Introduction

The Internet of Things (IoT) is a tangible “physical” entity; automatic meter reading, automatic recharge payment, and peak-shifting billing are among the most successful IoT applications in China, widely recognized by the public. However, many people are still unclear about what Industrial IoT is and how it differs from IoT. For B2B manufacturing, as Industrial IoT enters factories, factory managers and workshop directors must consider the procurement and selection of industrial computers and PLCs when implementing Industrial IoT projects, as they are the most crucial intelligent computing and control units in Industrial IoT. Today, we will discuss four industry buzzwords: IoT, Industrial IoT, industrial computers, and PLCs, along with their product application solutions.

01

Differences and Similarities Between IoT and Industrial IoT

Industrial IoT is the application of IoT in industrial environments. Industrial IoT focuses on machine-to-machine (M2M) communication, massive data, and machine learning. In contrast, IoT emphasizes the interconnection of commercial devices and applications, with more upstream data and less downstream data, focusing more on data collection than execution control. However, Industrial IoT and IoT share the same architecture, requiring sensors, devices, connectivity options, and data analysis. Industrial IoT devices need to be designed for rugged durability to withstand harsh industrial environments.

IoT connects more commercial devices, such as smartwatches, smart gadgets, and smart refrigerators, while Industrial IoT interconnects devices used in industrial environments, such as production lines, medical equipment, smart transportation, and other critical industrial deployments. Therefore, the devices used in Industrial IoT solution architectures must be robust and able to withstand challenging industrial conditions. Despite the differences between IoT and Industrial IoT devices, they still share the same IoT solution architecture.

02

Differences and Similarities Between Industrial Computers and PLCs

Automation is a key factor in increasing factory output and reducing manufacturing costs, and it is the core significance of Industrial IoT. Industrial PCs (IPC) and Programmable Logic Controllers (PLC) are the most important computing and control units in automation and even Industrial IoT, facilitating the level of industrial automation in machine and human interaction. Let’s first look at the differences and similarities between IPC and PLC, and then discuss which type of dual-control system is most suitable.

· About PLC

Programmable Logic Controllers (PLC) are widely used in factory automation processes. As early as the 1970s, PLCs changed the game for automation systems, designed to replace relays, electrical panels, and switch boxes. Over time, PLCs have been upgraded to more rugged designs, scalable functions, and programmable systems. The programming language of PLCs (known as ladder logic) allows PLCs to be highly customizable for machine automation. This ruggedness and versatility make PLCs a popular choice to replace old relays and switch boxes.

· About IPC

As computer chips have become more powerful, smaller, and cheaper, IPCs are gaining more attention in the automation industry. IPCs can cover supervisory control provided by PLCs but with more workloads, such as HMI, gateways, AI applications, etc. With performance accelerators like GPU, TPU, VPU, NVMe SSD, IPCs can integrate these workloads, reducing their hardware footprint in factory workshops. Ordinary computers and industrial computers share very similar basic components, such as CPU, RAM, SSD, and GPU. However, industrial computers are manufactured and designed to withstand extreme environmental conditions, from extreme temperatures to exposure to shocks and vibrations. IPCs’ extremely rugged designs and manufacturing materials feature fanless designs, integrated enclosures, and industrial-grade materials. They not only support the latest technologies but also commonly support traditional technologies used in factory automation, such as serial ports, COM, M12 connectors, DIO, GPIO, etc., leading to the rapid growth of industrial PCs in manufacturing automation.

· Seven Differences and Similarities Between IPC and PLC

1. Operational Throughput

PLCs come with a real-time operating system that continuously monitors inputs from connected devices and executes decision commands based on their programs. The operating systems of PLCs are designed specifically for executing control-related tasks, equipped with antivirus programs or registry cleaners, reducing operational processing throughput.

IPCs can perform the same tasks as PLCs, with operating systems that allow them to run complex applications that PLCs cannot use. IPCs not only achieve control but also integrate workloads, thereby reducing hardware footprint. The operating systems of IPCs (such as Windows and Linux) are vulnerable to network attacks, but current antivirus software and firewalls are advanced enough to mitigate this risk.

