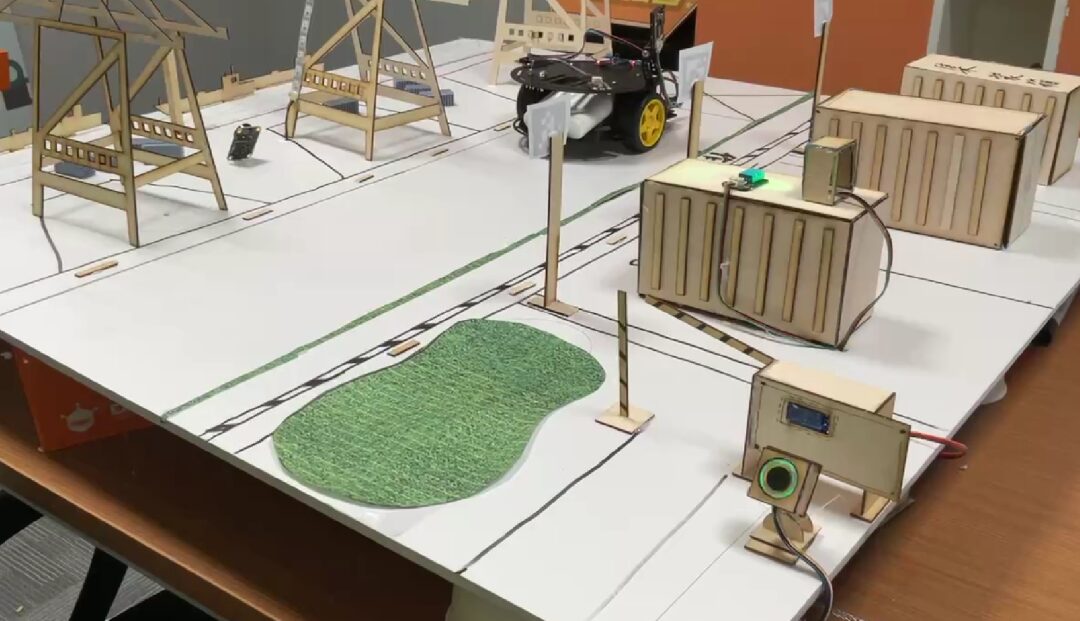

Shanghai Yangshan Deepwater Port is the world’s largest intelligent container terminal, marking China’s transition from a major shipping country to a strong shipping nation! This is also an important part of Shanghai’s construction of the “Five Centers”, with Yangshan Phase IV being a fully automated unmanned terminal. It deploys mobile container inspection systems, unmanned transport vehicles, and non-intrusive machine inspection scanning along the logistics corridor. With the support of artificial intelligence and automation, the port has achieved a 70% reduction in labor costs while increasing efficiency by 30%.

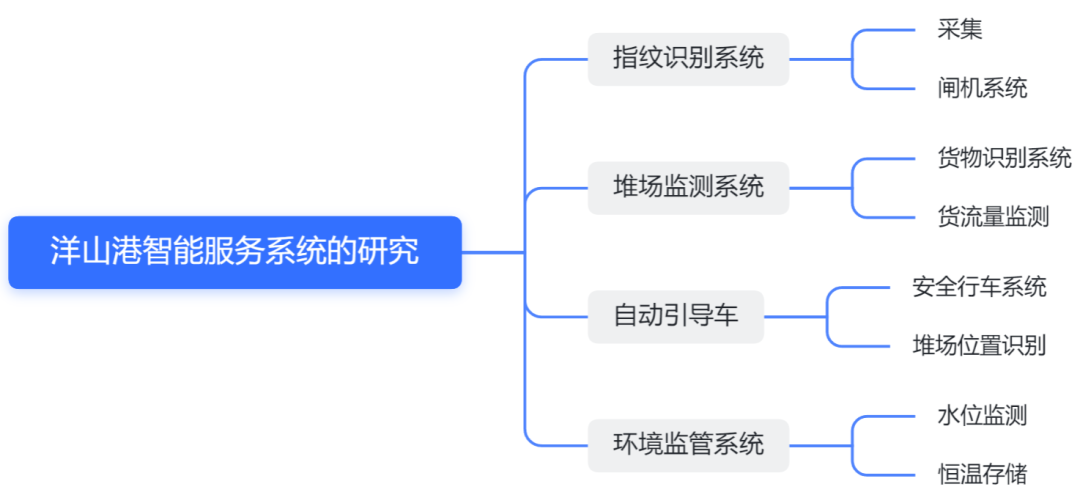

To ensure the safety of staff and improve the efficiency of terminal operations, we conducted innovation and research on the intelligent service system of Yangshan Port. This includes label management for cargo, real-time monitoring of port yard capacity, and meeting the operational needs of automated terminals without affecting cargo logistics. Yangshan Port is one of the important embodiments of the country’s technological progress, and we hope that its level of intelligence will continue to rise, creating a “new height for Yangshan”!

Function Introduction

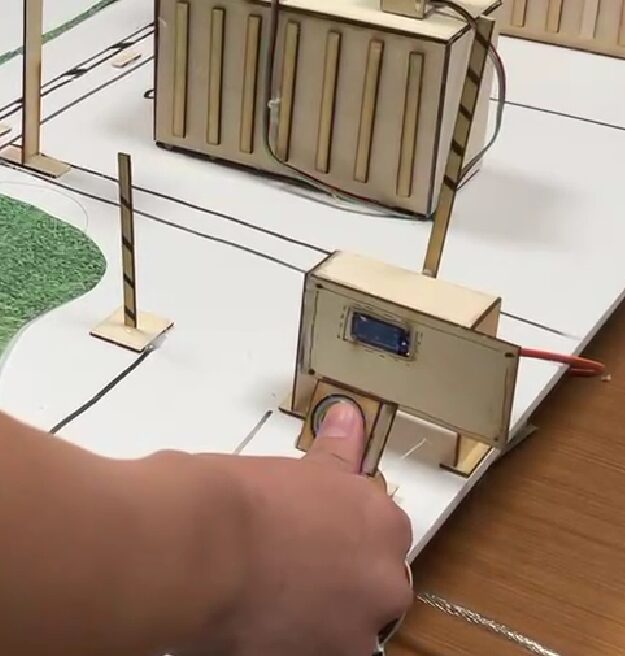

1. Fingerprint Recognition System: The fingerprint recognition system collects and identifies the fingerprint information of the terminal staff, ensuring personnel control during the pandemic. The gate will automatically open for detected personnel; otherwise, an error will be reported.

