1Introduction to the Results

2Illustrated Guide

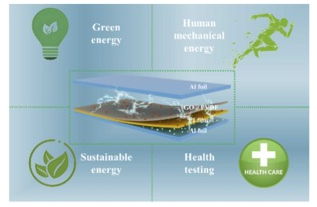

Figure 1. (a) Preparation process of GO@PVDF and GO@PVDF/PI films. (b) Schematic diagram of TL-TENG structure. (c) Current signal during the working cycle. (d) Working principle diagram of TL-TENG.

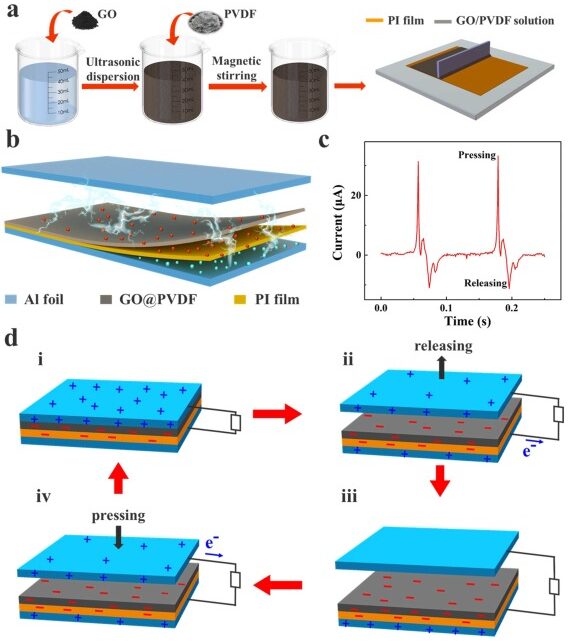

Figure 2. Orthogonal experiment of WTL-TENG electrical output performance.

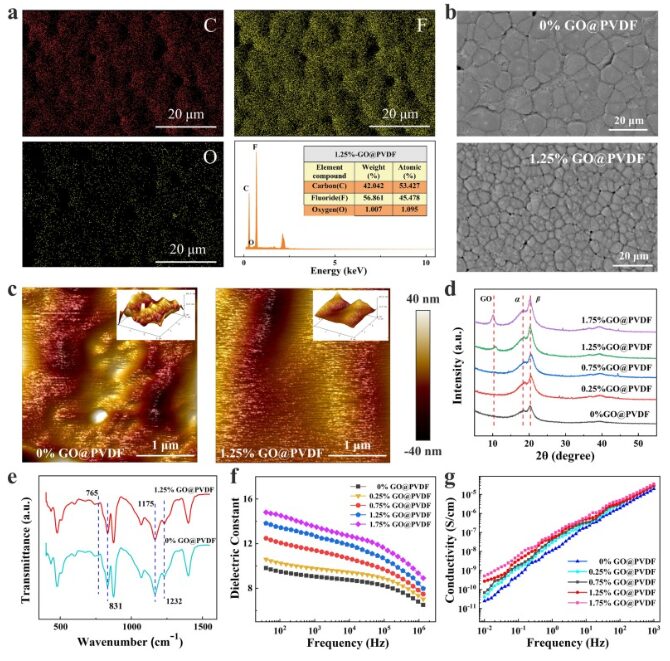

Figure 3. (a) EDS analysis of 1.25% GO@PVDF film. (b) SEM and (c) surface AFM images of 0% GO@PVDF and 1.25% GO@PVDF films (the inset corresponds to the three-dimensional morphology). (d) XRD, (e) FTIR, (f) dielectric constant, and (g) conductivity measurements of GO@PVDF films.

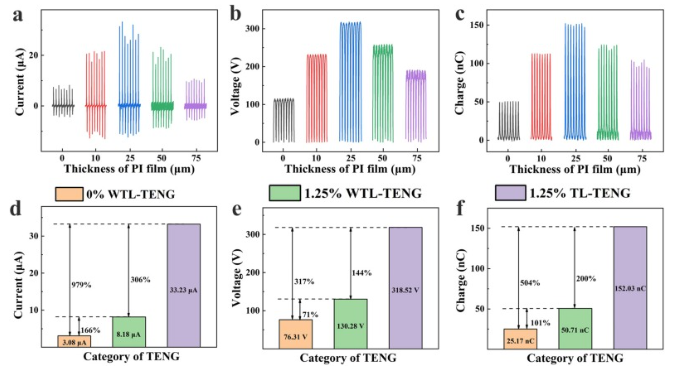

Figure 4. Different transition layer thicknesses of TL-TENG: (a) short-circuit current, (b) open-circuit voltage, and (c) charge amount. Comparison of electrical output performance of three TENGs: (d) short-circuit current, (e) open-circuit voltage, and (f) charge amount.

