Design and Reflection on Teaching Colored LCD Screens

Yaping Zhao1 Liang Hao2 Meina Yu3Hong Pan4 Ye Zhu5 Rui Wei6*

1.Peking University Affiliated High School, 100190

2.Beijing Yuying Middle School, 100036

3.Beijing University of Science and Technology, 100083

4.Foshan Education Bureau Research Office, Guangdong Province, 528000

5.San Fan Middle School, Beijing, 100120

6.Key Research Base for the Construction of Chemistry Textbooks in Primary and Secondary Schools, Institute of Science Education, Beijing Normal University, 100875

Author Introduction

Yaping Zhao, Master, First-Class Teacher.

Liang Hao, Doctor, Second-Class Teacher.

Meina Yu, Doctor, Associate Researcher.

Hong Pan, Bachelor, Senior Teacher.

Ye Zhu, Master, Second-Class Teacher.

Corresponding Author: Rui Wei, Doctor, Professor.

Article Structure

Abstract

This article completes a project-based teaching case for “Designing and Making Colored LCD Screens” by exploring real-life stories, the problem-solving ideas of scientists, and the “three-step” strategy, and reflects on the case.

Keywords

Project-based curriculum; Project-based teaching; Colored LCD; Interdisciplinary teaching

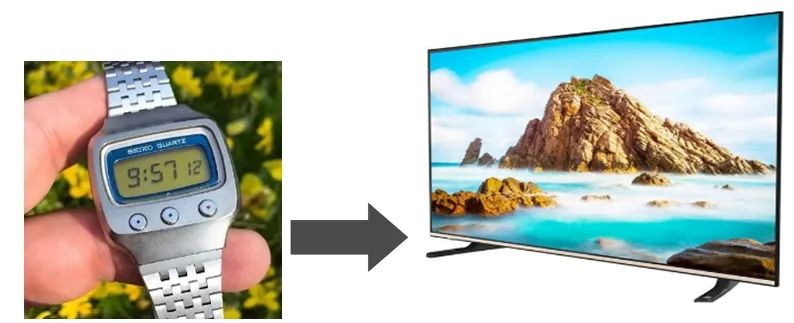

Currently, colored LCD screens are widely used in mobile phones, computers, televisions, etc. However, the invention process was not achieved overnight. From the early black-and-white LCD screens that could only display numbers to the current 4K colored LCD screens (see Figure 1), it has undergone continuous optimization by several generations of scientists.

Figure 1 Comparison between black-and-white LCD screen and colored LCD screen

The author designed the project-based teaching case for “Designing and Making Colored LCD Screens” using the “three-step” strategy. The first step is to locate and explore the real-life stories behind it; the second step is to externalize the problem-solving ideas of scientists; the third step is to convert these contents into project-based teaching materials. The following will detail the design and development process of the “three-step” strategy.

1. Excavating Real-Life Stories

After discovering liquid crystals, scientists painstakingly created the first black-and-white LCD watch, but it was still far from the colored LCD screens used today: the liquid crystal materials at that time faced instability and slow response issues; the LCD watch only needed 7 pixel bars to display numbers 0-9, but to display patterns, the “pixels” had to be made smaller, and correspondingly, the driving method would become more complex; the LCD watch screen was black and white and needed to be improved to full-color display; the screen was dim with low contrast, requiring an increase in contrast… In the face of these performance demands, scientists conducted targeted optimizations, which this article categorizes and elaborates on based on the scientists’ optimization contents.

1.1 Optimization of Liquid Crystal Materials

In 1973, British chemist G.W. Gray and others synthesized a new type of liquid crystal molecule (biphenyl compounds), improving the stability of liquid crystal molecules[1]. In 1977, German chemists synthesized phenylcyclohexane liquid crystal compounds, reducing viscosity by decreasing intermolecular forces, thereby improving response speed. In 1990, Merck in Germany developed a series of fluorinated liquid crystal materials, further reducing viscosity and becoming more efficient liquid crystal materials.

1.2 Optimization of Driving Circuits

In 1986, Japan’s Sharp Corporation used thin-film transistors (TFT) to control the voltage of each pixel, directly driving liquid crystal molecules, effectively avoiding mutual interference between pixel points, thus quickly capturing the market.