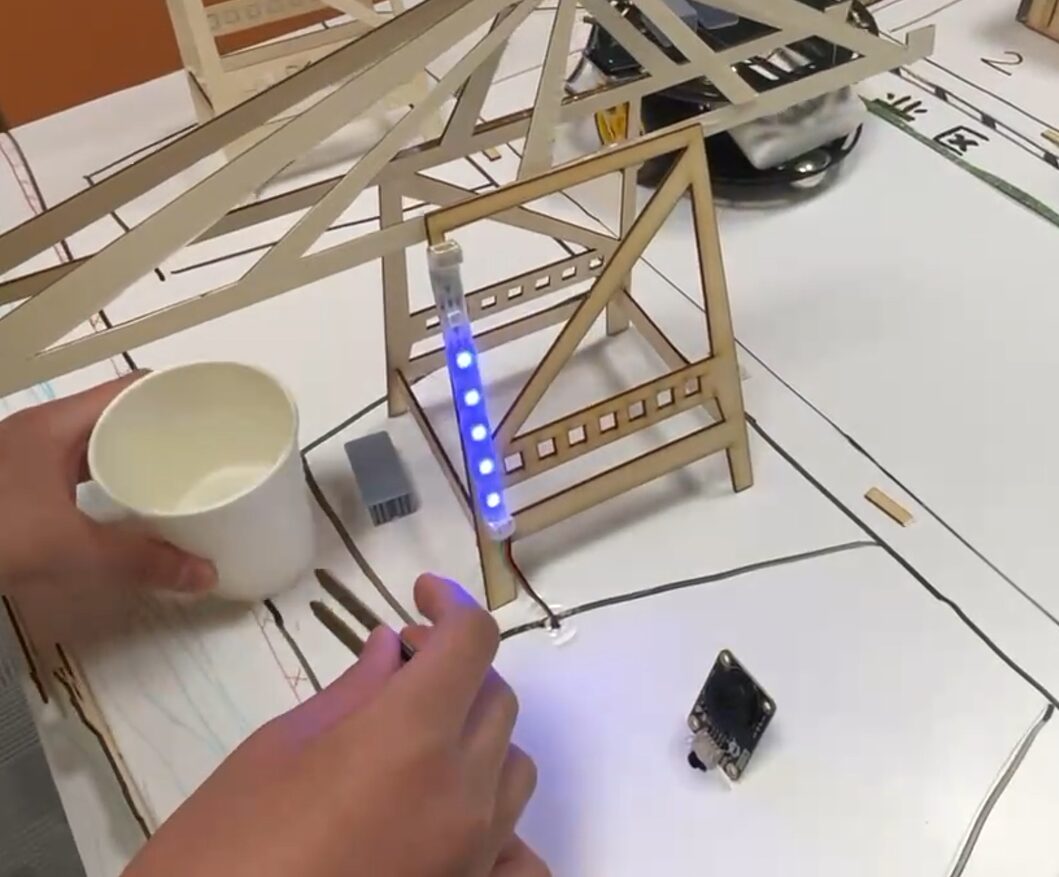

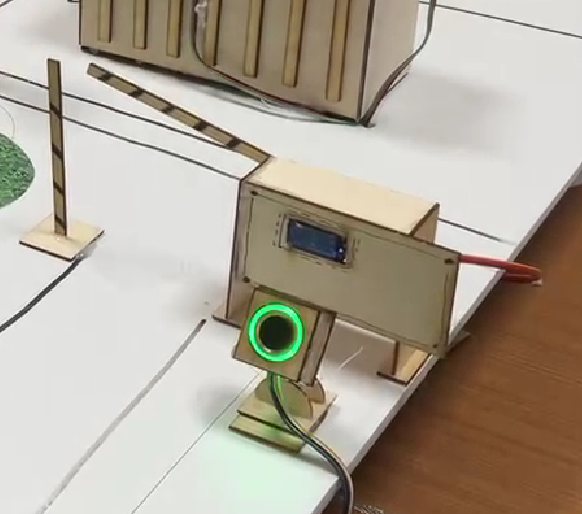

2. Yard Monitoring System: After completing non-intrusive safety inspections of containers, the system uses label recognition for classification and transport. It monitors cargo flow at different yards, providing data support for container classification management. This system consists of HUSKYLENS AI cameras, light sensors, light strips, and OLED displays. Once identified, containers are transported to their respective yards, and the light sensor detects changes in the surrounding light environment to determine whether there are stocks or shipments at corresponding locations, displaying the number of containers on the OLED screen. If the number of containers exceeds the maximum capacity, the light strip will flash, and an alarm will sound for manual intervention or yard stock replacement.

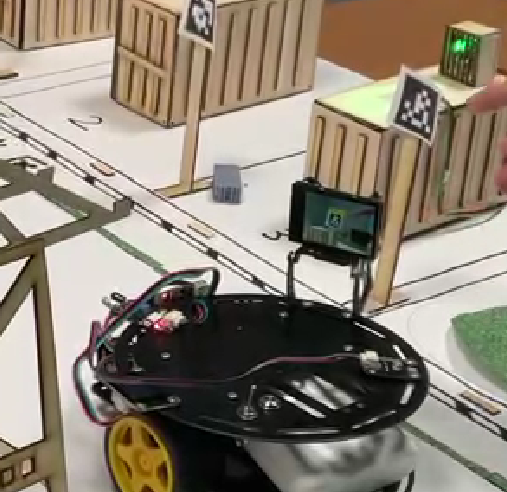

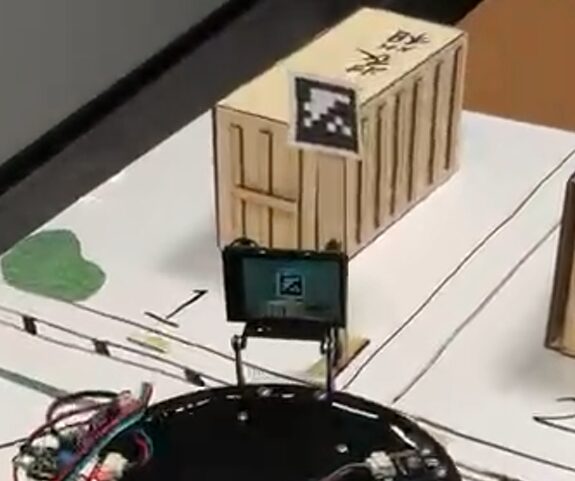

3. Automated Guided Vehicle System: Composed of a desktop robot platform, infrared obstacle avoidance sensors, and HUSKYLENS AI cameras, the system transports classified containers to their designated yard locations. The camera performs label recognition for precise parking, and the vehicle will stop and sound an alarm if it encounters pedestrians.

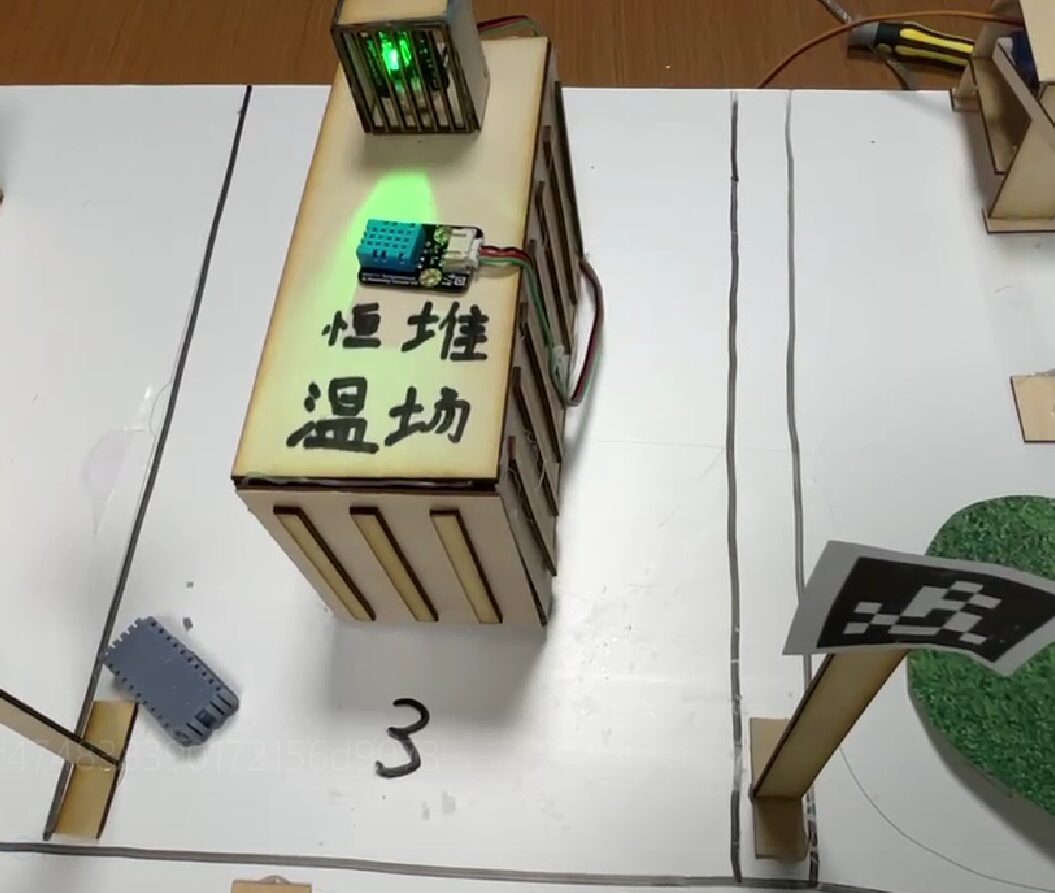

4. Environmental Monitoring System: This system uses temperature and humidity sensors to obtain the temperature and humidity values of the yard, ensuring constant temperature and humidity storage for containers with special storage requirements. It monitors water levels using a soil moisture sensor, triggering an alarm if the water level exceeds a warning line.

