Original SizeChange Image

In the current wave of industrial automation, the Siemens PCS7 system, with its extraordinary performance and wide range of applications, has become a key core technology for many industrial enterprises to achieve efficient production and intelligent control. It acts like a hidden intelligent “brain,” accurately coordinating every aspect of industrial production and laying a solid foundation for the steady advancement of Industry 4.0. Today, let us deeply explore the secrets of the Siemens PCS7 system.

1. PCS7 System Architecture: A Highly Integrated Intelligent Network

The Siemens PCS7 system adopts a cutting-edge distributed architecture, cleverly integrating control, operation, and management functions into one. Its core components include a central controller (CPU), input/output modules (I/O), and communication networks. The central controller serves as the “heart” of the system, possessing powerful data processing and computing capabilities, enabling rapid responses to various control commands. The input/output modules act like the system’s “nerve endings,” accurately collecting various signals from field devices and transmitting control signals to actuators without error.

In terms of network communication, the PCS7 system supports multiple communication protocols, such as Industrial Ethernet and PROFIBUS. Industrial Ethernet, with its high speed and stability, enables rapid data exchange between controllers, host computers, engineering stations, and operator stations, allowing operators to monitor production processes in real-time. Meanwhile, PROFIBUS focuses on communication at the field device level, tightly connecting numerous dispersed field instruments, sensors, and actuators to build a seamless automated control network. This highly integrated architectural design not only significantly enhances the system’s reliability and flexibility but also greatly reduces the difficulty of engineering implementation and maintenance.

2. Powerful Functional Features: Fully Meeting Industrial Needs

(1) Process Control Function

The PCS7 system possesses rich and robust process control algorithms, capable of precise control over various industrial process parameters such as temperature, pressure, flow, and liquid level. Whether it is simple single-loop control or complex multivariable decoupling control, PCS7 can handle it with ease. Its advanced self-tuning function can automatically optimize control parameters based on process characteristics, ensuring the system is always in optimal operating condition, effectively improving product quality and production efficiency.

(2) Alarm and Event Management

In industrial production, timely detection and handling of abnormal conditions are crucial. The PCS7 system has a comprehensive alarm and event management function that can monitor equipment operating status in real-time. Once an anomaly occurs, the system immediately issues audible and visual alarms and records detailed information about the alarm event, including time, location, and type. Operators can quickly identify issues through the alarm list and take appropriate measures to minimize production interruptions and losses.

