As the level of autonomous driving increases, the complexity of automotive systems has sharply risen. Traditional mileage-based real vehicle road tests can no longer meet the growing testing demands of autonomous vehicles. How to quickly complete the functional testing and validation of autonomous vehicles has become a pressing issue in the industry. Currently, scenario-based testing methods have become an industry consensus, and virtual simulation testing technology, by integrating relevant models and hardware and software, can conduct efficient, safe, low-cost, and repeatable tests on autonomous driving systems. Therefore, scenario-based virtual simulation testing technology has become a crucial part of the testing and validation of autonomous vehicles.

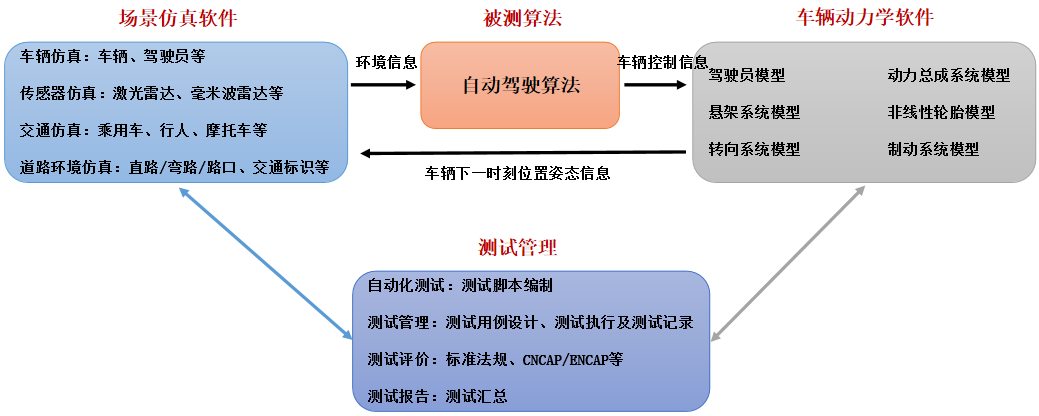

In the automotive V-process development phase, Software-in-the-Loop (SIL) testing is applied during the algorithm development stage of autonomous driving systems. The tested algorithm is built in a virtual simulation testing environment based on the SIL simulation toolchain. The SIL simulation toolchain mainly includes scenario simulation software, vehicle dynamics software, automated testing software, communication interface models, data conversion models, etc. First, key environmental information from the virtual scenario is sent to the tested algorithm, which calculates based on its internal functional logic and outputs vehicle control information to the vehicle dynamics software. The vehicle dynamics software then computes and feeds back position and posture information to the virtual testing scenario, thus forming a closed testing loop. Test cases are written in the automated testing tool, relying on evaluation metrics from standard regulations to validate the effectiveness of the autonomous driving functional logic.

Figure 1: SIL Integration Architecture

A complete SIL simulation toolchain integration environment construction mainly includes the following aspects:

01Virtual Testing Scenario Construction

Building a virtual testing environment is the foundation for conducting Software-in-the-Loop testing, providing realistic driving conditions for the tested control algorithm. Based on the driving conditions of intelligent connected vehicles during road tests, the testing environment for SIL should include meteorological conditions, road conditions, dynamic environments, and traffic flow environments.

Meteorological Environment:Includes information such as ambient temperature and humidity, lighting conditions, and weather conditions.

Road Environment:Includes information on road shape, surface conditions, traffic signs, traffic behavior, and obstacles.

Dynamic Environment:Includes dynamic indication facilities and communication environment information. Dynamic indication facilities include traffic signals, variable traffic signs, and traffic police; communication environment information mainly refers to the changing communication status between vehicles. The authenticity of dynamic environmental elements determines the credibility of the simulation results.

Traffic Flow Environment:Includes macro traffic flow environment and micro traffic flow environment. The macro traffic flow environment represents the overall traffic situation on a section of road within a certain time; the micro traffic flow environment represents the positions of vehicles around the tested vehicle and their corresponding motion states.

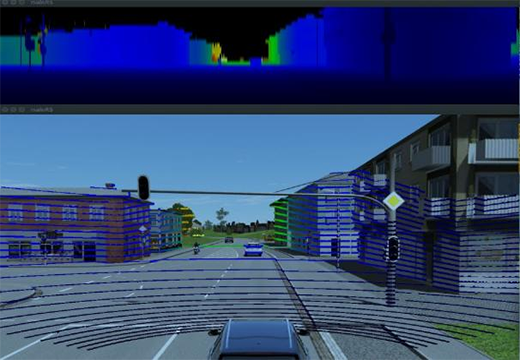

Figure 2: For various simulation software, CATARC has built nearly a thousand virtual testing scenarios to meet complex scenario testing needs.