Production Process

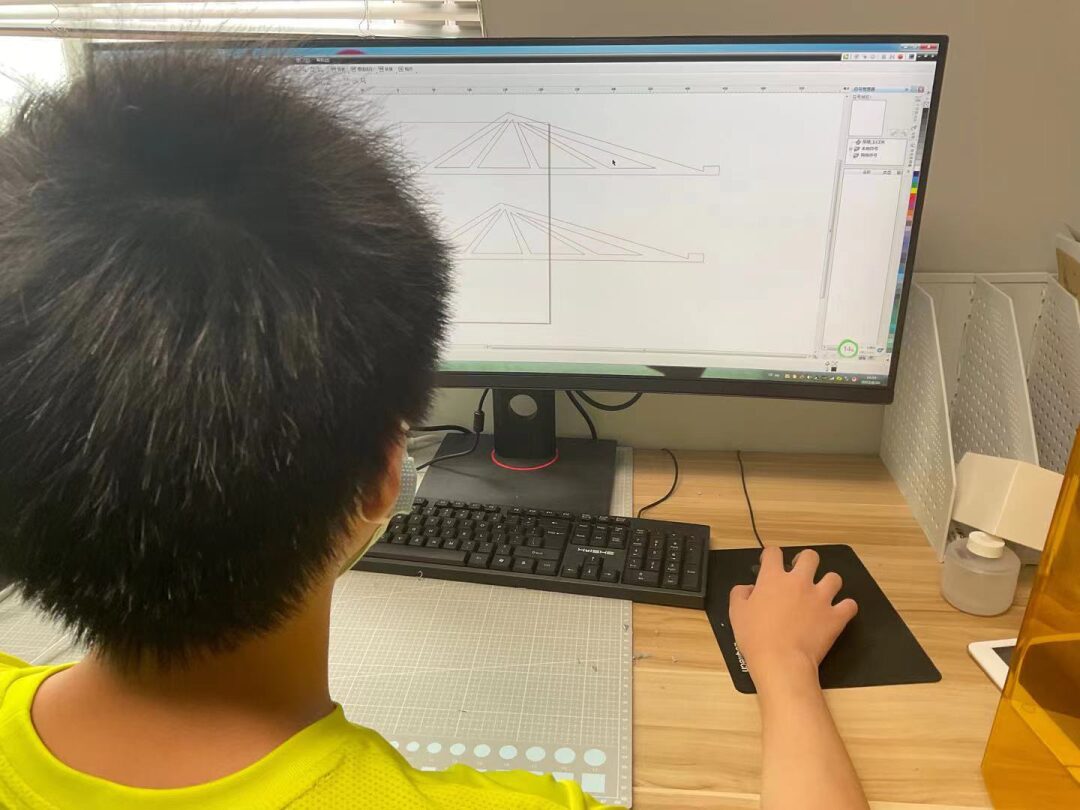

Structural Design

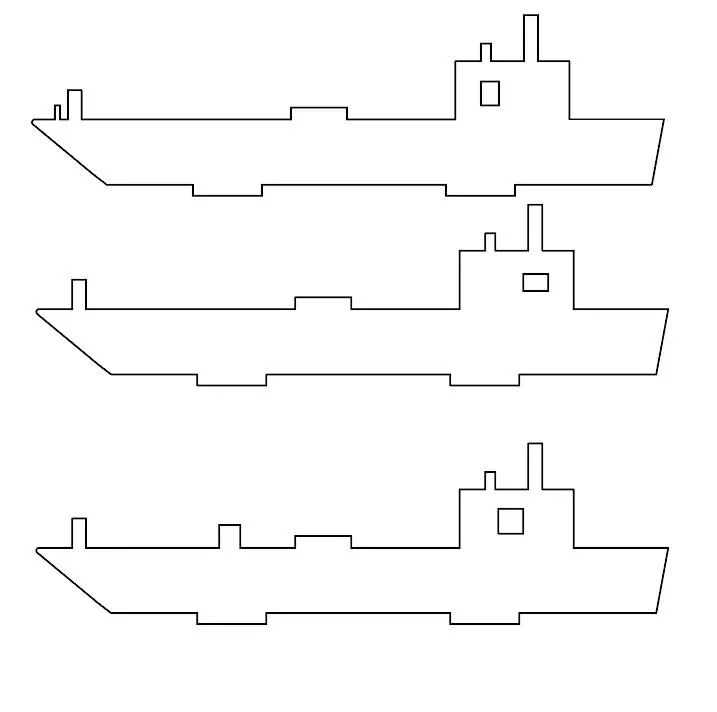

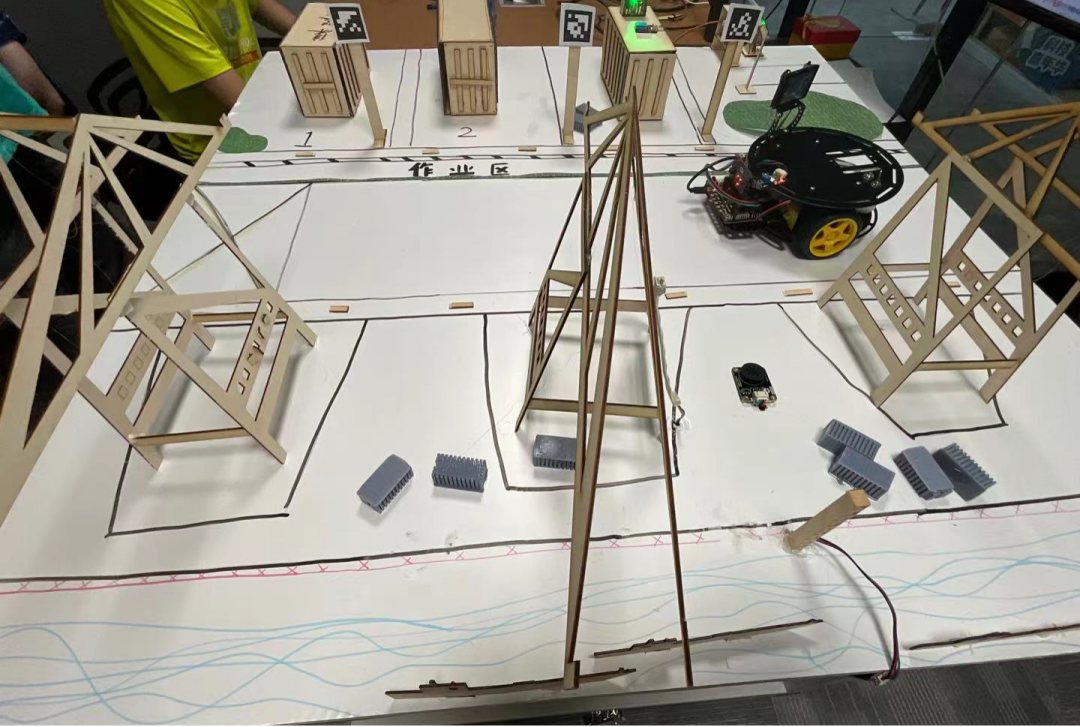

This work is a sand table model based on the fourth phase of Shanghai Yangshan Deepwater Port. The wooden parts were completed through laser cutting, and the resin models were made using 3D printing. It consists of a fingerprint recognition system, three yards, automated guided vehicles, environmental monitoring systems, and various automatic unloading platforms, green belts, road signs, labels, ships, and containers.

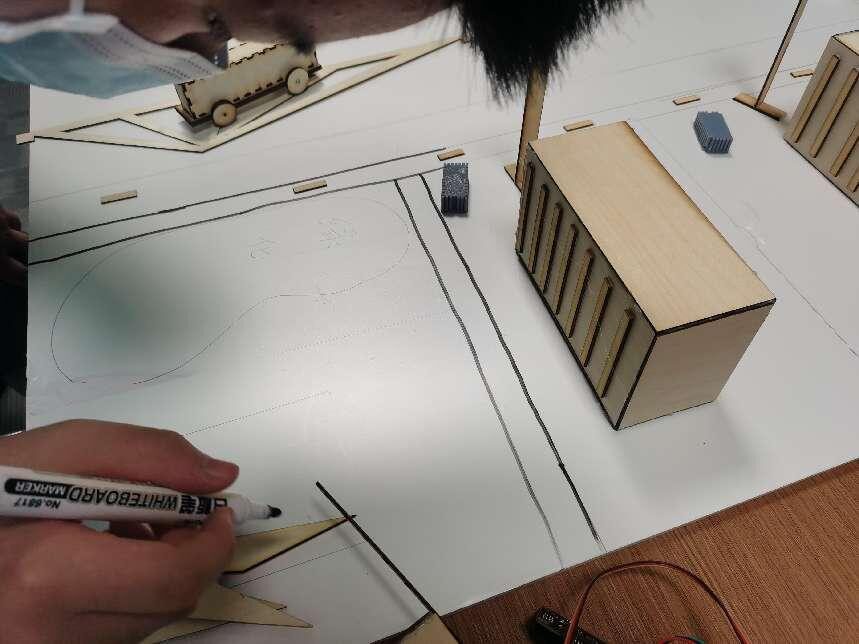

Hand-Drawn Design of the Sand Table Model of Yangshan Deepwater Port Intelligent Research

