Microporous graphene films (with pore diameters less than 2 nm) not only retain the high electrical conductivity and enhanced chemical stability of graphene but also exhibit high specific surface area and excellent flexibility, attracting widespread attention in high-performance devices such as flexible micro-energy storage. The traditional method for preparing microporous graphene films involves multiple steps: first, mixing reduced or microwave-exfoliated graphene oxide powder with an etching agent (such as KOH) and then activating it in a furnace filled with inert gas at high temperatures or via microwave, followed by a multi-step film-forming process. This method faces issues such as complexity, high costs, and poor controllability, and the resulting films have limited flexibility and foldability. Therefore, the efficient, low-cost, and highly controllable preparation of large-area and flexible microporous graphene films remains a challenge.

【Work Introduction】

Recently, Professor X. Chen and Professor Y. Chen from Guangdong University of Technology collaborated with Academician Z. Wang from the Georgia Institute of Technology in the USA, building on their previous research on ultraviolet ultrafast laser-induced graphene (Small Methods, 2019, 190020) and its high-performance devices (Advanced Materials, 2021, 2104290). They developed a technique for ultraviolet ultrafast laser induction and activation that can in situ prepare large-area, high specific surface area (>1300 m2 g-1), superhydrophilic (0° water contact angle), microporous few-layer activated graphene (LIAG) films in an air environment. This technique not only enables the activation etching of ultra-small pore diameters (<1 nm) but also effectively dopes a small amount of nitrogen (~3.0 wt.%) and potassium (~0.5 wt.%) atoms. Moreover, this technique does not require inert gases, adhesives, precursor synthesis, post-treatment, or hydrophilic treatment, and it has high controllability, allowing direct regulation of the activated area on flexible substrates. Combining traditional graphene activation processes with previously reported CO2 laser induction and activation techniques, it reveals for the first time the synchronous induction and activation mechanism of few-layer graphene films using ultraviolet picosecond lasers with short wavelengths and ultrashort pulse characteristics. Thanks to the balanced characteristics of specific surface area, heteroatom content, and lattice size, a planar micro-supercapacitor with a finger gap of 35 μm width achieved an ultra-high surface capacitance (128.4 mF cm-2), outperforming currently reported laser-prepared carbon-based planar micro-supercapacitors. Considering processing accuracy, efficiency, cost, and environmental friendliness, the devices prepared in this study received high overall evaluations. This article was published in the top international journalNano Energy. Dr. Huilong Liu from Guangdong University of Technology is the first author of this article.

【Core Content】

To improve the flexibility, foldability, and controllable generation and effective utilization of activated etched nanopores in devices, it is crucial to induce and activate porous graphene in situ on flexible substrates. This not only meets the requirements for efficient, easy-to-operate, and highly controllable preparation but also avoids the need for secondary transfer and the addition of adhesives or organic solvents, effectively preventing the destruction, collapse, or blockage of nanopores. The ultraviolet ultrafast laser induction and activation technology developed in this study utilizes the local high temperature and high pressure effects of the laser processing area, the enhanced chemical effects of ultraviolet lasers, and the overlapping scanning strategy of the laser spots to achieve the high-temperature activation of porous graphene while inducing it, ultimately enhancing the capacitance, energy density, and flexibility characteristics of planar micro-supercapacitors.