02Vehicle Dynamics Model Parameter Configuration

Mainstream dynamics software in the market can model based on vehicle assembly characteristics. It can establish a basic vehicle dynamics model and set simulation conditions using the software database even when structural data is not available in the early stages of vehicle model development. The database contains various sample templates for suspensions and steering systems and allows the creation of libraries for various components, vehicles, and test results, enabling quick switching between different vehicle models and simulation conditions, comparing simulation results, and making corresponding modifications to better optimize product design performance in the early stages of product design.

03Sensor Model Development

In SIL simulation testing of algorithms, different sensors such as LiDAR, cameras, millimeter-wave radar, and ultrasonic radar are used to actively perceive the surrounding environment. By collecting data, performing static and dynamic object recognition, detection, and tracking, and combining with navigation and map data, systematic calculations and analyses are conducted to alert drivers to potential dangers in advance, effectively increasing the safety and intelligent comfort of vehicle operation.

In terms of ADAS sensor perception, signals from light, electrical, and sound sources at the sensor front end are obtained from the environmental scene, and after digital signal processing, raw signals such as time-of-flight and Doppler shift are generated, which are then processed by perception algorithms and target tracking to produce a target list signal that is finally sent to the control algorithm.

During sensor simulation, sensor simulation models can be constructed from both raw data models and target list models to meet different application scenario testing needs.

Raw Data Model:Can output different physical effects, mainly used for component and raw signal processing development and testing;

Target List Model:The generated target list signal is independent of the physical characteristics of the sensor, easy to configure parameters, mainly used for rapid prototyping/concept validation.

Figure 3: Based on simulation software VTD, CATARC has completed the development of raw data simulation models for multiple sensors including LiDAR, cameras, millimeter-wave radar, and ultrasonic radar.

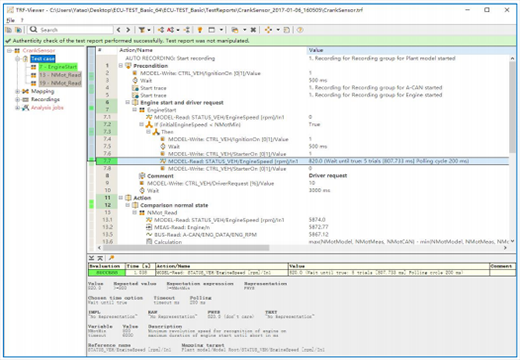

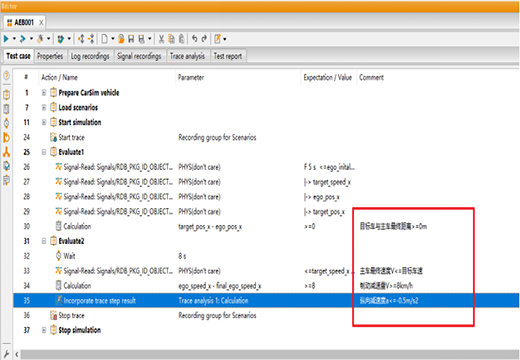

04Automated Testing and Evaluation

Based on the functional definitions, testing specifications, and interface information of the tested algorithm, testing functional points are sorted out, and relevant test cases are written based on virtual testing scenarios generated from natural driving scene data and standard regulations. Functional evaluations of the tested algorithm are completed based on authoritative testing evaluation procedures such as ISO, C-NCAP, and E-NCAP.

Figure 4: Based on authoritative testing evaluation procedures, CATARC has constructed a multi-indicator, multi-dimensional simulation testing evaluation system.

As intelligent driving simulation technology continues to be upgraded and applied, the testing of intelligent driving functions will inevitably become more complex. SIL testing, with its efficient and convenient advantages, can greatly enhance testing efficiency, allowing for early detection of system defects in the early stages of functional design development, thus shortening the development cycle. CATARC, based on years of virtual simulation engineering experience, has provided a complete intelligent connected vehicle simulation solution from scenario library construction to simulation platform integration and simulation validation (MIL/SIL) for many domestic automotive enterprises. In terms of MIL/SIL simulation validation, it offers multi-type sensor simulation model development, closed-loop debugging of simulation platforms, and multi-dimensional simulation testing evaluation, achieving efficient and rapid closed-loop simulation testing of autonomous driving functions.

If you need more information, please feel free to contact us!

Wang Qiang

Phone: 17694980926Email: [email protected]

CATARC

CATARC is based on automotive big data, with automotive domain model algorithms as its pillar, deeply engaged in energy-saving, low-carbon, green ecology, market research, and other work. Aiming at the development of “new infrastructure” and “new four modernizations”, it precisely focuses on the fields of cloud computing in the Chinese automotive industry, intelligent connectivity, intelligent cockpits, and industrial internet (industrial software), through the construction of data infrastructure for the Chinese automotive industry and the establishment of a national-level automotive industry data system, with the mission of “driving industrial transformation with data and leading the future of automobiles with intelligence”, dedicated to building a “national-level automotive industry data center, national-level decision support institution for the automotive industry chain, and national-level digital support institution for the automotive industry”.

Click the original text for more details!

Click the original text for more details!