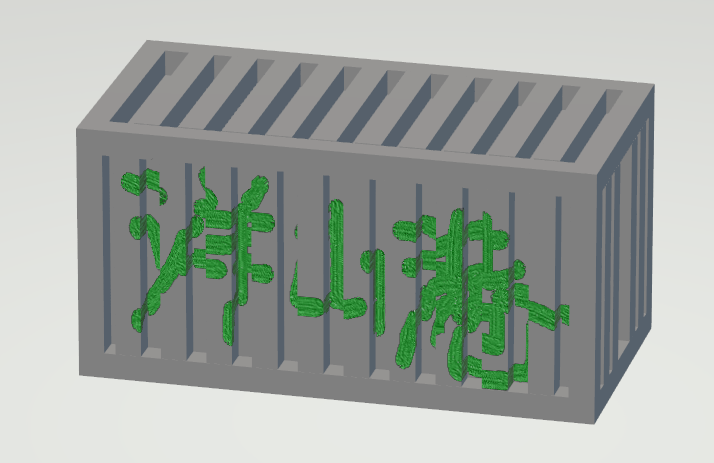

3D Model Design of Containers

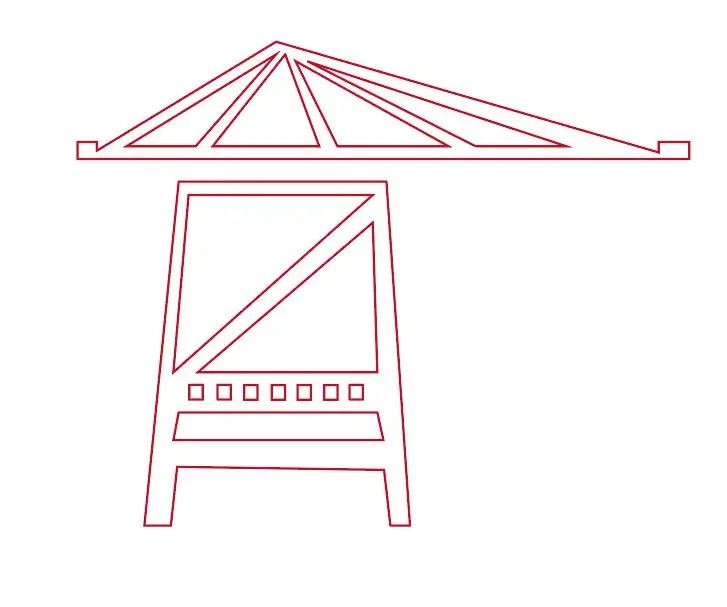

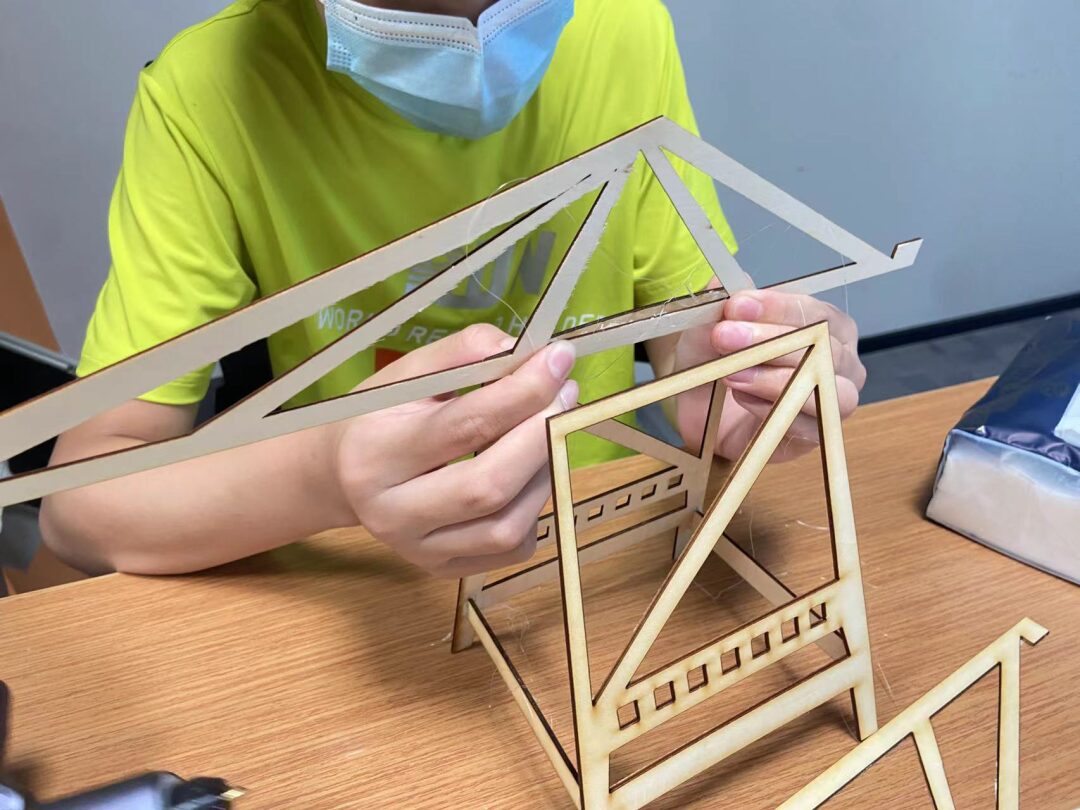

Laser-Engraved Tower Crane and Container Ship Models

Sand Table Model of Yangshan Deepwater Port Intelligent Research

Related Settings

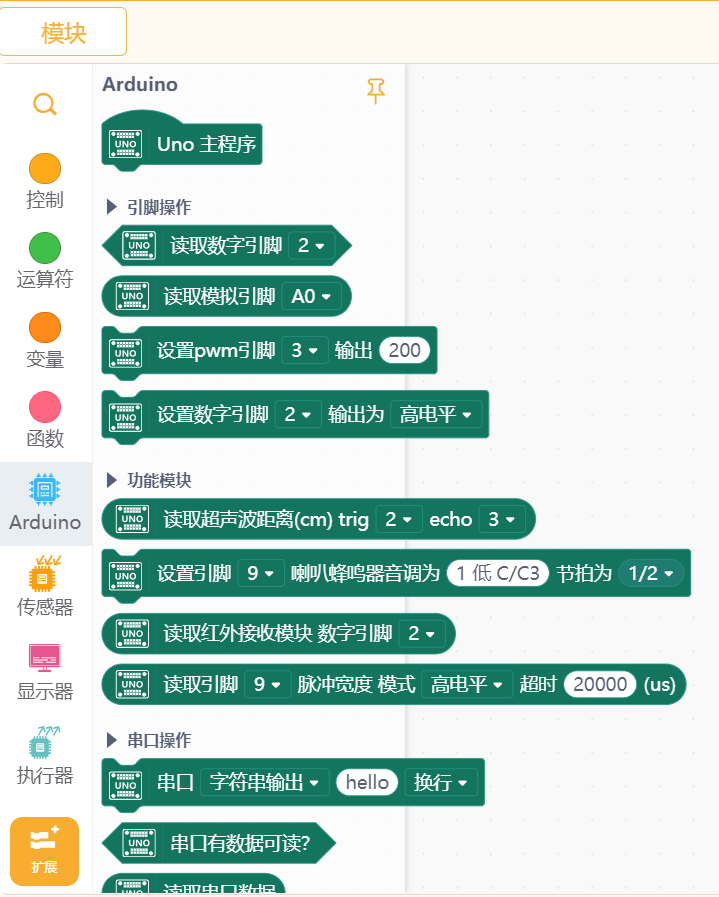

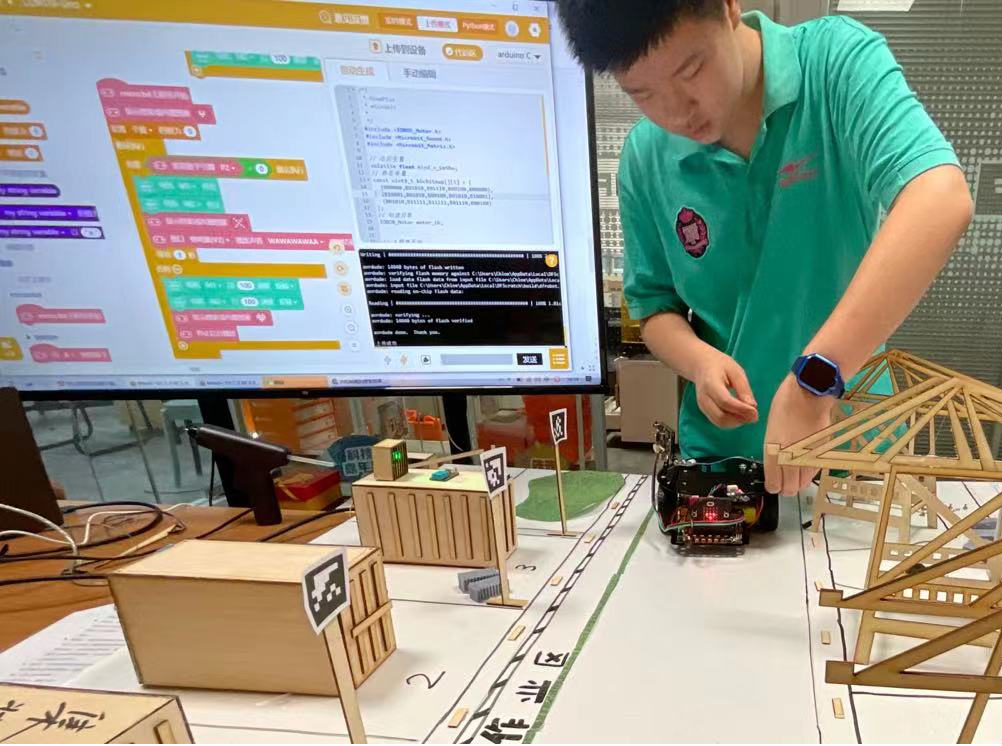

1. Programming Environment Setup

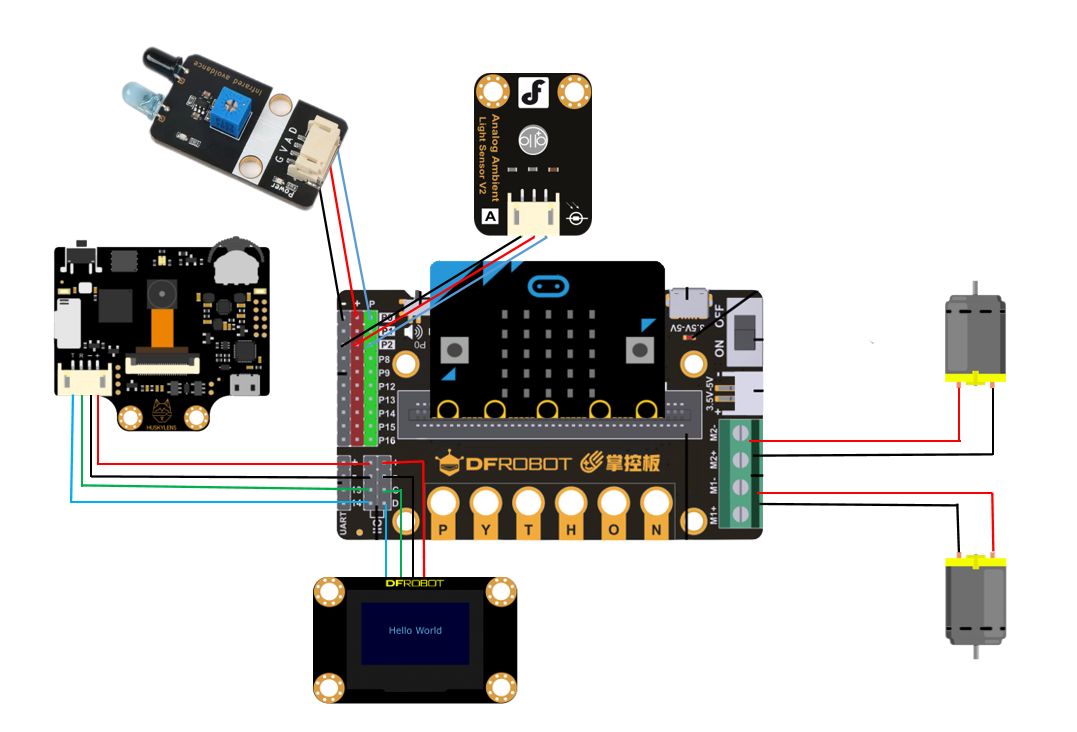

The programming is done using Mind+V1.7.2, involving hardware controllers like Micro:bit and Arduino UNO. The components for Micro:bit include: desktop robot platform, Micro:bit I/O expansion board, Huskylens AI camera, ambient light sensor, infrared obstacle avoidance sensor, and OLED display. The Arduino UNO includes: capacitive fingerprint recognition sensor, temperature and humidity sensor, soil moisture sensor, RGB LED strip, voice synthesis module, red LED module, and servo. Therefore, these extension command modules need to be added before writing the program, as shown in the pictures:

2. Module Addition

Step 1: Prepare the related program for the automated guided vehicle, add the Micro:bit controller, click the extension button, switch to the “Main Control Board” page, and add Micro:bit.

Add Micro:bit

Step 2: Add Huskylens AI camera and ambient light sensor, click the extension button, switch to the “Sensor” page, and add the sensors as shown below:

Add Sensor Module

Step 3: Add OLED display, click the extension button, switch to the “Display” page, as shown below:

Add OLED Display Module

Step 4: Prepare the Arduino UNO related program, add the Arduino UNO controller, click the extension button, switch to the “Main Control Board” page, and add Arduino UNO.

Add Arduino UNO

Step 5: Add temperature and humidity sensors, soil moisture sensors, and fingerprint sensors, click the extension button, switch to the “Sensor” page, and add the sensors as shown below:

Add Sensor Module

Step 6: Add servo and voice synthesis module, click the actuator button, switch to the “Actuator” page, and add the modules as shown below:

Add Actuator Module

Step 7: Add OLED display and LED light module, click the extension button, switch to the “Display” page, and add the modules as shown below:

