How MQTT Protocol Revolutionizes My Industrial Data Acquisition Practices

From Traditional Gateways to Protocol Integration: My Technical Transformation Journey

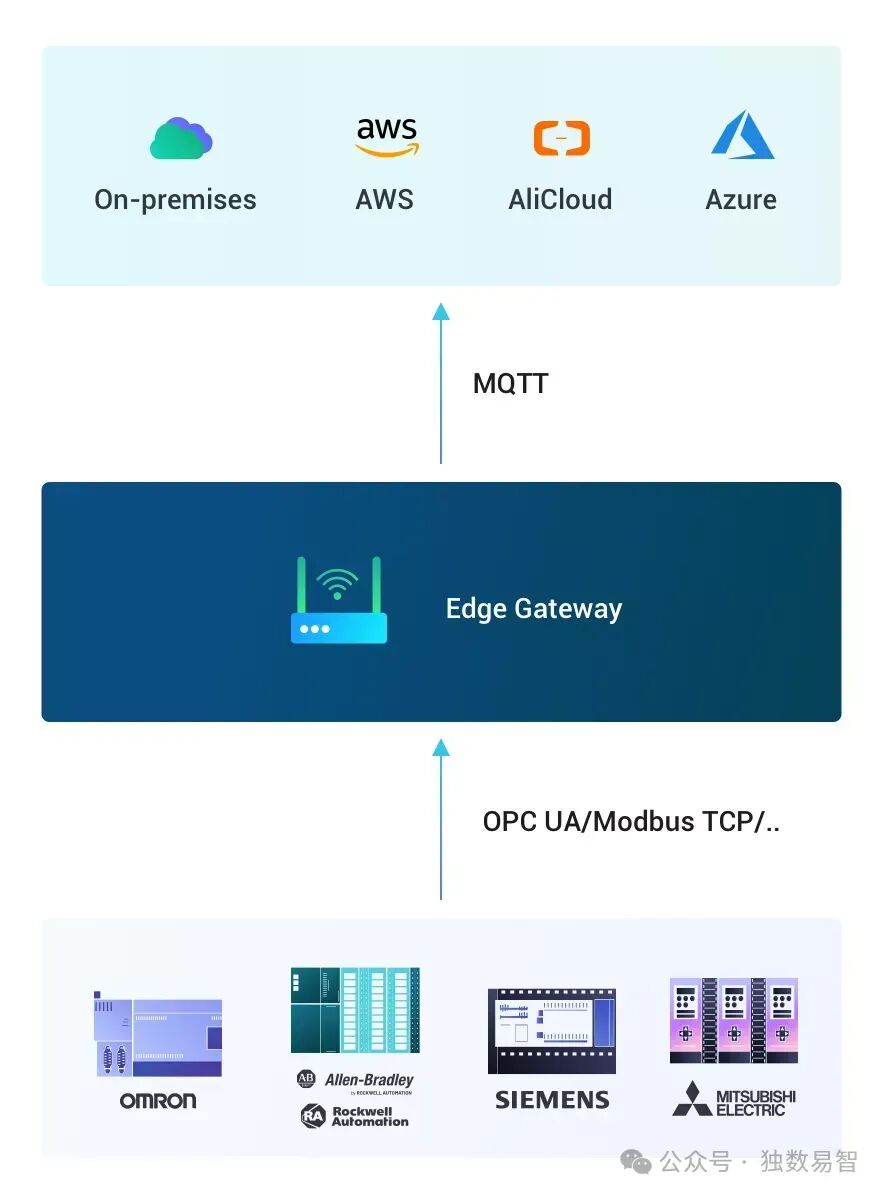

As a system integration engineer in the field of industrial automation, I have experienced the transition of industrial data acquisition technology from traditional edge gateways to protocol integration. Over a decade of experience, I have deeply understood the various pain points of traditional PLC data acquisition methods and witnessed the revolutionary changes brought by the MQTT protocol.

The Dilemmas of Traditional Acquisition Methods

When our team deployed a project in an automotive welding workshop, we encountered typical data acquisition challenges: – High Hardware Stacking Costs: Each production line required 3-5 different protocol gateway devices, with a single unit costing over 20,000 yuan – Limited Data Accuracy: When using a certain brand of gateway, the data sampling period for vibration sensors could only reach 500ms, resulting in the loss of early fault characteristics of critical equipment – Incredible Maintenance Complexity: In 2019, a project was delayed by 45 days due to firmware version incompatibility of the gateways

The most troublesome was a remote diagnosis project at a wind farm, where unstable data transmission from the gateway forced our team to make multiple trips to the site, with a single travel cost exceeding 80,000 yuan. This situation prompted me to seek better solutions.

Technical Breakthrough of MQTT Protocol

Changes Brought by Protocol Features

When I first encountered the MQTT 3.1.1 protocol, its lightweight design immediately caught my attention:

# MQTT client connection example

import paho.mqtt.client as mqtt

def on_connect(client, userdata, flags, rc):

print("Connected with result code " + str(rc))

client.subscribe("factory/plc/#")

client = mqtt.Client()

client.on_connect = on_connect

client.connect("emqx.io", 1883, 60)This simple connection code made me realize that the traditionally complex OPC UA configuration could be completely replaced. In actual tests, the memory usage of the MQTT client was only one-third of that of traditional solutions, which is crucial for resource-constrained embedded environments.

