The world of the Internet of Things (IoT) is vast, while the field of engineering monitoring is relatively small.

(This article takes about 5 minutes to read)

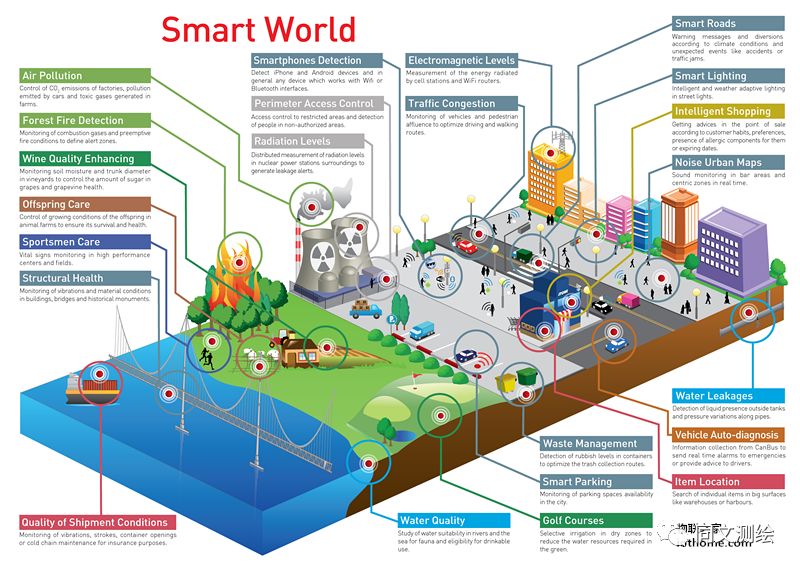

In the exciting world of IoT, sensors are the foundation where IoT solutions can be effectively utilized. Sensors will be ubiquitous across various fields, collecting various information anytime and anywhere, monitoring changes in all things. IoT solutions based on sensors will make the environment better, life more convenient, species more diverse, and industrial production more efficient.

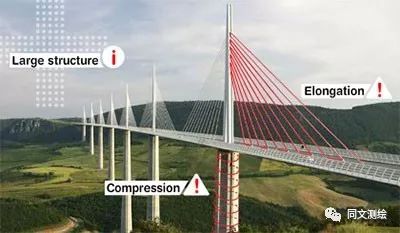

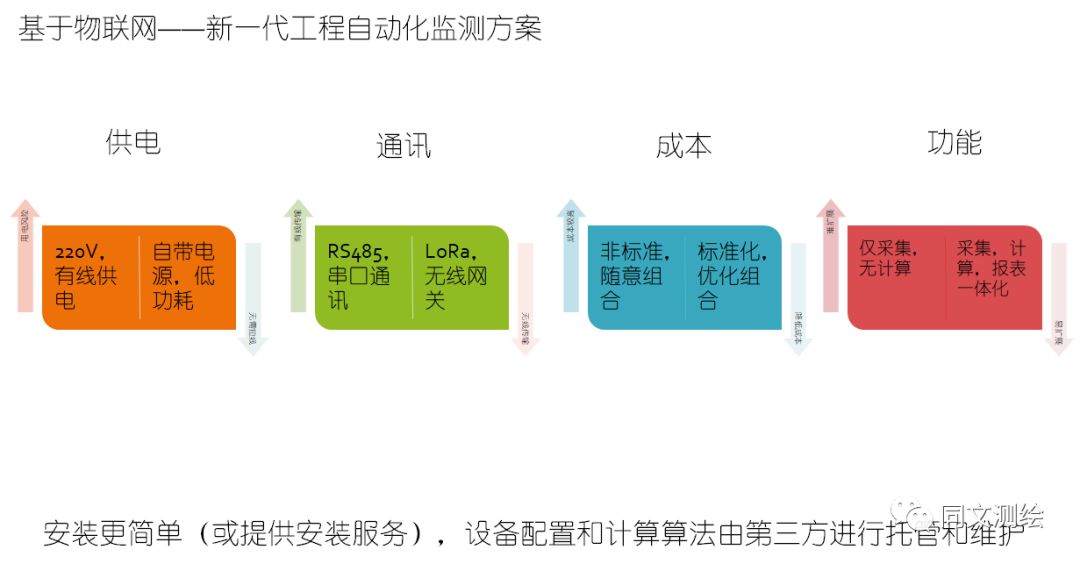

In the realm of engineering monitoring, traditional automated monitoring still has two “pain points” – 1. High power consumption, requiring cable connections for power supply, which is difficult and poses certain risks; 2. Weak communication, requiring cable connections for communication, with a variety of protocols. To solve these two problems, a huge cost is required – additional cables, protocol compatibility, time-consuming installation, and complex maintenance…