1.3 Optimization of Color Display

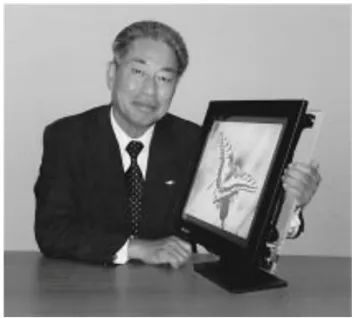

Scientists have always been committed to finding ways for color display. They once tried mixing dyes into liquid crystals or using colored liquid crystal materials to display colors, but these methods faced issues such as high required voltage and insufficient color light intensity, making full-color display unachievable[1]. Ultimately, scientists innovatively added red, green, and blue filters to the liquid crystal panel, utilizing the physical principle of optical primary colors to achieve full-color display. In 1988, Sharp launched the 14-inch TFT colored LCD screen (see Figure 2); in 1989, Toshiba launched the notebook computer with full-color LCD[2] (see Figure 3).

Figure 2 The first 14-inch TFT colored LCD screen

Figure 3 The first notebook computer with full-color LCD screen

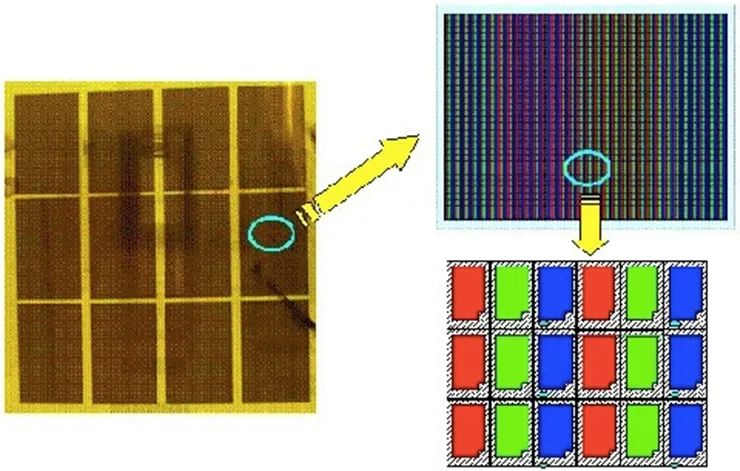

As shown in Figure 4, an ultra-high-definition 4K colored LCD TV contains “3840×2160” pixels. Each pixel’s structure is the same, consisting of a black-and-white liquid crystal pixel structure with added color filters. By adjusting the applied electric field’s strength, the arrangement of liquid crystal molecules changes, altering the light transmittance, resulting in different brightness combinations of red, green, and blue light. The spacing of the red, green, and blue filters on the screen is very small, and at a certain distance, the human eye cannot distinguish between the colored beams and can only see the mixed colored dots, thus presenting different colors[3].

Figure 4 Pixel structure of colored LCD TV

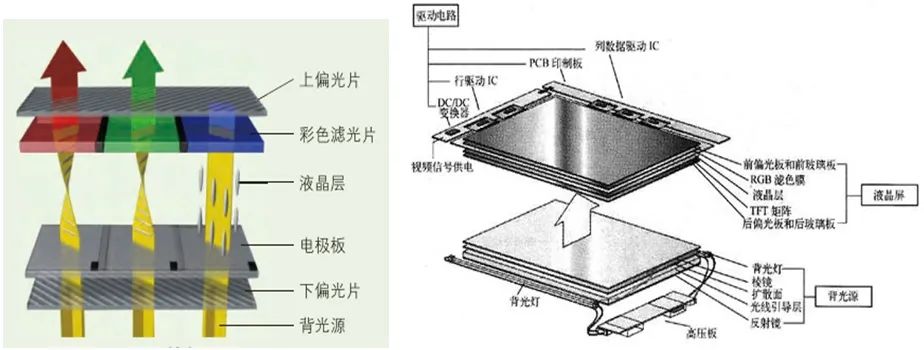

The entire colored LCD screen consists of three main components: the backlight source, the liquid crystal panel, and the driving circuit (see Figure 5). The backlight source provides white light, and the driving circuit controls the voltage, allowing the liquid crystal display to operate under the driving voltage.

Figure 5 Principle and structure of colored LCD screen

2. Externalizing Problem-Solving Ideas

Overall, scientists designed colored LCD screens based on the initial product (black-and-white digital display), to achieve certain functions by improving elements (liquid crystal materials, pixel size) or combining other elements (backlight source, filters), ultimately forming the design. Designing and producing colored LCD screen works is quite complex, thus requiring the overall goal to be broken down into multiple sub-goals to be achieved one by one, such as: improving the stability and response speed of liquid crystals, reducing pixel size, achieving full color, increasing brightness, and accurately controlling the voltage of each pixel.

