In all electronic devices and products, the presence of power management ICs is ubiquitous. With the rapid development of digital high-speed IC technology and chip manufacturing processes, the role of high-performance power ICs has become increasingly important. The rapid evolution of electronic product applications and the rise of environmentally friendly energy-saving demands have also put higher requirements on power ICs, giving rise to a new generation of highly integrated, high-performance, and high-efficiency power management ICs, which has become the eternal mission of power management IC manufacturers.

Power ICs need to “level up”. According to market research firm iSuppli, the power management IC market is expected to reach $38.7 billion in 2016, with major application markets in consumer electronics, network communications, and mobile internet, while automotive electronics and renewable energy are also gradually gaining traction. Driven by application demands and technological advancements, the technical requirements for power ICs are constantly increasing. Moreover, as applications continue to innovate, the market for power ICs is showing diversified demand and application segmentation, with a deepening and expanding market demand for more high-performance power ICs to better serve system innovation and performance enhancement.

On one hand, with the continuous upgrading of semiconductor process technology, the chips and components on the PCB boards are becoming more functional, faster, and smaller, driving power management ICs to provide lower and more precise core voltage and greater supply current, stricter voltage feedback accuracy, and higher efficiency performance. On the other hand, the application fields of power management ICs are constantly expanding and deepening, achieving better control functions, smarter control loops, faster dynamic response characteristics, and simplified peripheral layout designs, all of which are “indispensable.” To stand out, power management ICs must face these challenges directly.

Mark Davidson, the market director of Altera’s power business unit, stated that in order to help customers solve these challenges and simplify designs, digital, modular, and intelligent power ICs are becoming an inevitable trend.

For example, for FPGA customers, power management has increasingly become a strategic competitive advantage, especially in communication, computing, and industrial applications. With the continuous development of FPGAs and SoCs, designers have integrated a large number of mixed-signal functions into the next generation of embedded systems, achieving system-level performance that was previously unattainable. How to power FPGAs with increasing functionality, higher performance, and more advanced processes is indeed a very challenging issue. For instance, FPGAs using 14nm processes will have higher performance, which correspondingly requires more high-performance power solutions to match. Moreover, the 14nm FPGAs have more stringent requirements for power, and if the voltage range exceeds the specified requirements, it could lead to FPGA failure or even damage.

This also means that designers must find the best balance between the strict power rail requirements for FPGAs, system power consumption and thermal budget constraints, building a robust and reliable system, completing their projects on time within budget, and fully meeting the functional and performance requirements of their circuit boards and systems, which is no easy task.

Digital Power Injects Vitality. Major power management IC manufacturers are quickly strategizing to respond to this market trend, with digital power becoming their relentless “trick.” With its flexibility, rapid response, high integration, and highly controllable advantages, digital power has shown strong development momentum.

According to a report by IMS Research, a subsidiary of IHS, the global digital power market revenue is expected to reach $12.4 billion in 2017, and the digital power IC market will reach $2.6 billion. The digital power market is dominated by server and communication equipment applications while expanding into many other application areas.

POL converters generally provide voltage for low-voltage, high-current digital loads (such as FPGAs, microprocessors, DSPs, and other digital circuits with extremely high dynamic characteristics). Maintaining voltage regulation around 1V while using pure analog control technology to meet nearly 200A/ns load transient requirements is becoming increasingly challenging. Some digital controllers can offer functionalities that are difficult to achieve with traditional analog ICs, such as nonlinear control. In fact, nearly all POL digital controllers incorporate various control techniques aimed at improving transient response. These specialized control algorithms form the barrier for traditional analog power companies to enter digital power development. If a power supply internally utilizes a digital core to implement the control loop, it can meet extremely stringent transient requirements, achieve extremely low ripple voltage, and provide extremely high precision voltage regulation within the output voltage range. It can also support PMBus communication interfaces to enable remote precise monitoring of current, voltage, and temperature.

Digital power has injected new vitality into the power design field while also raising higher requirements for power management IC manufacturers. On one hand, power management IC manufacturers need to provide a range of integrated design solutions rather than single components, offering a full range of products from high-end to low-end; secondly, they also need a complete set of digital power development tools, including hardware and graphical user interfaces (GUIs); finally, they need to obtain relevant peripheral components such as Power Train to create complete solutions. On the other hand, if digital power IC manufacturers continue to operate in isolation, they will clearly be “overwhelmed.” Zhang Weichao, senior business manager of Altera’s Enpirion power products in China, mentioned that main chip manufacturers such as FPGA/ASSP/ASIC are rapidly advancing, and their performance requirements for power are exceptionally stringent. Power management IC manufacturers can no longer operate alone as they did in the past but must collaborate with digital chip manufacturers. Power IC manufacturers need to engage in effective technical communication with main chip manufacturers because only by understanding the needs of system chips can the target design specifications of power ICs become more meaningful. This customized power design for system performance needs can make a significant contribution to optimizing system power consumption. This collaboration can enhance the competitiveness of power management IC manufacturers’ products and help them gain more market share.

