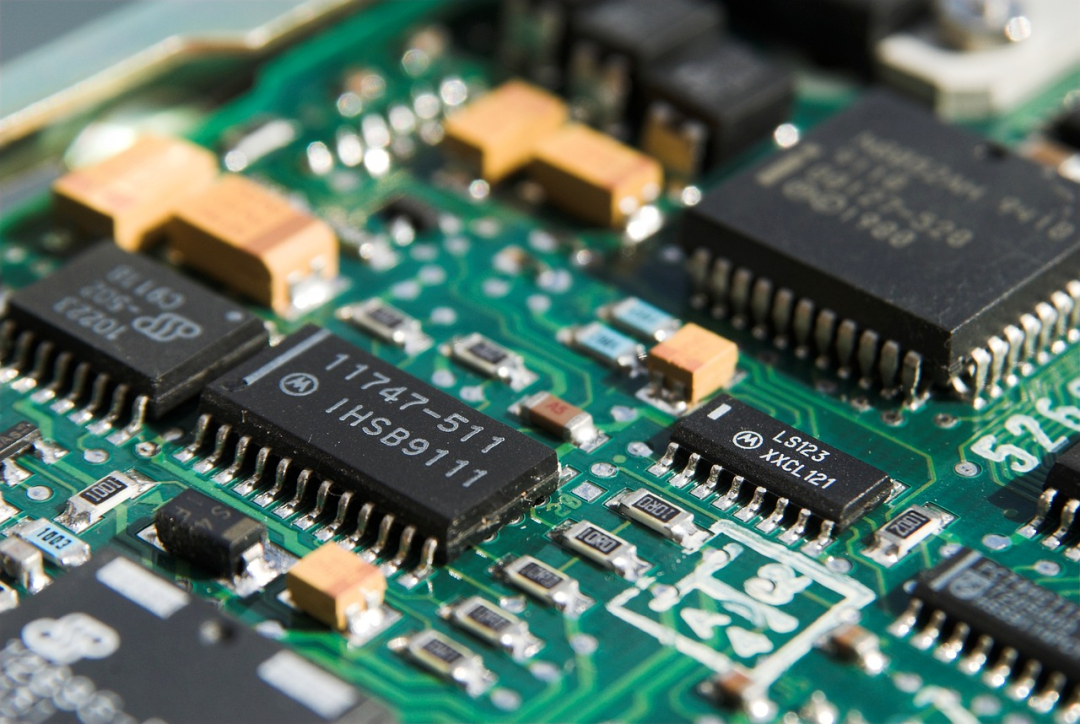

The laser depaneling machine utilizes non-contact laser processing technology, featuring stress-free, dust-free, and high-precision characteristics.

Compared to traditional mechanical cutting methods, the laser depaneling machine avoids the deformation issues of circuit boards caused by mechanical stress, making it particularly suitable for the processing needs of high-density assembly and miniaturized electronic products.

Core Performance Features

The laser depaneling machine boasts significant features such as high precision, intelligent automation, and material versatility.