1. Preparation and Characterization of LIAG Films

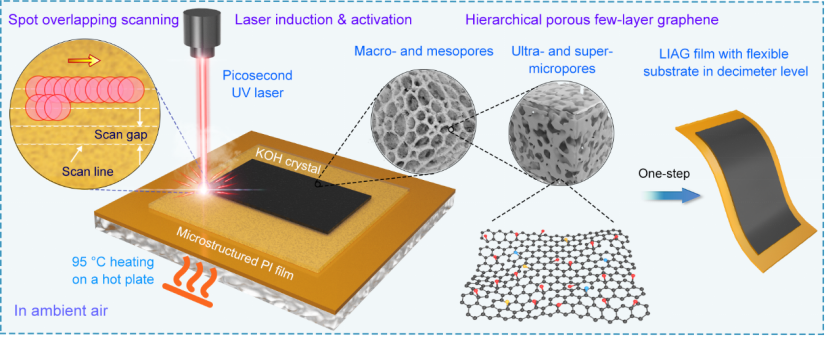

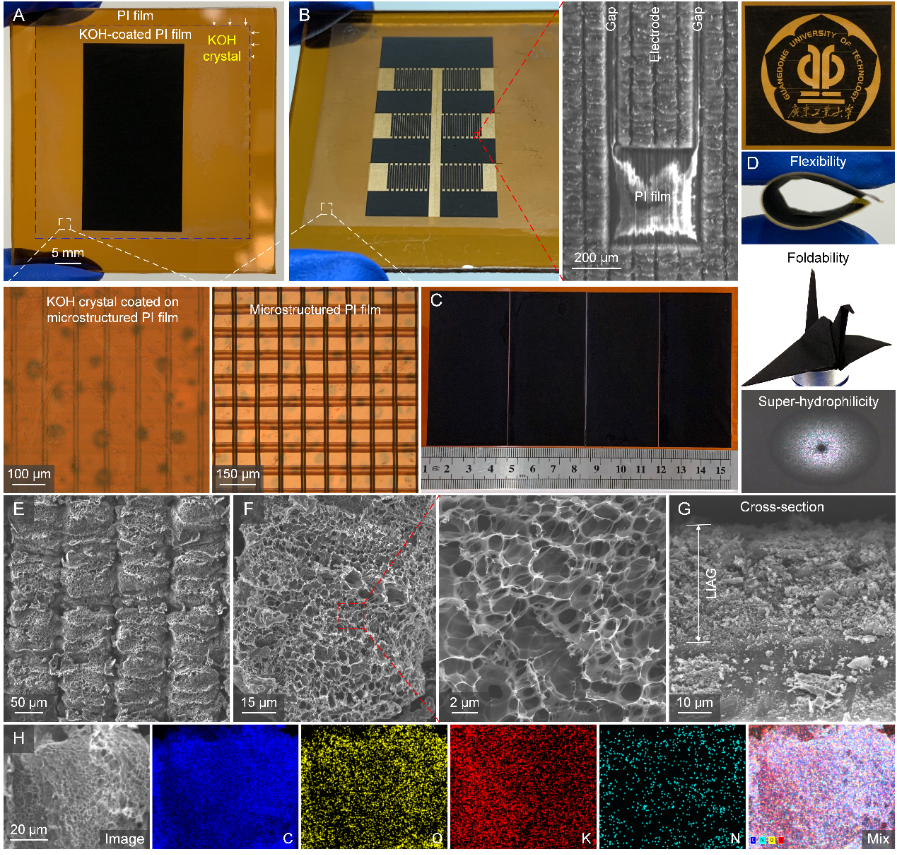

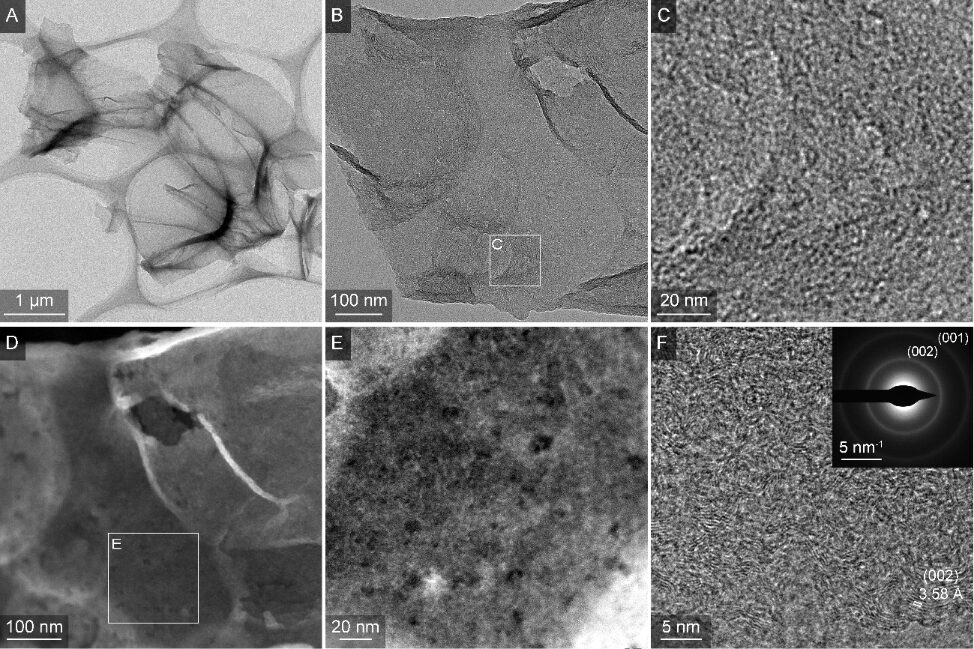

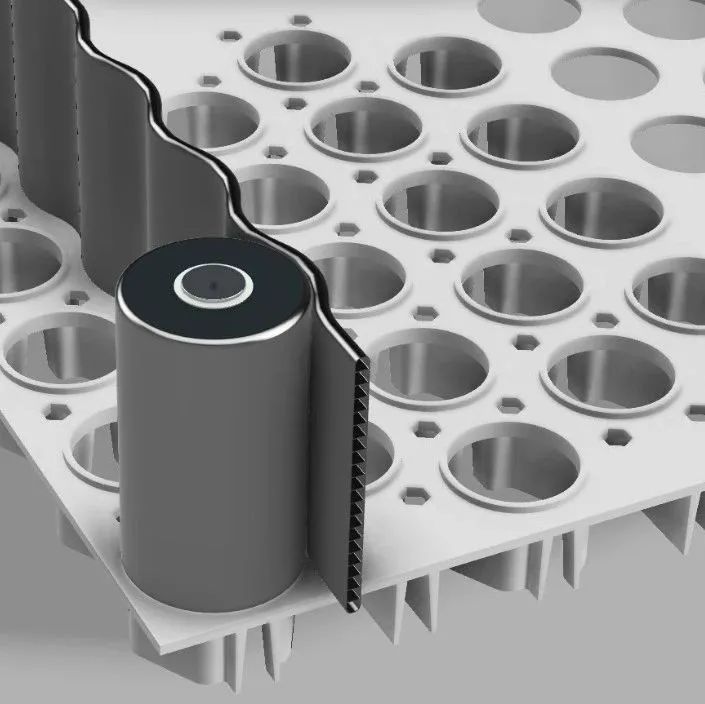

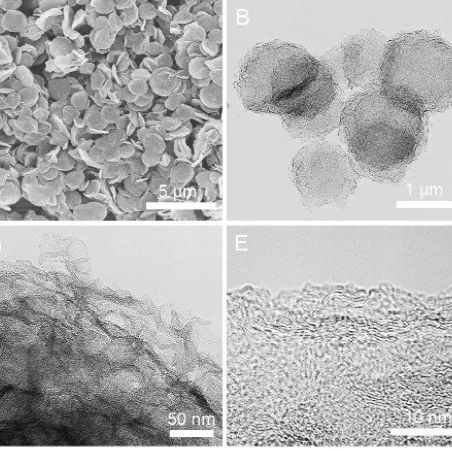

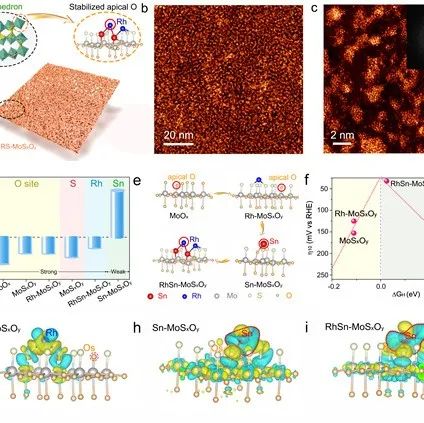

As shown in Figure 1, by using ultraviolet picosecond laser as a moving heat source on KOH-coated polyimide (PI) films, the LIAG films can be prepared in one step under optimized laser processing parameters and laser spot overlapping scanning. A micro-column structure is pre-constructed on the PI surface (enlarged views in Figures 1A and B), which not only facilitates the uniform coating of KOH but also improves surface wettability and charge storage due to the formed three-dimensional chessboard morphology and groove structure (Figures 1E and F). The prepared LIAG films can be precisely carved into high-resolution patterns of any shape by high-precision picosecond laser and exhibit large-area processing capabilities (Figure 1C) along with excellent flexibility and foldability (Figure 1D). The elemental distribution map in Figure 1H shows that besides carbon atoms, oxygen, nitrogen, and potassium atoms are uniformly distributed in the LIAG film, where potassium doping is beneficial for nanopore generation and increasing the carbon atomic lattice spacing. Figure 2 shows the transmission microscopic morphology of LIAG, intuitively indicating that the LIAG film is a few-layer graphene product (Figures 2A and F), with a large number of nanopores generated on its surface (Figures 2B-E) and an increase in carbon atomic lattice spacing (from unactivated ~3.46 Å to ~3.58 Å).