2.1 Clear Idea – Direct Design

When there is a clear idea, scientists can directly proceed with product design. For example, the problem-solving idea for “achieving full-color display” is as follows[4-5].

(1) Concept Design

Scientists start from the structure of black-and-white LCD screens, exploring the two ideas of “changing the elements themselves” and “combining other elements” for conceptual design. Changing the elements themselves: exploring whether synthetic colored liquid molecules can achieve full-color display; combining other elements: exploring whether adding dye molecules to liquid crystals or adding color filters can achieve full-color display.

(2) Detailed Design

For the sub-goal of detailed design of pixel size, spatial mixing can be used to achieve color display. For the sub-goal of increasing brightness, the combination with a backlight source can be implemented; for the sub-goal of accurately controlling pixel voltage, thin-film transistors can be combined. Thereafter, various components can be combined to form the display.

2.2 No Clear Idea – Find Causes Before Designing

When there is no clear idea, scientists need to first find the cause before proceeding with “product design”. For example, the problem-solving idea for “improving liquid crystal stability and response speed” is as follows.

(1) Define the “difficulty”

Existing liquid crystal molecules are unstable, and the response time under electric drive is long.

(2) Find the cause

By analyzing liquid crystal molecules, it was found that the central group of liquid crystal molecules leads to reduced stability; the phenyl rings of liquid crystal molecules increase intermolecular forces, resulting in increased viscosity, leading to longer response times.

(3) Product Design

Conduct molecular design, including changing or removing the central group and reducing intermolecular forces. This entire process reflects both analytical thinking of breaking down elements and analysis of elements, as well as systematic thinking in combining elements while considering the whole.

3. Project-Based Curriculum Teaching Design

3.1 Teaching Functional Value Analysis

(1) Implementing the Big Concept of “Structure and Function”

The “General High School Chemistry Curriculum Standards (2017 Edition)” requires students to understand the relationship between the structure and properties of substances. Understanding the relationship between structure and properties is crucial for optimizing material structure and improving material performance. Various versions of high school physics and chemistry textbooks introduce the display principles of liquid crystal screens but do not delve deeply. The project-based teaching case of “Designing and Making Colored LCD Screens” deeply explores related subject content, developing students’ ability to apply “molecular structure and function” to solve problems through the task of improving liquid crystal molecules and allowing students to understand the relationship between “component structure and function” by combining liquid crystals with other components to achieve color display, implementing the concept of “structure and function” from two angles.

(2) Promoting Interdisciplinary Knowledge Integration

The “Compulsory Education Physics Curriculum Standards (2022 Edition)” require students to understand new materials and their applications; under the theme of “Sound and Light”, students have already learned about the composition of light and the phenomenon of different colored light mixing. Colored LCD screens are a fusion and creative application of the aforementioned content. The “General Technology Curriculum Standards for Ordinary High Schools (2017 Edition)” suggest that students observe entities, shells, and frame structures starting from real life to understand different structures and their applications. The project-based curriculum of “Designing and Making Colored LCD Screens” involves tasks such as “disassembling LCD screens”, responding to the above curriculum standards. The task of “designing colored LCD screen solutions” helps develop students’ ability to integrate organic properties of chemistry and relevant knowledge of physics, understand the circuit driving of liquid crystal pixels, experience the assembly of display screen works, and understand their real composition, thereby cultivating students’ ability to integrate interdisciplinary knowledge to solve real problems, enhancing their practical skills and innovative transfer abilities.

(3) Enhancing Students’ Experience of International Cooperation and Scientific Community Concepts

Liquid crystal display is a disruptive, global scientific research project. European scientists broke through new synthesis techniques for liquid crystal materials, American scientists deciphered the principles of liquid crystal display, and Asian scientists solved the productization issues of liquid crystals. Liquid crystal display is the result of international competition and cooperation, and through learning, students should establish the concept of international cooperation and scientific community, taking on the responsibility for technological innovation.

3.2 Teaching Design Ideas

The driving question designed for this project is: What problems exist in black-and-white LCD screens that people expect to use liquid crystals for displays in televisions, computers, etc.? How to optimize?

The final physical outcome is: to produce a set of colored liquid crystal pixels and design and assemble liquid crystal display screen works.