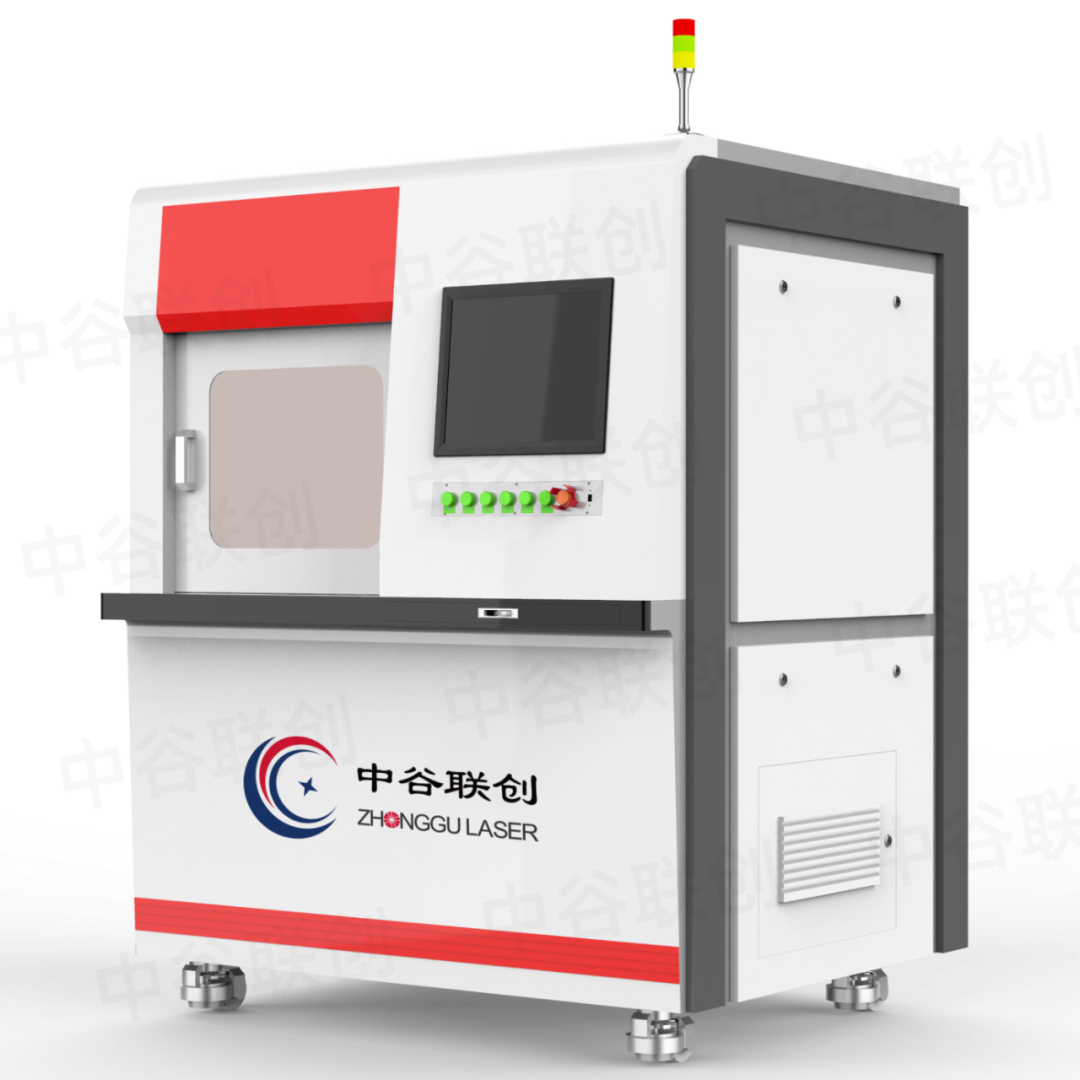

The Zhonggu Lianchuang laser depaneling machine

combines a low-drift galvanometer with a coreless linear motor system platform, capable of maintaining micron-level precision while cutting quickly;

equipped with Windows system control software and a CCD automatic positioning system, it is easy to operate and can achieve one-click processing mode;

utilizes solid-state UV lasers, which have good beam quality and low thermal effects, capable of processing various materials such asPCBs,FPCs, ceramics, and glass.

Additionally, the equipment features advanced functions such as automatic focusing and a dust removal system, ensuring a clean and efficient processing environment.

Main Application Areas

The laser depaneling machine is widely used in consumer electronics, automotive electronics, medical devices, and aerospace fields.

In smartphone production, it is used to cut motherboards, ensuring smooth and precise edges;

In automotive electronics, it processes circuit boards for onboard control units, enhancing system reliability;

In medical device manufacturing, it meets high precision and safety requirements;

In the aerospace sector, it provides precision cutting for satellite circuit boards.

It is particularly suitable for high-precision scenarios such as flexible circuit boards and rigid-flex boards, capable of handling irregular cuts and complex pattern processing.

Comparison with Traditional Depaneling Technologies

Compared to traditional depaneling equipment such as knife-type and milling-type machines, the laser depaneling machine has revolutionary advantages:

No tool wear, maintaining stable cutting quality over time;

Extremely high design freedom, unrestricted by shape; material utilization can be improved by30% or more;

The processing process is free from dust pollution, meeting cleanroom requirements.

Although the initial investment in equipment is higher, the overall benefits are significant in high-volume, high-quality production scenarios. Traditional depaneling machines still have advantages in efficiency and mass processing, creating a complementary relationship between the two.

With the trend towards lighter and thinner electronic products, the laser depaneling machine market continues to grow, and future equipment will develop towards greater intelligence, integrating functions such as automated loading and unloading and MES system docking, while new technologies like green laser depaneling machines will drive continuous innovation in the industry.

About Us

Wuhan Zhonggu Lianchuang Optoelectronic Technology Co., Ltd. was established in 2001 and has been focused on the research and production of laser intelligent equipment. The company’s main business includes three-dimensional five-axis cutting machines, laser welding machines, precision laser processing machines, laser marking machines, as well as the research, production, and sales of lasers and laser power supplies, providing customers with advanced, reliable, and comprehensive laser application solutions.

Upholding the corporate spirit of “bravery in struggle, relentless effort, and hard work“, Zhonggu Lianchuang will focus on customer needs, continuously promote and innovate laser equipment intelligence, contributing greater strength to the optoelectronic industry!