Practical Application of Quality of Service Levels

In a smart grid project in Chongqing, we set QoS levels for different data categories: – QoS 0: Used for environmental temperature and humidity monitoring (allowing occasional data loss) – QoS 1: Applied to device status data (must ensure delivery) – QoS 2: Critical control command transmission (absolutely no duplicates allowed)

This tiered strategy improved network bandwidth utilization by 40% while ensuring the reliability of critical data. During a network fluctuation, the system automatically switched to offline caching mode, achieving a data completeness rate of 99.98% afterwards.

Engineering Practice of PLC Protocol Integration

Siemens S7-1500 Transformation Case

In 2022, when we collaborated with Siemens to transform a certain injection molding factory, we first attempted native MQTT integration: 1. Library File Loading: Importing the MQTT library file into TIA Portal took only 15 minutes 2. Data Point Configuration: Achieved flexible mapping of over 2000 data points through structured text programming 3. Security Reinforcement: Implemented mutual TLS authentication with a certificate validity period set to 90 days for rotation

The transformed system directly connected to the EMQX cluster, reducing data transmission latency from the original 1.2s to 80ms. More importantly, it eliminated the need for 7 gateway devices, saving hardware costs of 160,000 yuan directly.

Optimization Techniques for Time-Series Databases

In the data storage phase, we summarized three golden rules: – Label Normalization: Adopt a four-level naming structure of <span>factory/area/device/parameter</span> – Sampling Alignment: Utilize NTP services for millisecond-level time synchronization – Compression Strategy: Use ZSTD compression algorithm for historical data, saving 65% of storage space

Practice in a lithium battery production line showed that this solution reduced real-time query response time from 3s to 300ms, fully meeting the needs of the MES system.

In-Depth Exploration of Innovative Application Scenarios

Algorithm Practice for Predictive Maintenance

The vibration analysis model developed by our team successfully advanced bearing fault warnings by 800 hours: 1. Feature Extraction: Extracted 23 time-frequency domain features from raw waveforms 2. Anomaly Detection: Implemented unsupervised learning using the isolation forest algorithm 3. Root Cause Analysis: Established a Bayesian network combining PLC operating condition data

In the validation of 10 wind turbines, the false positive rate was controlled below 5%, reducing the annual maintenance cost of a single unit by 180,000 yuan.

Real-Time Mapping of Digital Twins

Based on real-time data streams from MQTT, we constructed a high-precision digital twin of the hydraulic system: – Physical Modeling: Established a multi-body dynamics model using Modelica language – Data-Driven: Used Kalman filtering for state estimation – Virtual-Real Synchronization: A refresh rate of 500Hz ensured simulation error < 0.5%

This system helped the client identify pipeline resonance issues during the debugging phase, avoiding potential losses of millions.

Insights on Building a Security Framework

Establishing Defense in Depth

Our security architecture includes four layers of protection: 1. Transport Layer: Mandatory use of TLS 1.3 protocol 2. Authentication Layer: Device identity authentication based on X.509 certificates 3. Application Layer: Access control using OAuth 2.0 4. Audit Layer: Complete behavior logs retention (for 180 days)

In a penetration test at an automotive factory, this system successfully defended against 37 known attack methods, receiving high praise from the client’s security team.

Practices for Security Updates

Through EMQX’s online upgrade feature, we achieved: – Incremental Updates: Single node updates took < 30 seconds – Rollback Mechanism: Retained the last 3 stable versions – Gray Release: Verified in the test cluster for 72 hours first

This strategy maintained system availability at over 99.99%, fully meeting continuous production requirements.

Reflections on Future Technological Evolution

Integration of 5G and TSN

In a high-end machine tool project under research, we are testing: – 5G URLLC: Striving to compress end-to-end latency to below 10ms – TSN Scheduling: Implementing deterministic transmission using IEEE 802.1Qbv standard – Edge Inference: Deploying lightweight CNN models for real-time quality detection

Preliminary test data shows that image processing latency has been reduced to 50ms, with defect identification accuracy reaching 99.7%.

Proactive Layout of Quantum Encryption

Although quantum communication is still in the laboratory stage, we have initiated: – Algorithm Migration: Evaluating the post-quantum security of existing encryption systems – Key Management: Designing key distribution schemes based on quantum random number generators – Standard Tracking: Actively participating in the formulation of relevant standards by IEC/TC65

This technological reserve ensures the forefront of our solutions, having gained technical recognition from two Fortune 500 companies.

Looking back on a decade of technological journey, from the initial handheld programmer to today’s protocol integration, I have deeply realized the evolution speed of the Industrial Internet of Things. The MQTT protocol is not just a technical tool but the core engine driving industrial intelligence. In the face of the wave of Industry 4.0, we need to continuously maintain technical sensitivity and create real value for customers with innovative solutions.