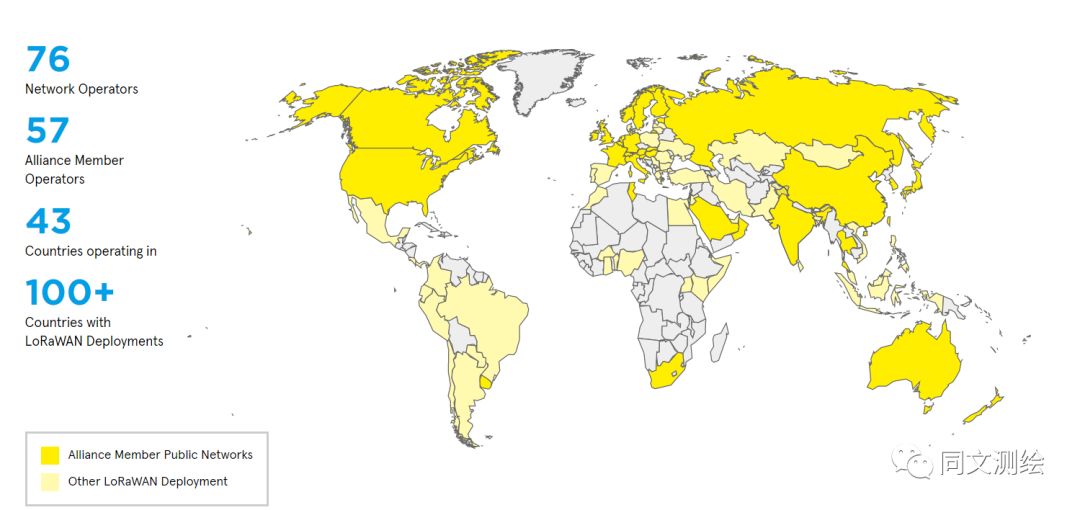

With the “maturity” and “implementation” of IoT technology, solving these two “pain points” has gradually become less distant. Taking LoRaWAN™ sensors as an example – LoRaWAN™ sensors deliver long life, are cost-effective, available in volume, with global reach using public or private networks.