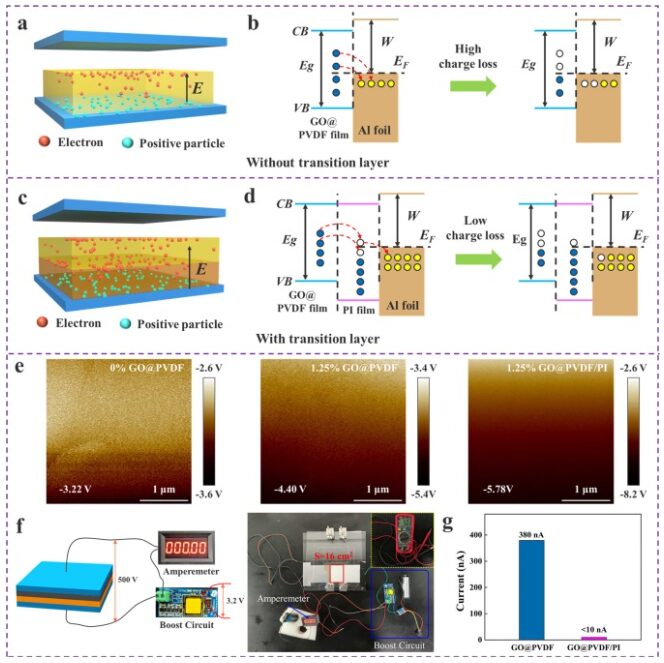

Figure 5. (a-d) The composite process of negative charges in GO@PVDF and GO@PVDF/PI films. (e) Surface potential distribution of three films detected using KPFM. (f) Schematic diagram and physical image of the detection circuit and (g) experimental results.

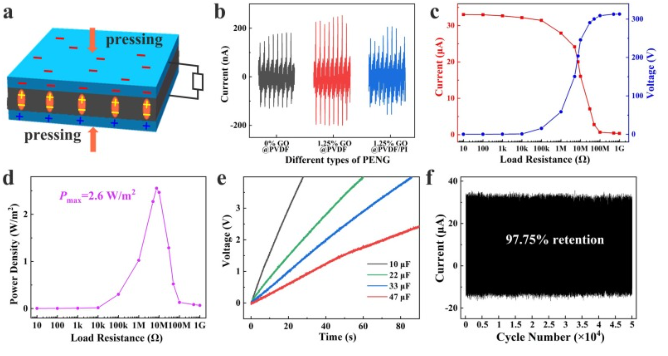

Figure 6. Piezoelectric and performance testing

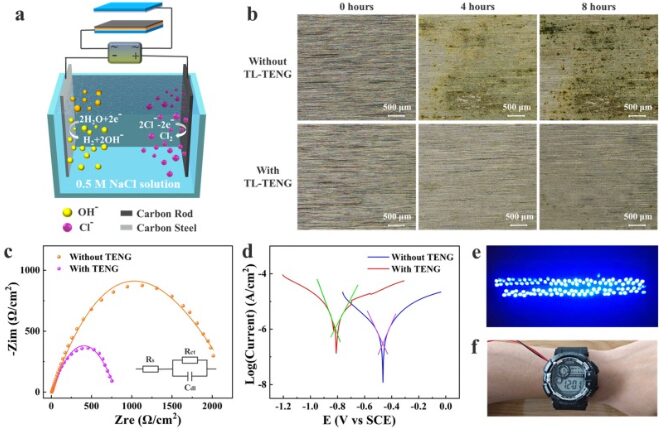

Figure 7. (a) Schematic diagram of cathodic protection device. (b) Morphological changes of carbon steel surface under different conditions. (c) EIS analysis and (d) Tafel polarization curves of carbon steel coupled and decoupled with TL-TENG. (e) Powering at least 107 blue LEDs. (f) Harvesting energy from human motion to power a digital watch.

3Conclusion

This study successfully prepared a high-performance TL-TENG material through a simple method, achieving the coupling optimization of charge generation and loss. The results show that GO and PI films significantly affect the electrical output performance of TENG. As the GO content increases, the β-phase content in the film gradually increases, reaching saturation at 1.25%, while the dielectric constant increases by 51% at 1.75%. However, excessive GO can increase the conductivity of the film, making it easier for triboelectric charges to recombine with positive charges in the electrode, increasing charge loss. Based on the interactions of the three components, the 1.25% WTL-TENG exhibits the best electrical output performance. Compared to WTL-TENG, introducing PI films of different thicknesses can effectively reduce triboelectric charge loss, significantly improving the electrical output performance of TL-TENG. KPFM results show that the surface potential gradually decreases, confirming the effectiveness of the combination of GO and PI films in enhancing the electrical output performance of TENG. Compared to adding GO, the transition layer has a more significant improvement on TENG performance, likely because the transition layer reduces the electron drift rate by 97.37%. Under a 7.5 MΩ external load, the maximum power density of the 1.25% TL-TENG reaches 2.6 W/m² and charges a 33 μF capacitor to 4 V within 86 seconds. After 5×104 contact-separation cycles, the ISC only decreased by 2.25%, demonstrating stable power output of the device. Furthermore, this TL-TENG can effectively protect metals and harvest energy from vibrations and human motion, sufficient to power digital watches and light up 107 LEDs. In summary, improving charge generation and reducing loss can effectively enhance TENG performance, providing valuable insights for designing high-output TENG devices.

References:

https://doi.org/10.1016/j.nanoen.2024.110436

Source: The article is from Nano Energy, organized and edited by Material Analysis and Applications.

Copyright and Disclaimer:

1. All works indicated as “Material Analysis and Applications” are copyrighted by Material Analysis and Applications. Unauthorized reproduction, extraction, or use in other ways is not permitted. Works authorized by this site should be used within the scope of authorization and should indicate “Source: Material Analysis and Applications”. Violators will be held legally responsible.

2. All works marked as “Source: xxx (not this site)” are reprinted from other media, aimed at conveying more information, and do not represent this site’s endorsement of their views or responsibility for their authenticity, nor do they bear direct or joint liability for any infringement actions. If other media, websites, or individuals download and use from this site, they must retain the indicated “source of the manuscript” and bear the legal responsibility for copyright.

3. If there are any issues regarding the content or copyright of the works, please contact this site within three days of publication; otherwise, it will be deemed as a waiver of related rights.