Figure 1 Schematic diagram of the ultraviolet ultrafast laser induction and activation preparation of LIAG films, actual samples, and surface microscopic morphology images

Figure 2 Transmission microscopic morphology TEM images of LIAG films prepared by ultraviolet ultrafast laser induction and activation

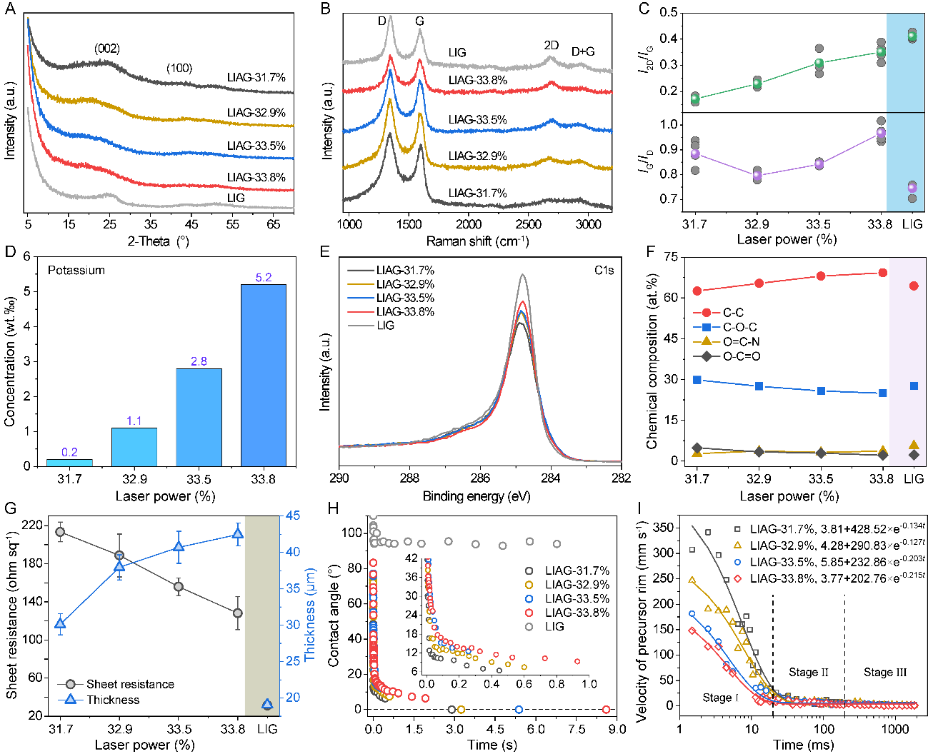

Figure 3 systematically studied the key chemical and physical properties of LIAG films processed at different laser powers. The results show that increasing the laser power causes an increase in the laser energy density in the processing area, leading to the disordered stacking of LIAG sheets and a reduction in the number of layers (Figures 3A-C), an increase in potassium atomic content (Figure 3D), a decrease in oxygen-containing groups (Figures 3E and F), a reduction in thin layer resistance, and an increase in thickness (Figure 3G). However, excessive laser power is not conducive to the generation of nanopore defects (Figure 3C). High-speed cameras observed that the LIAG film exhibited super hydrophilicity due to the combined action of surface microstructures and oxygen-containing groups (Figure 3H). Further analysis of the droplet diffusion behavior on the film surface revealed that the maximum diffusion speed of LIAG films processed at low laser power could reach 424.7 mm s-1 (Figure 3I).