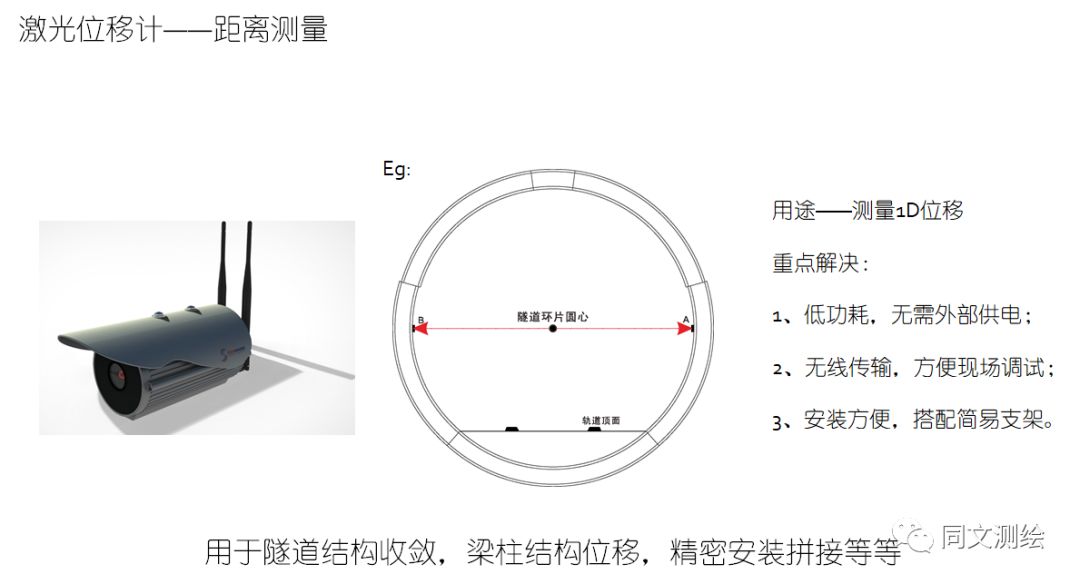

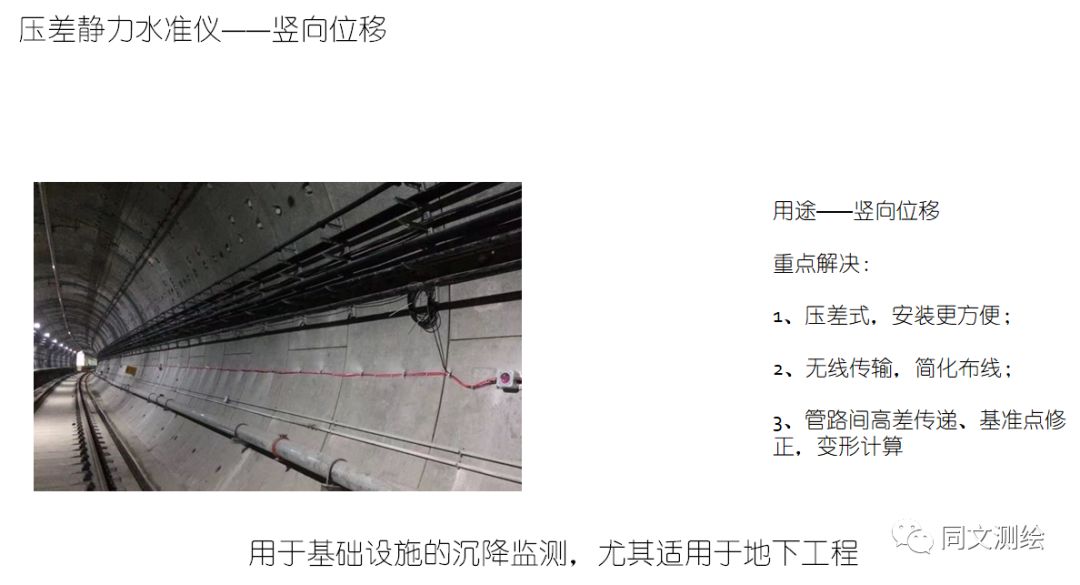

Riding on the booming development of the LoRa Alliance, the new generation of low-power, wireless sensors has entered the mainstream market, capable of meeting the requirements for common monitoring items such as planar displacement, vertical displacement, deep horizontal displacement, angle, clearance convergence, water level, pore water pressure, stress, etc., and has been rapidly promoted and applied in some large construction projects or monitoring units.

The following explores the specific work of implementing low-power, wireless sensors based on the LoRa protocol in engineering monitoring projects.