The students’ cognitive development outcome is: to establish a methodological approach to improve organic molecules based on property requirements, forming a general idea for product design.

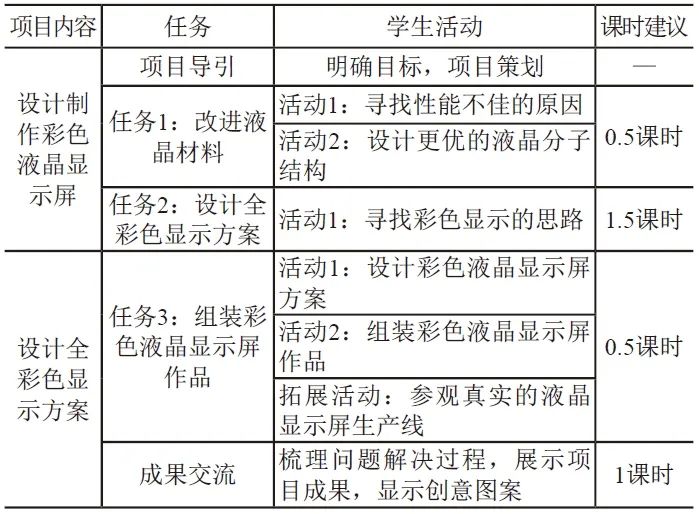

Based on the two main optimization tasks completed by scientists (improving liquid crystal materials and designing full-color display solutions) and the resulting colored LCD screen products, the project is broken down into three tasks: Task 1 and Task 2 are optimizations of sub-goals, while Task 3 is the combination to form the works (see Table 1).

Table 1 Tasks and Activities Breakdown of the Project-Based Curriculum of “Designing and Making Colored LCD Screens”

4. Main Content

4.1 Project Guidance

First, clarify the goal of further designing colored LCD screens, allowing students to plan the project, identifying the problems present in black-and-white LCD screens, and breaking down the overall goal into sub-goals to be achieved one by one. Guide students to first solve the sub-tasks of liquid crystal materials and color display, and then address other issues to assemble the colored LCD screen works.

4.2 Task 1 Improving Liquid Crystal Materials

Task 1 is divided into two activities. Activity 1: Students analyze the structure of the first-generation liquid crystal molecules and discuss the reasons for instability and long response times. Activity 2: Students independently design second-generation liquid crystal molecules, and groups report on the reasons for the excellent properties of that molecule. Afterward, they read the history of science to understand the process by which scientists improved liquid crystal materials.

Design Intent: To let students experience that molecules can be designed and synthesized, understand the relationship between the structure and properties of substances, know that new substances with expected properties can be discovered based on structure, and realize that studying material structure is significant for understanding the relationship between structure and performance, optimizing material structure, and improving material performance.

Using student activities of “finding causes and molecular design” as an example, the core activities of Task 1 are illustrated.

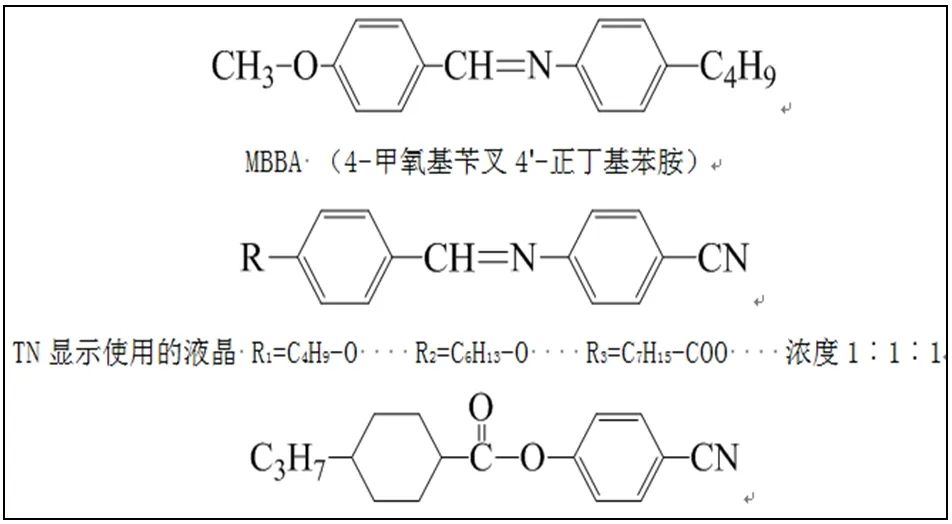

Discussion: Explore solutions for improving the water resistance and ghosting issues of liquid crystal materials. Based on the information from data cards, think and discuss the following questions in groups: The three molecules shown in Figure 6 are the first-generation liquid crystal materials. By analyzing the functional groups of the molecules, identify the structural elements that lead to the instability of liquid crystal molecules and the strong intermolecular forces.