2. Programming Engineer Demographics

The next difference between IPCs and PLCs lies in the way programs are developed and executed. PLCs typically implement scan-based program execution, while IPCs usually employ event-driven software. For example, PLC software logic is specified in the IEC 61131-2 standard, such as ladder logic or other proprietary vendor languages. In contrast, IPCs use programming languages such as C/C++/.NET running on Windows or Linux operating systems. It is evident that the programming engineer demographic for IPCs is larger, as ladder logic requires specialized training for programming personnel. Therefore, IPCs are easier to program and allow interaction with more machines and devices.

3. Security

Security is one of the disadvantages of industrial automation and a current technical weakness. Industrial systems should address two security fundamentals. First, prevent attacks from unauthorized external access. Second, restrict user access based on user rights or specifications. Industrial PCs utilize embedded TPM (Trusted Platform Module) 2.0 on the motherboard for data encryption. PLCs are secure because they lack wireless connections. PLCs employ hybrid security measures using watchdogs and software encryption, represented by Siemens secure PLCs or B&R KNOWHOW safety modules.

Related reading: “Embedded Device Security, Old Soldiers New Transmission, Relation to IoT Security” published on I Love Solutions Network on July 1, offers a detailed interpretation of embedded device security.

4. Rugged Quality

Both IPCs and PLCs are designed to operate in extreme environments and are highly rugged, possessing the following seven elements:

1) Fanless design

2) Efficient heat dissipation

3) Wide temperature range

4) Shock and vibration resistance

5) High IP rating

6) Expandable modules

7) Equipped with power ignition management

5. Expandability

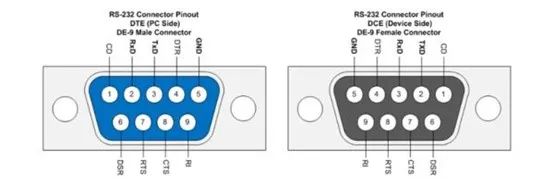

Both IPCs and PLCs need to control various devices for control, monitoring, and communication. They are equipped with multiple COM ports and other I/O industrial communication protocols, including CANbus, Modbus, Profibus, EtherCAT, and Ethernet/IP. Although both can support these technologies, IPCs have an expansion slot structure, providing high flexibility, while PLCs have built-in motherboards that cannot be expanded. For instance, IPCs feature various COM ports, LAN, USB, and HDMI ports, as well as expansion for wireless cards, 5G modules, SSD storage, and GPU accelerators. These capabilities enable IPCs to integrate workloads from different hardware, not just PLCs. IPCs can run HMI applications independently, while PLCs require separate HMI applications to display anything on the panel.

6. Processing Power and Storage

IPCs can be equipped with advanced processors (CPU, NPU, GPU, etc.) and memory, enabling not only traditional IPC functions but also Industrial IoT edge computing capabilities, enhancing the intelligence of terminal devices and network operational efficiency. PLCs use dedicated microprocessors to achieve specific control functions, with fast speed, high efficiency, small programs, and high flexibility. For example, PLCs excel at managing high-speed I/O.

7. Cost

When comparing costs between IPCs and PLCs, PLCs are cheaper for smaller applications, while industrial PCs have a higher initial cost. However, as applications become more complex and computational demands increase, the cumulative cost of PLCs may exceed that of industrial PCs. Although PLCs have a lower initial cost, prices can escalate exponentially when additional computing power or peripheral devices are required. In contrast, industrial PCs have a higher initial cost but are much cheaper when it comes to upgrading computing capabilities and scalability.

· Balancing IPC and PLC Selection

When selecting a solution PCBA for building computing control devices in industrial automation systems, both IPCs and PLCs have their respective places. PLCs are more suitable for running small automation systems with specific functions. PLCs are rugged, cost-effective, and highly secure, making them suitable for industrial deployment. IPCs, on the other hand, are ideal for scenarios with high computational and storage demands, suitable for multifunctional complex tasks. The total cost of ownership (TCO) for IPCs is lower; some applications can simultaneously use both IPCs and PLCs to balance costs and benefits.

03

Recommended Industrial IoT Gateways

· ISG-503 Edge Computing Intelligent Gateway

· ISG-210 Protocol Conversion Intelligent Gateway

· ISG-300 High-Performance Low-Power Edge Computing Gateway

· ISG-200 General Standard Intelligent Gateway

· ISG-100 High-Performance Protocol Conversion Intelligent Gateway