Add Display Module

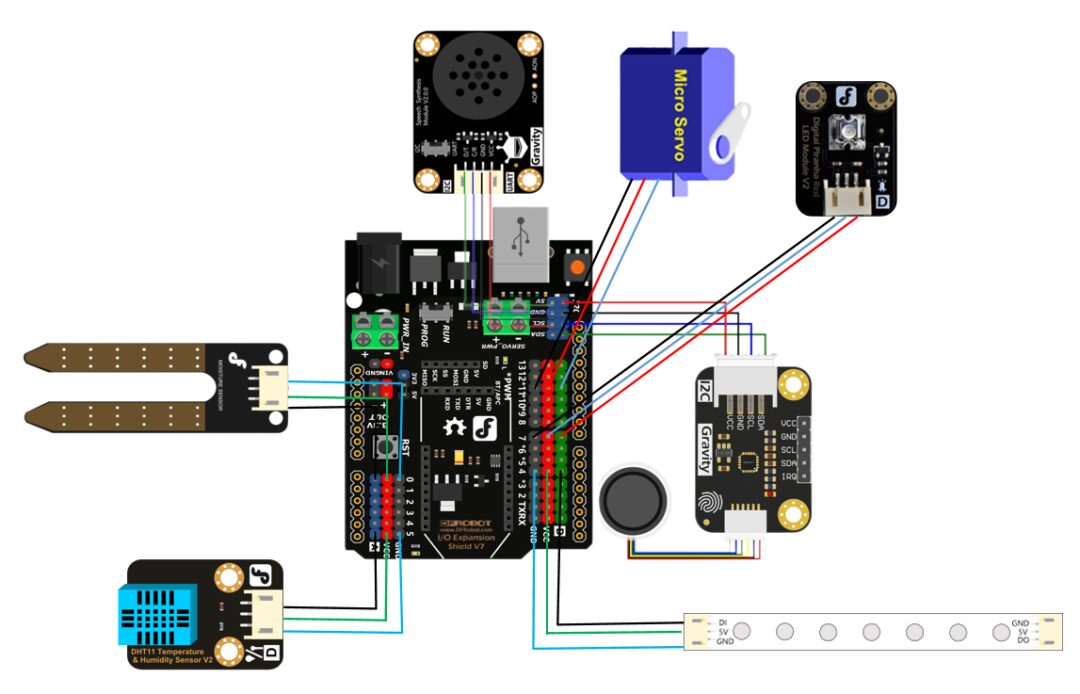

Circuit Wiring

Micro:bit Module Wiring Diagram

Arduino UNO Module Wiring Diagram

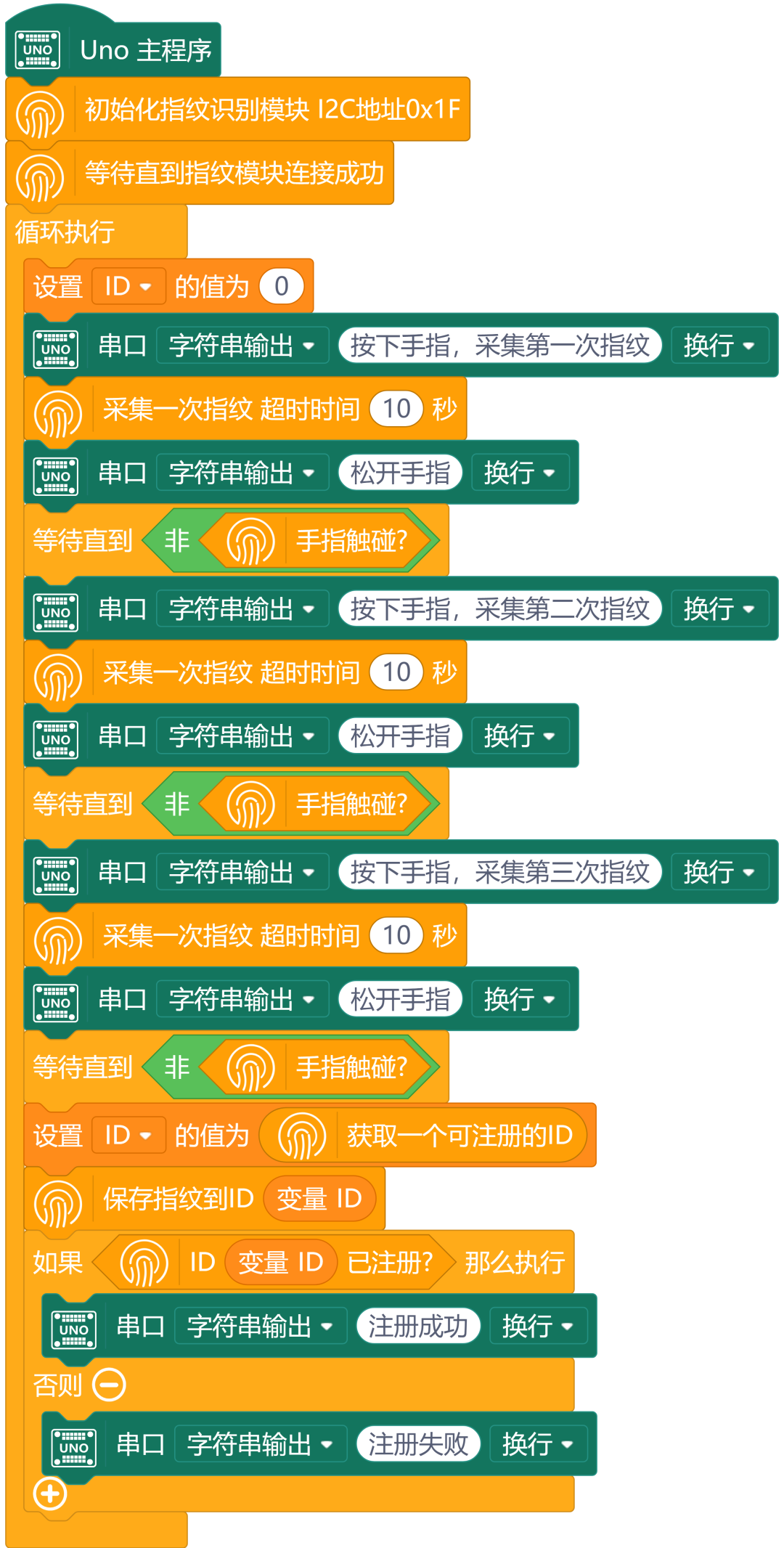

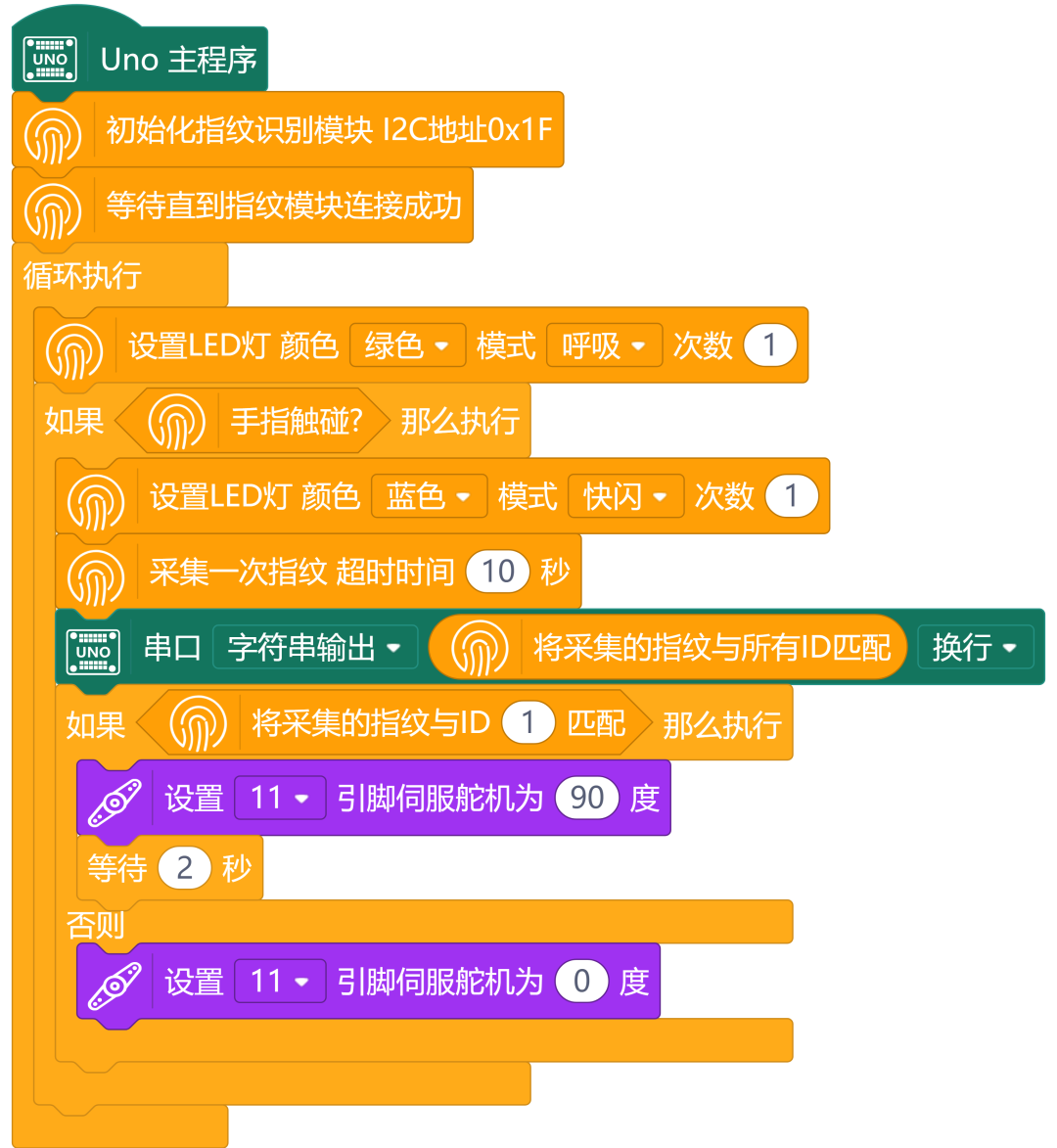

Code Writing

Automated Guided Vehicle Program

Fingerprint Registration Program

Fingerprint Recognition System Program

Environmental Monitoring System Program

Device Assembly

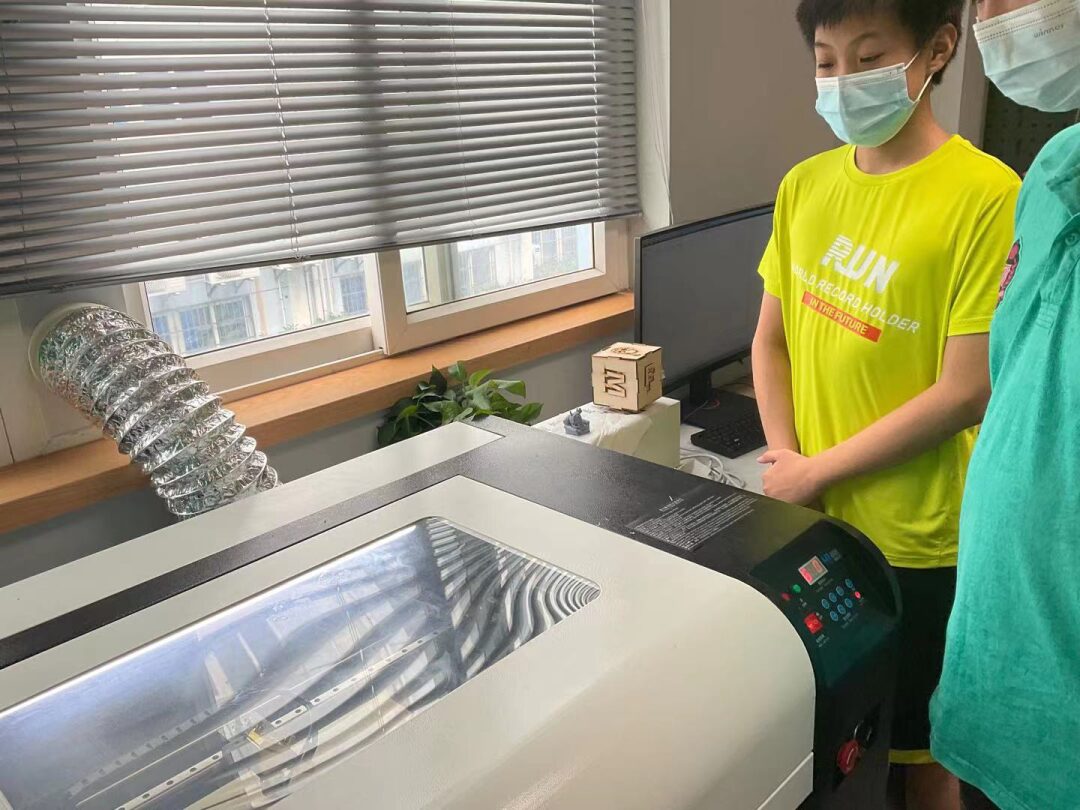

1. Laser Cutting

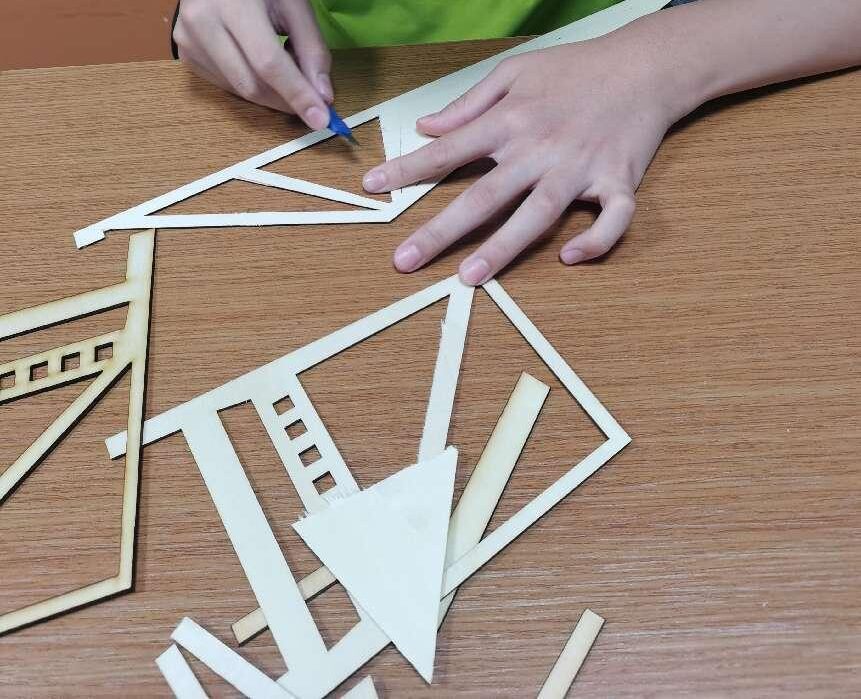

Design Laser Cutting Material and Production

Assembly of Port Crane Control Console

2. Container Production

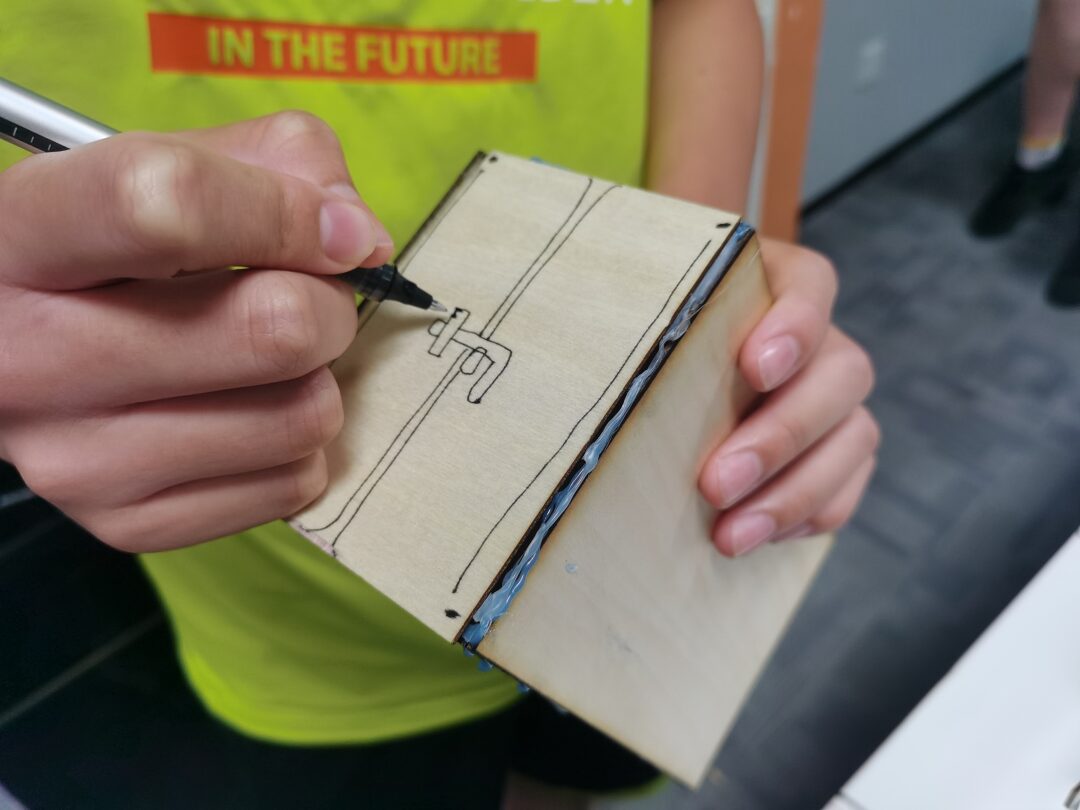

Container Adhesion and Detail Painting

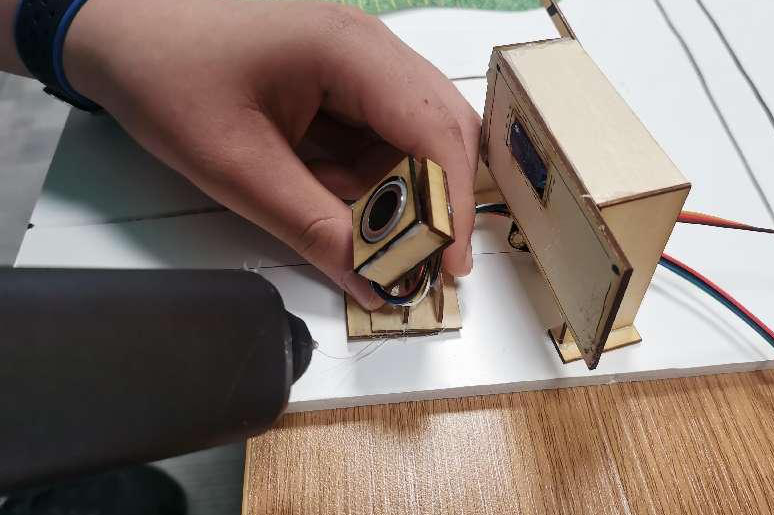

3. Fingerprint Recognition System Production

Fingerprint Recognition System Encapsulation and Fixation

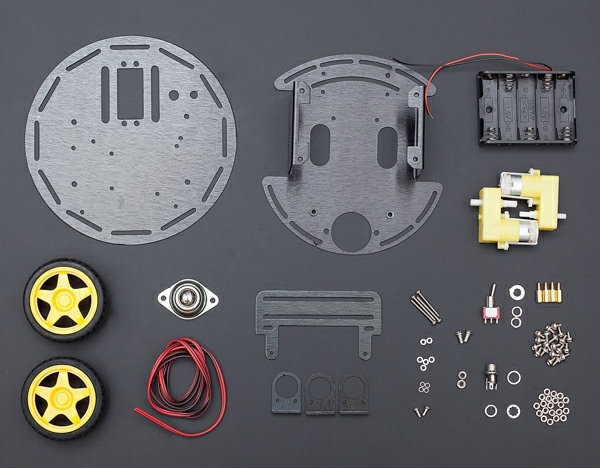

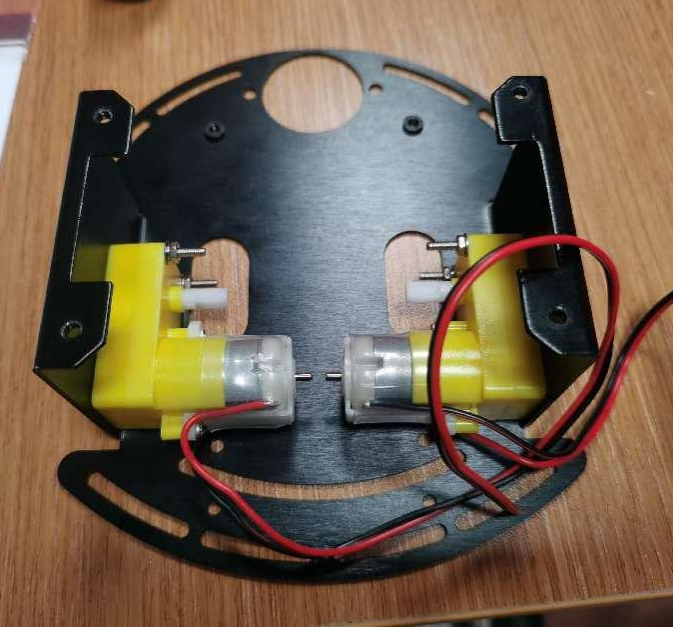

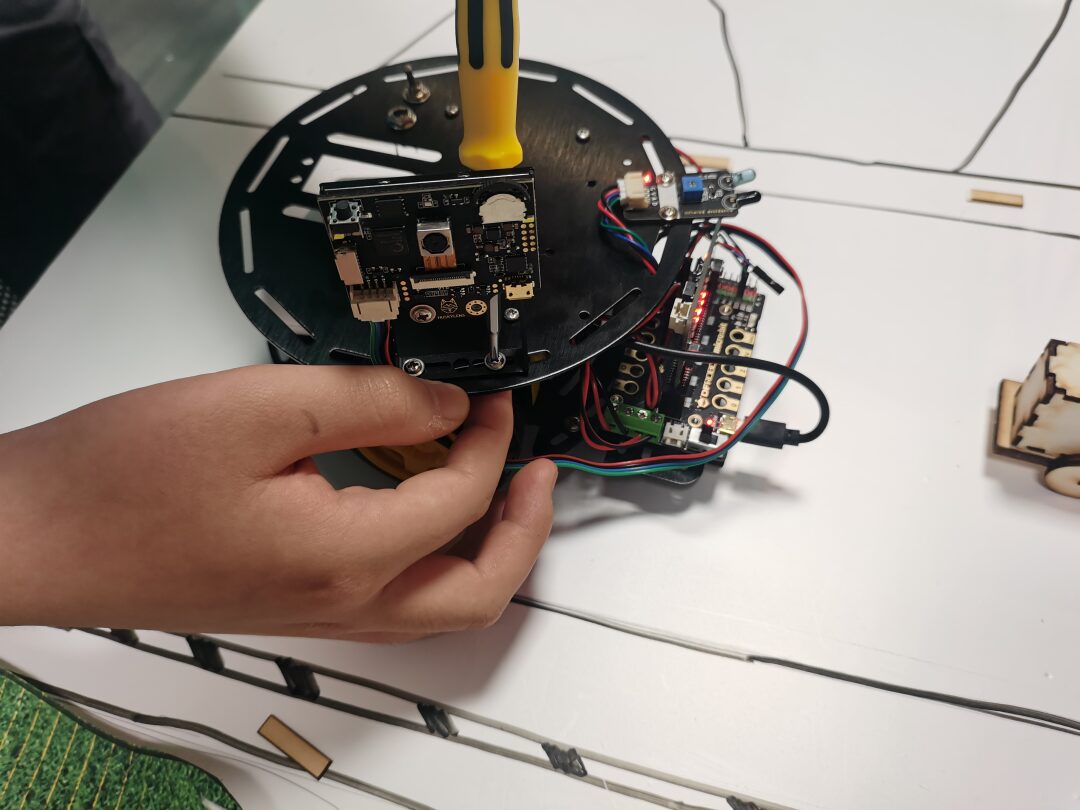

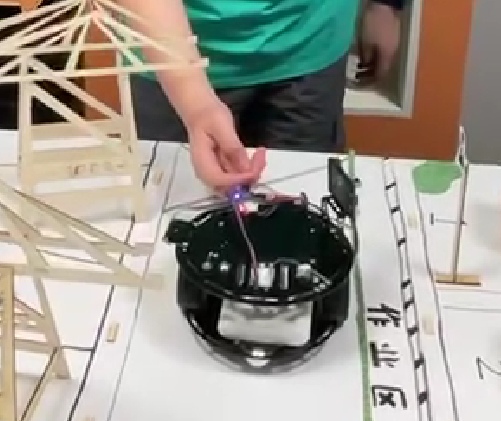

4. Automated Guided Vehicle System Production

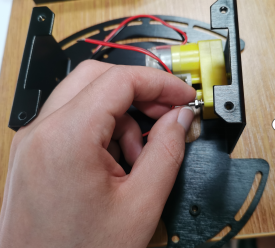

Desktop Robot Platform Assembly

Installation of Automated Guided Vehicle

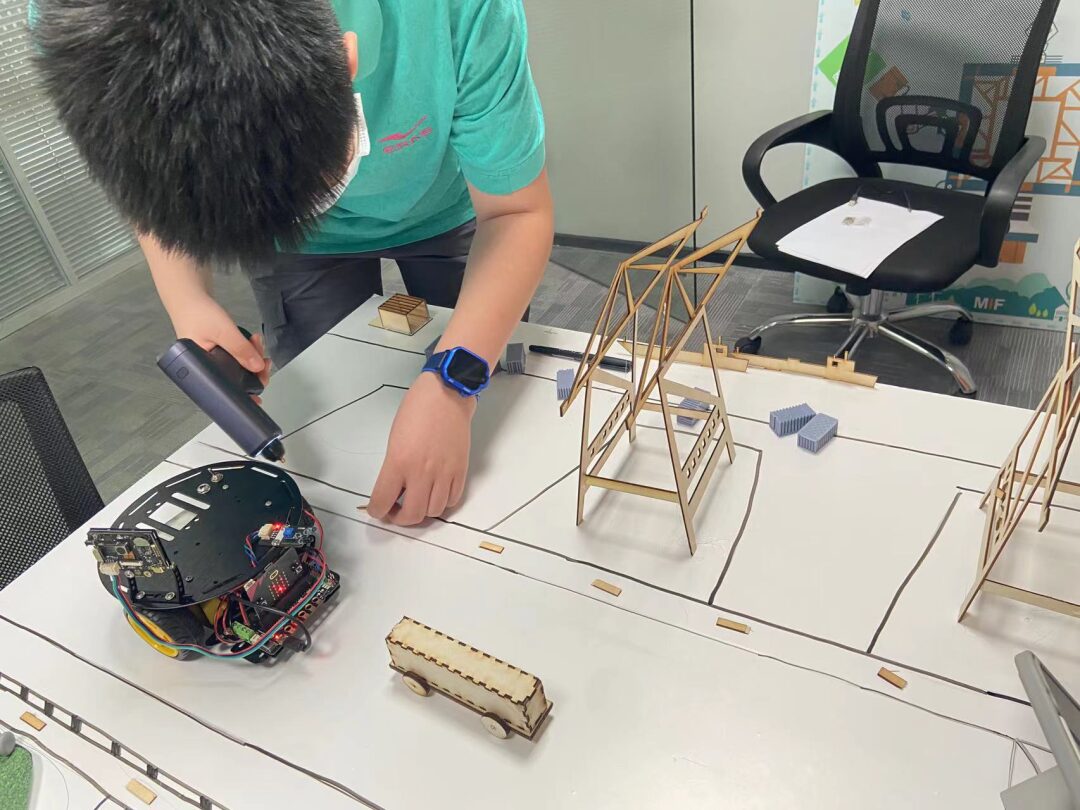

5. Sand Table Layout and Constant Temperature Yard Production

Green Belt and Road Design

Yard Design and Production

6. Debugging Process

Debugging of Automated Guided Vehicle

Water Level Monitoring and Constant Temperature Storage Debugging

Fingerprint Recognition System Debugging