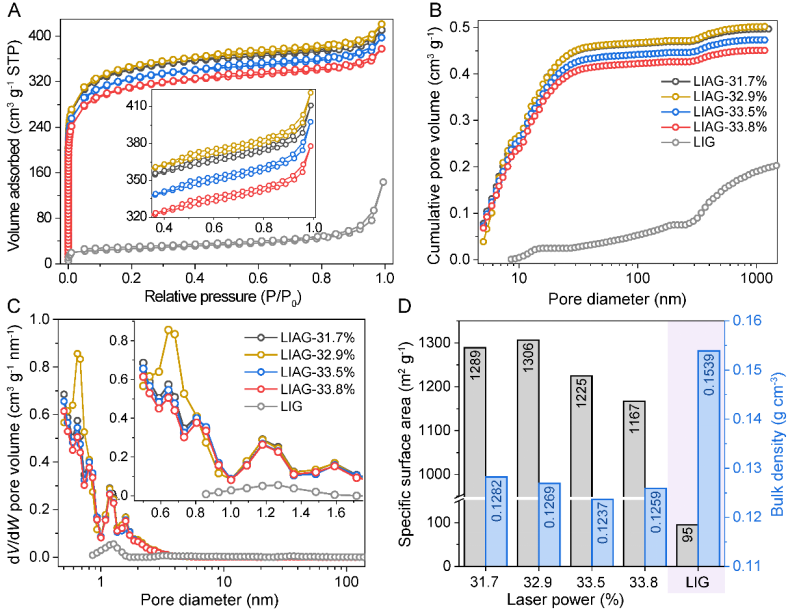

To quantitatively analyze the specific surface area and pore size distribution of LIAG at different laser powers, this study conducted low-temperature nitrogen adsorption/desorption experiments, as shown in Figure 4. The results show that compared to unactivated porous graphene, the specific surface area of LIAG increased more than tenfold, primarily due to the generation of a large number of ultra-micropores (0.5-1.0 nm and 1.0-2.0 nm) and a small number of mesopores (2.0-6.8 nm and 27-50 nm) on the surface of porous graphene. Additionally, Figure 4C shows that LIAG processed at different laser powers all demonstrated ordered pore size distribution, indicating the high controllability of the ultraviolet picosecond laser induction and activation technology in this study. Analysis in Figure 4D indicates that moderate laser power is more favorable for nanopore generation and the enhancement of LIAG’s specific surface area, which is consistent with Raman spectroscopy results, and it was also found that the specific surface area of LIAG is basically inversely proportional to its volume density (Figure 4D).

Figure 3 Key chemical and physical property characterization of LIAG films processed at different laser powers

Figure 4 Pore characterization analysis of LIAG films processed at different laser powers