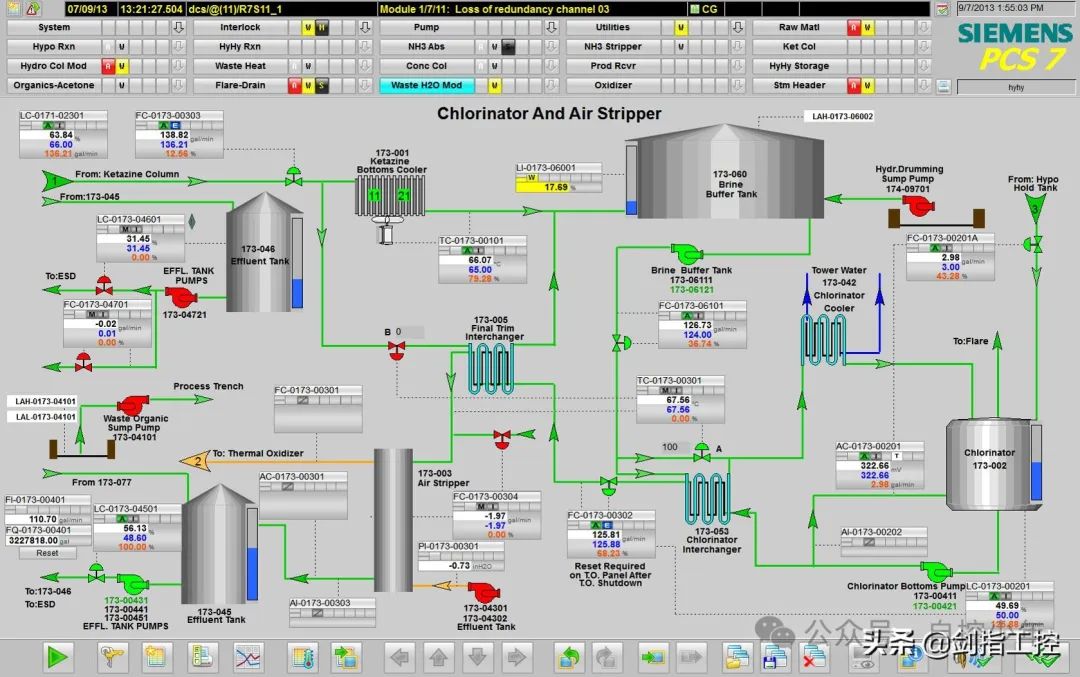

(3) Visual Operation Interface

A good human-machine interaction experience plays a key role in enabling operators to efficiently manage production processes. The PCS7 system provides an intuitive and user-friendly visual operation interface that graphically displays production processes and equipment status. Operators can monitor and control production processes with simple mouse clicks and drag-and-drop operations. Additionally, the interface supports multiple language displays, making it convenient for operators from different regions.

(4) Data Recording and Analysis

Production data is a valuable resource for enterprises to optimize production and enhance management levels. The PCS7 system has powerful data recording capabilities, allowing real-time collection and storage of various data during the production process. With data analysis tools, enterprises can deeply mine historical data, analyze production trends, equipment operating conditions, and product quality fluctuations, providing strong support for decision-making.

3. Wide Application Fields: Supporting Prosperity Across Industries

(1) Chemical Industry

The chemical production process is complex and requires high safety and stability. The PCS7 system, with its precise control capabilities and reliable architecture, is widely used in chemical production for reaction process control, distillation tower control, material transport control, and more. It ensures that chemical production can proceed under stringent process conditions, effectively preventing accidents and improving product quality and yield.

(2) Power Industry

In power systems, the PCS7 system is applied in power plant unit control, substation automation, and power grid dispatching. By real-time monitoring and optimizing control of power generation equipment, it improves generation efficiency and reduces energy consumption. At the same time, it ensures the safe and stable operation of the power system, providing reliable power supply to society.

(3) Pharmaceutical Industry

The pharmaceutical industry has stringent requirements for sterilization, automation, and quality control in production processes. The PCS7 system can meet the needs of pharmaceutical companies in production process automation, formula management, batch tracking, and compliance with GMP (Good Manufacturing Practice) requirements. From raw material input to finished product output, it achieves precise control and data traceability throughout the process, ensuring the safety and quality of pharmaceuticals.

(4) Food and Beverage Industry

Food and beverage production emphasizes production efficiency, hygiene standards, and product quality consistency. The PCS7 system is applied in this industry for production process control, automated equipment cleaning, packaging production line control, and more. It helps enterprises achieve efficient production, ensure stable product quality, and meet the strict hygiene standards of the food and beverage industry.

4. Development Trends of the PCS7 System: Embracing Intelligence and Digitalization

With the in-depth development of Industry 4.0 and smart manufacturing, the Siemens PCS7 system is also continuously evolving. In the future, PCS7 will place greater emphasis on the integration of intelligent and digital technologies. On one hand, it will introduce artificial intelligence and machine learning algorithms, enabling the system to possess stronger self-learning and adaptive capabilities. For example, by learning from massive production data, the system can predict equipment failures and perform maintenance in advance, reducing downtime. On the other hand, it will deepen digital transformation, achieving a profound integration of virtual factories and real production. By leveraging digital twin technology, production processes can be simulated, optimized, and validated in a virtual environment before applying the optimized solutions to actual production, enhancing production efficiency and product quality.

Additionally, the PCS7 system will strengthen its connection with the Internet of Things (IoT), achieving broader interconnectivity and data sharing between devices. Through cloud platforms, enterprises can remotely monitor and manage production facilities located in various places, obtaining production data and operational status anytime and anywhere, enabling intelligent decision-making and collaborative production.

The Siemens PCS7 system, as an outstanding example in the field of industrial automation, provides strong support for the intelligent transformation of industrial enterprises with its excellent system architecture, powerful functional features, wide application fields, and broad development prospects. In the future industrial development process, PCS7 will undoubtedly continue to play a key role, leading industrial automation to new heights.