Yard Label Recognition Debugging

Materials List

|

1✖ |

Micro:bit |

|

1✖ |

Micro:bit I/O Expansion Board |

|

1✖ |

Arduino UNO + Sensor Expansion Board |

|

1✖ |

HUSKYLENS AI Camera |

|

1✖ |

Voice Synthesis Module |

|

1✖ |

Capacitive Fingerprint Recognition Sensor |

|

1✖ |

Ambient Light Sensor |

|

1✖ |

Temperature and Humidity Sensor |

|

1✖ |

Infrared Obstacle Avoidance Sensor |

|

1✖ |

Soil Moisture Sensor |

|

1✖ |

Red LED Module |

|

1✖ |

OLED Display |

|

1✖ |

RGB LED Strip |

|

1✖ |

Desktop Robot Platform |

|

1✖ |

Servo |

|

1✖ |

Several Connecting Wires |

Project Showcase

Project Summary

1. In this project, we learned about the design and layout of the sand table, recognizing the advanced level of automation at Yangshan Deepwater Port. Through technologies like label recognition and biometric identification, we reinforced and learned about artificial intelligence and IoT, while also using 3D design and printing as well as laser cutting to create sand table elements, gaining a lot.

2. Throughout the production process, we constantly brainstormed, experienced the significance of teamwork, learned how to better integrate into the group, how to arrange tasks, and how to discuss solutions when encountering problems.

3. In the future, we will continue to optimize and improve this work, for example, by adding facial recognition at the entrance, IoT technology, and uploading personnel information to the system for automatic statistics. We hope to find more suitable methods and algorithms to detect personnel entry and exit actions. We hope this system can truly be applied in national automation construction projects, and we aim to contribute to the development of technology in the future.

Shanghai Yangshan Deepwater Port represents an important step in the construction of the shipping center in Shanghai’s “Five Centers”. The completion of Yangshan Port marks China’s transition from a major shipping country to a strong shipping nation! In this project, we conducted innovation and research on the intelligent service system of Yangshan Port. While ensuring the safety of staff, we aim to improve terminal operations more efficiently, and we hope that the level of intelligence at Yangshan Port will continue to rise, creating a “new height for Yangshan”! This is a pride for our country and for Shanghai! This is my hometown – Shanghai!

Attachment Download

Send the keyword “Competition Project” in the public account backend to download attachments (for other inquiries, please add WeChat for consultation: DFRobot2019)

Previous Recommendations

[Excellent Works of the Competition] The Dragon Gate Number of Morning Flowers and Evening Collecting

[Excellent Works of the Competition] Contactless Product Traceability System Based on RFID

[Excellent Works of the Competition] Rising Sun Chang Ticket Number Simulator

[Excellent Works of the Competition] Rising and Gathering All Rivers

[Excellent Works of the Competition] I Love Shanghai – The Amazing Electronic Pop-Up Book