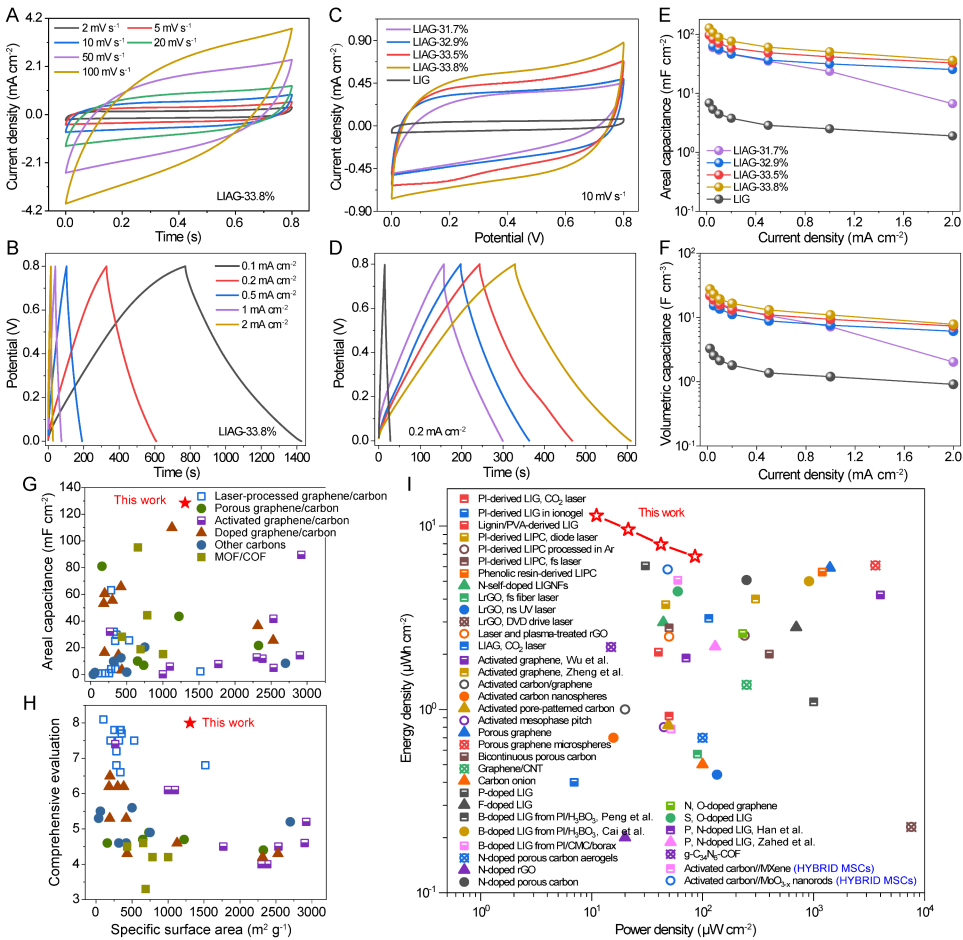

2. Electrochemical Performance Study of LIAG Planar Micro-Supercapacitors

LIAG films processed at different laser powers were carved into comb-finger-shaped electrodes and coated with PVA/H2SO4 solid electrolyte to assemble planar micro-supercapacitors. Through cyclic voltammetry and constant current charge/discharge tests, it was found that due to improvements in specific surface area, heteroatom doping, wettability, and thickness, the electrochemical performance of the device significantly improved, and studies showed that the higher the laser power, the better the electrochemical performance of the device, with a maximum surface capacitance reaching 128.4 mF cm-2 (Figures 5C-F). However, due to the poor conductivity of the LIAG film (Figure 3G), the LIAG devices in this study are only suitable for low/medium scanning speeds and current densities. Compared to carbon-based materials produced by laser, porous/activated carbon-based materials, other carbon materials, and a small number of metal framework materials, it was found that although the specific surface area of the LIAG devices is not as good as those prepared by traditional graphene activation processes, their capacitance and energy density significantly increased (Figures 5G and I), mainly due to the fact that traditional processes only target powdered materials, which can destroy, collapse, and block nanopores during the film preparation process, resulting in low effective utilization of charge storage, and the presence of a small amount of heteroatom doping in LIAG. Furthermore, since the LIAG devices are generated through synchronous induction-activation by ultraviolet picosecond lasers and high-precision electrode pattern carving, under the conditions of processing accuracy, efficiency, cost, and environmental friendliness, the LIAG devices produced in this study demonstrated an outstanding overall evaluation (Figure 5H).

Figure 5 Electrochemical performance of LIAG planar micro-supercapacitors processed at different laser powers

3. Comprehensive Characterization Study of LIAG Planar Micro-Supercapacitors

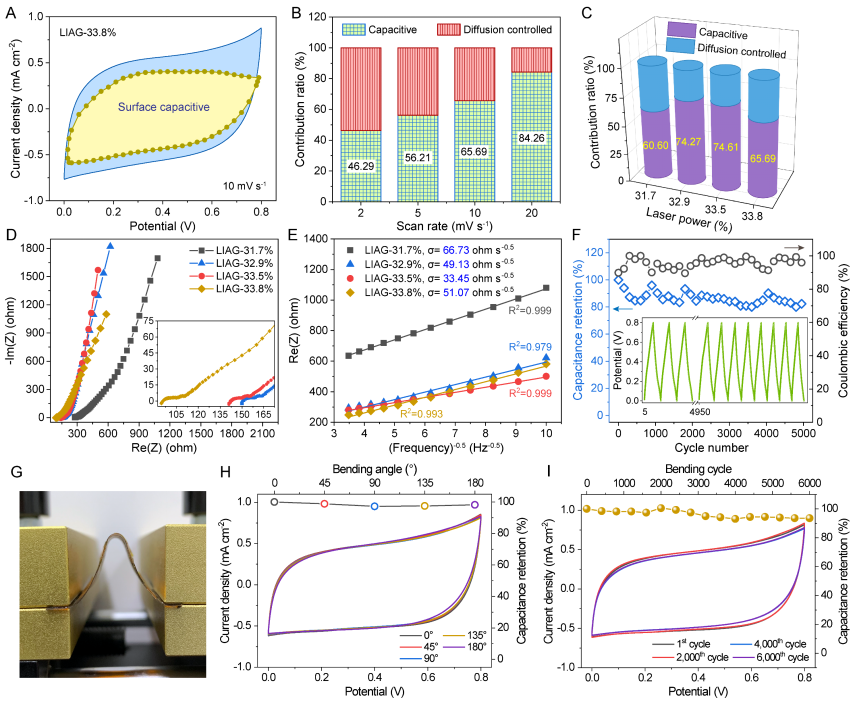

Furthermore, the energy storage mechanism of LIAG planar micro-supercapacitors processed at different laser powers was analyzed, as shown in Figures 6A-E. The results indicate that due to the increased carbon atomic lattice spacing and the doping of heteroatoms, the capacitance behavior of the LIAG devices is not solely controlled by surface adsorption but is influenced by both surface adsorption control and diffusion control, which facilitates charge storage. Through electrochemical impedance spectroscopy (EIS), the electronic transfer mechanism and kinetics at the electrode/electrolyte interface of the device were analyzed, revealing that the LIAG devices processed at high laser power exhibit the highest ion diffusion resistance due to the high proportion of diffusion control (Figure 6E). Additionally, further analysis of the cycling stability and flexibility performance of LIAG devices processed at high laser power showed that after 5000 cycles of constant current charge/discharge, the devices still maintained a high capacity (~82.3%) and Coulombic efficiency (~96%). The relatively poor and unstable capacitance retention is mainly due to the higher thin-layer resistance of the LIAG electrode and the lack of current collectors and conductive materials, leading to an increase in internal resistance and a decrease in the proportion of diffusion control during the device cycling process. Analysis in Figures 6G-I shows that the LIAG devices in this study exhibit excellent flexibility characteristics, maintaining over 90% capacitance retention even after bending at 180° or 6000 bends.