1. The “Pain Points” of Monitoring Work

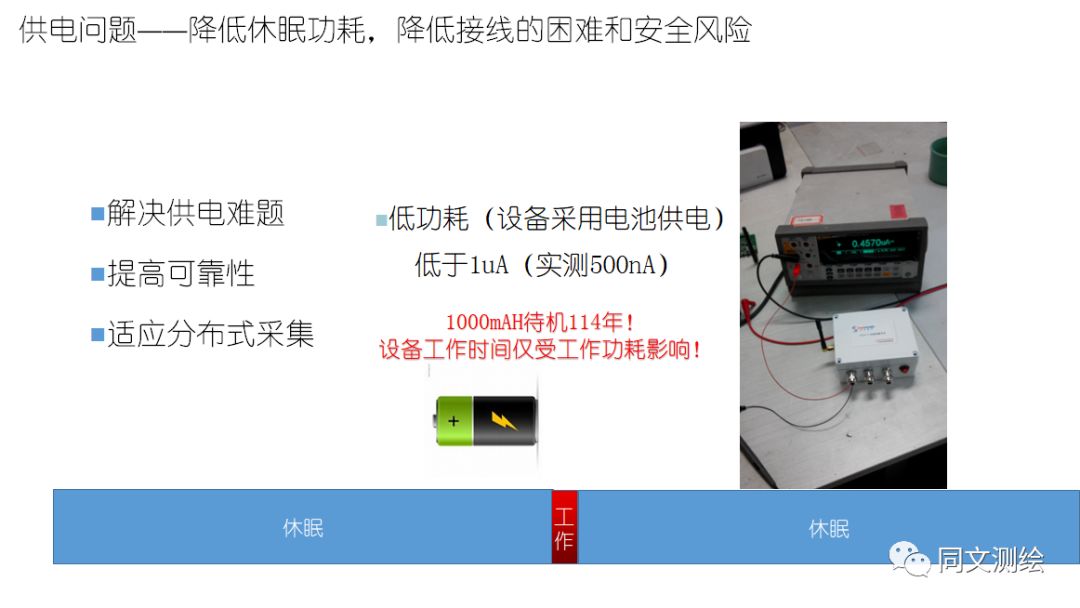

The requirement for low power consumption aims to upgrade the traditional cable-powered supply to a longer-term battery-powered supply, such as replacing the battery every 3-36 months.

Wireless communication aims to integrate sensors into standardized wireless communication networks, thus reducing the complexity of on-site equipment installation and debugging. Connecting and debugging with RS485 cables is not something ordinary monitoring personnel can easily solve, and it accounts for at least 10% of hardware costs.

Plug and play aims to make it usable right out of the box, without the need for time-consuming and labor-intensive on-site installation and debugging, especially to meet the rapid deployment requirements during emergency monitoring periods, reducing installation and debugging can lower costs by 10%.

Cost and IoT platform aim to replace most manual labor…

2. The Advantages of the New Generation Solution Transformed into “Benefits”

By using wireless power supply, sharing LoRa communication modules, and saving installation and maintenance costs, the overall cost can be reduced by about 20%.

In terms of power supply, using built-in batteries to power the device keeps standby power consumption at a low level, thus maintaining a longer working time.

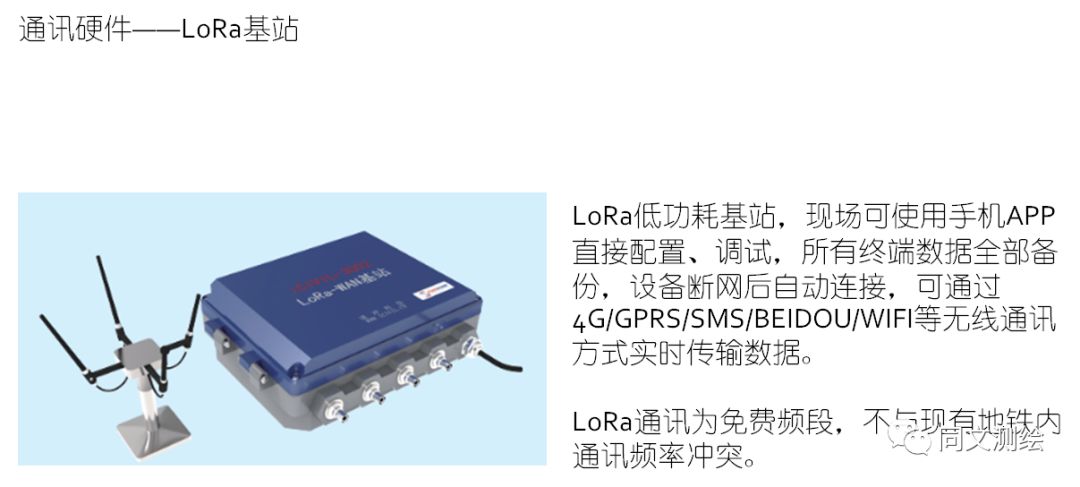

In terms of communication, using LoRa low-power communication reduces the visibility of cables on-site, thus minimizing installation time, limiting risks, and construction impact, which can lower installation and maintenance costs.