Recent market acquisitions undoubtedly corroborate this trend. Qualcomm acquired Summit, Mediatek acquired Richtek, Microchip acquired Micrel, Altera acquired Enpirion, and recently acquired the digital power controller division of the innovative German chip company ZMDI. The rationale is consistent; the industry recognizes and executes similar strategies. The benefits of acquiring a power company are often more “direct” than collaborating with a power company.

Mark Davidson stated that generally, large power management IC manufacturers have many different application areas for their power devices, and they cannot and will not focus all their energy on the FPGA field. By acquiring, Altera can pay more attention to the application of power devices in FPGAs. He emphasized that by acquiring Enpirion, we become one company, allowing us to combine experts in power, FPGA system engineering, and circuit board layout to develop better solutions together.

Modular Trends Stand Out. Influenced by the trend of SoC design, in recent years, power management IC technology has shown an increasingly strong modular trend. On one hand, devices are becoming more complex, requiring more functional features and faster, more complex processors that need more advanced power management solutions. Power management technology must integrate more functions onto smaller silicon chips while achieving stronger system power performance with higher design flexibility, which is changing traditional power design methods. On the other hand, modular power management ICs can effectively reduce system design complexity, save circuit board space, improve long-term reliability of the system, and also effectively lower system costs, with benefits that are evident.

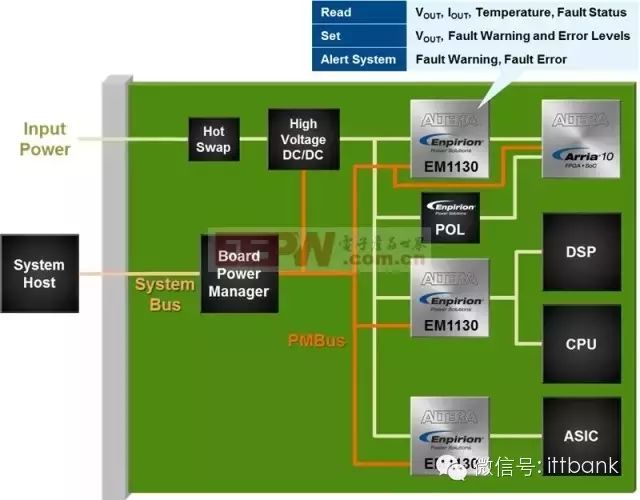

As a result, modular power management ICs are beginning to emerge in the market. Recently, Altera added a 30amp PowerSoC DC-DC buck converter EM1130 to its Enpirion power solutions. This product, viewed by Altera as a “milestone,” is the first product in the integrated digital DC-DC buck converter series, providing power management functionality for Altera’s 10th generation FPGAs. The EM1130 is “powerful,” with a pin layout density that is the highest in the industry, occupying less than half the area of other solutions, and not only providing strict high output voltage regulation and fast transient response but also allowing remote measurement of key parameters such as current, voltage, and temperature.

Zhang Weichao explained that the greatest advantage of the integrated Enpirion power single-chip system is that it greatly enhances system reliability and usability, while modular power has a small size, low EMI, and achieves faster load transient response and lower noise through digital control loops, thus intelligently adapting to platform manufacturers’ latest demands for reducing system power consumption while enhancing performance under stringent challenges. By combining the proven Enpirion power SoC solutions with Altera’s FPGAs, customers can complete their designs on the smallest possible circuit board while maximizing performance and minimizing power consumption, accelerating time to market, reducing material costs, and enhancing system reliability.

Figure: Altera’s Enpirion power SoC solution combined with Arria 10 FPGA significantly reduces power consumption and improves system performance.

Figure: Altera’s Enpirion power SoC solution combined with Arria 10 FPGA significantly reduces power consumption and improves system performance.

Moreover, the modular trend of power management ICs is also reflected in the “integration” with other chips on the board. The integration of communication and monitoring functions between power management ICs and main control chips in the market is also increasing. Zhang Weichao mentioned that in the future, Altera will leverage Enpirion’s technology in power to integrate certain power modules into FPGAs, making the circuit board design simpler, optimizing power consumption and cost, and further simplifying the development of FPGA systems.