Figure 6 Structures of three liquid crystal molecules

Data Card: —CH=N— is prone to hydrolysis, and its stability against light, electric fields, and chemical reagents is also poor.

Summary: Based on the data, it can be analyzed that the structural elements leading to the instability of liquid crystal molecules are —CH=N— and the ester group. High viscosity is due to strong intermolecular forces, which is related to the number of phenyl rings; the more phenyl rings, the more delocalized electrons, and the greater the intermolecular forces, resulting in higher viscosity of liquid crystal materials.

Discussion: How to stabilize it? How to reduce the viscosity of liquid crystals? Please design a possible structure for the second-generation liquid crystal molecule that meets the conditions of “rigid rod-like structure with polar groups at the ends”.

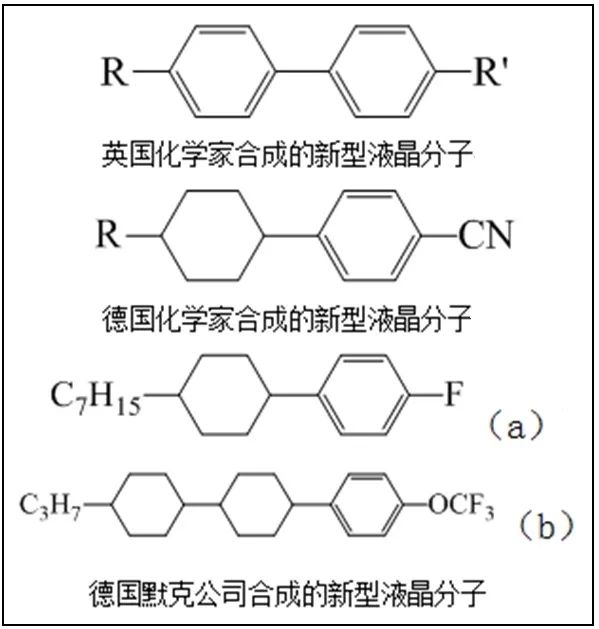

Summary: To stabilize liquid crystal molecules, students change or remove the central group; to reduce the viscosity of liquid crystals, students saturate the phenyl rings with hydrogen, reducing delocalized electrons. Historically, scientists have persistently made many attempts, and the molecular design ideas align with everyone’s thoughts (see Figure 7).

Figure 7 New liquid crystal molecule structure synthesized by scientists

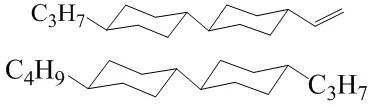

Currently, the low-viscosity liquid crystal materials used in LCD TVs are even organic compounds connected by two cyclohexanes (see Figure 8).

Figure 8 Structure of liquid crystal molecules used in modern LCD TVs

4.3 Task 2 Designing Full-Color Display Solutions

Using the design of full-color display solutions as the driving task, students first seek ideas for achieving color display from the methods of concept design (changing the elements themselves, combining other elements). Then, reflect on the difference between color and full color, clarifying the design goal through experiments on the three primary colors of light, forming a full-color display solution, and evaluating the solution through hands-on experiments. Finally, design a mixing color scheme and use a magnifying glass to observe the pixel points of mobile phone screens, experiencing the similarities and differences with their own designs.

This task does not directly provide principles for students to rigidly understand; instead, it allows students to experience the design process like scientists, fully appreciating the thought process of product design, and through innovative experiments, enabling students to practice hands-on and realize their designs, forming project outcomes, while also allowing students to undergo a progressive design process from color, full color, to mixing colors, realizing that solving a problem involves reflection and iteration. The design process utilizes knowledge from chemistry, physics, and other disciplines, allowing students to experience that solving a complex problem requires collective efforts using interdisciplinary knowledge.

Using student activities of “designing full-color solutions and evaluating comparisons” as an example, one of the core activities of Task 2 is illustrated (it includes both cognitive activities and hands-on activities).