Figure 6 Comprehensive characteristics of LIAG planar micro-supercapacitors processed at different laser powers

3.3 Final Core Conclusions

In summary, this study utilizes the developed ultraviolet ultrafast laser induction and activation technology to in situ prepare high specific surface area, a small amount of heteroatom doping, superhydrophilic, microporous few-layer activated LIAG films in an air environment in one step. The results indicate: 1) This technology can achieve the activation etching of ultra-micropores on the surface of porous graphene and the doping of a small amount of potassium atoms; 2) Doping potassium atoms causes the expansion of carbon atomic lattices and the generation of defect products, which helps improve the diffusion-controlled capacitance behavior of LIAG planar micro-supercapacitors, thereby enhancing energy storage; 3) Moderate laser power is more favorable for nanopore generation and the enhancement of LIAG specific surface area, and there is an inverse relationship between specific surface area and volume density; 4) The capacitance of LIAG planar micro-supercapacitors is not solely dependent on specific surface area, but is the result of a balance among specific surface area, lattice quality, heteroatom doping, volume density, and wettability; 5) In situ preparation of LIAG electrodes on flexible substrates can significantly improve the controllability of the processing technology, effective utilization of activated etched nanopores, and the electrochemical performance and flexibility of the devices. The developed ultraviolet ultrafast laser induction and activation technology has significant advantages and bright prospects in high-performance device processing.

Huilong Liu, Yixin Zheng, Kyoung-sik Moon, Yun Chen*, Dachuang Shi, Xin Chen*, Ching-Ping Wong*, Ambient-air in situ fabrication of high-surface-area, superhydrophilic, and microporous few-layer activated graphene films by ultrafast ultraviolet laser for enhanced energy storage, Nano Energy (2021) 106902. https://doi.org/10.1016/j.nanoen.2021.106902.

Corresponding Author Profile:

Chen Xin, born in February 1960 in Lixian County, Hunan Province, obtained a bachelor’s, master’s, and doctoral degree in mechanical engineering from Changsha University of Science and Technology, Harbin Institute of Technology, and Huazhong University of Science and Technology in 1982, 1988, and 1995, respectively. He served as a visiting professor at the University of Nottingham in the UK from May to November 2001. From 2003 to 2008, he was the vice president of Guangdong University of Technology, from 2008 to 2010, he served as the deputy director of the Guangdong Provincial Department of Science and Technology, and from 2010 to 2020, he was the president of Guangdong University of Technology. He is currently the director of the National Key Laboratory of Electronic Precision Manufacturing Technology and Equipment, co-established by the provincial and ministerial levels, and concurrently serves as an executive director of the Chinese Mechanical Engineering Society, vice president of the Guangdong Mechanical Engineering Society, vice president of the Guangdong Association for Science and Technology, and an editorial board member of the Journal of Mechanical Engineering. He has long been committed to the research and development of high-speed and high-precision manufacturing equipment for microelectronic devices and electronic products, leading the team to overcome many technical challenges in “high-precision operation under high-speed and high-acceleration,” with several patents in various subfields ranking first in the country/world. The jointly developed equipment/components have broken the Western monopoly, and several technologies have achieved leadership, supporting enterprises to create numerous products with sales ranking first in the country and even globally. The first completer has won one second-class national scientific and technological progress award, one second-class national technological invention award, two second-class national teaching achievement awards, five provincial and ministerial first-class scientific and technological progress awards, etc.

Chen Yun, professor, doctoral supervisor, serves as the vice dean of the School of Electromechanical Engineering at Guangdong University of Technology, and assistant director of the National Key Laboratory of Precision Electronic Manufacturing Technology and Equipment co-established by the provincial and ministerial levels. He mainly engages in research on advanced electronic packaging processes and equipment, semiconductor wet etching processing technology and devices, laser processing technology and equipment, etc. He obtained his bachelor’s and doctoral degrees from Central South University in 2009 and 2014, respectively, and conducted related research at City University of Hong Kong (2013-2014), Georgia Institute of Technology (2016-2017), and Chinese University of Hong Kong (2017-2019). He has hosted two National Natural Science Foundation projects, one Central Military Commission Equipment Pre-research Fund project, and six provincial and ministerial projects. He has published more than 40 SCI papers in international professional journals such as Advanced Materials, Nano Letters, Nano Energy, Small, etc. (H index: 15), with 10 papers having an impact factor >10; he has been granted 8 US invention patents and more than 80 Chinese invention patents, and serves as a reviewer for more than 20 international journals. He has received the first prize of the Excellent Scientific Research Achievement Award (Science and Technology) from higher education institutions (2015), the first prize of Guangdong Provincial Scientific and Technological Progress Award (2018), the second prize of the Science and Technology Progress Award from the China Machinery Industry Federation (2018), the Outstanding Doctoral Dissertation of Hunan Province (2017), and the Best Poster Award at the Hong Kong Scholars Annual Meeting (2019). He was selected for the Hong Kong Scholars Program in 2017.