Intelligent Upgrades Enhance Intelligence. The intelligence of power management ICs is also a trend that cannot be ignored, as it must actively “cooperate” with the main chip platform’s continuously upgrading demands. Zhang Weichao stated that as system functions become increasingly complex and energy consumption requirements rise, customers’ demands for the perception and control of power operating status are also increasing. Power designers are no longer satisfied with real-time monitoring of current, voltage, and temperature; they also require diagnostics of power supply conditions and flexible setting of each output voltage parameter. Furthermore, power management ICs must effectively connect with the devices requiring power on the circuit board, as the system requires more real-time collaboration and cooperation between the power subsystem and the main system, even supporting monitoring via the cloud. Intelligent management and control have become essential.

How to achieve intelligence? Zhang Weichao indicated that efforts need to be made in two areas: first, power management ICs must achieve communication with the core, allowing various parts to communicate and control dynamically in real time, along with seamless communication, which can create an intelligent power management system capable of detecting, analyzing, and responding to changing power demands in real time, greatly improving system efficiency. Second, internal parameters should be adjustable online, meaning that the dynamic characteristics of power can vary, adapting to load changes over a considerable range while ensuring certain performance. Digital power plays an important role in this aspect and also requires continuous breakthroughs in control algorithms and adaptivity.

Through continuous innovation, Altera has made new progress in this area. Recently, Altera held the 2015 Altera Technology Day event in 14 cities across the Asia-Pacific region, showcasing the latest FPGA, SoC, and Enpirion power solutions. Among them, the combination of Arria 10 and Enpirion’s digital PowerSoC achieved an intelligent FPGA power system with the lowest power consumption. Its specific characteristics include the following aspects:

1. All power supply requirements for FPGA design lead to the establishment of an FPGA power tree, where different resources require different power-up sequences, which places higher demands on power converters. Enpirion devices have “Power OK” or “Power Good” pins that support grouping and ordering the power rails of different resources in the FPGA, sending signals to the system controller or ordering device that a certain FPGA input has powered on, allowing the next ordering step to begin;

2. Another common system power requirement is the ability to perform remote monitoring, allowing real-time monitoring of various power parameters, fault alarms, and corresponding adjustments. The simplest, cheapest, and most compact way is to use a power regulator integrated with remote monitoring functions and corresponding communication buses. Through the smart voltage ID (SmartVID) feature, Altera’s Arria 10 FPGA and SoC determine the required VCC voltage and communication between the Enpirion voltage regulator system, dynamically adjusting the core voltage rail to the minimum possible without sacrificing system performance. At the same time, the PMBus-supported Enpirion ED8101P0xQI single-phase digital controller, paired with the ET4040QI high-current power supply, can realize various remote monitoring and low-power features for the FPGA.

FPGA power supply design has some common requirements. Understanding how FPGA design and applications affect power consumption and power supply requirements can clarify the design process and make it easier to succeed. Altera’s Enpirion power solutions are designed to meet these stringent FPGA power requirements. In the future, the functions of electronic systems will increasingly become complex, diverse, and intelligent, and the requirements for power management systems will also continue to rise. A deep understanding of the characteristics and power supply needs of various systems, in line with the trends of digitization, modularization, and intelligence, is essential to provide a tailored “perfect” power supply guarantee for the system.

Source: Electronic Product World

Thanks to the original author for their hard work. If there are any infringements or inappropriate issues with the article, please contact the author, and we will handle it promptly. Thank you! Email: [email protected], Phone: 15818560804.

ITTBANK : Our world is changed by technology!

Cloud Egg (ittstore)

IC Bank: You deposit, he withdraws, sharing resources!

Note: One person can only join one group (if you join multiple groups, you will be rejected, please understand!)

Welcome to join QQ group 199699487 – Amlogic S802/S805/S812 and other solution platform network player

Welcome to join the dashcam QQ group: 294132591 – The most professional dashcam review group

1. Mobile industry technology exchange group 3 (134917677)

2. Tablet technology exchange group (378173769)

3. Set-top box OTT box exchange group (361764225)

4. Capacitive touch technology exchange group 2 (257209943)

5. Camera technology exchange group (377648136)

6. LCD screen technology exchange group 2 (249572580)

7. Wireless WIFI technology exchange group 2 (416431905)

8. Security technology exchange group (308535073)

9. Memory storage exchange group (204191613)

10. Mobile, MID, capacitive touch, LCD screen sales and purchase group (374763457) – Exclusive sales and purchase group

11. Cross-border e-commerce exchange (384299409)

12. Global maker space (188561451)

13. Global electronic technology exchange platform (370733047) – (This group is purely a technical exchange group, dedicated to engineers’ communication platform, traders are not allowed! Thank you! When adding the group, please add a standard remark, region + industry + nickname, such as Shenzhen – Bluetooth WiFi solution – Engineer Xie!)

Submission email: [email protected]

ITTBANK customer service hotline:

400-0933-666