In addition to fixed sensors, the new generation of monitoring can also utilize micro-robots for mobile detection or monitoring. For example, the two types of devices shown in the image can be used for inspections underground, inside pipelines, and industrial facilities…

3. What Pits are There from “Concept” to “Implementation”?

For monitoring units, the main “pits” include: 1. Intense market competition, the cost is still relatively high compared to manual monitoring; 2. Lack of self-awareness or emphasis, existing personnel lack motivation to learn and master new technologies; 3. Original suppliers do not know how to do it, nor do they actively promote it; 4. First observe peers, unwilling to be the “pioneer”; 5. Complex on-site environment, existing solutions are not entirely applicable.

For equipment sales companies, their business and income mainly come from equipment sales, and they may not possess the capabilities for system consulting, system integration, or technical support. After business negotiations and product delivery, they may not continue to track – whether the equipment installation is smooth, issues during use, improvements in system functions, etc…

For instrument manufacturers, although they have the willingness and ability to improve and perfect monitoring systems, the fragmentation of customers and demands makes it difficult for them to make targeted improvements and optimizations. For example, a certain MOS has been launched for nearly 20 years, with an annual shipment of 3-5K sets, and there is no reason to care about the needs of customers who only order 2-3 sets a year.

4. Current Implementable Automated Monitoring

More low-power, wireless transmission sensors include: displacement meters, strain gauges, crack meters, rebar meters, axial force meters, thermometers, wireless accelerometers, multifunctional combined acquisition instruments, LoRaWAN communication base stations, etc.

5. Conclusion

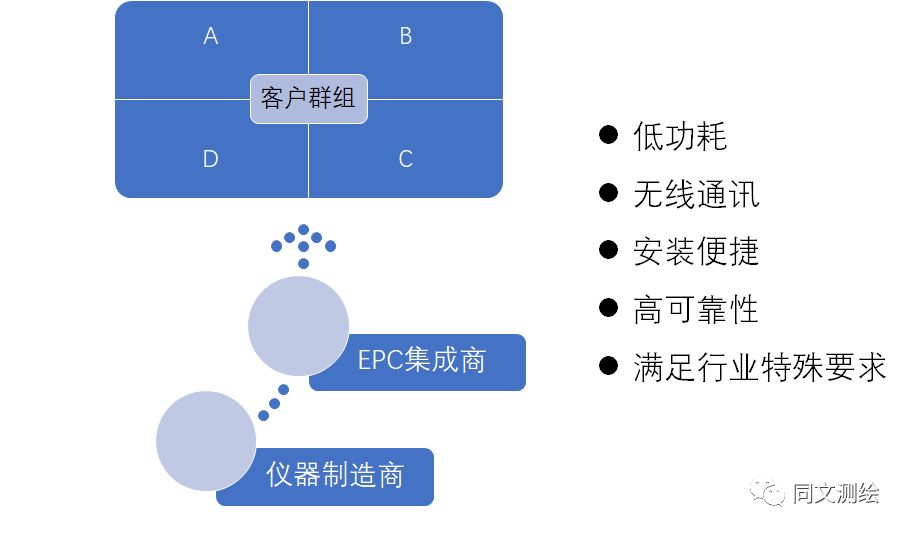

One may refer to the EPC model of the engineering industry, where monitoring units entrust automated monitoring projects to capable and reputable EPC integrators (consortia) for implementation –

Engineering includes overall planning of monitoring solutions, equipment selection, platform design, etc.; Procurement is not simply about sensor procurement, but extends to solution optimization, personnel training, etc.; Construction content not only includes equipment delivery and on-site installation but also encompasses all normal standards, operational tuning, maintenance monitoring, etc., allowing owners to use them normally upon takeover.

EPC integrators comprehensively segment application needs, jointly plan the system architecture, system platform, and evolution plan for automated monitoring solutions with customers, and share the price advantages brought by bulk procurement with customer groups to provide more economical, safe, and reliable solutions for small and medium-sized customers.

(End of article)

The field is small, and we must work harder to create value for customers.

[Follow our WeChat subscription account – “Tongwen Surveying and Mapping”]

Discuss innovative elements of surveying and geographic information products

Share the growth experience of a “Survey Product Manager”

Customize lightweight surveying software services

For deeper discussion and cooperation, please add WeChat ID shanyechaju or email [email protected].