First Author Profile:

Liu Huilong, postdoctoral researcher under the Guangdong University of Technology’s “Youth Hundred Talents Program,” jointly trained in the research group of Academician C.P. Wong at Georgia Institute of Technology from 2018 to 2019, graduated from South China University of Technology in 2020 with a major in mechanical engineering under the supervision of Professor Tang Yong. He mainly engages in research on functional structure laser micro-nano processing and advanced manufacturing of flexible energy storage/sensor devices. As the first author, he has published 9 academic papers in journals such as Nano Energy, Chem. Eng. J., J. Mater. Process. Tech., Surf. Coat. Tech., and Journal of Mechanical Engineering (with the doctoral supervisor as the first author and himself as the second author), among which 4 papers have an impact factor >13 and 6 papers are from top journals. He has hosted 4 provincial projects, including the general project of the China Postdoctoral Science Foundation and the general project of the Guangdong Provincial Natural Science Foundation, and serves as a reviewer for international journals such as RSC Adv., and was shortlisted for the national “Boxin Program” review defense in 2021.

【5th Anniversary Recruitment Event】 Online Presentation by Leading Battery Companies!

2022-01-06

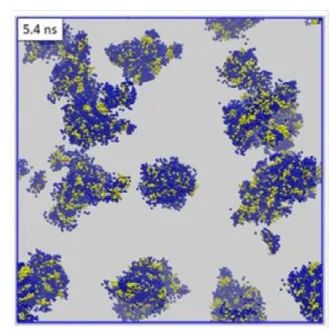

Argonne National Laboratory: The Impact of Nano Aggregates on Electrolyte Performance

2022-01-06

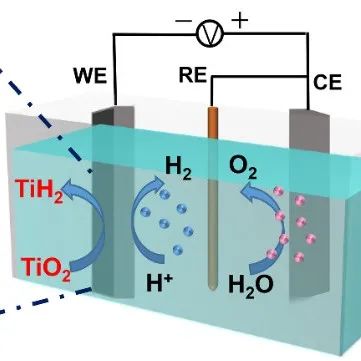

Professors Liu Hong and Zhou Wei from Jinan University: Nano Energy: Metallic TiH2/Ti Electrode Prepared by Electrochemical In Situ Hydrogenation Enhances HER Activity through Saturated Hydrogen Regulation

2022-01-06

Team of Zhang Genqiang from the University of Science and Technology of China: EnSM: Synchronously Regulating Anion/Cation Adsorption Dynamics for High-Performance Potassium-Ion Hybrid Capacitors

2022-01-06

Fan Hongjin/Li Shuzhou AM: Charge Distribution Steward, Stability Relies on It

2022-01-05

Xing Lidan & Xu Kang: New Breakthroughs in Wide-Temperature High-Voltage Aqueous Lithium-Ion Batteries

2022-01-05

Soochow University/Xiamen University: Red Phosphorus/Carbon Composite Materials with Practical Prospects for Sodium-Ion Batteries

2022-01-05

Shanghai Jiao Tong University/Xijiang University Nano Letters: Selective Regulation of Redox Reactions on Metal Selenides

2022-01-05

Tsinghua University: Lyu Ruitao & Li Jia ACS Nano: Mo2C-MoO2 Heterostructure Quantum Dots for Efficient Electrocatalytic Nitrogen Reduction to Ammonia

2022-01-05

Nature Energy: Chloride Solid Electrolyte Coupled with NCM85 All-Solid-State Battery Runs 3000 Cycles, Endures High Voltage of 4.8V!

2022-01-04

Li Nanwen/Yu Wei: Ultramicroporous Membranes Achieve Stable Operation of Fuel Cells at -20°C ~ 200°C

2022-01-04

“Vascular Biomimicry + Deep Learning” Helps Design Fast-Charging Batteries: Duke University Xu Bojun’s Research Group AEM

2022-01-04

Hong Kong City University: Halogenated MXenes Assist High-Performance Zinc Anodes

2022-01-04

Professor Sun Jie from Tianjin University Nano Letters: Simple Membrane Modification Strategy Captures Soluble Polyphosphides to Enhance the Electrochemical Performance of Phosphorus Anodes

2022-01-04