Limited Time Download | Complete Learning Materials for ABB and FANUC Robots

By regularly cleaning the controller’s ventilation openings and fans, maintaining good heat dissipation of the controller helps to keep the robot’s electrical components stable, prevents accidents, and extends its lifespan.

Fan Cleaning Procedure (to be performed with the controller powered off):

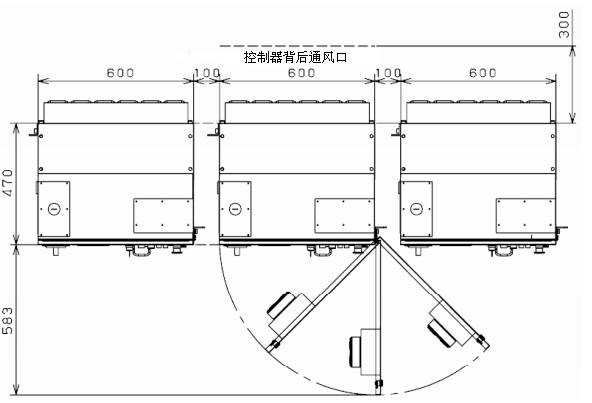

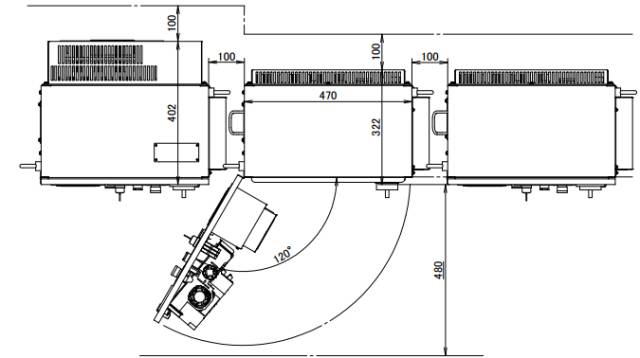

1. R-30IB A Cabinet Controller1.1 Confirm that the space between the controller and surrounding equipment meets the requirements.

1.2 Clean the fan on the front of the controller door.

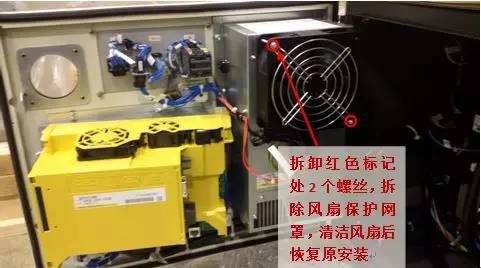

1.3 Clean the fan behind the controller door.

1.3 Clean the fan behind the controller door.

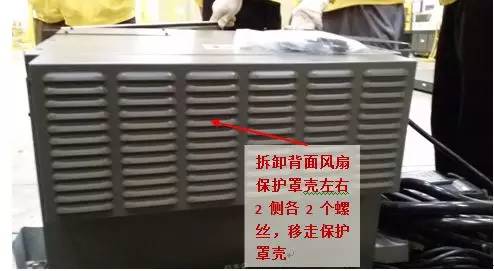

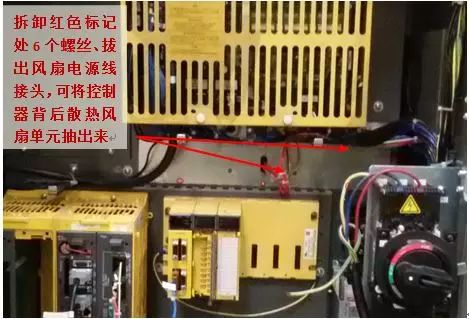

1.4 Clean the fan on the back of the controller.

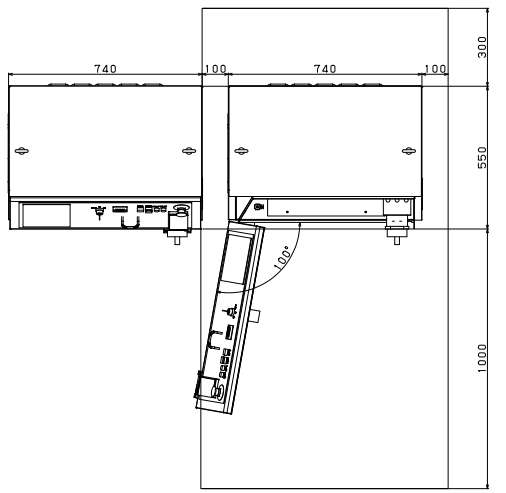

2. R-30IB B Cabinet Controller2.1 Confirm that the space between the controller and surrounding equipment meets the requirements.

2.2 Clean the fan behind the controller door.

2.2 Clean the fan behind the controller door.

2.3 Clean the fan on the back of the controller.

2.3 Clean the fan on the back of the controller.

3. R-30IB MATE Cabinet Controller3.1 Confirm that the space between the controller and surrounding equipment meets the requirements.

3.2 Clean the fan on the front of the controller door.

3.3 Clean the fan behind the controller door.

3.3 Clean the fan behind the controller door. 3.4 Clean the fan on the back of the controller (this fan is not installed on machines with a load capacity of 5KG or less).

3.4 Clean the fan on the back of the controller (this fan is not installed on machines with a load capacity of 5KG or less).

4. Main Control Unit Cooling Fan4.1 It is recommended to regularly replace the 24V DC cooling fan mounted on the backplane of the main control unit inside the controller.

——-End——-

Source: Intuitive Mechanical Learning

|

December 14 |

Industrial Robot Application Engineer Training Class Debugging and Maintenance (WeChat: 15899838594) |

Guangdong |

|

December21st |

Industrial Robot Application Engineer Training Class Mechanical Design, Electrical Design (WeChat: 18042300073) |

Hangzhou |

|

February28th |

Automobile Complete Vehicle FactoryWelding Line Robot Debugging Class (WeChat: 15998178977) |

Shanghai |

Follow the official account, reply 1000 to get 1000G of valuable materials

▼

Only a Follow Away from Becoming an Industrial Robot Expert

Guidance Car Robot Academy, Cradle of Robot Engineers