Discussion: It is known that achieving monochrome or simple color changes using liquid crystals is feasible, which can be achieved by selecting colored liquid molecules or adding color films. However, there is a distinction between color and full color. How is full color achieved?

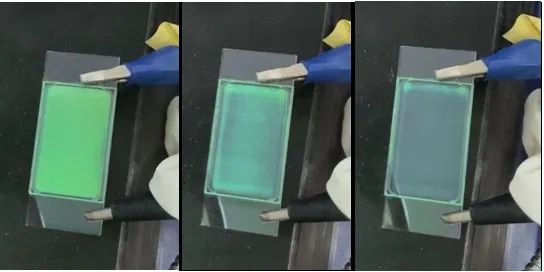

Hands-on Operation: Using teaching aids, adjust the different intensities of red, green, and blue light and observe which colors can be formed (see Figure 9).

Figure 9 Colors that liquid crystal molecules can present

Summary Discussion: The experiment found that by controlling the strengths of red, green, and blue light and adjusting their ratios, various colors of light can be formed.

Experimental Exploration: Based on the design ideas of scientists, evaluate suitable schemes for color display, discuss in groups, and report.

Exploration Scheme 1: Synthesize colored liquid molecules. Use cholesteric liquid crystal molecules, observe their reflected colors; place them in an electric field and apply voltages from 0 to 30V, and the color can be seen to gradually diminish until it becomes colorless (see Figure 10). As the external electric field continues to increase, the cholesteric liquid crystal molecules change from a helical arrangement to an arrangement along the electric field lines, causing the original selective reflection to disappear, thus reducing the reflected light and enhancing the transparency to light.

Figure 10 Colored liquid crystal sheets gradually become transparent as voltage increases (from left to right)

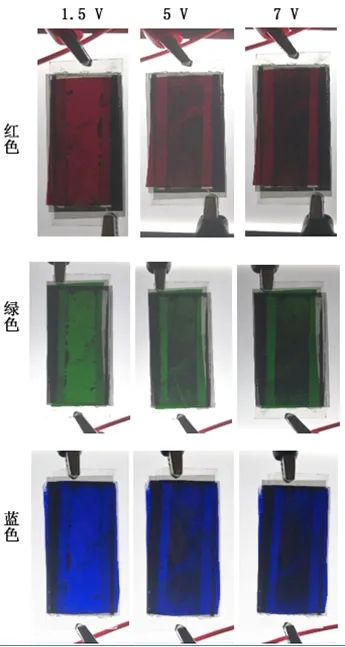

Exploration Scheme 2: Use TN-type black-and-white liquid crystal boxes with color filters. Cut red, green, and blue filters into small pieces, stick them on three liquid crystal boxes, and place them on a white backlight source to emit three colors of light. Apply 1.5V, 5V, and 7V voltages to the liquid crystal boxes, and observe the changes in light intensity (see Figure 11).

Figure 11 Changes in light intensity of red, green, and blue pixel points under different voltages

Summary Discussion: The black-and-white liquid crystal box has orthogonally glued polarizers on both sides. When no electric field is applied, the liquid crystal molecules are arranged in a helical pattern, and the light from the backlight panel passes through the lower polarizer to become polarized light, then through the rotating liquid crystal molecules, causing the polarization direction to rotate 90° to pass through the upper polarizer, resulting in high transmittance; when an external electric field is applied, the liquid crystal molecules align along the electric field lines, and the light from the backlight panel, after passing through the lower polarizer and liquid crystal layer, propagates vertically upward, with the polarization direction perpendicular to the transmission axis direction of the upper polarizer, thus unable to pass through the upper polarizer, and the stronger the voltage, the more orderly the liquid crystal molecules align along the electric field lines, resulting in lower transmittance. Based on the required voltage and light intensity comparison, Scheme 1 requires a high voltage and has low reflected light intensity; Scheme 2 requires a low voltage, and increases backlight source, resulting in high light intensity and color saturation, hence Scheme 2 is chosen as the better solution for full-color display.

4.4 Task 3 Assembling Real LCD Display Works

Students are asked to reconsider real product design, comparing the starting and ending points of the design, solving other sub-goals, including: how to reduce pixel size and how to place the driving circuit? How to accurately drive each pixel? Students combine various components to form the liquid crystal display design scheme, then compare it with the disassembled liquid crystal display teaching aids, and students introduce the function of each part. In this task, students continue to design products closer to reality, understanding the structure and working principles of the display screen, allowing students to experience that designing real products requires solving many detailed issues, which embodies the collective wisdom of scientists and engineers.

Discussion: People pursue larger screens and higher resolutions, meaning pixel points must be smaller and the total number of pixel points must be greater. Therefore, each pixel point must be equipped with a chip to control its voltage.

Explore the structure of colored LCD screens: If you were an engineer who has overcome some of the above issues, could you combine all the components to design a complete colored LCD screen? Please sketch the design scheme.

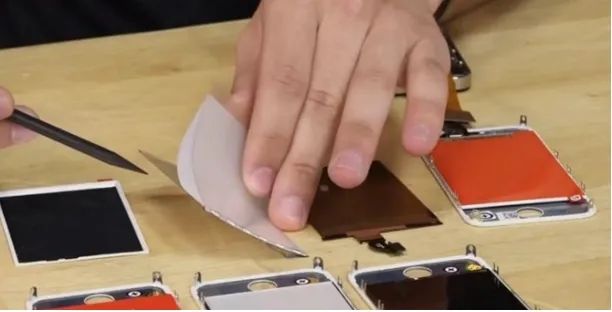

Hands-on Operation: Reassemble the disassembled liquid crystal display components, observe their structure, and understand the function of each component (see Figure 12).

Figure 12 Disassembled LCD display panel

Summary Discussion: It turns out that colored LCD screens have a complex structure with many layers stacked. The screen mainly consists of a backlight, backlight panel, and liquid crystal panel, and also requires assembling the driving circuit and casing, reflecting the ingenious design of engineers.

5. Reflection and Discussion

The project-based curriculum teaching of “Designing and Making Colored LCD Screens”[6-7] connects chemical, physical, and engineering knowledge by exploring the optimization process behind colored displays, allowing students to experience the integration of disciplines in solving real problems. It is essential to allow students to undergo the design process rather than directly providing existing solutions for rigid understanding. By exploring solutions for color display, students understand the wisdom of scientists and the comprehensive application of knowledge across chemistry, physics, and engineering. The development of this project-based curriculum emphasizes in-depth exploration of the subject itself, transforming it into teaching objectives, such as exploring molecular structure improvements and molecular design, allowing students to experience how familiar groups combine to form liquid crystal molecules with unique properties. It is recommended to implement this project-based curriculum over 4 class hours, ensuring ample space for independent thinking, allowing students to fully communicate, practice hands-on, and showcase their work.

References

[1] Xiu Songsheng. Strange Liquid Crystals[M]. Beijing: People’s Education Press, 1985.

[2] Zhong Qixiu. Toshiba Company Developed a 10-inch Large Colored LCD Display[J]. Vacuum Electronics Technology, 1986(4):65.

[3] Liu Yongzhi, Yang Kaiyu. Liquid Crystal Display Technology[M]. Chengdu: University of Electronic Science and Technology Press, 2000.

[4] Wei Rui, Tang Longchang. Ideas and Methods for Developing Project-Based Learning Courses for Teenagers[J]. China Science and Technology Education, 2021(12):10-14.

[5] Wei Rui, Zhu Ye, Dang Yujie, et al. Program for Developing Project-Based Courses that Promote Students’ “Learning to Think”[J]. Basic Education Curriculum, 2023(22):4-11.

[6] Hao Liang, Zhao Yaping, Pan Hong, et al. Research on Project-Based Curriculum Teaching Case of “Designing and Making Black-and-White LCD Screens”[J]. China Modern Education Equipment, 2024(4):24-28.

[7] Pan Hong, Zhao Yaping, Hao Liang, et al. “Exploring the Magic of Liquid Crystals” Project-Based Teaching Design[J]. China Modern Education Equipment, 2024(2):21-25.

Funding Project:Key Research Base for the Construction of Chemistry Textbooks in Primary and Secondary Schools, “Research on Secondary School Chemistry Curriculum and Textbook Development Supporting the Cultivation of Top Innovative Talent”; Research results from the Institute of Science Education at Beijing Normal University, “Development of Project-Based Courses for Promoting Science and Technology Innovation Talent Cultivation in Primary and Secondary Schools”, with the China Education Innovation Research Institute at Beijing Normal University providing support as a collaborative unit.

This article is published in the March 2024 issue of China Modern Education Equipment. Please indicate the source if reproduced.

Editor | Miao Xuanming

Typesetting | Li Yuewei

Release | Zhang Xin